A lafeo co-modified with au and cl 3 Ethanol gas sensor and preparation method thereof

A gas sensor, ethanol-based technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of gas response and selectivity to be improved, unfavorable low-power device research, insufficient gas response, etc., and achieve high selectivity and selectivity. Stability, easy operation, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

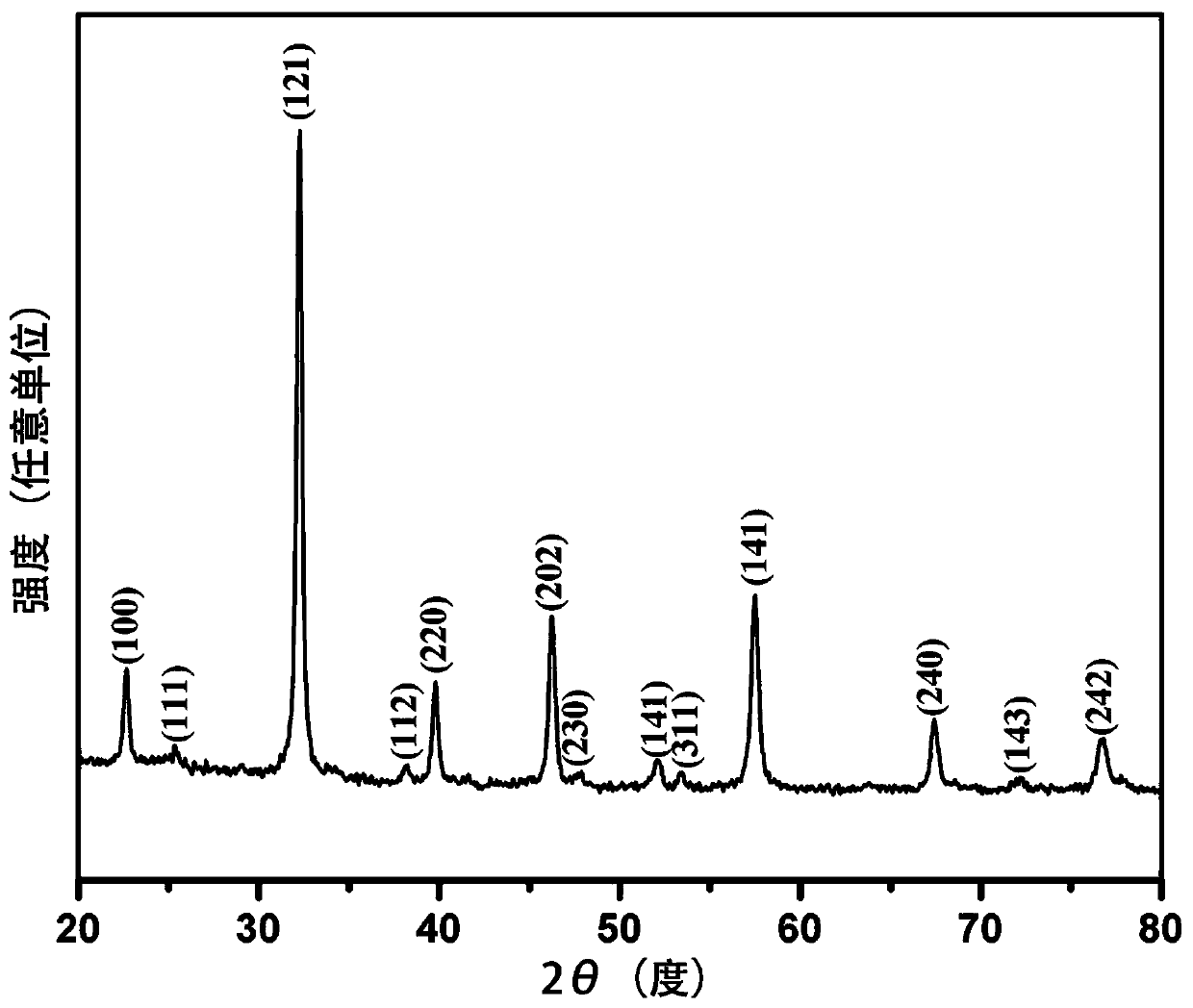

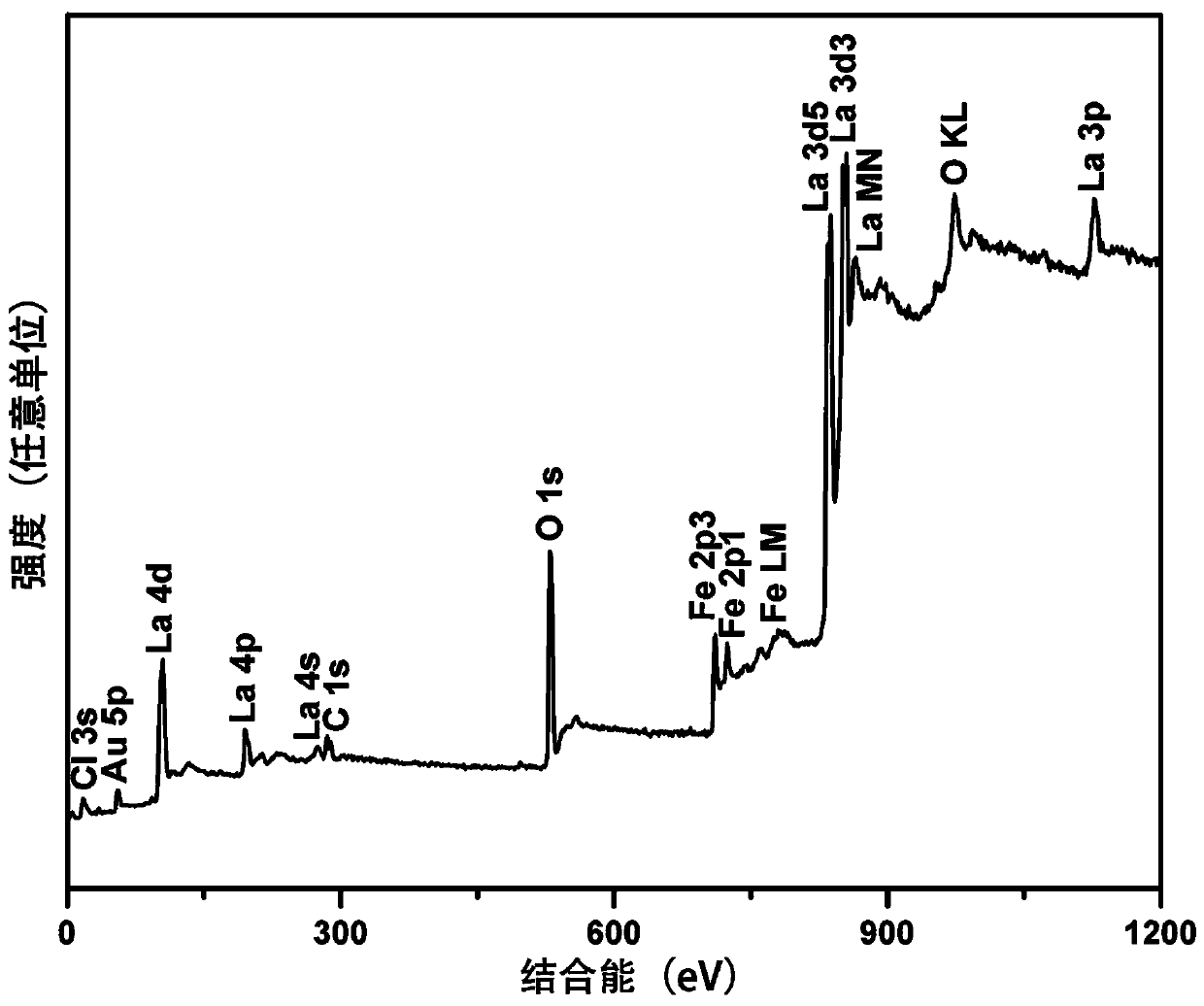

[0018] Example 1: A kind of Au and Cl co-modified LaFeO 3 ethanol based gas sensor, in LaFeO 3 The solution was added with LaFeO 3 1% HAuCl with a mass ratio of 1:100 4 Aqueous solution, preparation of Au and Cl co-modified LaFeO by sol-gel method 3 The nanopowder is then prepared into a side-heated ceramic tube structure gas sensor element.

[0019] The specific preparation method is:

[0020] (1) LaFeO 3 Preparation of nanopowder: accurately weigh 0.02mol La(NO 3 ) 3 · 6H 2 O and Fe(NO 3 ) 3 9H 2 O, dissolved in deionized water; add 0.08mol citric acid and 2g polyethylene glycol PEG-6000, add 4.85ml HAuCl with a mass fraction of 1% 4 Put the aqueous solution in a 70-80°C water bath and stir to form a sol, and continue to stir until it is in the state of dry gel; put the dry gel in a crucible and heat it at 380-420°C until the dry gel burns completely and turns into a powder state, no longer Before burning, organic matter is removed, the obtained powder is fully g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com