Gas-liquid interface processing method for a semiconductor gas sensor

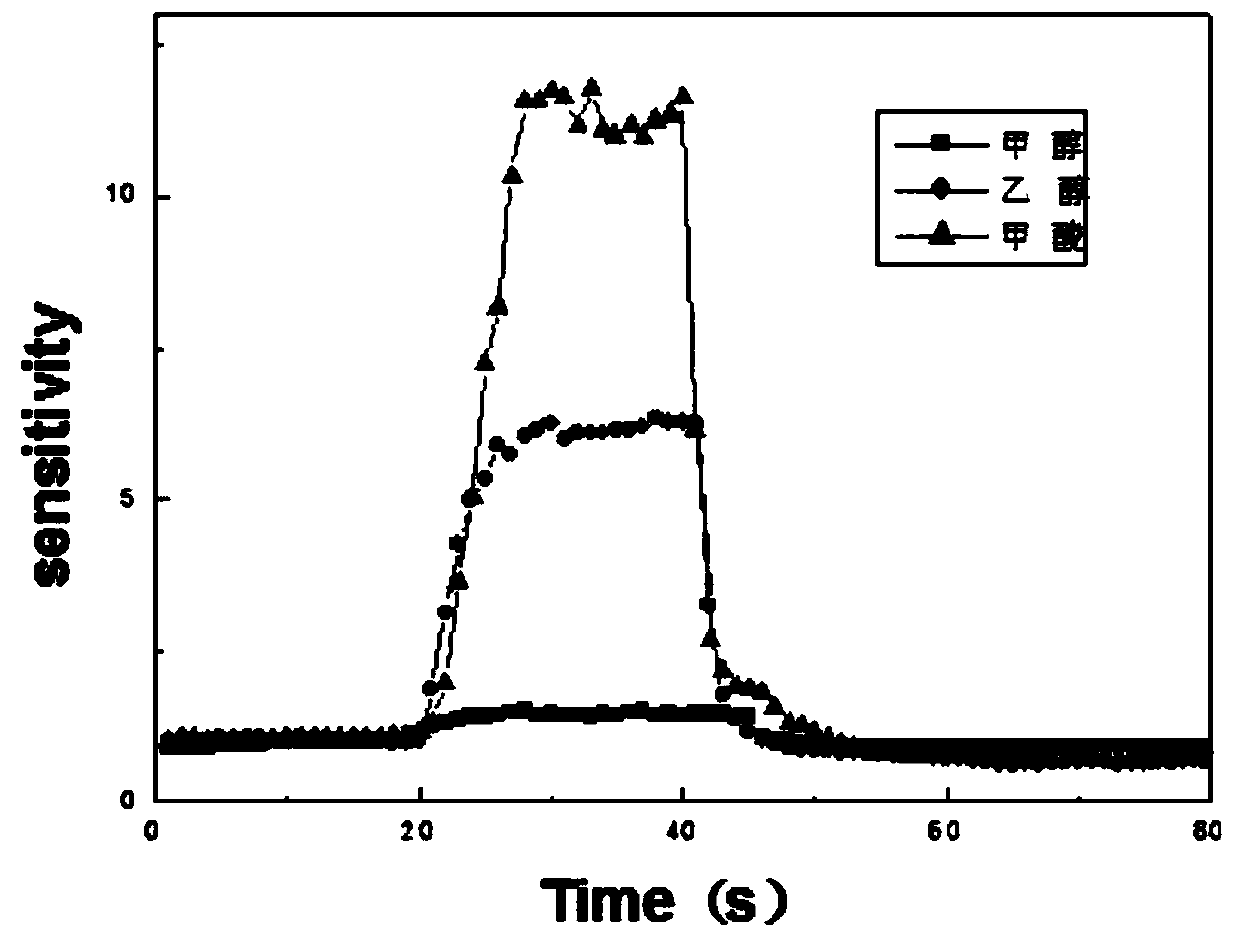

A gas sensor and processing method technology, applied in the direction of material resistance, etc., can solve the problems of difficult repeated batch production, unstable properties of gas sensors, etc., and achieve the effects of simple process, good gas response and recovery performance, easy operation and mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add 0.025mol / l cadmium sulfate and 0.025mol / l sodium thiosulfate into 200ml deionized water for ultrasonic dissolution to obtain a cadmium precursor;

[0029] Cover the petri dish with plastic wrap, transfer it to a dark room, and place it under two 8W, 254nm ultraviolet lamps for a certain period of time;

[0030] After reacting for 24 hours, use a clean glass piece to pick up the film on the surface;

[0031] Float the film to the surface of deionized water, let it stand for 0.1 hour, pick it up gently with a ceramic tube, and then dry it at 60°C to obtain cadmium-rich cadmium sulfide nanotubes;

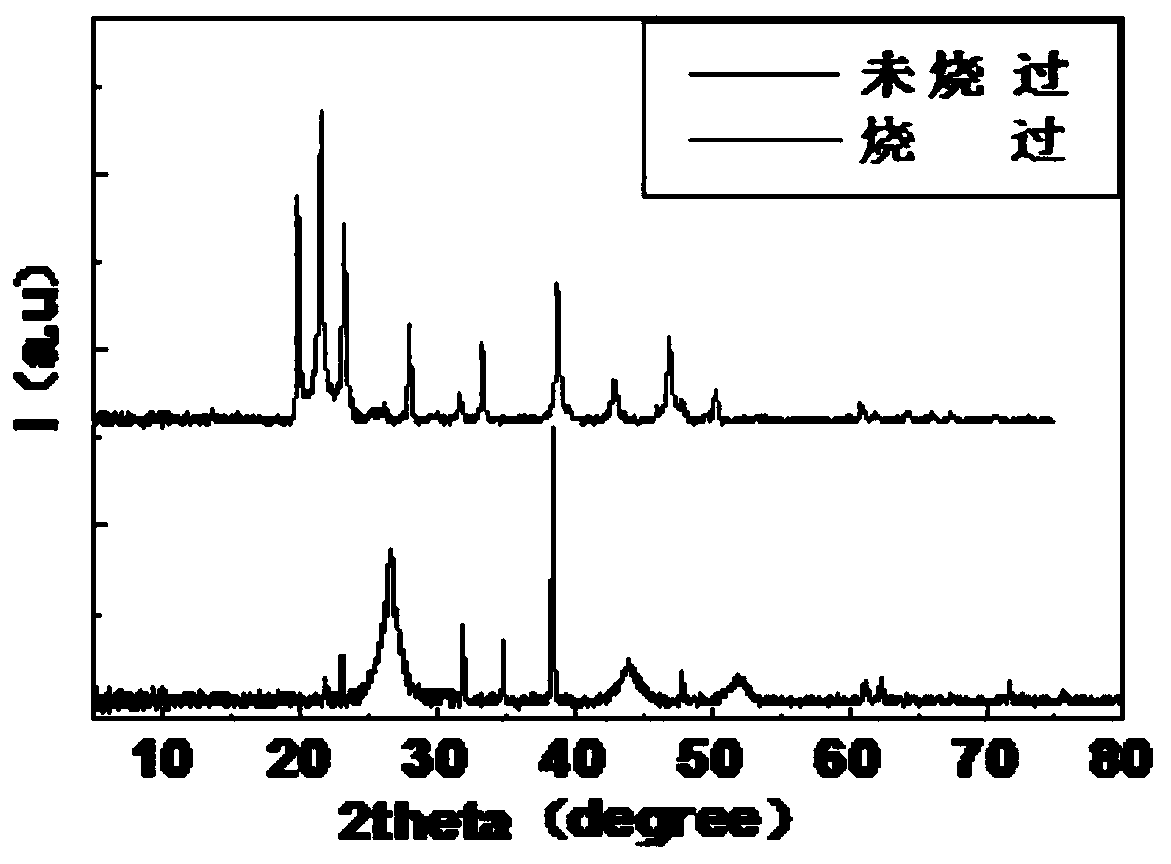

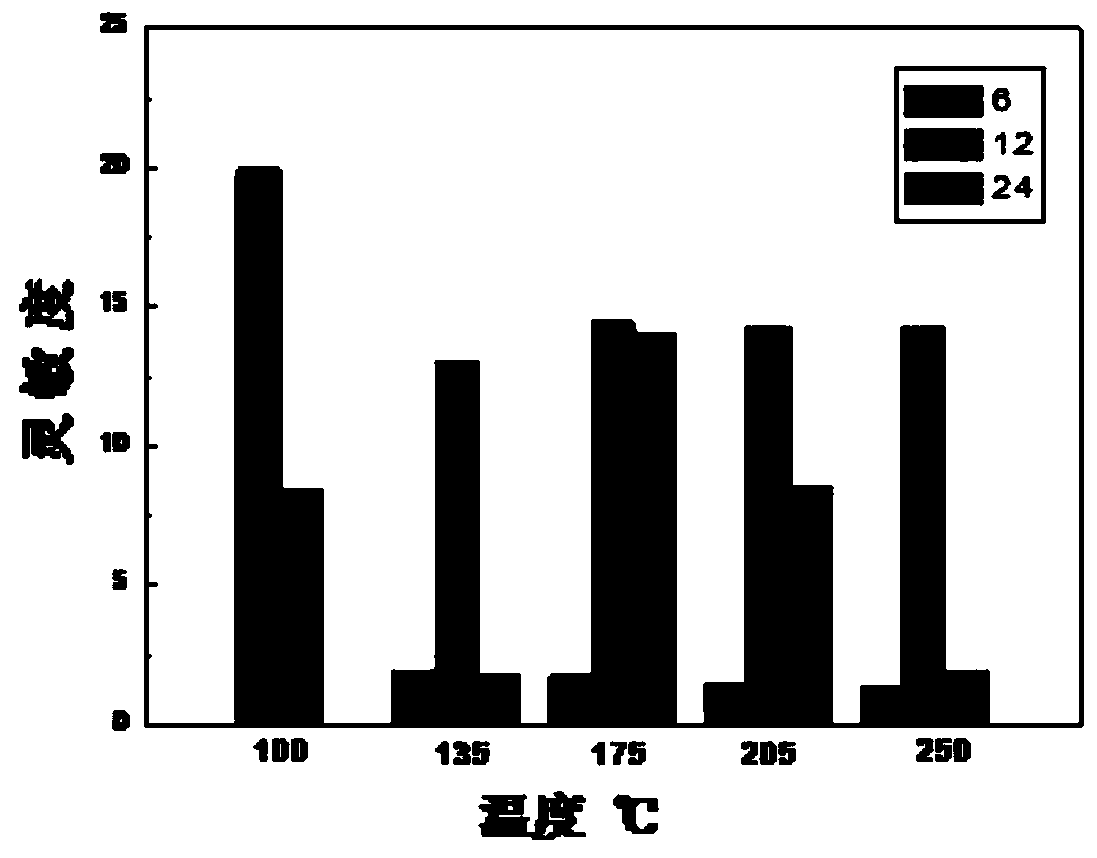

[0032] The ceramic tube was welded on the base, loaded with resistance wire, and heat-treated at 180°C for 0.5 hours to obtain a cadmium oxide-cadmium sulfide composite film gas sensor.

Embodiment 2

[0034] Add 0.2mol / l cadmium sulfate and 0.1mol / l sodium thiosulfate into 200ml deionized water for ultrasonic dissolution to obtain a cadmium precursor;

[0035] Cover the petri dish with plastic wrap, transfer it to a dark room, and place it under two 8W, 254nm ultraviolet lamps for a certain period of time;

[0036] After reacting for 12 hours, use a clean glass piece to pick up the film on the surface;

[0037] Float the film to the surface of deionized water, let it stand for 0.25 hours, pick it up gently with a ceramic tube, and then dry it at 60°C to obtain cadmium-rich cadmium sulfide nanotubes;

[0038] The ceramic tube was welded on the base, loaded with resistance wire, and heat-treated at 200°C for 0.8 hours to obtain a cadmium oxide-cadmium sulfide composite film gas sensor.

Embodiment 3

[0040] Add 1.2mol / l cadmium sulfate and 0.2mol / l sodium thiosulfate into 200ml deionized water for ultrasonic dissolution to obtain a cadmium precursor;

[0041] Cover the petri dish with plastic wrap, transfer it to a dark room, and place it under two 8W, 254nm ultraviolet lamps for a certain period of time;

[0042] After reacting for 6 hours, use a clean glass piece to pick up the film on the surface;

[0043] Float the film on the surface of deionized water, let it sit for fifteen minutes, then gently pick it up with a ceramic tube, and then dry it at 60°C to obtain cadmium-rich cadmium sulfide nanotubes;

[0044] The ceramic tube was welded on the base, loaded with resistance wire, and heat treated at 250°C for 1 hour to obtain a cadmium oxide-cadmium sulfide composite thin film gas sensor.

[0045] Cadmium sulfate can obtain a cadmium sulfide layer with a certain thickness and uniformity at a concentration of 0.025mol / l-1.2mol / l at 25°C. If the concentration is too sma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com