Method for building three-dimensional enzyme electrode surface by using coaxial nanofibers

A nanofiber, electrode surface technology, applied in nanotechnology, nanotechnology, battery electrodes, etc., can solve the problem of inability to use direct electrospun enzyme-containing fiber membranes to modify electrode preparation, difficulty in electron transfer between enzymes and electrodes, and comprehensive performance of enzyme electrodes To improve the stability of the enzyme solidification, increase the electron transfer rate, and solve the stability problem.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

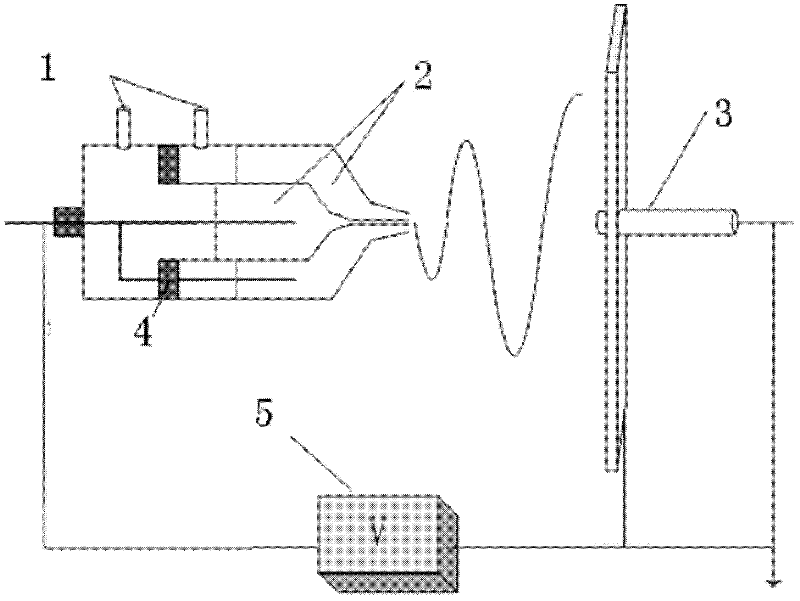

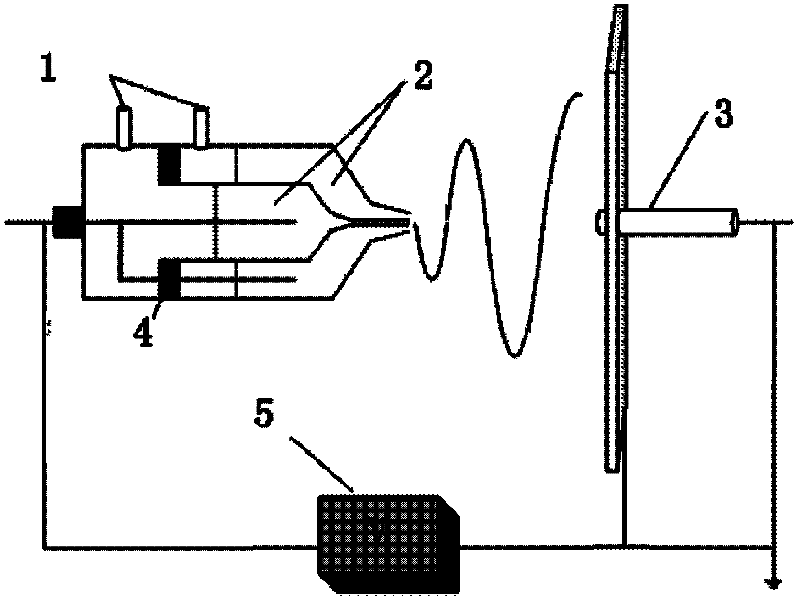

[0018] In the preparation process, hemoglobin is used as an enzyme with catalytic activity, polyethylene glycol is used as a polymer matrix, and carbon nanotubes are used as a doping phase to improve the conductivity of the inner core. Its preparation process is as follows: 0.005 g of hemoglobin and 0.2 g of polyethylene glycol were dissolved in 2 ml of water as the electrospun shell. 0.2 polyethylene glycol and 0.01 g single-walled carbon nanotubes were dissolved in trifluoroethanol as the electrospun core. The nanofibers were spun on the electrode surface by coaxial electrospinning technique. Spinning voltage: 12kV; liquid flow rate: 1mL / h; spinning distance: 20cm. The obtained electrode is cross-linked by a cross-linking agent for several hours and the electrode required for the experiment is obtained.

Embodiment 2

[0020] Using serum albumin as the enzyme with catalytic activity, polyethylene glycol as the polymer matrix, single-walled carbon nanotubes as the doping phase, and other conditions as in Example 1, a coaxial fiber membrane modified electrode can be prepared.

Embodiment 3

[0022] Using glucose oxidase as the enzyme with catalytic activity, polyethylene glycol as the polymer matrix, single-walled carbon nanotubes as the doping phase, and other experimental conditions as in Example 1, a coaxial fiber membrane modified electrode can be prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com