High gas response and selective LaFeO3-based ethanol gas sensor element and preparation method thereof

A gas sensor and gas response technology, applied in the direction of instruments, scientific instruments, measuring devices, etc., can solve the problems of insufficient gas response, unfavorable environmental protection, high cost, etc., to improve gas response and selectivity, improve gas response and selection Sex, good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

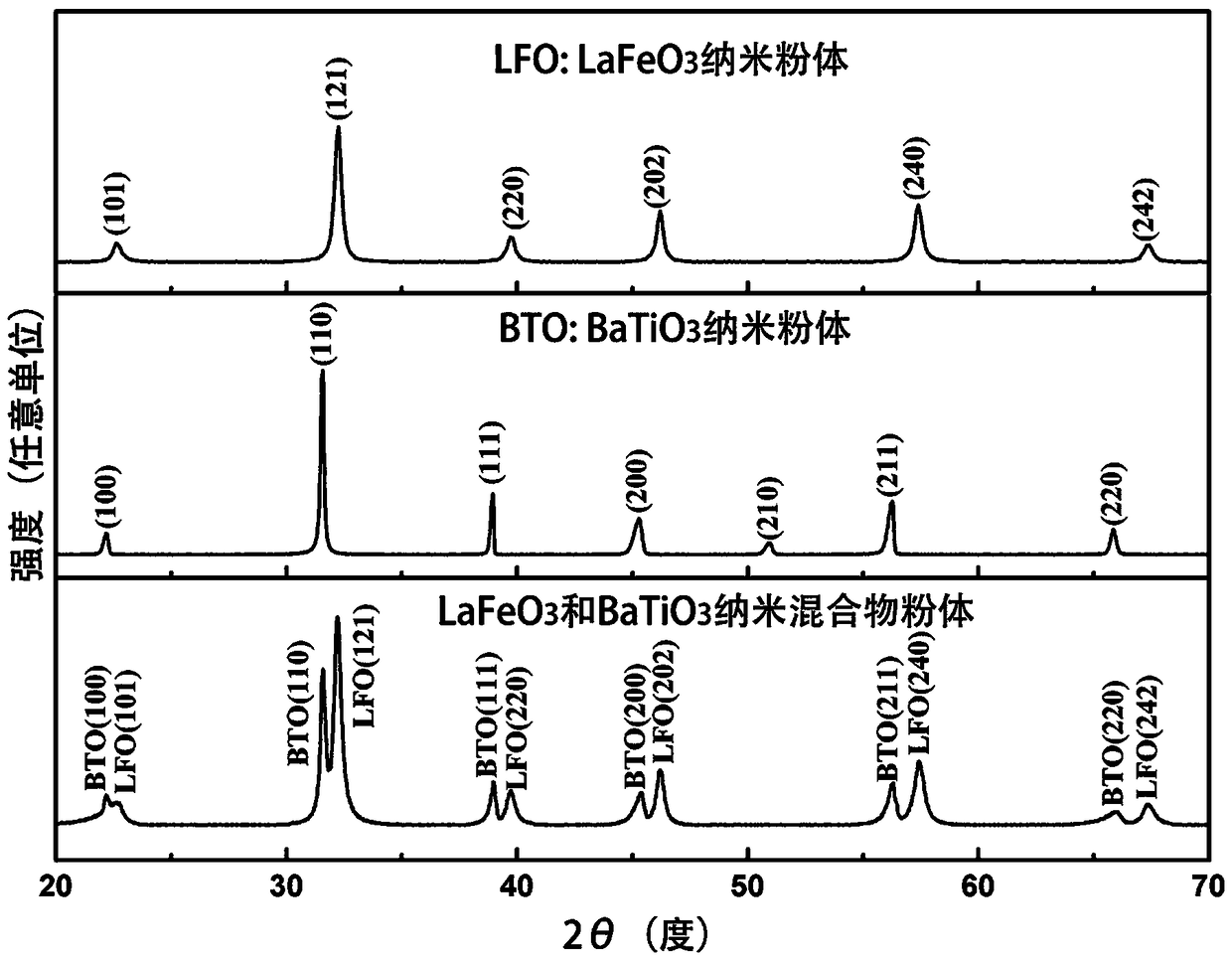

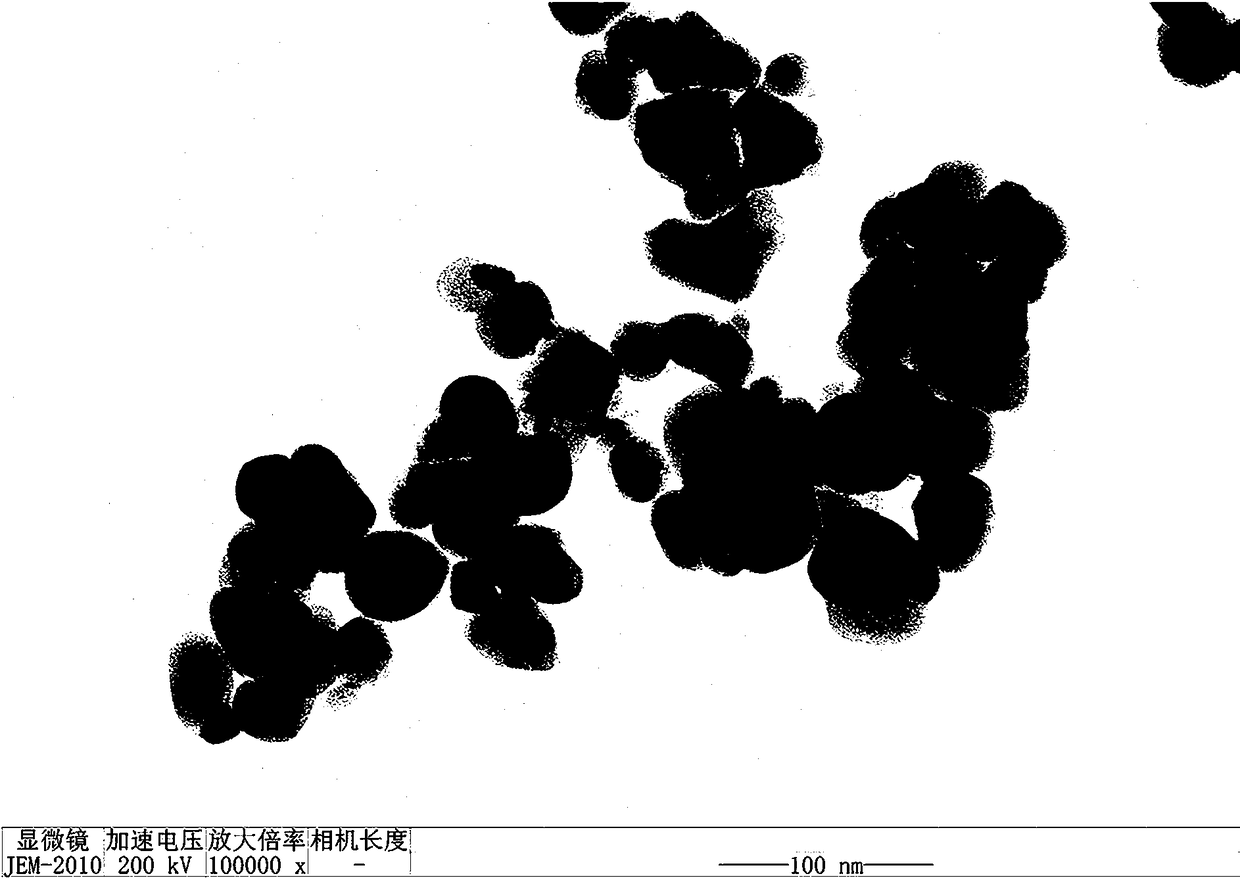

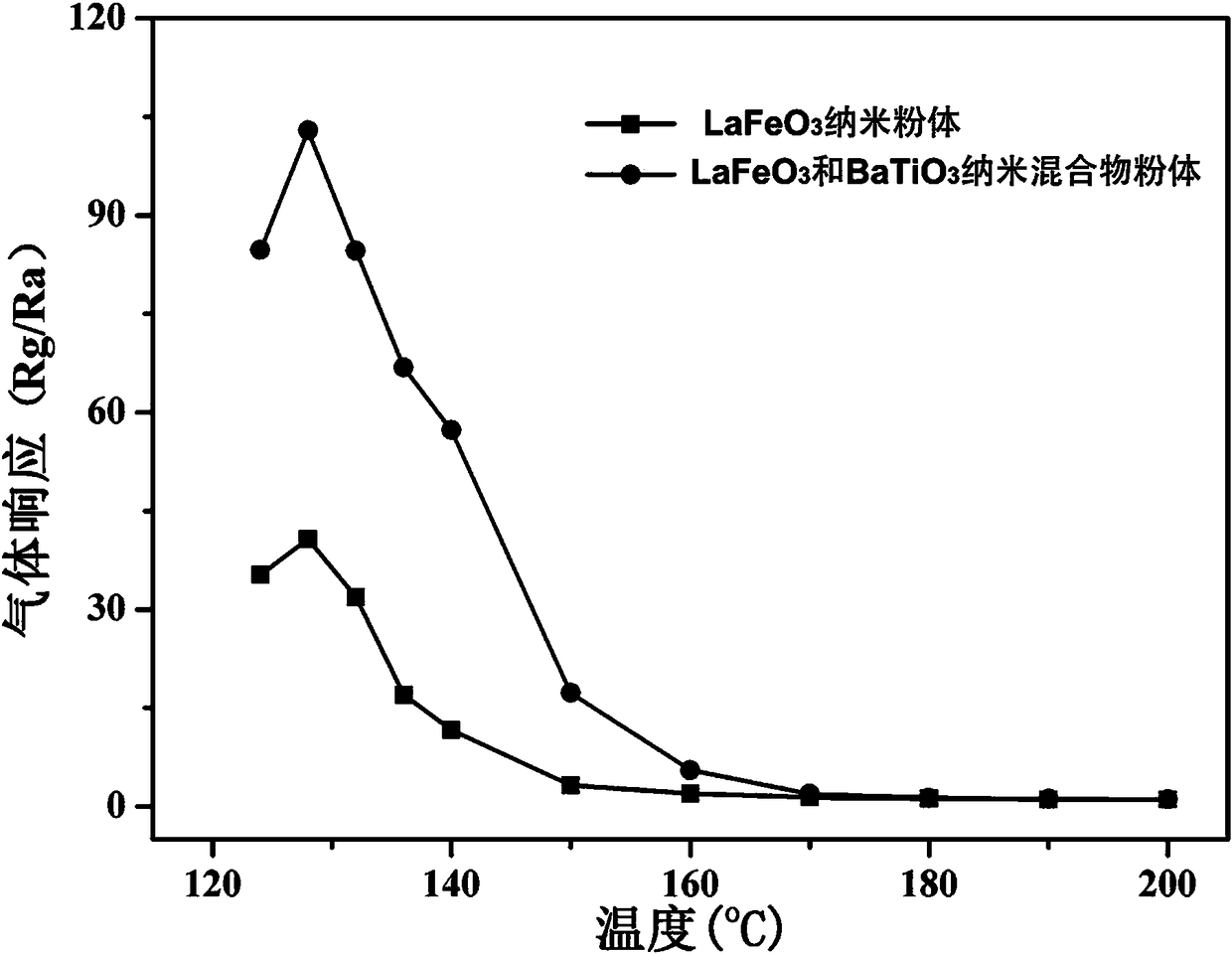

[0021] Embodiment 1: A kind of LaFeO of high gas response and selectivity 3 ethanol based gas sensor element, LaFeO 3 Nano and BaTiO 3 Nano-powders are mixed according to the molar ratio of 2:1, and sintered in a muffle furnace at 190-210°C for 2 hours to obtain nano-gas-sensing materials, and then prepared into side-heated ceramic tube structure gas sensor elements.

[0022] The specific preparation method is:

[0023] (1) LaFeO 3 Preparation of nanopowder: accurately weigh 0.02mol of La(NO 3 ) 3 ·6H 2 O and Fe(NO 3 ) 3 9H 2 O, dissolved in deionized water; add 0.08mol citric acid and 2g polyethylene glycol PEG-6000 successively, place in a water bath at 70-80°C and stir to form a sol, and continue to stir until the dry gel state; put the dry gel Heat in a crucible to remove organic matter, and the obtained powder is fully ground and placed in a muffle furnace, and sintered at 590-610 °C for 2 h to obtain nano-sized LaFeO 3 Powder;

[0024] (2) BaTiO 3 Preparation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com