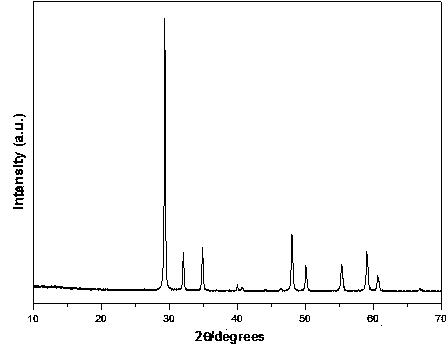

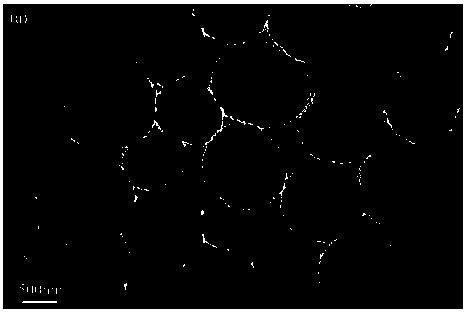

Preparation method for cadmium molybdate porous spheres

A technology of porous balls and cadmium molybdate, applied in chemical instruments and methods, molybdenum compounds, inorganic chemistry, etc., can solve problems such as troublesome processing and unreasonable performance, and achieve good crystallinity, excellent performance, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1, cadmium chloride is dissolved in deionized water to form an aqueous cadmium chloride solution, and the Cd in the solution is adjusted 2+ The ion concentration is 0.15mol / L;

[0024] Step 2, dissolving sodium acetate in deionized water to form an aqueous solution of sodium acetate, and adjusting the CH in the solution 3 COO - The ion concentration is 0.15mol / L;

[0025] Step 3. Dissolve sodium molybdate in deionized water to form an aqueous solution of sodium molybdate, and adjust the MoO in the solution 4 2- The ion concentration is 0.15mol / L;

[0026] Step 4, mixing the cadmium chloride solution prepared in step 1 with the sodium acetate solution prepared in step 2 to obtain cadmium acetate precipitation as a reaction precursor;

[0027] Step 5, mix the sodium molybdate solution prepared in step 3 with the cadmium acetate precipitation solution prepared in step 4, then add it to the inner tank of the reactor, adjust the volume of the reaction material in t...

Embodiment 2

[0031] Step 1, cadmium chloride is dissolved in deionized water to form an aqueous cadmium chloride solution, and the Cd in the solution is adjusted 2+ The ion concentration is 1.65mol / L;

[0032] Step 2, dissolving sodium acetate in deionized water to form an aqueous solution of sodium acetate, and adjusting the CH in the solution 3 COO - The ion concentration is 1.65mol / L;

[0033] Step 3. Dissolve sodium molybdate in deionized water to form an aqueous solution of sodium molybdate, and adjust the MoO in the solution 4 2- The ion concentration is 1.65mol / L;

[0034] Step 4, mixing the cadmium chloride solution prepared in step 1 with the sodium acetate solution prepared in step 2 to obtain cadmium acetate precipitation as a reaction precursor;

[0035] Step 5, mix the sodium molybdate solution prepared in step 3 with the cadmium acetate precipitation solution prepared in step 4, then add it to the inner tank of the reactor, adjust the volume of the reaction material in t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com