Method for improving gas-sensitive response performance of ZIF-8 to ethanol gas

A ZIF-8 and gas technology, which is applied in the field of improving the gas-sensing response performance of ZIF-8 to ethanol gas, can solve the problems of restricting development, high power consumption and high working temperature, so as to improve the gas-sensing response performance and avoid the decrease of stability. , the effect of reducing the working temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Preparation of ZIF-8:

[0029] Adopt normal temperature and pressure method to prepare ZIF-8, the specific preparation method is: under room temperature condition, Zn(NO 3 ) 2 ·6H 2 O (1.485 g, 4.99 mmol) was added to 20 ml of methanol solution and stirred ultrasonically for 3 minutes. 2-Methylimidazole (1.642g, 20.00mmol) was added to another beaker containing 20ml of methanol and stirred ultrasonically for 3 minutes, and the two colorless solutions obtained by stirring were mixed and stirred ultrasonically for 2 minutes, then allowed to stand 24h. Next, the mixed solution was put into a centrifuge and washed three times by ethanol centrifugation, and the obtained white product was dried at a constant temperature at 70° C. to finally obtain the product ZIF-8.

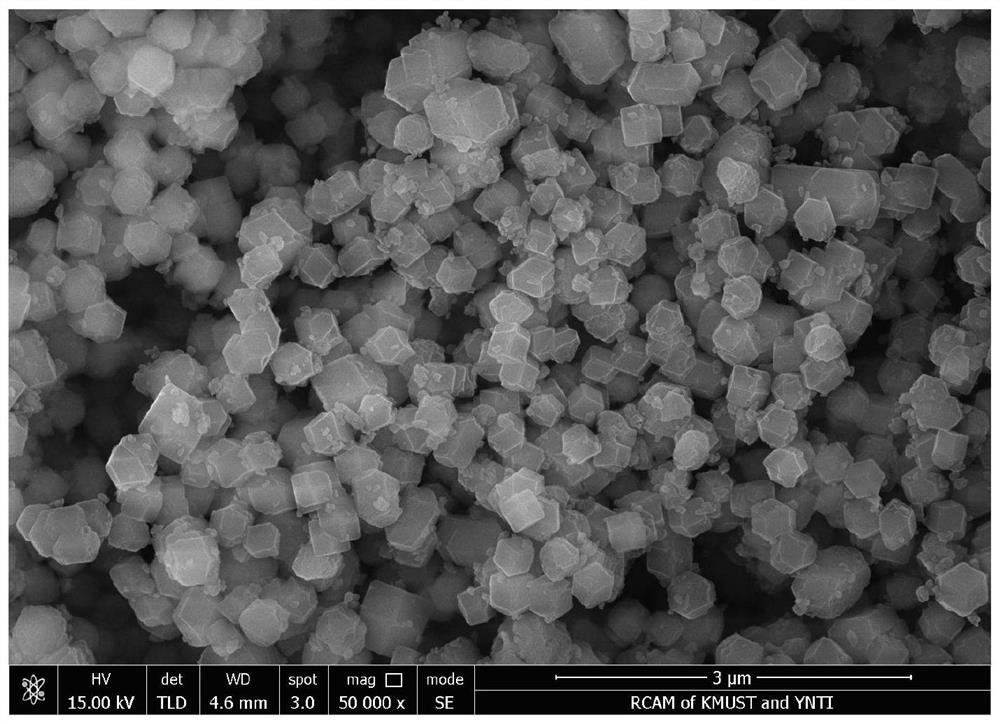

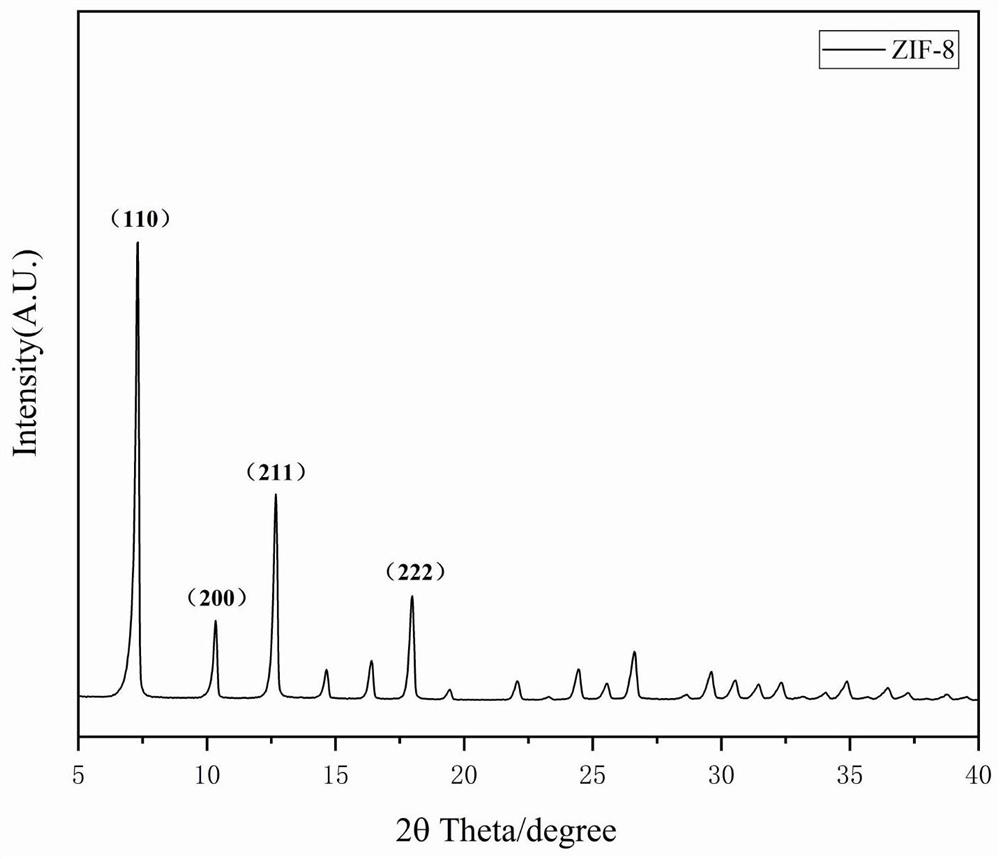

[0030] The SEM figure of the ZIF-8 prepared above is as follows figure 1 As shown, the XRD pattern is as figure 2 shown by figure 1 and figure 2 It can be seen that ZIF-8 was successfully synthesized; ...

Embodiment 2

[0035] ZIF-8 tests 200ppm ethanol gas, including the following steps:

[0036] Add ultraviolet light LED light source in four-channel gas-sensitive test instrument, make ultraviolet light LED light source be in passage state, first carry out ultraviolet light excitation to the ZIF-8 that embodiment 1 prepares; Treat that ZIF-8 is in light excitation condition After the chemical equilibrium state, that is, after the resistance value of ZIF-8 does not change under air conditions, the thermal excitation conditions are added to the ZIF-8 material, the temperature is 50°C, and the ultraviolet light excitation is continued during the test period; the test The gas sensitive response of ZIF-8 to the concentration of 200ppm ethanol gas under the low temperature condition of 50℃. Such as Figure 4 shown by Figure 4 It can be seen that under the condition of combined photothermal excitation, ZIF-8 has an excellent gas sensitive response to 200ppm ethanol gas at a low temperature of 50...

Embodiment 3

[0038] ZIF-8 tests 200ppm ethanol gas, including the following steps:

[0039] Add ultraviolet light LED light source in four-channel gas-sensitive test instrument, make ultraviolet light LED light source be in passage state, first carry out ultraviolet light excitation to the ZIF-8 that embodiment 1 prepares; Treat that ZIF-8 is in light excitation condition After the chemical equilibrium state, that is, after the resistance value of ZIF-8 does not change under air conditions, the thermal excitation condition is added to the ZIF-8 material, the temperature is 75°C, and the ultraviolet light excitation is continued during the test period; the test Gas-sensing response of ZIF-8 to 200ppm ethanol gas at a low temperature of 75°C. The results show that under the conditions of combined photothermal excitation, ZIF-8 has an excellent gas-sensing response to 200ppm ethanol gas at a low temperature of 75°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com