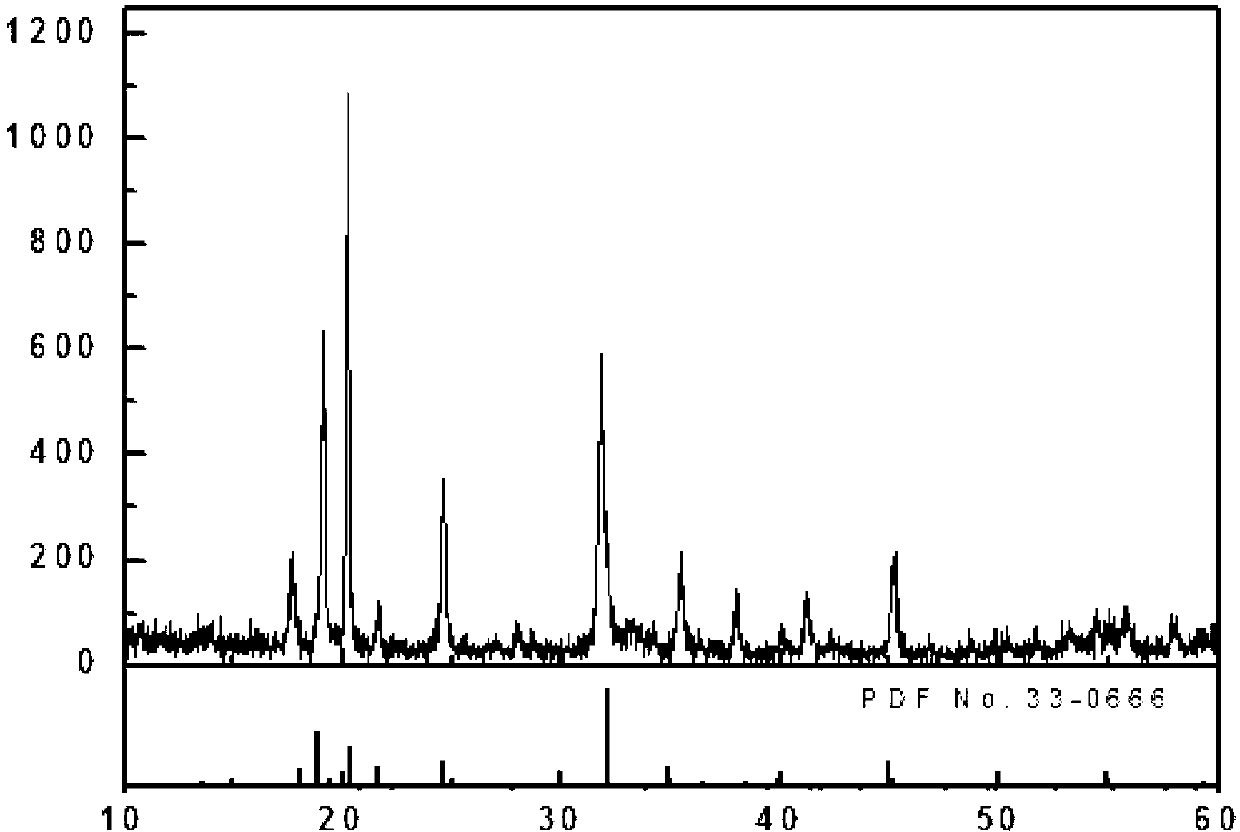

Shape-controlled battery grade iron phosphate and preparation method thereof

An iron phosphate and battery-level technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve the problems of low lithium ion diffusion rate and limited battery reaction kinetics, and achieve good monodispersity and short ion migration The effect of distance and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

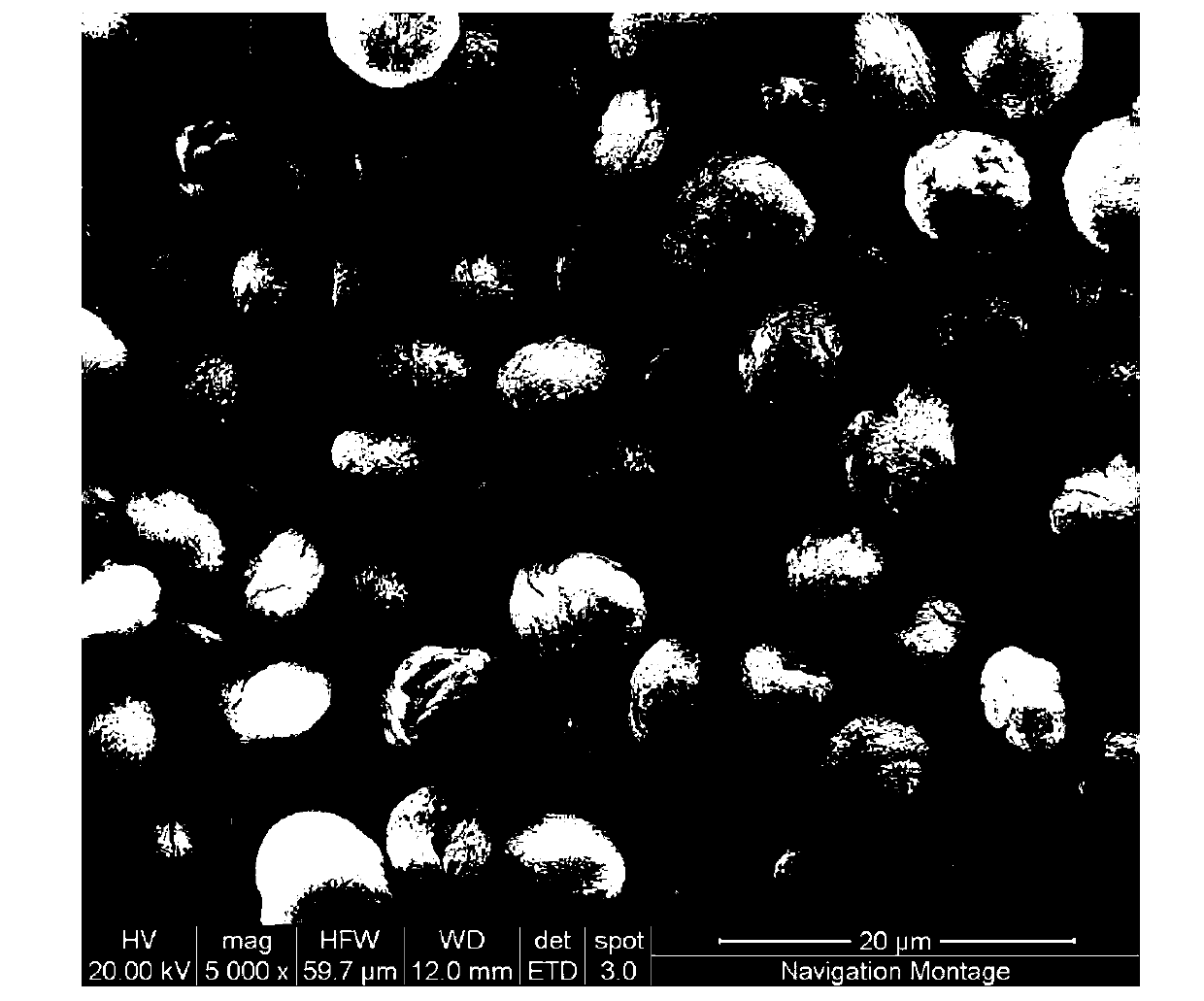

[0025] Measure deionized water 55.0mL and ethylene glycol 5.0mL, configure reaction mother liquor; Weigh 0.82g ferric chloride hexahydrate (99%), 2.08g phosphoric acid (85%), 0.33g urea (99%) respectively and Dissolve in the above mother liquor to form a reaction solution; transfer the reaction solution to a 100mL hydrothermal reaction kettle, and react at 180°C for 2 hours; filter, wash and dry the product to obtain spherical ferric phosphate with a particle size of about 6 μm. The scanning electron microscope photo is as follows: figure 2 .

Embodiment 2

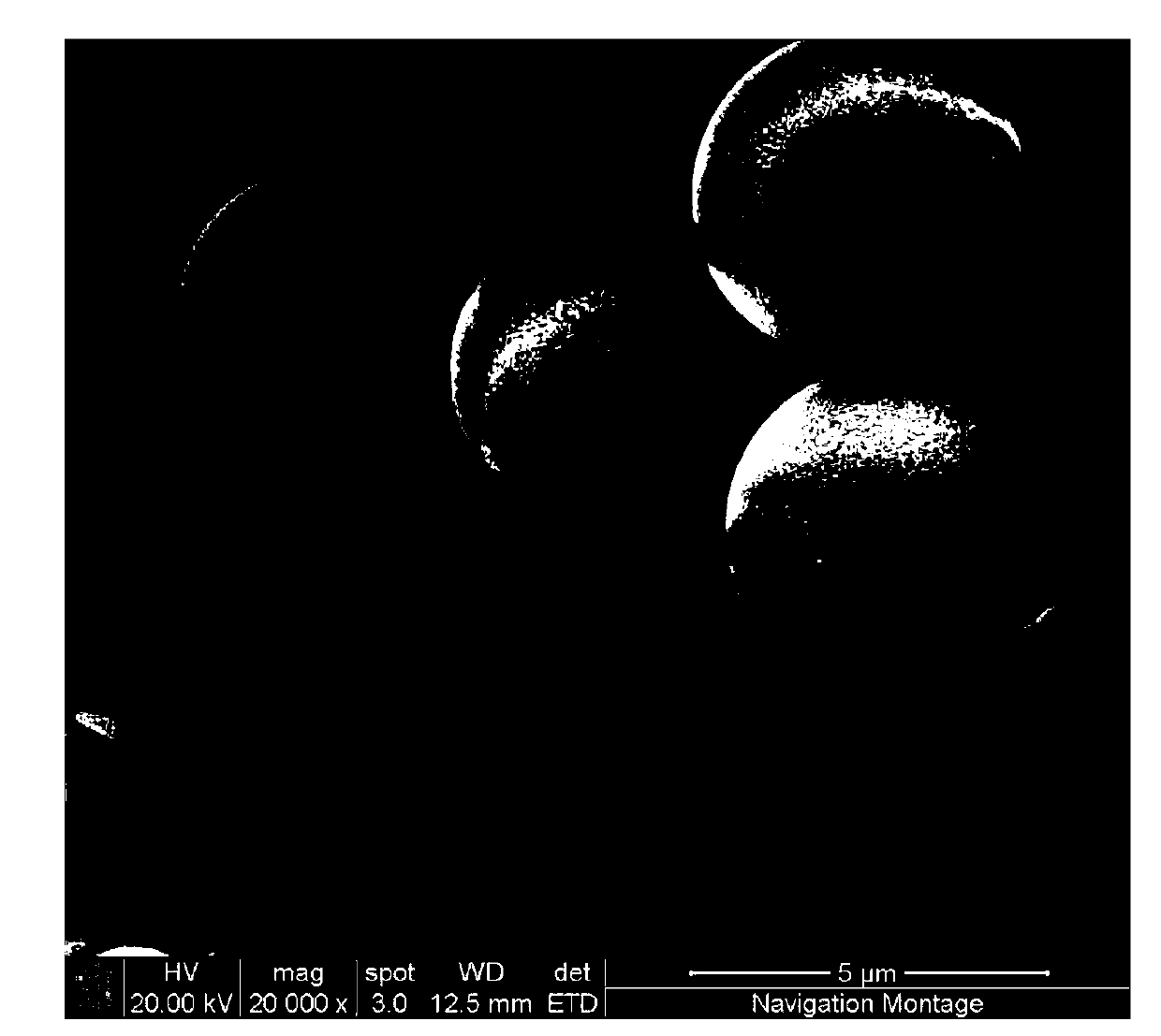

[0027] Measure the filtrate 60mL in embodiment 1 as reaction mother liquor; Take by weighing 0.82g ferric chloride hexahydrate (99%), 0.69g phosphoric acid (85%), 0.33g urea (99%) respectively and be dissolved in above-mentioned mother liquor, form Reaction solution; transfer the reaction solution to a 100mL hydrothermal reaction kettle, and react at 180°C for 2 hours; filter, wash and dry the product to obtain solid spherical iron phosphate with a particle size of about 5 μm, and the scanning electron microscope photo is as follows image 3 .

Embodiment 3

[0029] Measure 30mL of deionized water and 30mL of ethylene glycol to configure the reaction mother liquor; weigh 0.82g of ferric chloride hexahydrate (99%), 2.08g of phosphoric acid (85%), and 0.33g of urea (99%) respectively and dissolve them in The above mother liquor was used to form a reaction solution; the reaction solution was transferred to a 100mL hydrothermal reaction kettle, and reacted at 180°C for 2 hours; the product was filtered, washed and dried to obtain a disc-shaped iron phosphate with a diameter of about 4 μm, scanning electron microscope photos Such as Figure 4 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com