Method for producing compressed charing poplar three-layer wood composite flooring

A technology of solid wood composite flooring and production methods, which is applied in the direction of joining of wooden veneers, chemical instruments and methods, layered products, etc., can solve problems such as development restrictions, and achieve simple and easy manufacturing methods, good market prospects, and enhanced texture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

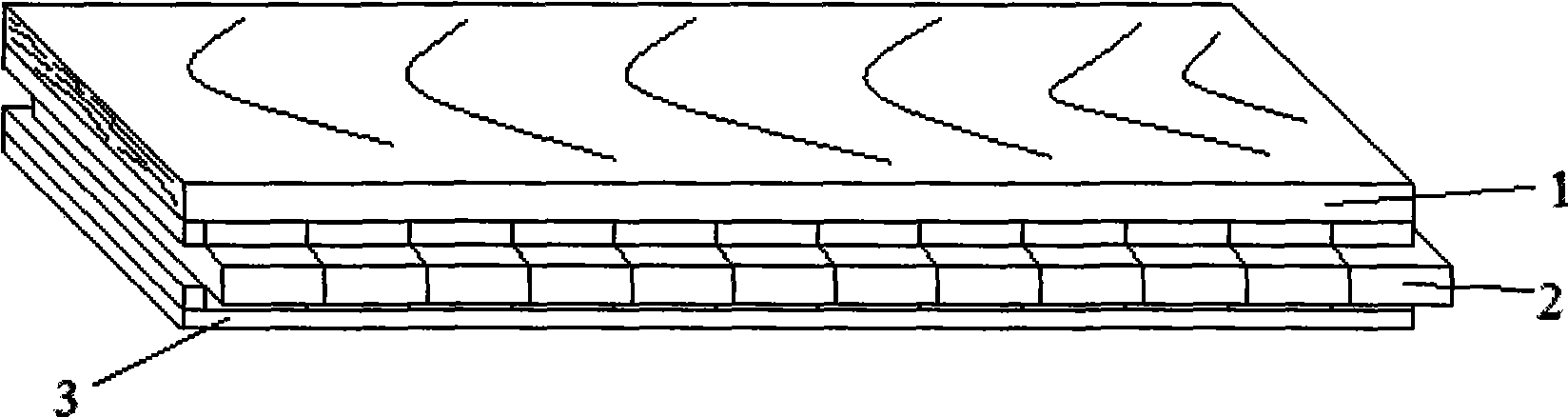

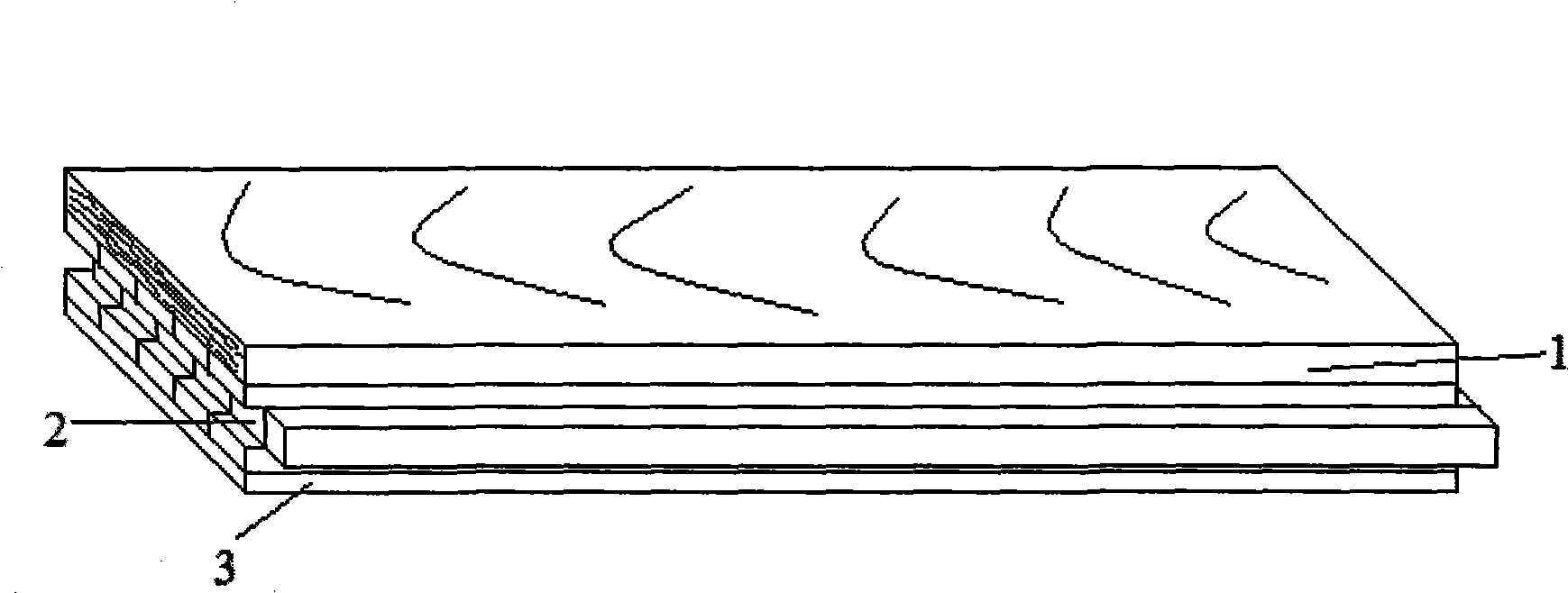

[0018] Attached below figure 1 The poplar three-layer solid wood composite floor of the present invention is described in further detail with example:

[0019] ① Use a frame saw machine or a multi-blade original saw machine to cut the poplar wood into boards, dry, plan, and process them into poplar wood veneers with a thickness of 6.5, 7.5, and 9mm and a moisture content of about 30%, together with the fixture Put them together into a single-layer hot press, compress to 4.5mm, the hot pressing temperature is 100°C, and the compression rates are 30%, 40%, and 50% respectively; after the compression is completed, fix the fixture, release the pressure, and then perform high-temperature carbonization treatment , the treatment temperature is 200°C, and the time is 3 hours. After the treatment, take out the fixture and cool it; when the temperature of the poplar veneer in the fixture drops to 40-60°C, open the fixture, take out the poplar veneer, and sand the poplar veneer The thic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com