Indium oxide material for gas detection and preparation method thereof

A gas detection, indium oxide technology, applied in nanotechnology for materials and surface science, chemical instruments and methods, analytical materials, etc., to meet the requirements of fast response recovery, short response recovery time, excellent selectivity and stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

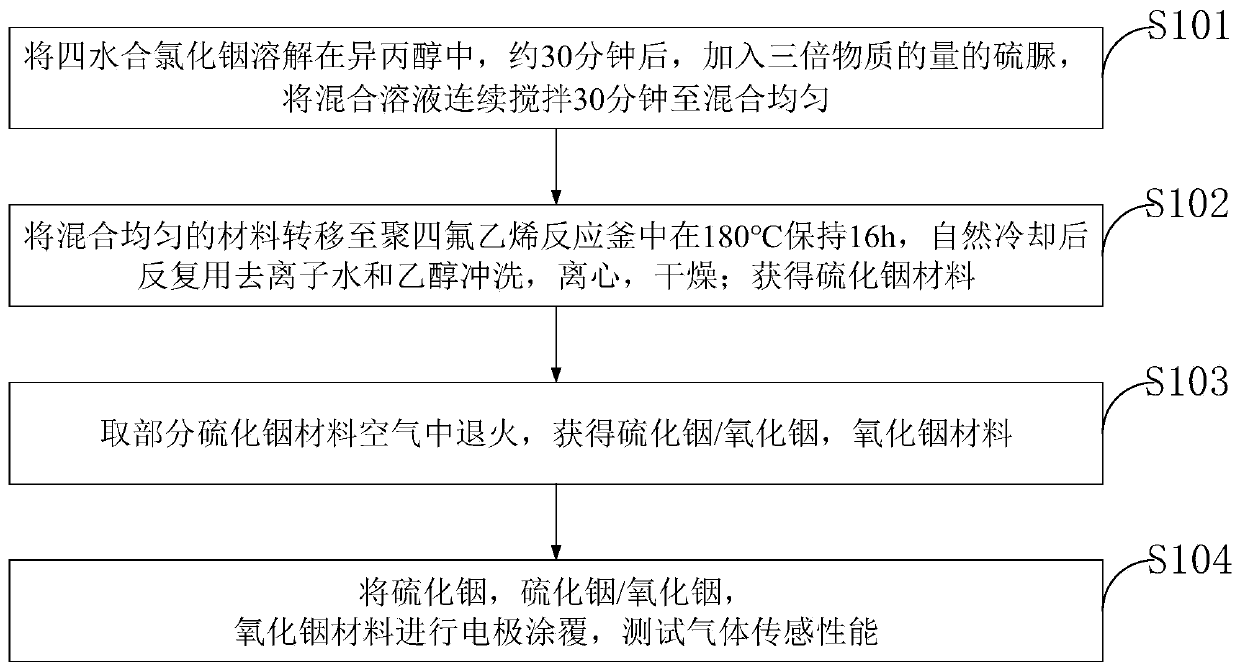

[0038] The synthesized indium oxide material of the invention is used as a gas sensor. The composition of the annealed material is controlled by controlling the annealing temperature of indium sulfide in air. Finally, the three materials are tested for gas sensitivity, and the gas sensitivity response of indium oxide is the best. In air atmosphere, raise from 20°C to 400°C at a rate of 2°C / min, hold for 1h, then cool down to room temperature at 5°C / min (to obtain indium sulfide / indium oxide), from 20°C at a rate of 2°C / min Rise to 500°C and keep for 1h, then cool down to room temperature at 5°C / min (to obtain indium oxide)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com