Process of methanol conversion for preparing arene and catalyst and catalyst preparation method

A methanol conversion and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, molecular sieve catalysts, etc., can solve the problems of low selectivity of target products and complicated processes, and achieve high aromatics selectivity and total selectivity Improve the effect of high flexibility in process operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

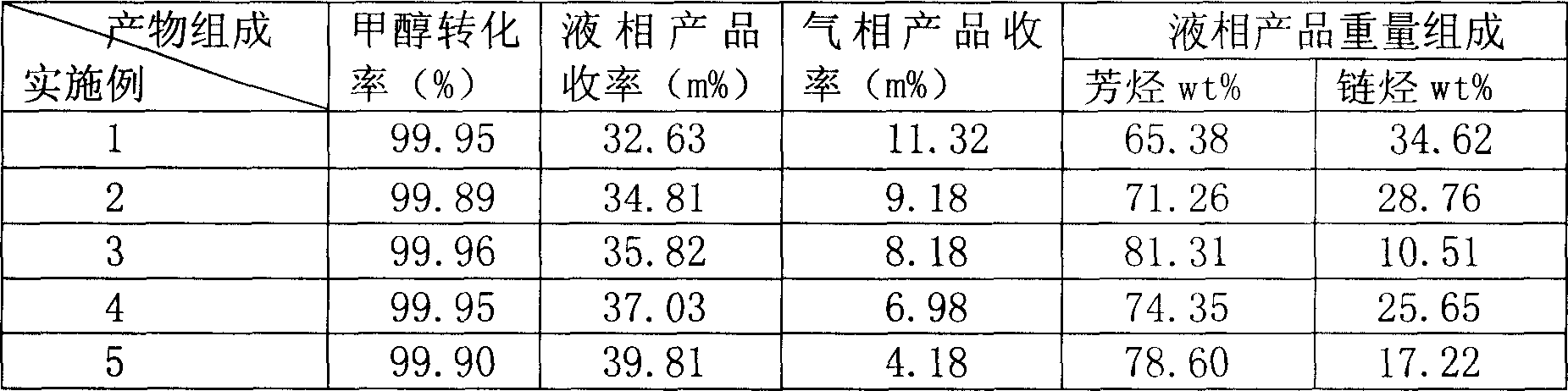

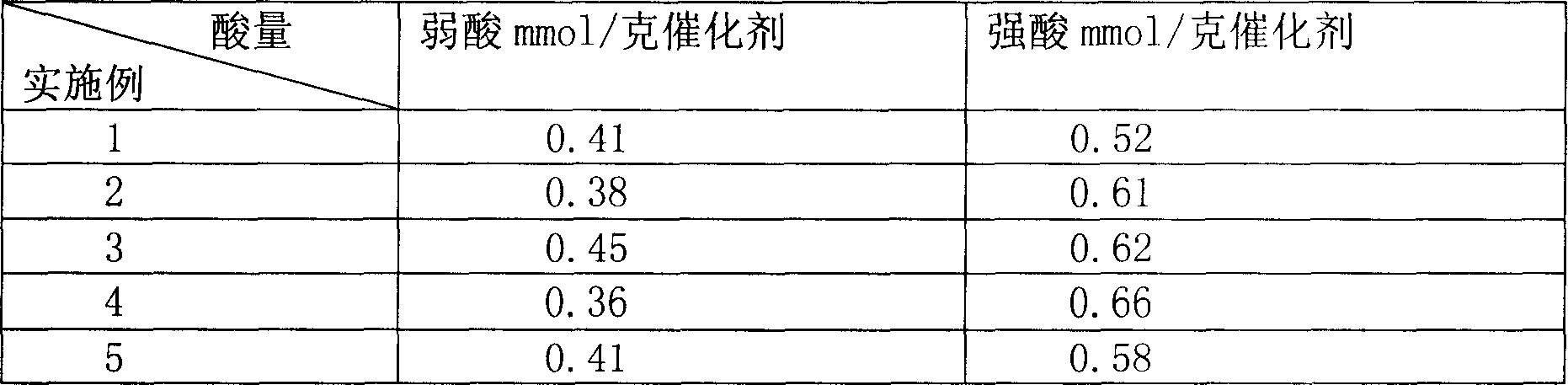

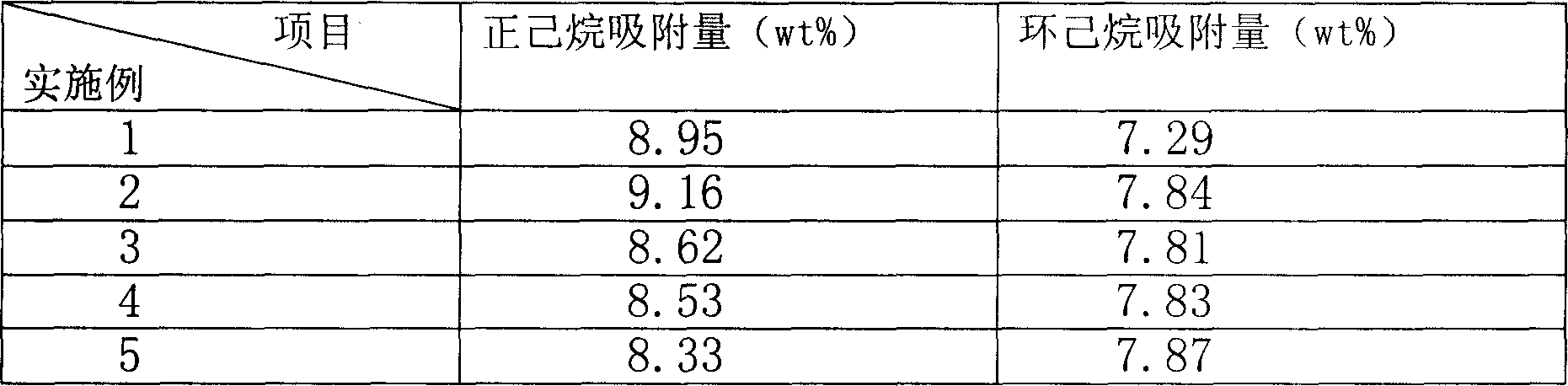

Examples

Embodiment 1

[0053] 1. Preparation and characterization of the first-stage catalyst

[0054] (1) Take nSiO 2 / nAl 2 o 3 Ratio of 30.28, 30 grams of small-grain ZSM-5 molecular sieves with an average particle size of 0.1 μm was roasted at 520° C. for 5 hours to remove physically adsorbed impurities. For the specific preparation method of the above-mentioned molecular sieve, see Chinese patent 00109593.5;

[0055] (2) Perform ion exchange with 0.5mol / L ammonium nitrate solution in a boiling state for 2 hours, filter, wash 3 times with deionized water, dry in an oven at 120°C, and then place it in a roasting furnace at 540°C keep for 5 hours;

[0056] (3) Get 20 grams of molecular sieves obtained in step (2), 7 grams of γ-Al 2 o 3 , mixed in a mortar, and ground evenly;

[0057] (4) Add 3% nitric acid solution dropwise to the ground material, knead properly, extrude it into a columnar shape of Ф2 with a screw extruder, put it in an oven and dry it at 120°C;

[0058] (5) Crush strip-sh...

Embodiment 2

[0075] 1. Preparation of one-stage reforming catalyst

[0076] (1) Take nSiO 2 / nAl 2 o 3 Ratio is 30 grams of small-grain ZSM-5 molecular sieves of 40.12 and roasted at 540° C. for 4 hours to remove its physically adsorbed impurities;

[0077] (2) Perform ion exchange with 0.5mol / L ammonium nitrate solution in a boiling state for 2 hours, filter, wash 5 times with deionized water, dry in an oven at 120°C, and then place it in a roasting furnace at 520°C Keep it for 5 hours to get small grain HZSM-5 molecular sieve;

[0078] (3) Combine 14 grams of molecular sieve with 6 grams of γ-Al 2 o 3 At the same time, put it into the mortar and mix it, and grind it evenly;

[0079] (4) Add 3% nitric acid solution dropwise to the ground material and knead properly, extrude it into a columnar shape of Ф2 with a screw extruder, put it in an oven and dry it at 110°C;

[0080] (5) Crush strip molecular sieves to 10-40 mesh and put them in a muffle furnace to heat up to 510°C and roast...

Embodiment 3

[0093] 1. Preparation of one-stage conversion catalyst

[0094] (1) Add nSiO 2 / nAl 2 o 3Ratio is 30 grams of small-grain ZSM-5 molecular sieves of 54.36 and roasted at 540° C. for 5 hours to remove its physically adsorbed impurities;

[0095] (2) Perform ion exchange with 0.5mol / L ammonium sulfate solution in a boiling state for 2 hours, filter, wash 4 times with deionized water, dry in an oven at 120°C, and then place it in a roasting furnace at 530°C Keep it for 5 hours to get small grain HZSM-5 molecular sieve;

[0096] (3) 14.4 grams of molecular sieves are mixed with 5.6 grams of pseudo-thin water alumina in a mortar and mixed evenly;

[0097] (4) Add 3% nitric acid solution dropwise to the ground material and knead properly, extrude it into a columnar shape of Ф2 with a screw extruder, put it in an oven and dry it at 115°C;

[0098] (5) Crush strip molecular sieves to 10-40 meshes, put them in a muffle furnace and heat up to 520 ° C for 3 hours to remove nitric aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com