Wireless passive H2 gas sensor based on WO3 and preparation method thereof

A gas sensor, wireless passive technology, applied in the direction of inductance/transformer/magnet manufacturing, coil manufacturing, instruments, etc., can solve the problems of high working temperature, difficult design, complex structure, etc., to reduce the working temperature, speed up the reaction rate, The effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

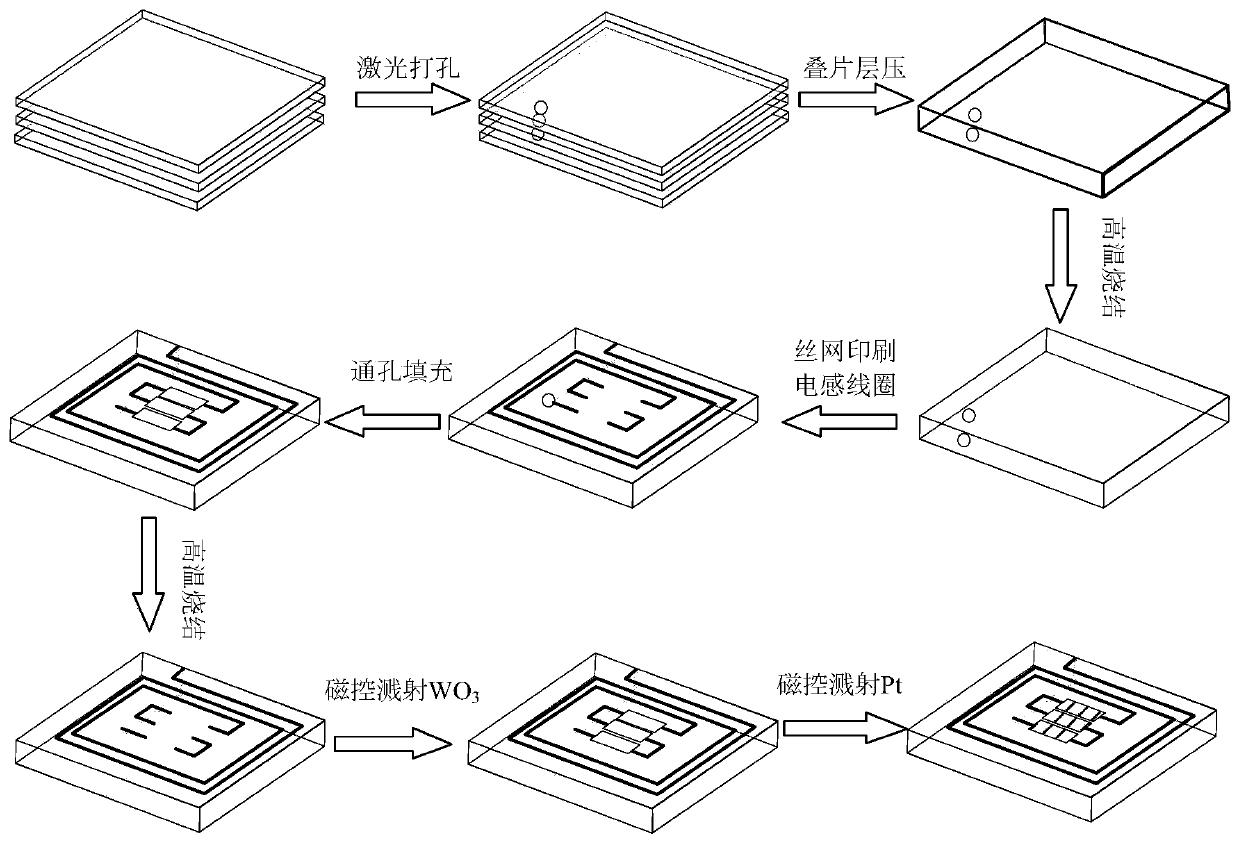

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with specific embodiments. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

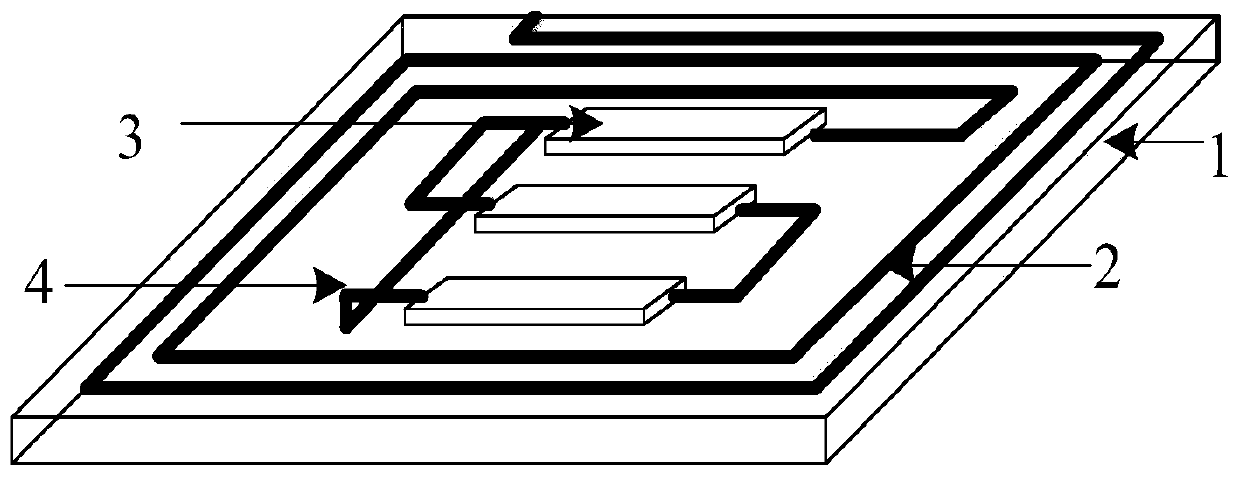

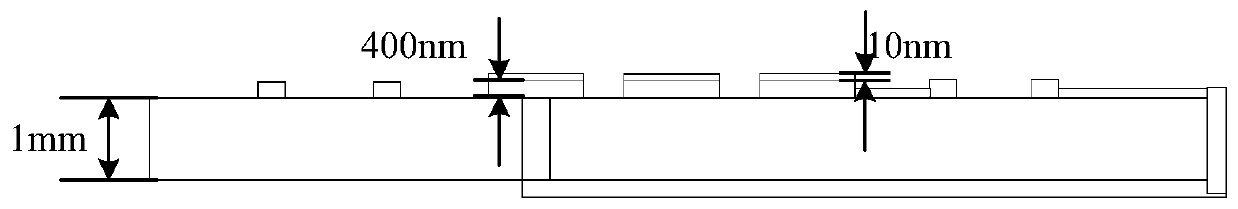

[0035] like Figure 2-Figure 3 As shown, the embodiment of the present invention provides a WO-based 3 The wireless passive H 2 Gas sensor, the gas sensor adopts the principle of wireless non-contact testing, by analyzing the Q value that changes with the resistance, it realizes the gas H 2 The non-contact test includes: a high temperature resistant ceramic substrate 1, an inductance coil 2 and a composite gas sensor 3 printed on the ceramic substrate 1, and the outer end of the inductance coil passes through the silver paste and composite gas filled in the through h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com