Spherical cathode material for lithium-ion secondary battery and preparation method of spherical cathode material

A secondary battery and positive electrode material technology, applied in the direction of secondary batteries, battery electrodes, circuits, etc., can solve problems such as difficult to obtain, achieve the effects of inhibiting rapid growth, improving rapid charge and discharge performance, and shortening the diffusion distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1. Weighing of raw materials: Weigh 2.4g of lithium hydroxide, 8.6g of iron phosphate, 3.2g of glucose and 19.2g of oxalic acid, and measure 500mL of deionized water.

[0032] 2. Mixing: Mix the raw materials weighed above with deionized water, heat and stir to dissolve.

[0033] 3. Atomization: Pour the above solution into an atomizer, atomize to form droplets, and then introduce the droplets into the low-temperature zone (-196°C) of the freeze dryer to obtain solid powder.

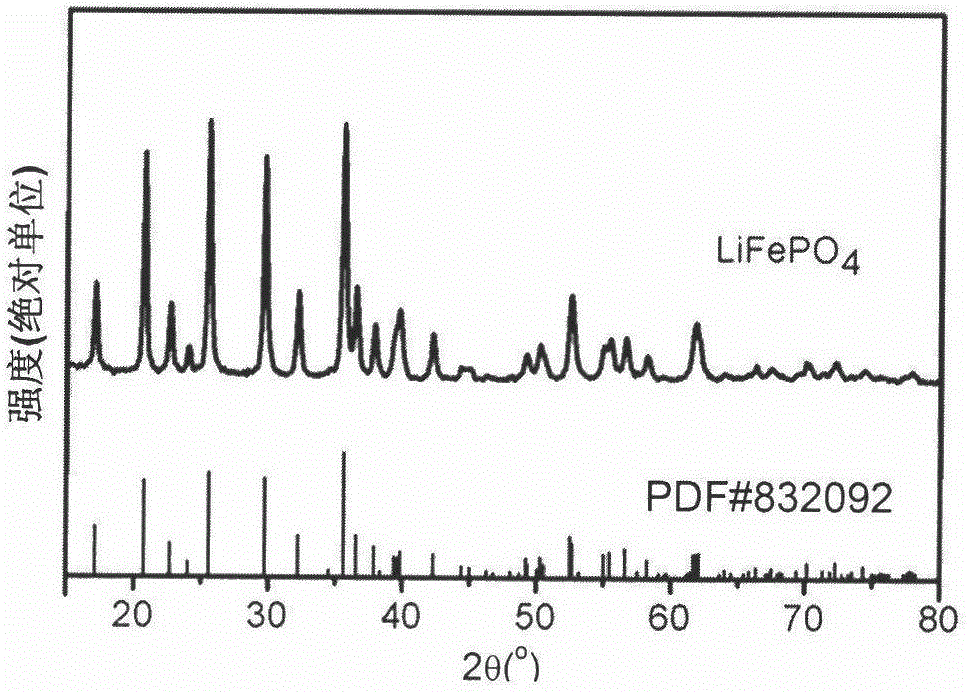

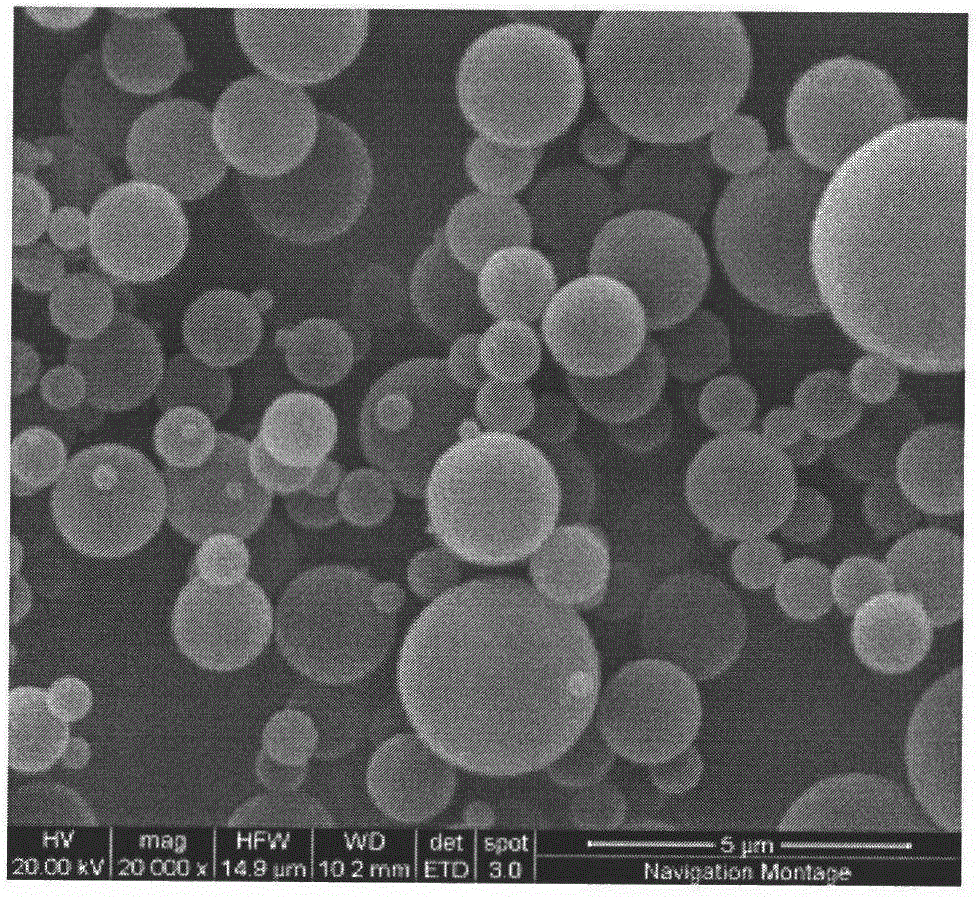

[0034] 4. Drying: The solid powder is dried by a freeze dryer, and the obtained powder is rapidly pyrolyzed in a high-temperature furnace. The pyrolysis temperature is 750°C, and the pyrolysis time is 5 minutes. The obtained [LiFe x mn 1-x PO 4 , (x=1)] the powder is collected for later use. Its XRD diffraction pattern is shown in figure 1 , SEM photo see figure 2 shown.

Embodiment 2

[0036] 1. Weighing of raw materials: Weigh 3.9g of lithium nitrate, 8.6g of iron phosphate, 3.2g of glucose and 19.2g of oxalic acid, and measure 1000mL of deionized water.

[0037] 2. Mixing: Mix the raw materials weighed above with deionized water, heat and stir to dissolve.

[0038] 3. Atomization: Pour the above solution into an atomizer, atomize to form droplets, and then introduce the droplets into the low-temperature zone (-196°C) of the freeze dryer to obtain solid powder.

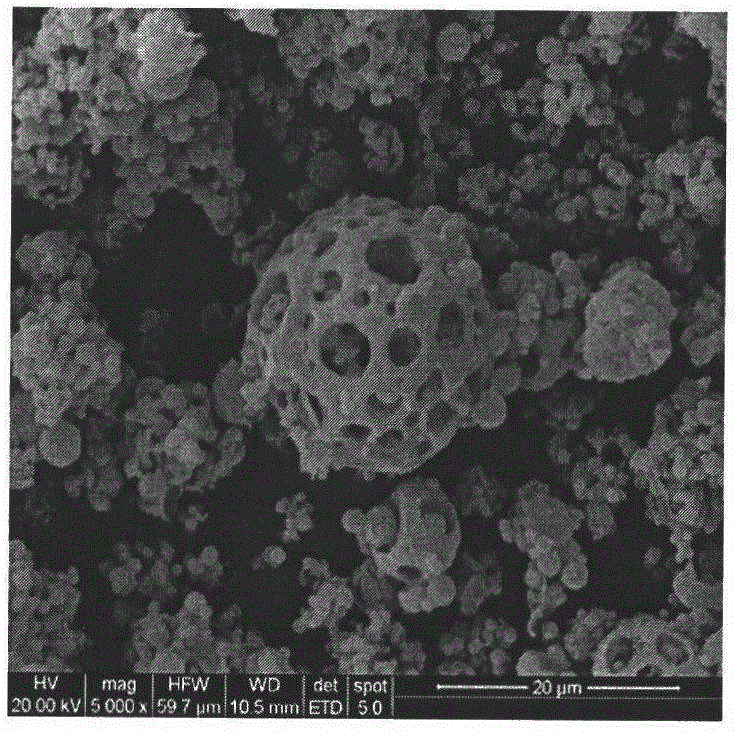

[0039] 4. Drying: The solid powder is dried by a freeze dryer, and the obtained powder is rapidly pyrolyzed in a high-temperature furnace. The pyrolysis temperature is 750°C, and the pyrolysis time is 5 minutes. The obtained [LiFe x mn 1-x PO 4 , (x=1)] the powder is collected for later use. Its SEM photo see image 3 shown.

Embodiment 3

[0041] 1. Weighing of raw materials: Weigh 4.2g of lithium carbonate, 8.6g of iron phosphate, 3.2g of glucose and 19.2g of oxalic acid, and measure 1000ml of deionized water.

[0042] 2. Mixing: Mix the raw materials weighed above with deionized water, heat and stir to dissolve.

[0043] 3. Atomization: Pour the above solution into the atomizer and atomize to form mist.

[0044] 4. Drying: Then the mist is introduced into a hot air furnace (350°C) to dry to obtain a solid powder, and then the obtained solid powder is rapidly pyrolyzed in a high-temperature furnace with a pyrolysis temperature of 750°C and a pyrolysis time of 5 minutes , the resulting [LiFe x mn 1-x PO 4 , (x=1)] the powder is collected for later use. Its TEM picture is shown in Figure 4 As shown, the discharge capacity measured at different rates is shown in Figure 5 As shown, the discharge capacity and cycle life performance at different rates are shown in Figure 6 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com