Porous spherical lithium manganate cathode material and preparation method thereof

A spherical lithium manganate, cathode material technology, applied in the direction of positive electrode, manganate/permanganate, nanotechnology for materials and surface science, etc., can solve pore size regulation, increase energy consumption, process Complex problems, to achieve the effect of easy operation, energy saving, wide source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation method of porous spherical lithium manganese oxide cathode material comprises the following steps:

[0016] (1) Dissolve the manganese salt in the aqueous solution, and add a certain molar amount of hydrogen peroxide:

[0017] (2) Under stirring conditions, add the aqueous solution of sodium carbonate and sodium hydroxide to the above solution, and centrifuge, wash and dry the obtained precipitate;

[0018] (3) Mix the dried precipitate with lithium carbonate evenly, and then roast at 700°C for 3 to 10 hours to obtain a porous lithium manganate material.

[0019] The invention regulates the size of the pore diameter by regulating the usage amount of hydrogen peroxide, the usage amount and the molar ratio of sodium hydroxide and sodium carbonate.

[0020] In the step (1) of the present invention, the manganese salt is manganese sulfate, or manganese acetate, or manganese chloride, and the molar concentration of manganese ions is 0.2 mol / L~1.5 mol / L; the ...

Embodiment 1

[0028] (1) Mn(C 2 h 3 o 2 ) 2 .4H 2 O is dissolved in water, where the molar concentration of manganese ions is 0.2 mol / L, and then 0.1 mol of H is added 2 o 2 ;

[0029] (2) Under stirring conditions, add sodium carbonate and sodium hydroxide aqueous solution with a molar ratio of 10:1 to the above aqueous solution, and the sodium ion concentration of the added sodium carbonate and sodium hydroxide is 0.4 mol / L;

[0030] (3) The solid precipitate generated in the solution is processed by centrifugation, washing, drying and other steps, and the obtained solid precipitate powder is manually ground with Li 2 CO 3 Mix well (Li:Mn=1.05:2), and calcinate the mixture at 700°C for 5 hours to obtain porous spherical lithium manganate material.

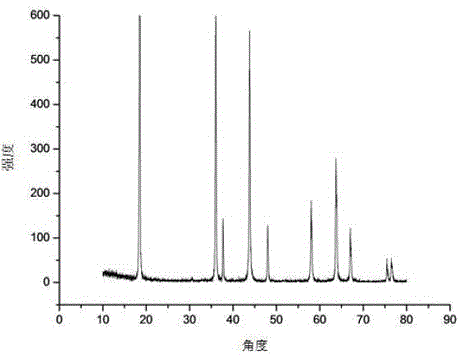

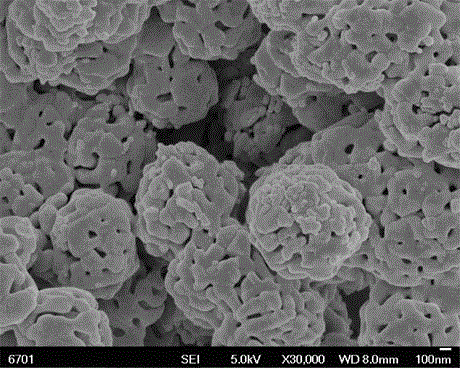

[0031] The prepared lithium manganate cathode material has a porous structure with an average pore diameter of 40 nm and a specific surface area of 30 m 2 / g; the diameter is 500 nm, and it is formed by the accumulation of particles ...

Embodiment 2

[0033] (1) Mn(C 2 h 3 o 2 ) 2 .4H 2 O is dissolved in water, where the molar concentration of manganese ions is 1.5 mol / L, and then 0.85 mol of H is added 2 o 2 ;

[0034] (2) Under stirring conditions, add sodium carbonate and sodium hydroxide aqueous solution with a molar ratio of 10:1 to the above aqueous solution, and the sodium ion concentration of the added sodium carbonate and sodium hydroxide is 4.5 mol / L;

[0035] (3) The solid precipitate generated in the solution is processed by centrifugation, washing, drying and other steps, and the obtained solid precipitate powder is ball milled and Li 2 CO 3 Mix well (Li:Mn=1.05:2), and calcinate the mixture at 700°C for 10 hours to obtain porous spherical lithium manganate material.

[0036] The prepared lithium manganate cathode material has a porous structure with an average pore diameter of 60 nm and a specific surface area of 13 m 2 / g; the diameter is 2 μm, and it is formed by the accumulation of particles of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com