Preparation method for iron phosphate used for lithium battery

A technology for iron phosphate and lithium batteries, applied in battery electrodes, secondary batteries, chemical instruments and methods, etc., can solve problems such as difficulty in ensuring safety, poor material stability, and poor cycle performance, and achieve reduced ion diffusion resistance, good Wetting property and the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to describe the technical content, achieved goals and effects of the present invention in detail, the following descriptions will be made in conjunction with the embodiments and accompanying drawings.

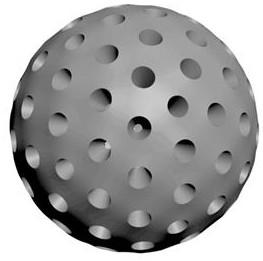

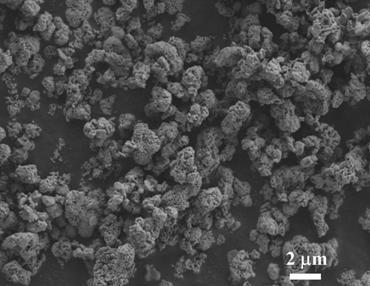

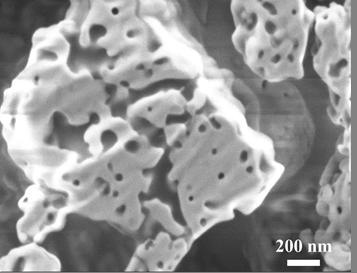

[0047] Embodiment one of the present invention is: a kind of iron phosphate, such as figure 1 As shown, the primary particle of the iron phosphate has a hollow porous spherical structure; the secondary particle has a hollow porous spherical structure. The preparation method includes the steps of hydrolysis nucleation pretreatment, hydrothermal, centrifugal water washing and etching dehydration. Specifically, the following steps are included:

[0048] Step 1: hydrolysis nucleation pretreatment: configure sodium hydroxide solution 100ml, concentration is (10 -4 ~10 -2 mol / L), corresponding to a pH of 10~12; place the reaction vessel in a water bath at 40~60°C and stir at a constant speed, slowly add tetraethyl orthosilicate dropwise to it, and use it to hydroly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com