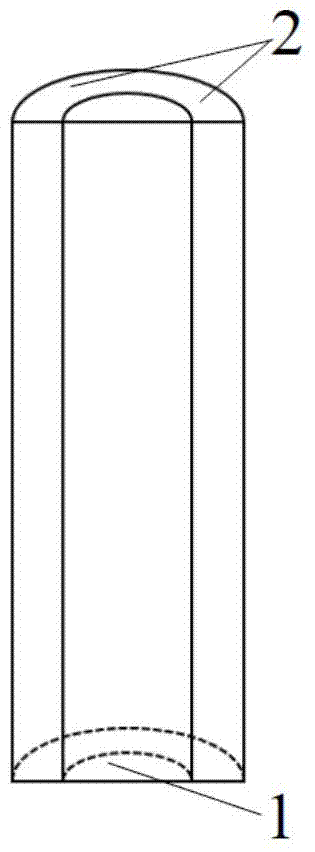

Method for preparing dense micro/nano ceramic fiber by virtue of coaxial electrospinning technology

A coaxial electrospinning, ceramic fiber technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of large diameter of ceramic fibers, low fiber density, and high preparation temperature, Achieve the effect of small fiber diameter, broad application prospects and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

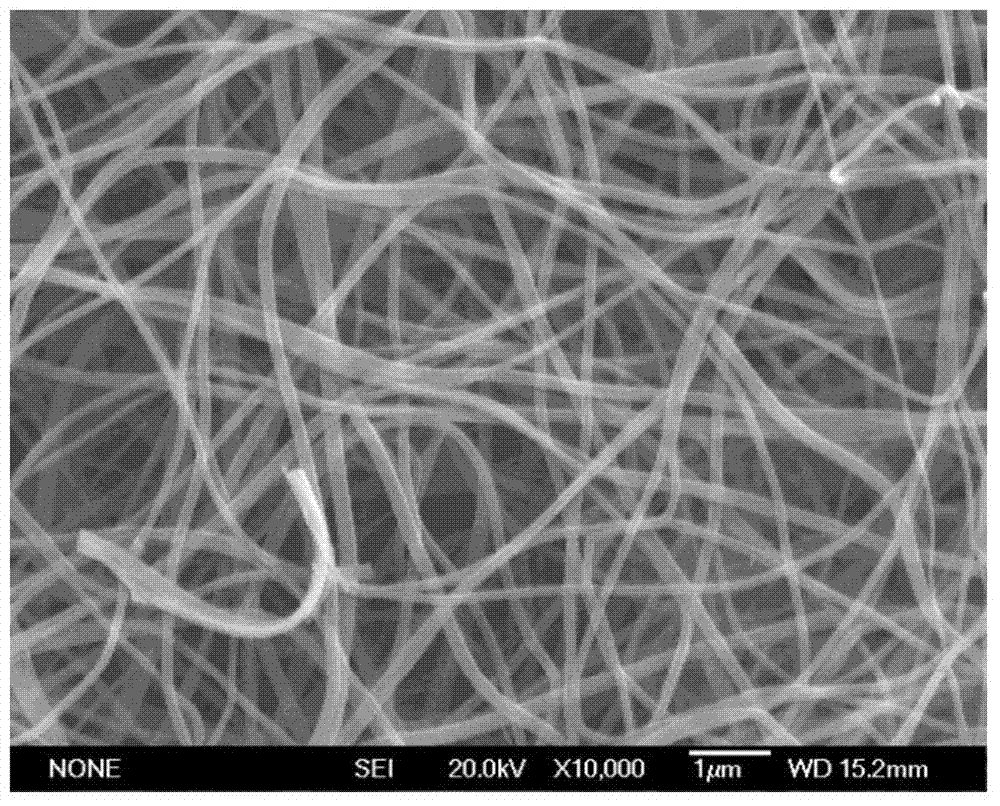

Embodiment 1

[0044] Weigh 0.83g of polyvinylpyrrolidone and dissolve it in 20g of absolute ethanol, stir well at room temperature to prepare a shell spinning solution with a concentration of 4%; weigh 1.67g of zirconium oxychloride and dissolve it in 15g of deionized water, After uniform stirring, a core layer spinning solution with a concentration of 10% was prepared. Pour the shell spinning solution into the shell micropump, pour the core spinning solution into the core micropump, and set the spinning parameters as follows: the diameter of the core spinneret is 0.1mm, and the diameter of the shell spinneret is 0.6mm, core layer spinning solution propulsion rate 0.1mL / h, shell layer spinning solution propulsion rate 0.2mL / h, spinning voltage 10kV, receiving distance 8cm, spinning environment relative humidity 20%, obtained by electrospinning The shell layer is polyvinylpyrrolidone, and the core layer is coaxial structure spun fibers; the coaxial structure spun fibers are calcined at 700°C...

Embodiment 2

[0046] Weigh 1.92g polystyrene and dissolve it in 30g N-N dimethylformamide, stir it evenly at room temperature to make a shell spinning solution with a concentration of 6%; weigh 6.08g yttrium nitrate and dissolve it in 20g tert-butanol After stirring evenly at room temperature, a core layer spinning solution with a concentration of 23.3% was prepared. Pour the shell spinning solution into the shell micropump, pour the core spinning solution into the core micropump, and set the spinning parameters as follows: the diameter of the core spinneret is 0.2mm, and the diameter of the shell spinneret is 0.7mm, core layer spinning solution advancing rate 0.6mL / h, shell layer spinning solution advancing rate 1.2mL / h, spinning voltage 20kV, receiving distance 14cm, spinning environment relative humidity 33%, obtained by electrospinning The shell layer is polystyrene and the core layer is coaxial structure primary fiber of yttrium nitrate; the primary fiber is calcined at 1000°C for 2 ho...

Embodiment 3

[0048] Weigh 2.17g of polyvinyl alcohol and dissolve it in 25g of deionized water, and stir it evenly at room temperature to obtain a shell spinning solution with a concentration of 8%; weigh 5.77g of ferric chloride and dissolve it in 10g of methanol, and stir it evenly at room temperature A core spinning solution with a concentration of 36.6% was prepared. Pour the shell spinning solution into the shell micropump, pour the core spinning solution into the core micropump, and set the spinning parameters: the diameter of the core spinneret is 0.3 mm, and the diameter of the shell spinneret is 0.8mm, core layer spinning solution advancing rate 1.1mL / h, shell layer spinning solution advancing rate 2.2mL / h, spinning voltage 30kV, receiving distance 20cm, spinning environment relative humidity 46%, obtained by electrospinning The shell layer is polyvinyl alcohol, and the core layer is ferric chloride as-spun fiber with coaxial structure; the as-spun fiber with coaxial structure is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com