Composite cathode material of lithium ion battery and preparation method thereof

A technology for lithium ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve problems such as limiting the application of metal oxides, losing electrochemical activity, and deteriorating electrical conductivity, and achieves good industrialization prospects and good circulation. Stability, simple production method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the lithium ion battery composite negative electrode material of the present invention includes the following steps:

[0022] 1. Dissolve the zinc salt in deionized water at a zinc atom concentration of 0.1-10 mol / L, stir magnetically, at a temperature of 25-50 ℃, rotate at 10-25 r / min, and time for 30-180 min, until the zinc salt is completely dissolved , Get the zinc salt solution. The iron salt is dissolved in deionized water according to the iron atom concentration of 0.1~10mol / L, magnetically stirred, the temperature is 25~50℃, the speed is 10~25r / min, and the time is 30~180min, until the iron salt is completely dissolved. Iron salt solution.

[0023] The zinc salt is zinc nitrate, zinc chloride or zinc acetate.

[0024] The iron salt is iron nitrate, iron chloride or iron citrate.

[0025] 2. The zinc salt solution and the iron salt solution, according to the ratio of the amount of zinc salt to iron salt substance of 1~24:8, the temperature is ...

Embodiment 1

[0037] 1. Weigh 74.37g (0.25mol) Zn(NO 3 ) 2 ·6H 2 O was dissolved in 300ml of deionized water at a temperature of 25°C, a rotation speed of 10r / min, and a magnetic stirring for 180min to obtain a zinc salt solution with a zinc atom concentration of 0.83mol / L. Weigh again 202g (0.5mol) Fe(NO 3 ) 3 .9H 2 O was dissolved in another 300ml deionized water at a temperature of 25°C, a rotation speed of 10r / min, and a magnetic stirring for 180min to obtain an iron salt solution with an iron atom concentration of 1.67mol / L.

[0038] 2. Mix the zinc salt solution with the iron salt solution, the molar ratio of the zinc salt to the iron salt is 1:2, the temperature is 25°C, the speed is 10r / min, and the magnetic stirring is 180min to obtain the iron-zinc mixed solution.

[0039] 3. Slowly add 52.535g (0.25mol) C to the iron-zinc mixed solution 6 H 8 O 7 ·H 2 O, at 50℃, rotating speed 10r / min, constant temperature magnetic stirring for 120min, then add 11.88g (0.06mol) C to it 6 H 12 O 6 ·H 2 ...

Embodiment 2

[0048] 1. Weigh 67.9g (0.5mol) ZnCl 2 Dissolve in 300ml deionized water, temperature 50℃, rotating speed 25r / min, magnetic stirring for 30min, obtain zinc salt solution with zinc atom concentration of 1.67mol / L. Weigh again 202g (0.5mol) Fe(NO 3 ) 3 ·9H 2 O was dissolved in another 300ml of deionized water at a temperature of 50°C, a rotational speed of 25r / min, and magnetic stirring for 30 minutes to obtain an iron salt solution with an iron atom concentration of 1.67 mol / L.

[0049] 2. Mix the zinc salt solution with the iron salt solution, the molar ratio of zinc salt to iron salt is 1:1, the temperature is 50°C, the speed is 25r / min, and the magnetic stirring is 30min to obtain the iron-zinc mixed solution.

[0050] 3. Slowly add 105g (0.5mol) C to the iron-zinc mixed solution 6 H 8 O 7 ·H 2 O, at 70℃, rotating speed 25r / min, constant temperature magnetic stirring for 30min, then add 12g (0.06mol) C to it 6 H 12 O 6 ·H 2 O, then at 70 ℃, rotating speed 25r / min, constant temperat...

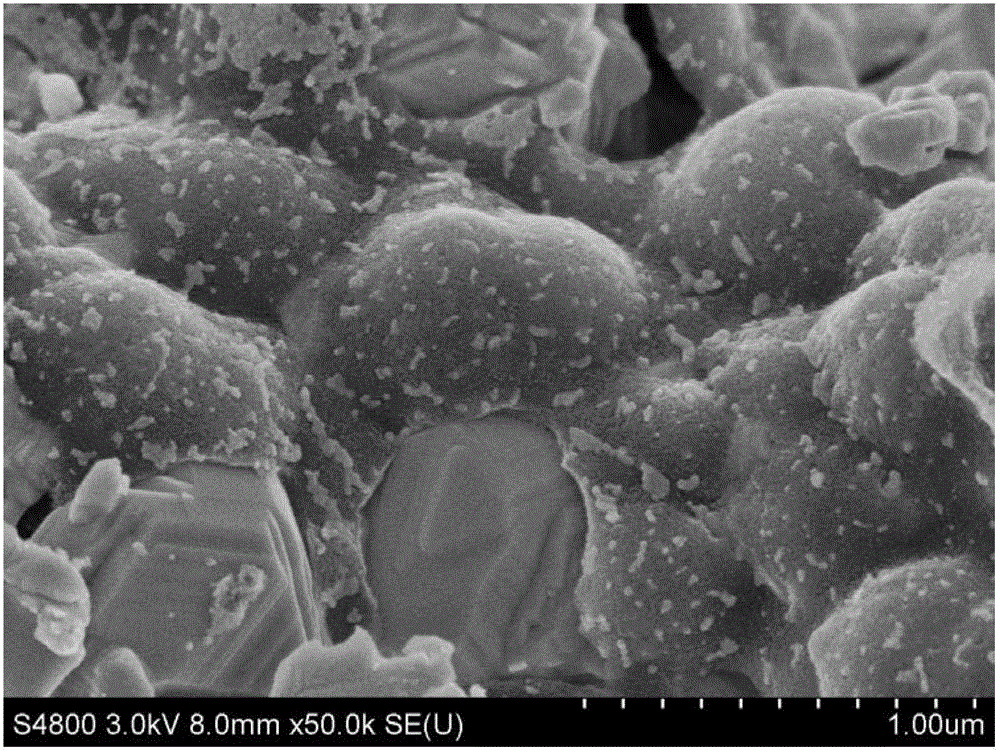

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com