Single-sheet surface paper preheating mechanism, corrugated paper board production lines and process and control method

A technology of corrugated cardboard and single-sheet face paper, which is applied in the direction of machining/deformation, and can solve problems such as easy edge warping, difficulty in preheating single-sheet face paper, and uneven moisture in the upper and lower layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

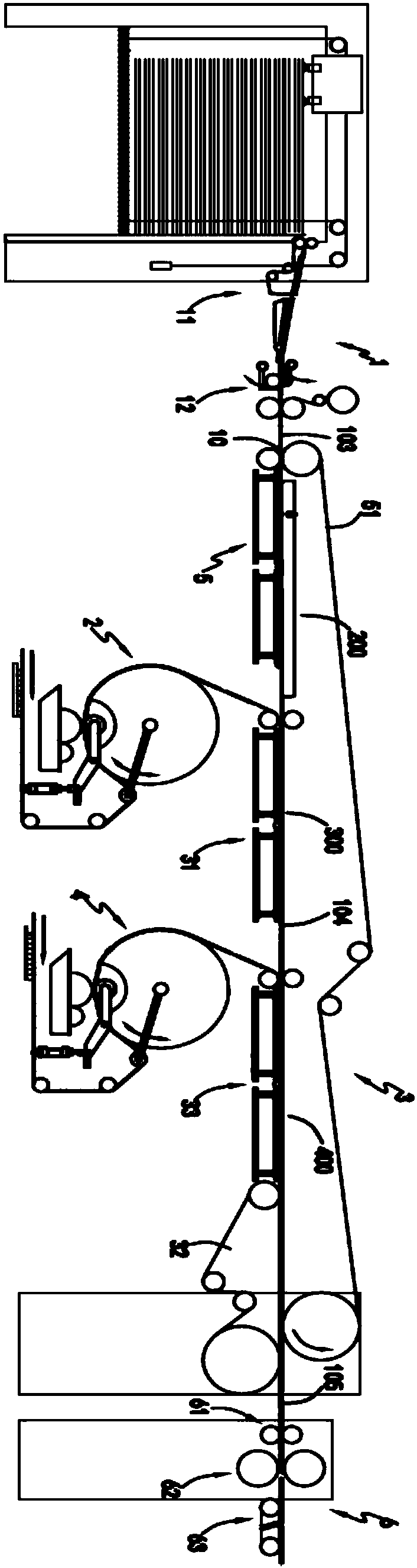

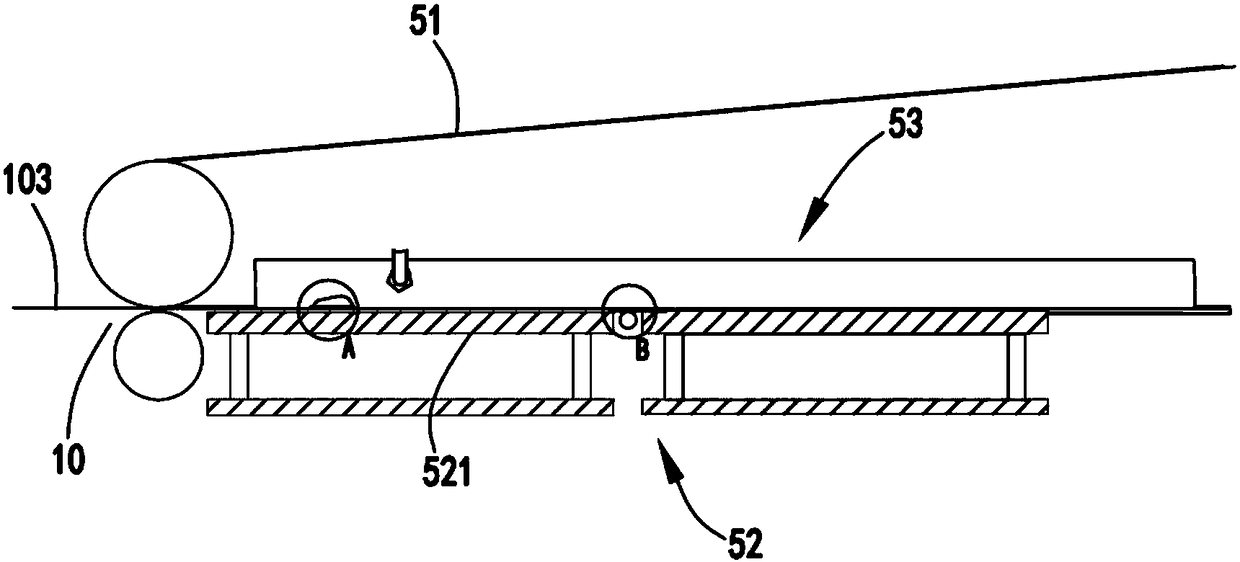

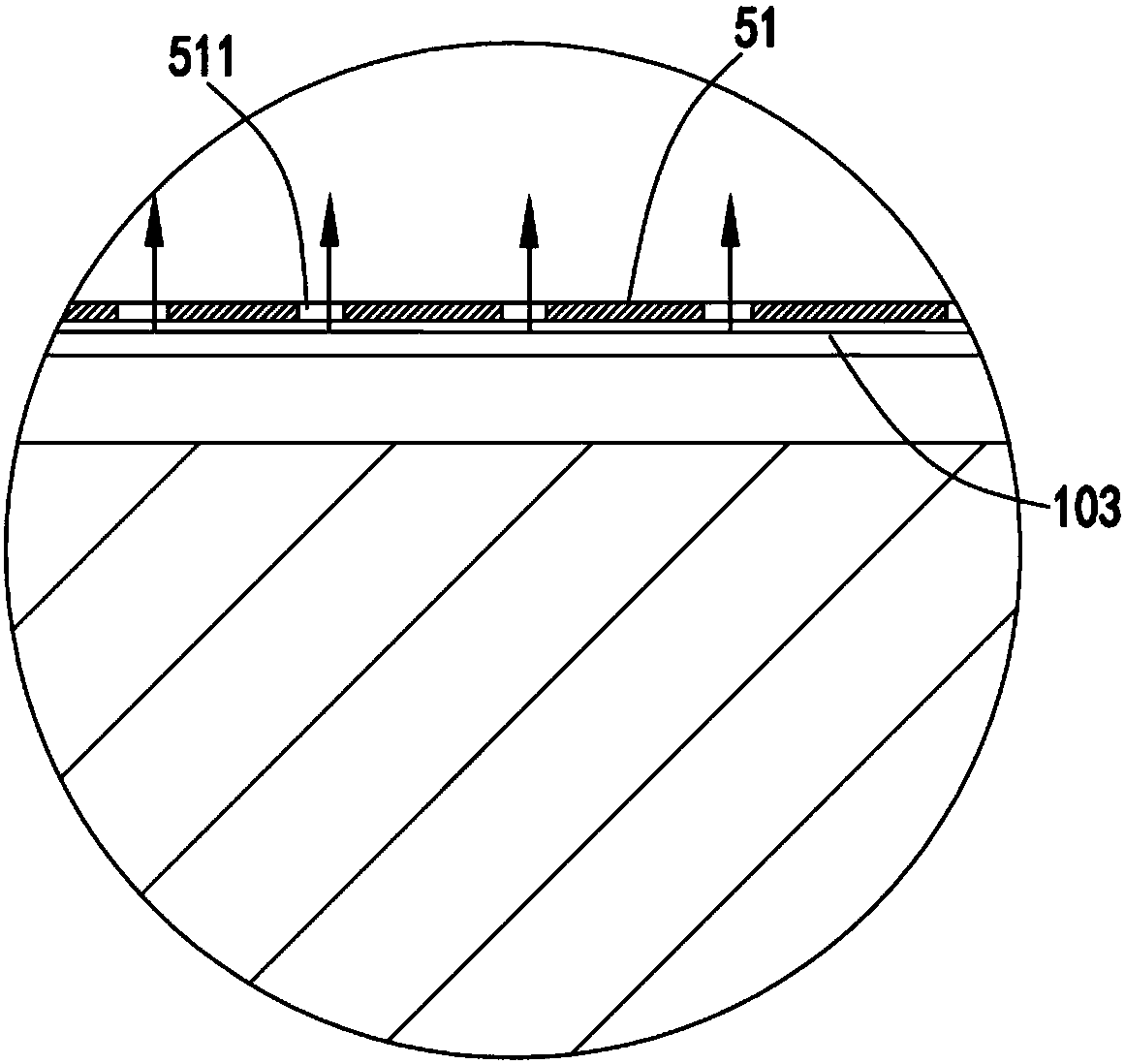

[0071] Such as figure 2 , image 3 , Image 6 , Figure 7 , Figure 8 with Figure 9 As shown, a continuous output type single facial paper preheating mechanism includes a facial paper feeding device 1 for continuously conveying a single facial paper to the first paper inlet 10, and also includes a facial paper feeding device 1 arranged at the facial paper feeding The facial tissue preheating device 5 at the rear of the device 1, the facial tissue preheating device 5 includes a conveyor belt a51 and a preheating mechanism 52 arranged below the conveyor belt a51, and there is a space between the conveyor belt a51 and the preheating mechanism 52. Single facial paper 103 is transported to the preheating channel 100 for preheating, and the transmission belt a51 is divided into a section 200, b section 300 and c section 400, and when the single facial paper 103 is in a section 200, it is between the transmission belt a51 The space is relatively stationary and driven by the tr...

Embodiment 2

[0080] Components that are the same as or corresponding to those in the first embodiment use the reference numerals corresponding to those in the first embodiment. For the sake of simplicity, only the differences from the first embodiment are described below. The difference between the second embodiment and the first embodiment is that in this embodiment, the transmission belt a51 is made of silica gel material, the friction force between the transmission belt a51 and the face paper is f1, and the face paper and the preheated The friction force between the mechanisms 52 is f2, f1 and f2 are satisfied, f1>f2≥0, the transmission speed of the transmission belt a51 is v, and v1, f1 and f2 meet the requirements of the transmission belt a51 to drive the facial paper transmission During the process, the face paper and the conveyor belt a51 remain relatively still.

[0081] It should be noted that the transmission belt a51 is not limited to be made of the silica gel material described...

Embodiment 3

[0083] Such as figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 As shown, a three-layer corrugated cardboard production line also includes a second paper inlet 20 behind the first paper inlet 10, a first first corrugated paper 101 that is used to transport the glued first corrugated paper 101 to the second paper inlet 20. The corrugated paper conveying device 2 and the bonding device 3 for bonding the single face paper 103 and the first corrugated paper 101 to form a three-layer corrugated board 104 .

[0084] Specifically, the first corrugated paper conveying device 2 includes a gluing assembly a21 for gluing the first corrugated paper 101 and a preheating assembly arranged behind the gluing assembly a21 for preheating the first corrugated paper 101 a22.

[0085] Further, the first corrugated paper conveying device 2 also includes a deviation correcting component a23 for correcting the deviation of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com