Ultraviolet-cured thin film with adjustable refractive index and preparation method of ultraviolet-cured thin film

A refractive index and ultraviolet technology, applied in the field of optical materials, can solve the problems of structural collapse and cannot meet the high-energy transmission requirements of strong laser devices, and achieve the effect of high resistance to laser damage and excellent resistance to laser damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A kind of ultraviolet curing film with adjustable refractive index, its preparation method comprises the following steps:

[0026] (1) Mix ethyl orthosilicate, deionized water, and ethanol in a molar ratio of 1:3:10, and then follow the principle of silane hydrolysis and polycondensation to react at 10°C for 18 hours to obtain oligomers, and continue at 50°C Under aging for 60h, SiO was prepared by self-assembled clusters of oligomers 2 porous ball;

[0027] (2) Mix silane methacrylate, deionized water, and ethanol at a molar ratio of 1:5:10, and then follow the principle of silane hydrolysis and polycondensation to react at 120°C for 7 hours to obtain oligomers. 4% photoinitiator TPO by mass and stir evenly to obtain UV-curable sol;

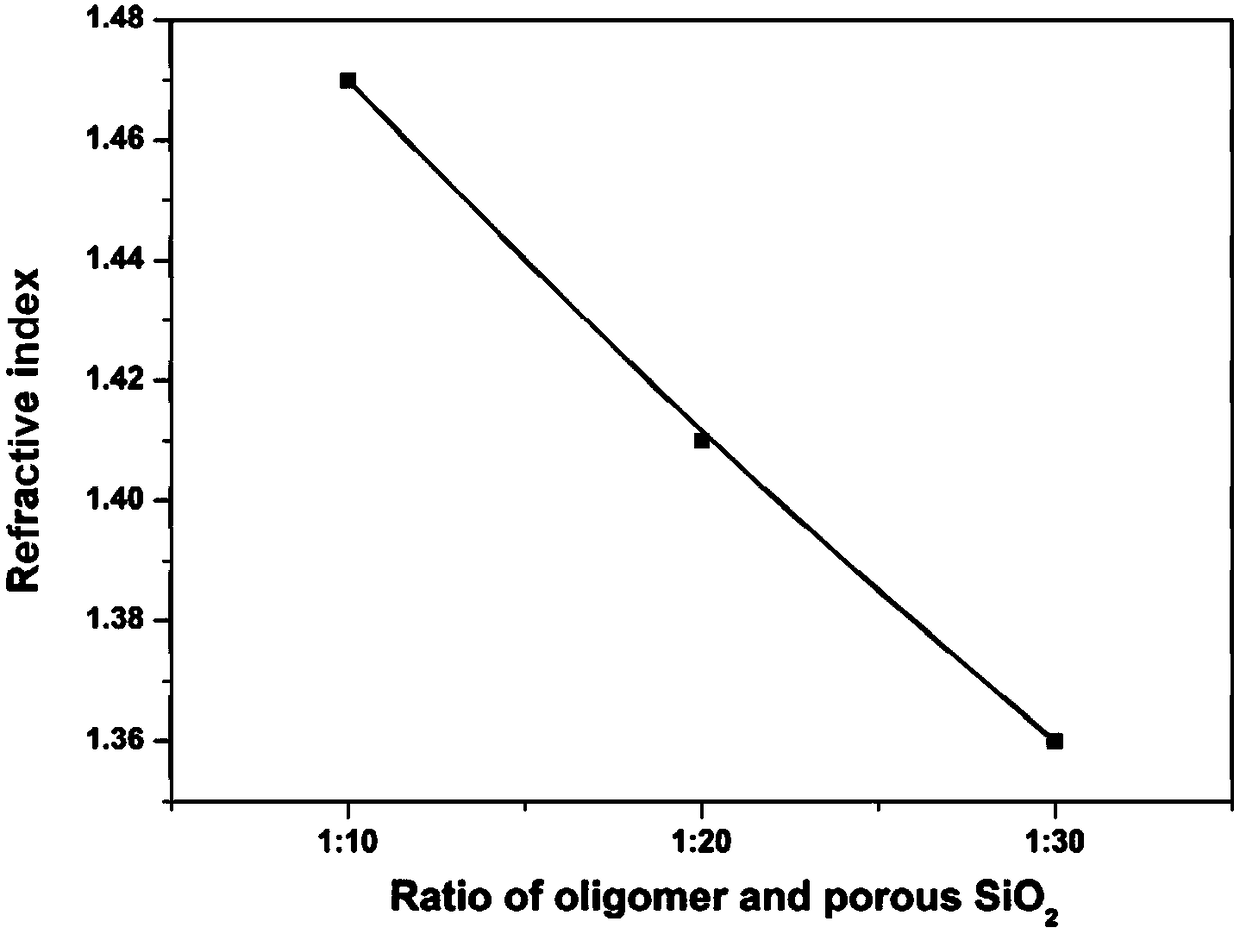

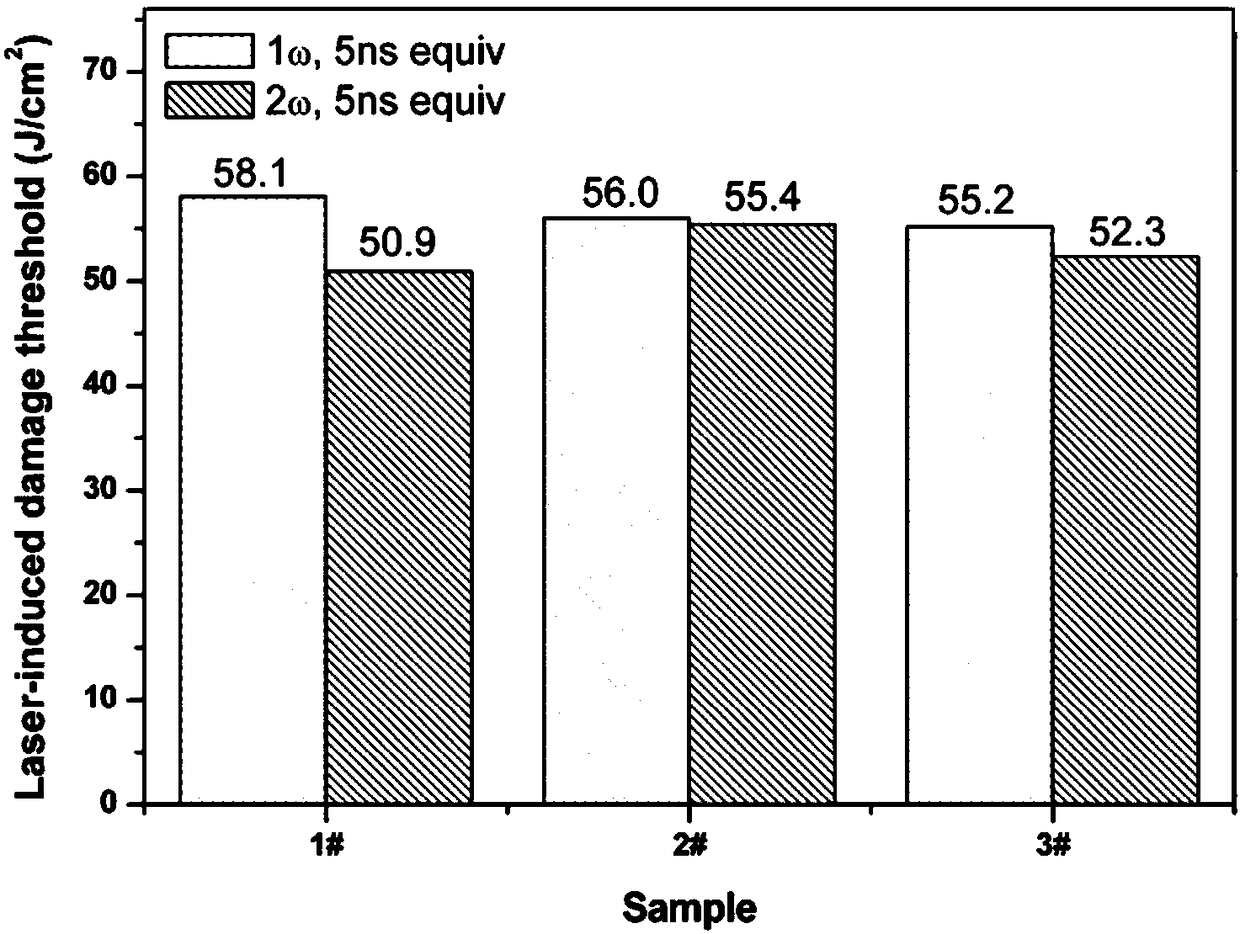

[0028] (3) Combine UV-curable sol and SiO 2 The porous balls are mixed evenly according to the mass ratio of 1:10, and then coated on the fused silica substrate by the spin coating method, and the film to be cured is prepared by using ...

Embodiment 2

[0032] A kind of ultraviolet curing film with adjustable refractive index, its preparation method comprises the following steps:

[0033] (1) Mix ethyl orthosilicate, deionized water, and acetone at a molar ratio of 0.8:2.5:8, and then follow the principle of silane hydrolysis and polycondensation to react at 8°C for 24 hours to obtain oligomers, and continue at 45°C Under aging for 72h, SiO was prepared by self-assembled clusters of oligomers 2 porous ball;

[0034] (2) Mix silane methacrylate, deionized water, and acetone at a molar ratio of 0.8:4:8, and then follow the principle of silane hydrolysis and polycondensation to react at 110°C for 8 hours to obtain oligomers. 5% photoinitiator TPO by mass and stir evenly to obtain UV curable sol;

[0035] (3) Combine UV-curable sol and SiO 2 The porous balls are mixed evenly according to the mass ratio of 1:20, and then coated on the fused silica substrate by the spin coating method, and the film to be cured is prepared by usi...

Embodiment 3

[0039] A kind of ultraviolet curing film with adjustable refractive index, its preparation method comprises the following steps:

[0040] (1) Mix ethyl orthosilicate, deionized water, and decane in a molar ratio of 1.2:3.5:12, and then follow the principle of silane hydrolysis and polycondensation to react for 12 hours at 12°C to obtain oligomers, and continue at 55°C SiO was prepared by oligomer self-assembled clusters after aging for 48 h under the same conditions 2 porous ball;

[0041] (2) Mix silane methacrylate, deionized water, and decane at a molar ratio of 1.2:6:12, then follow the principle of silane hydrolysis and polycondensation reaction at 130°C for 6 hours to obtain oligomers, and add Zhan to the reaction system The total mass of 3% photoinitiator TPO is stirred evenly to obtain a UV-curable sol;

[0042] (3) Combine UV-curable sol and SiO 2 The porous balls are mixed evenly according to the mass ratio of 1:30, and then coated on the fused silica substrate by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com