Zinc oxide gas-sensitive film material, preparation method therefor and application of zinc oxide gas-sensitive film material

A zinc oxide film, zinc oxide technology, applied in the direction of zinc oxide/zinc hydroxide, analytical materials, material resistance, etc., can solve the problems of complex reaction system, complex solution system, difficult operation, etc., and achieve simple solution system and simple process. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method of the zinc oxide gas-sensitive film material of the present invention first prepares a ZnO seed crystal film on an electrode substrate to provide an in-situ growth crystal nucleus of a nanostructured zinc oxide film. ZnO seed film can be prepared by sol-gel method, thermal evaporation, sputtering and other methods.

[0027] Then, a zinc oxide precursor solution is prepared from zinc salt and alkali, and the molar ratio of zinc salt to alkali is 0.1-0.3. Zinc salt is Zn(NO 3 ) 2 , Zn(CH 3 COO) 2 , ZnSO 4 , ZnCl 2 One of them; the alkali is one of NaOH, KOH and ammonia water.

[0028] The substrate is immersed in the zinc oxide precursor solution, the solution is kept at 0-25° C. for 0.1-10 hours, and the ceramic substrate is taken out, washed and dried. Nanostructured ZnO films can be grown in situ at room temperature.

Embodiment 1

[0030] (1) Weigh a certain amount of KOH and Zn(NO 3 ) 2 , respectively dissolved in distilled water; mixing and stirring the above solutions to obtain a zinc oxide precursor solution;

[0031] (2) Immerse the ceramic substrate covered with the zinc oxide seed crystal film in the zinc oxide precursor solution, and let it stand in a water bath at 25° C. for 2 hours;

[0032] (3) After standing still, take out the ceramic substrate, wash and dry.

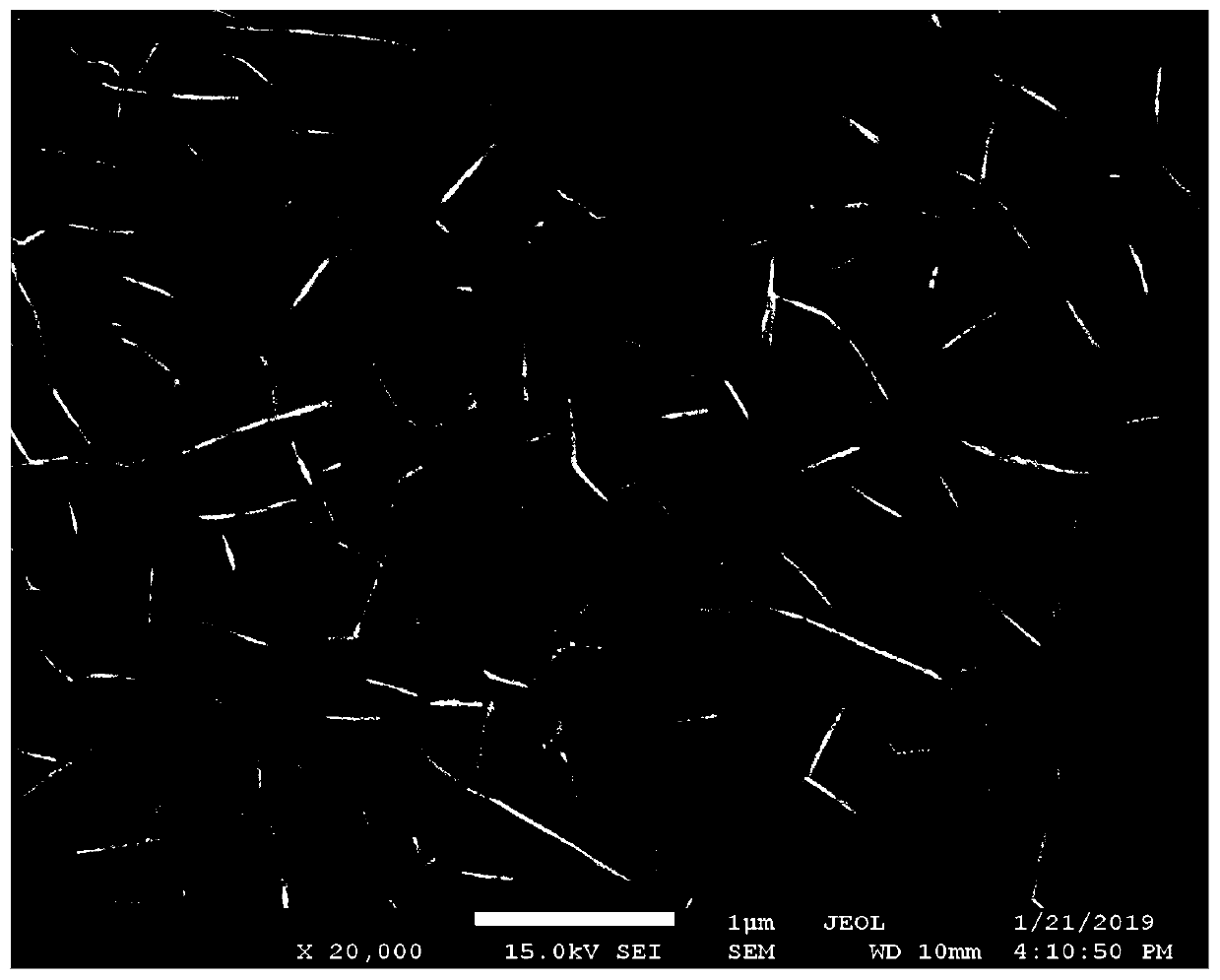

[0033] The product prepared in this embodiment is put into a scanning electron microscope to observe, as figure 1 As shown, the prepared nano-zinc oxide film is composed of nano-sheets with a thickness of about 20 nm, and the nano-sheets grow vertically to form a network structure.

Embodiment 2

[0035] (1) Weigh a certain amount of NaOH and ZnSO at a molar ratio of 1:0.2 4 , respectively dissolved in distilled water; mixing and stirring the above solutions to obtain a zinc oxide precursor solution;

[0036] (2) Immerse the ceramic substrate covered with the zinc oxide seed crystal film in the zinc oxide precursor solution, and let it stand in a water bath at 10° C. for 5 hours;

[0037] (3) After standing still, take out the ceramic substrate, wash and dry.

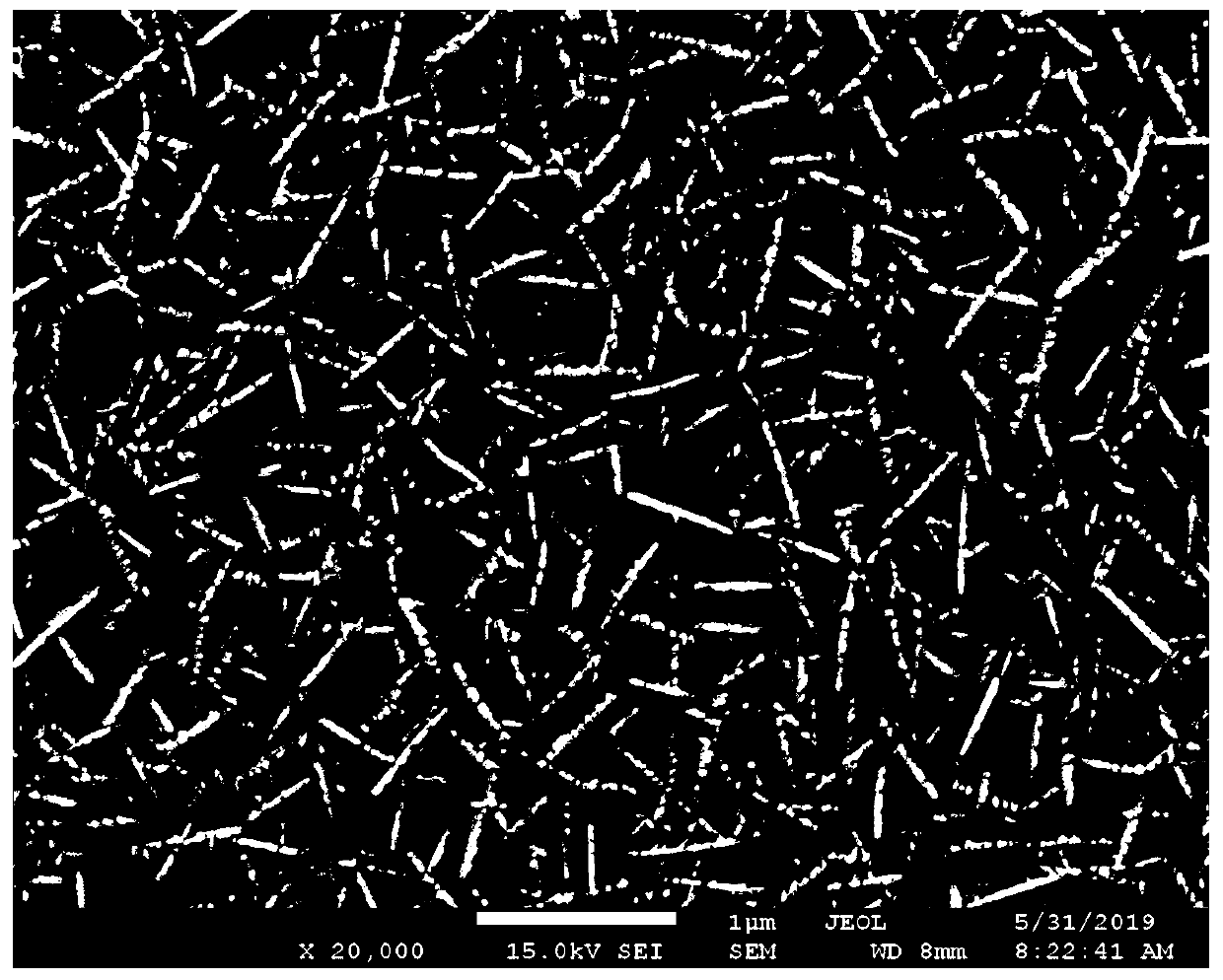

[0038] like figure 2 As shown, the prepared nano-zinc oxide film is composed of nano-sheets with a thickness of about 30 nm, and the nano-sheets grow perpendicular to the substrate to form a network structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com