Anion exchange chromatographic filler for purification of low molecular weight heparin, preparation method, chromatographic column filled thereby and purification method

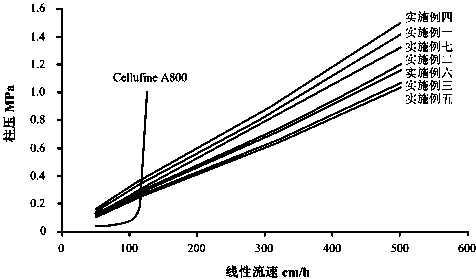

A low-molecular-weight heparin and exchange chromatography technology, which is applied in the field of purifying low-molecular-weight heparin, can solve problems such as poor pressure resistance, low dynamic adsorption capacity of chromatographic columns, and low purification efficiency of low-molecular-weight heparin, and achieve good pressure resistance and dynamic High adsorption capacity and high purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: the method for preparing anion exchange chromatographic filler.

[0025] Steps.

[0026] 1. Preparation of cross-linked polyglycidyl methacrylate-ethylene glycol diester methacrylate substrate microspheres:

[0027] a. Add 1g of polyvinyl alcohol (average molecular weight: 88-130KDa) and 360g of sodium chloride into a 4L reactor, then add 3000mL of water, and seal the reactor. Stir the materials in the reaction kettle while raising the temperature inside the kettle to 60°C. After stirring continuously for 5 hours, the polyvinyl alcohol and sodium chloride are fully dissolved, stop heating and stirring, and cool the temperature inside the kettle to room temperature to obtain an aqueous phase;

[0028] b. Add 20mL glycidyl methacrylate (GMA), 80mL ethylene glycol diester methacrylate (EDMA), 30mL cumene, 70mL n-dodecyl alcohol and 1g benzoyl peroxide in a beaker and mix them mixing to obtain a mixed material; stirring the mixed material while ultrasonica...

Embodiment 2

[0035] Embodiment 2: the method for preparing anion exchange chromatographic filler.

[0036] Steps.

[0037] 1. Preparation of cross-linked polyglycidyl methacrylate-ethylene glycol diester methacrylate substrate microspheres:

[0038]a. Add 3g of polyvinyl alcohol (average molecular weight: 88-130KDa) and 450g of sodium chloride into a 4L reactor, then add 2700mL of water, and seal the reactor. Stir the materials in the reaction kettle while raising the temperature inside the kettle to 65°C. After 4 hours of continuous stirring, the polyvinyl alcohol and sodium chloride are fully dissolved, stop heating and stirring, and cool the temperature inside the kettle to room temperature to obtain an aqueous phase;

[0039] b. Add 50mL of GMA, 50mL of EDMA, 50mL of toluene, 58mL of isooctyl alcohol and 2g of 2,2'-azobisisovaleronitrile into a beaker and mix them to obtain a mixed material; stir the mixed material to 2, 2'-Azobisisovaleronitrile is completely dissolved to obtain a...

Embodiment 3

[0046] Embodiment 3: the method for preparing anion exchange chromatographic filler.

[0047] Steps.

[0048] 1. Preparation of cross-linked polyglycidyl methacrylate-ethylene glycol diester methacrylate substrate microspheres:

[0049] a. Add 5g of polyvinyl alcohol (average molecular weight: 88-130KDa) and 300g of sodium chloride into a 4L reactor, then add 2000mL of water, and seal the reactor. Stir the materials in the reaction kettle while raising the temperature inside the kettle to 70°C. After continuous stirring for 3 hours, the polyvinyl alcohol and sodium chloride are fully dissolved, stop heating and stirring, and cool the temperature inside the kettle to room temperature to obtain an aqueous phase;

[0050] b. Add 225mL of GMA, 75mL of EDMA, 100mL of toluene and 9g of benzoyl peroxide into a beaker and mix them to obtain a mixed material; stir the mixed material while ultrasonicating until the benzoyl peroxide is completely dissolved to obtain an organic phase; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Surface charge density | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com