Electrodeless semiconductor gas sensor and preparation method thereof

A gas sensor and semiconductor technology, applied in the direction of material resistance, etc., can solve the problems of restricting the design and preparation of flexible gas sensors, high production costs, and high prices, and achieve the goal of avoiding excessive gas adsorption capacity, low cost, and excellent mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of above-mentioned semiconductor gas sensor is:

[0030] (1) Uniformly disperse the colloidal nanocrystal / graphene composite powder in an organic solvent to obtain a mixed solution. Specifically, the organic solvent is acetone.

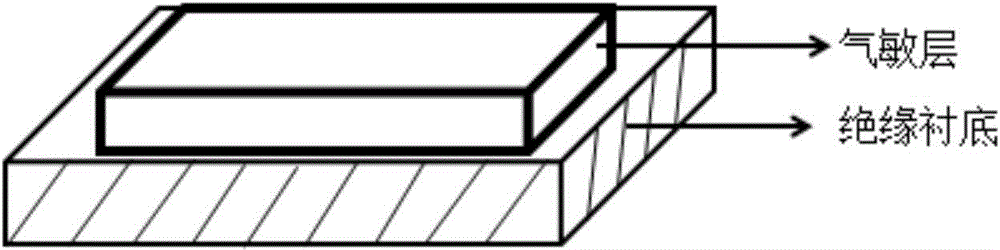

[0031] (2) Coating the mixed solution obtained in step (1) on an insulating substrate to form a uniform film. Specifically, the mixed solution can be coated on an insulating substrate to form a film at room temperature by means of drop coating, spin coating, dipping, spraying, printing, etc.; the insulating substrate is paper, plastic or ceramics.

[0032] (3) Repeat step (2) to obtain a gas-sensitive layer with a desired thickness, and complete the preparation of the gas sensor.

[0033] Specifically, colloidal nanocrystal / graphene composite powder is PbS colloidal nanocrystal / graphene composite powder and / or PbSe colloidal nanocrystal / graphene composite powder, wherein, the mol ratio of Pb atom and C atom is 1: (0.5~12...

Embodiment 1

[0040] Take 40mg of graphene oxide (GO) and 0.106g of lead acetate, disperse it in a mixed solvent composed of 2.5ml DMSO and 27.5ml DMF, and ultrasonically disperse it evenly for 1 hour to obtain a mixed solution; move the mixed solution to a 50ml reaction In the kettle, react at a high temperature of 180°C for 12 hours, pour out the upper liquid after the reaction, and take out the lower solid precipitate; wash the solid precipitate with acetone and ethanol to remove the remaining reactants. The specific process is as follows: : Add 10ml of acetone and 15ml of ethanol to the solid sediment successively, put it into a centrifuge and rotate at a speed of 5000rpm for 3 minutes, then pour out the supernatant and leave the sediment, the first cleaning process is over, repeat the process three times Cleaning is completed; the solid precipitate after cleaning is placed in the air and dried naturally for 24 hours to obtain a PbS colloidal nanocrystal / reduced graphene oxide (rGO) comp...

Embodiment 2

[0043] Get 30mg graphene oxide and 0.675g lead acetate, disperse it in the mixed solvent that 2.5ml DMSO and 27.5ml DMF form, ultrasonic 1 hour makes it disperse evenly, obtain mixed solution; Move mixed solution in the reaction kettle of 50ml, React at a high temperature of 180°C for 12 hours, pour the mixed solution after the reaction into the upper liquid, and take out the lower solid precipitate; wash the solid precipitate with acetone and ethanol to remove the remaining reactants. The specific process is: Add 10ml of acetone and 15ml of ethanol to the solid precipitate, put it into a centrifuge and spin at a speed of 5000rpm for 3 minutes, then pour out the supernatant and leave the precipitate. After the first cleaning process is over, repeat this process three times to complete the cleaning; The washed solid precipitate was naturally dried in air for 24 hours to obtain a PbS colloidal nanocrystal / rGO composite powder, in which the molar ratio of Pb atoms to C atoms was 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com