High-temperature-resistant sound-absorbing fiber membrane and preparation method

A fiber membrane, high temperature resistant technology, applied in fiber processing, textiles and papermaking, non-woven fabrics, etc., can solve the problems of poor sound absorption performance, large occupied volume, poor sound absorption effect, etc., to achieve excellent sound absorption performance, large porosity, performance stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

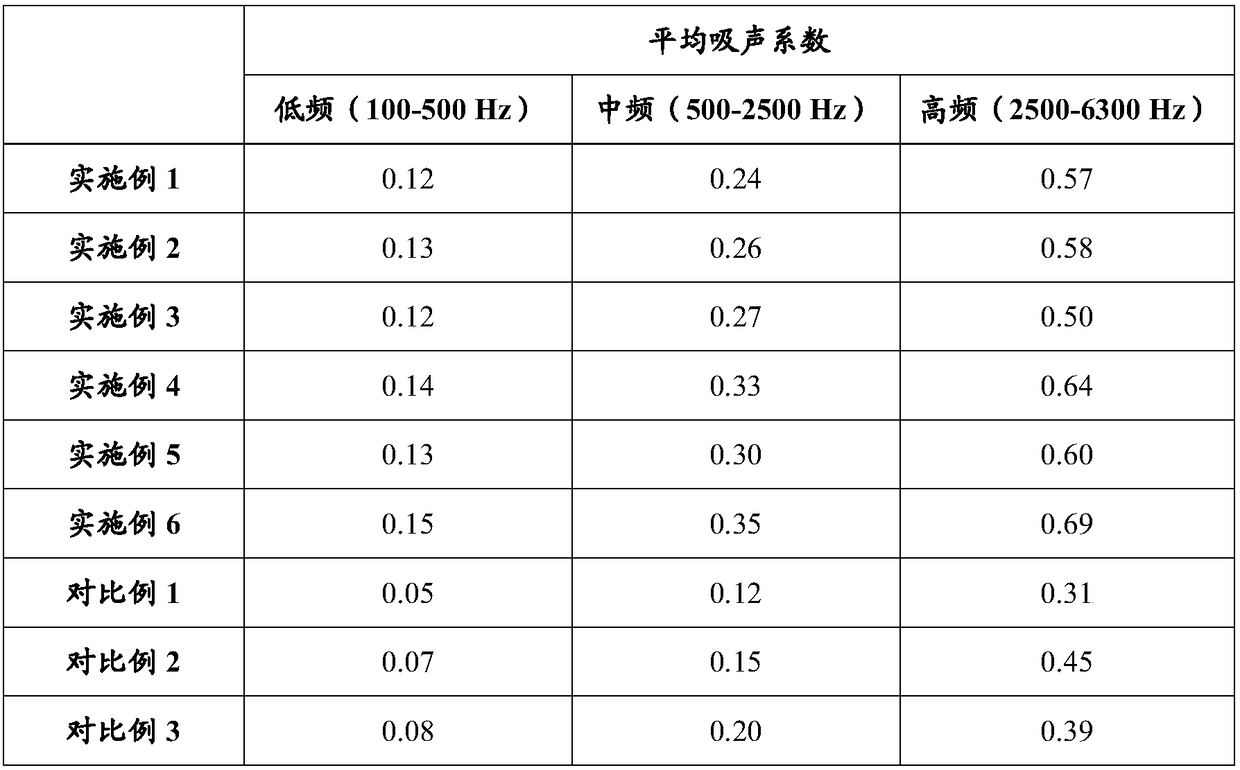

Examples

Embodiment 1

[0035] (1) Weigh 3.1 g of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride and 2.0 g of 4,4'-diaminodiphenyl ether in equimolar amounts, and mix 4,4'-diamino Dissolve diphenyl ether in 23ml of DMF, mechanically stir until it is completely dissolved, then add 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride, stir in an ice-water bath for 4 hours, and obtain a mass fraction of 18% PAA solution; add 0.95g barium titanate (20wt%) and 0.09g graphene (2wt%) to the solution, after mixing uniformly, ultrasonically disperse at room temperature for 30min to obtain PAA / piezoelectric ceramic shell spinning solution;

[0036] (2) Weigh 3.0g PS and dissolve it in 14.5ml of DMF, and mechanically stir until completely dissolved to obtain a PS solution with a mass fraction of 18%;

[0037] (3) Select a 10ml syringe, use the above-mentioned PAA solution as the shell spinning solution, and the PS solution as the core spinning solution, and fix it on a coaxial spinning device for electros...

Embodiment 2

[0041] (1) Weigh 3.1 g of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride and 2.0 g of 4,4'-diaminodiphenyl ether in equimolar amounts, and mix 4,4'-diamino Dissolve diphenyl ether in 18ml of DMF, mechanically stir until completely dissolved, then add 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride, stir in an ice-water bath for 4 hours, and obtain a mass fraction of 22% PAA solution; add 0.95g barium titanate (20wt%) and 0.09g graphene (2%wt) to the solution, after mixing uniformly, ultrasonically disperse at room temperature for 30min to obtain PAA / piezoelectric ceramic shell spinning solution;

[0042] (2) Weigh 3.0g PS and dissolve it in 14.5ml of DMF, and mechanically stir until completely dissolved to obtain a PS solution with a mass fraction of 18%;

[0043] (3) Select a 10ml syringe, use the above-mentioned PAA solution as the shell spinning solution, and the PS solution as the core spinning solution, and fix it on a coaxial spinning device for electrospinnin...

Embodiment 3

[0047] (1) Weigh 3.1 g of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride and 2.0 g of 4,4'-diaminodiphenyl ether in equimolar amounts, and mix 4,4'-diamino Dissolve diphenyl ether in 16ml of DMF, mechanically stir until completely dissolved, then add 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride, stir in an ice-water bath for 4 hours, and obtain a mass fraction of 24% PAA solution; add 0.95g barium titanate (20wt%) and 0.09g graphene (2%wt) to the solution, after mixing uniformly, ultrasonically disperse at room temperature for 30min to obtain PAA / piezoelectric ceramic shell spinning solution;

[0048] (2) Weigh 3.0g PS and dissolve it in 14.5ml of DMF, and mechanically stir until completely dissolved to obtain a PS solution with a mass fraction of 18%;

[0049] (3) Select a 10ml syringe, use the above-mentioned PAA solution as the shell spinning solution, and the PS solution as the core spinning solution, and fix it on a coaxial spinning device for electrospinnin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com