A heat transfer oil circulating combustion furnace and method thereof

A technology of circulating combustion and heat conduction oil, which is applied in the field of heat conduction oil heating, to achieve the effects of preventing heat loss, simple structure, and stable fuel combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

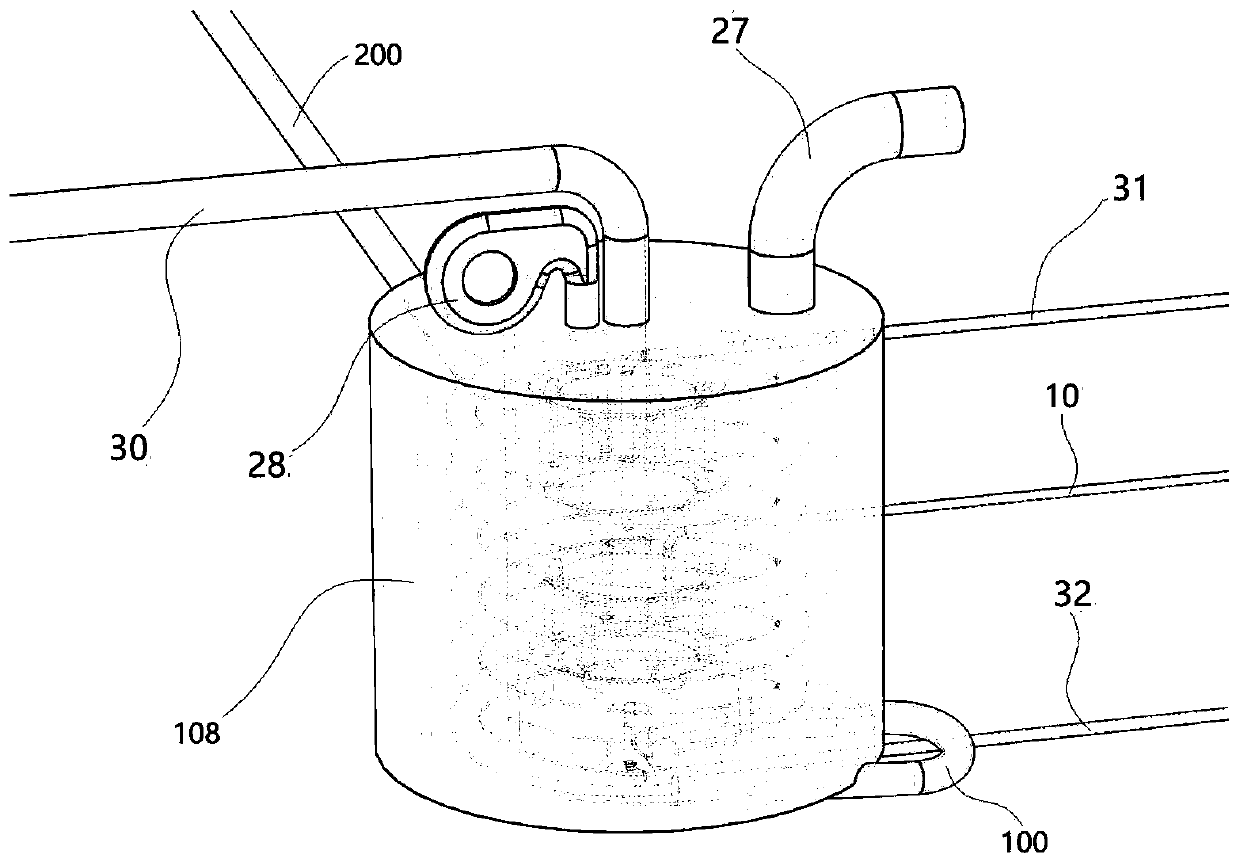

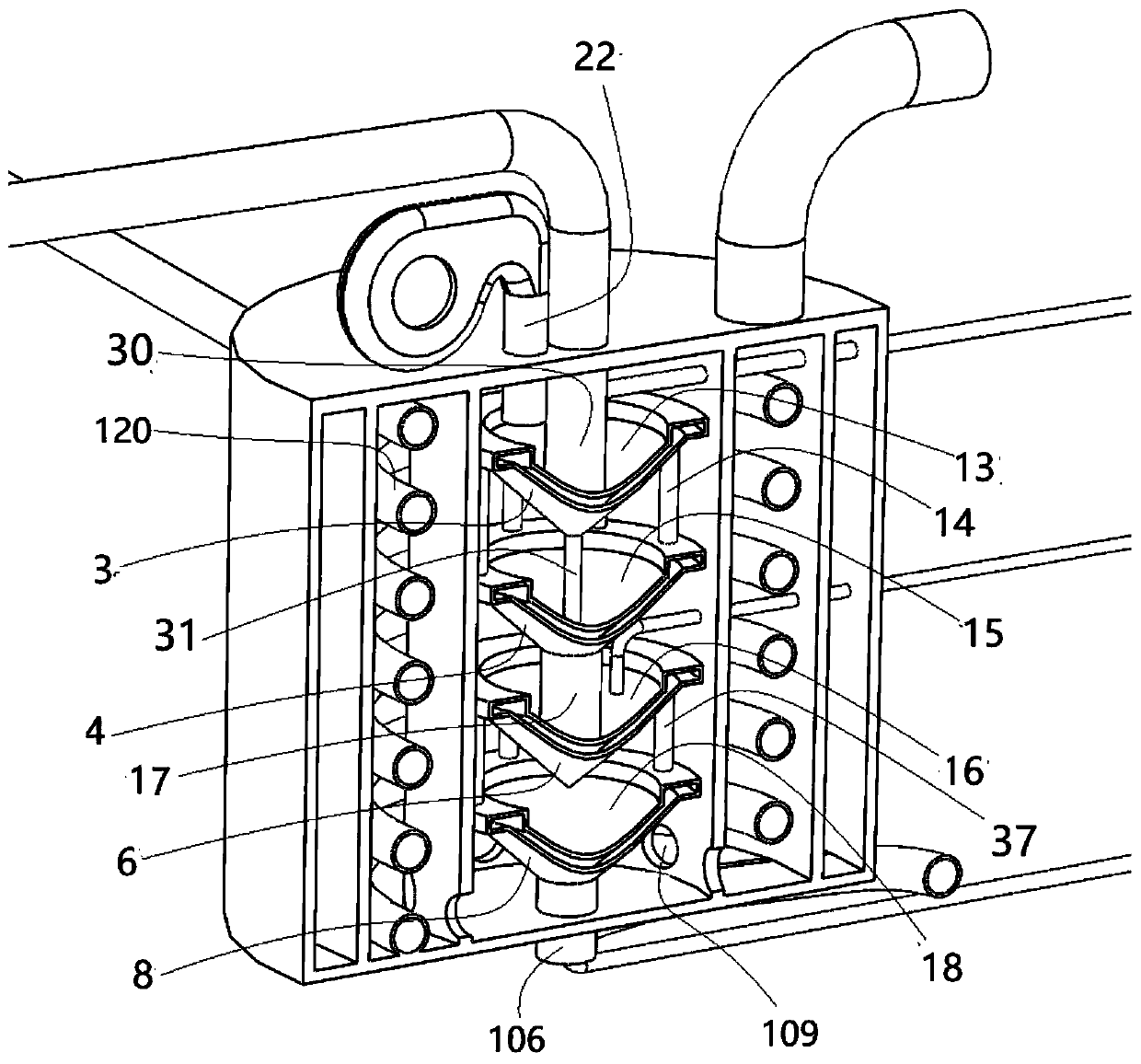

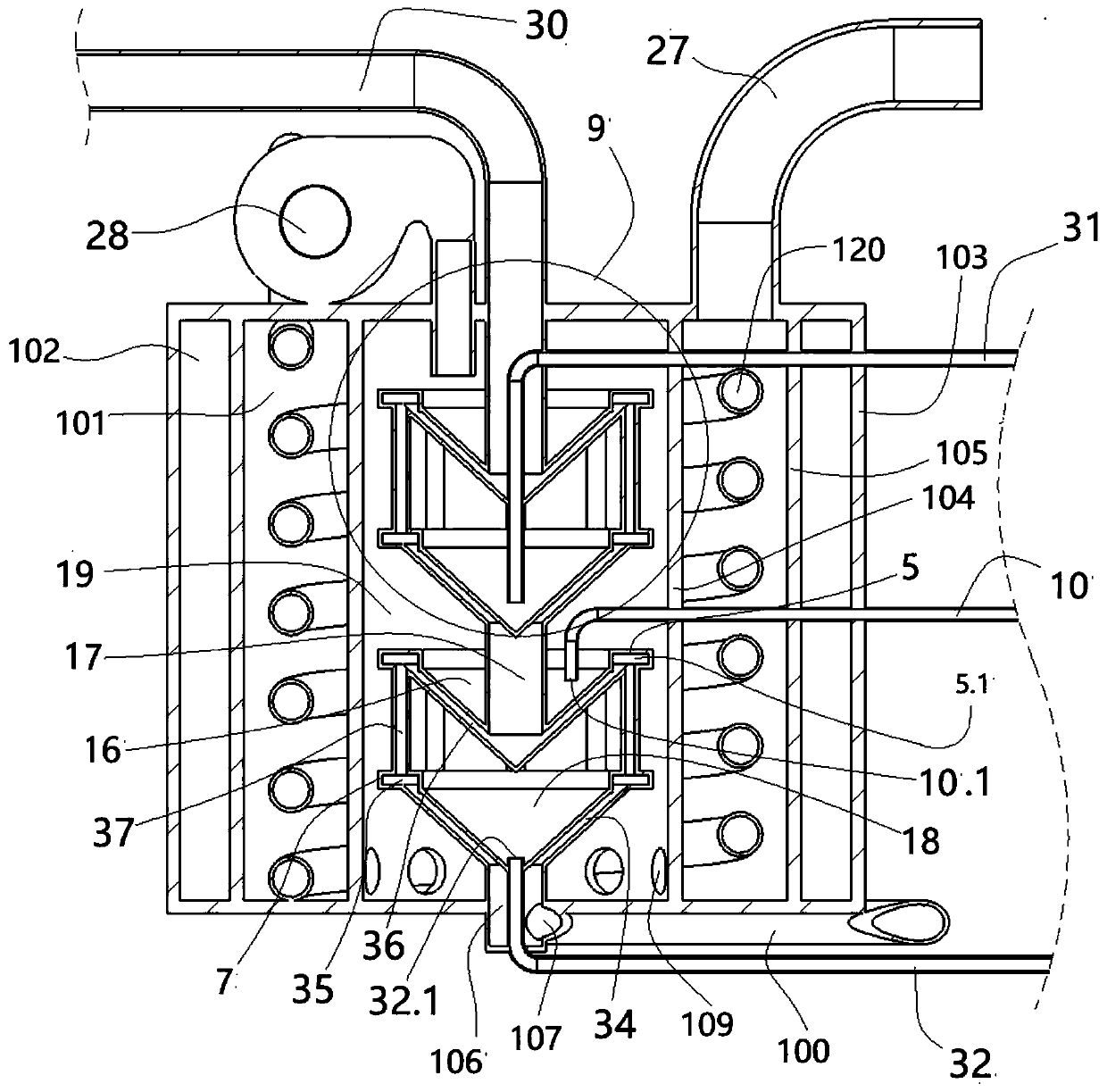

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

[0023] Structure introduction: attached Figures 1 to 4 The heat transfer oil circulating combustion furnace shown includes a combustion furnace body 108, the combustion furnace body 108, a cold heat transfer oil supply pipe 200 and a heat transfer oil outlet pipe 30, and the oil outlet end of the cold heat transfer oil supply pipe 200 The oil inlet end of the combustion furnace body 108 is communicated with, and the oil outlet end of the combustion furnace body 108 is connected with the oil inlet end of the heat conduction oil outlet pipe 30 .

[0024] The combustion furnace body 108 includes an outer thermal insulation shell 103, the outer thermal insulation shell 103 is a vertical cylindrical airtight shell structure, the inner cavity of the thermal insulation shell 103 is coaxially provided with a flue gas wrapping shell 105, The flue gas wrapping shell 105 is an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com