Gas fuel porous medium surface combustor

A porous medium, surface combustion technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of unstable gas fuel combustion, small power adjustment range, low pollutant emissions, etc., to overcome easy tempering. , The effect of stable combustion and high combustion temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

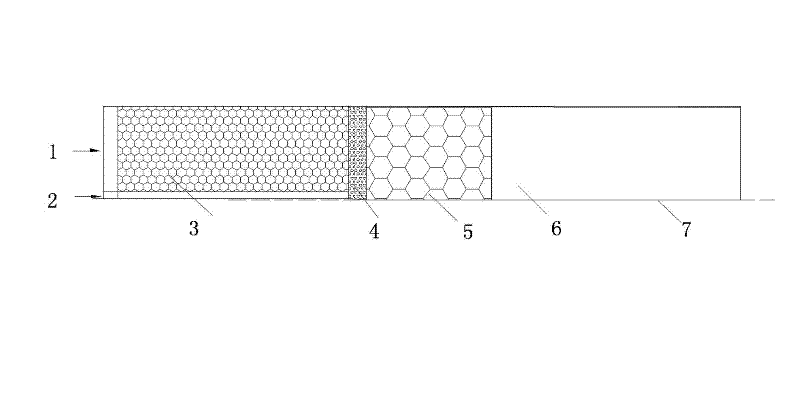

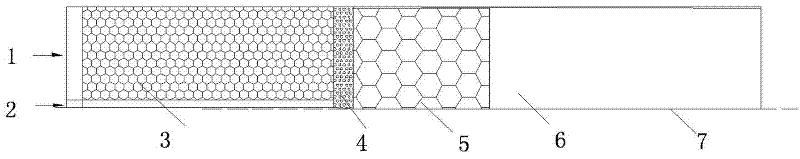

[0017] The casing structure is adopted, including porous area I and porous area II. The porous area I and the porous area II are respectively provided with a sphere I3 and a sphere II5. The diameter of the sphere II5 is larger than that of the sphere I3. The fuel gas 2 is supplied by a gas storage tank or a fuel pipe. Supply, air 1 is supplied by a compressor, gas and air nozzles are both steel pipes and arranged coaxially. The gas nozzle is an inner ring, and the air nozzle is an outer ring, and is connected to the burner shell through a pipe, the inner ring and the outer ring A sphere II5 is set in between to balance the air flow, and a sphere I3 is set above the gas nozzle to enhance the performance of fuel and air mixing. By adjusting the arrangement of the sphere, the flame main body is on the surface of the burner, and part of the flame is stabilized in the porous medium. The high temperature resistant steel wire mesh 4 is placed above the fuel nozzle.

[0018] The inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com