Composite photochromic polyaminoester material and preparation method thereof

A technology of color-changing materials and composite light, applied in the field of photochromic materials, to achieve the effects of low-cost production, wide application range, and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Preparation of polyurethane colloid

[0028] Take component A, component B, solvent, and catalyst 200:200:2000:20ml and pour them into the container one by one for preliminary mixing, and then pour them into the reaction kettle with magnetic stirrer and thermometer condenser tube to stir, and react 2-5 hours, the reaction temperature is about 30°C.

Embodiment 2

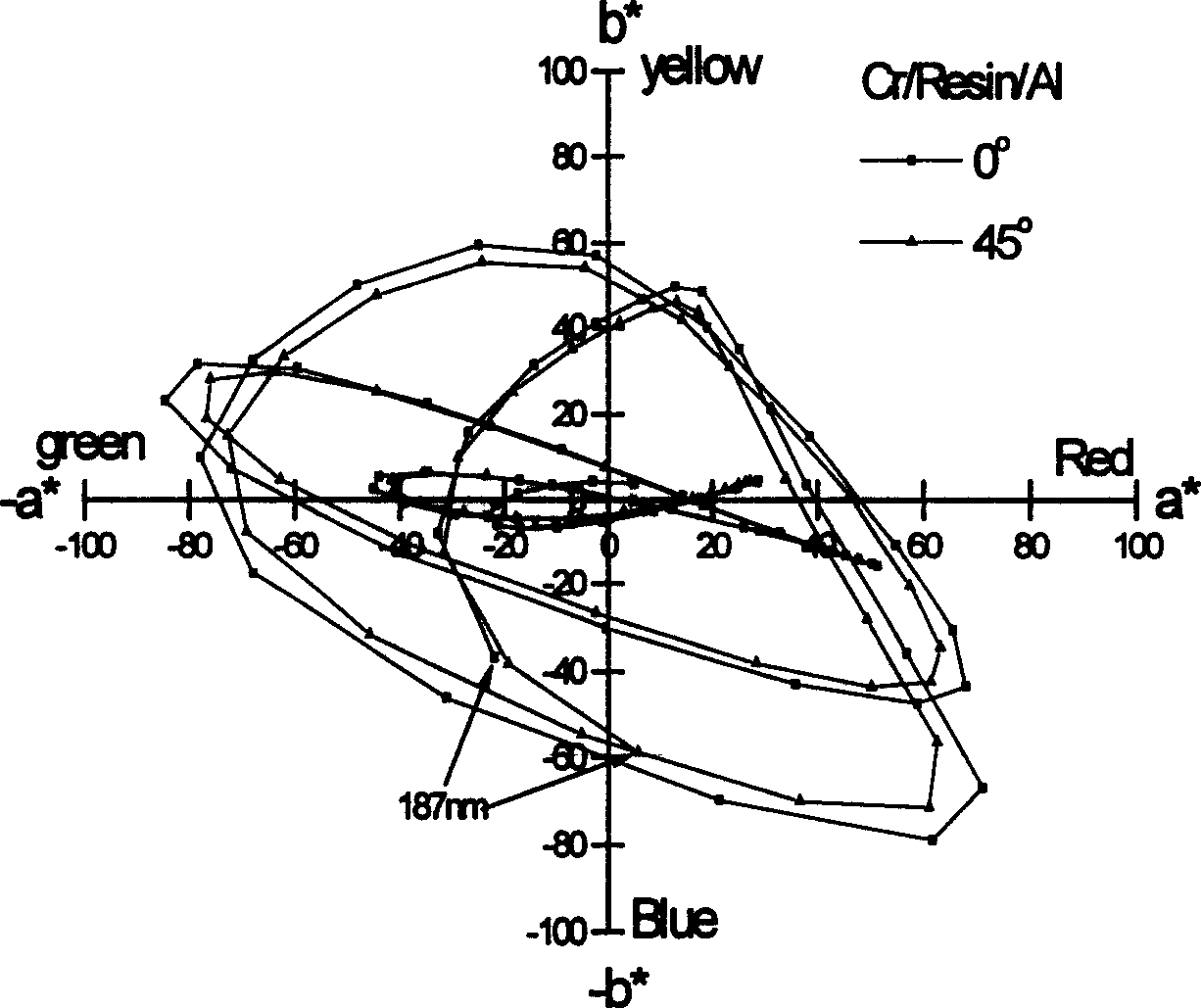

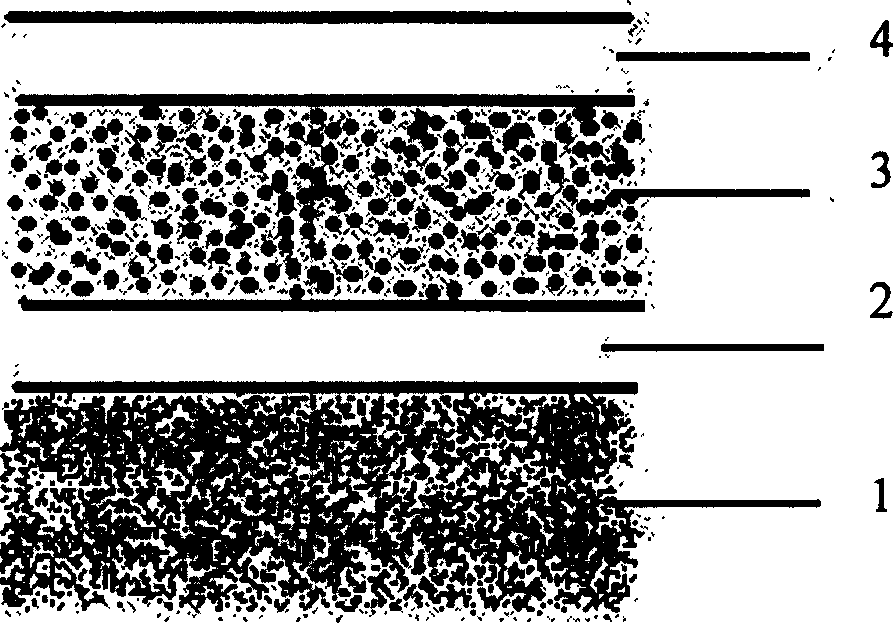

[0030] Metal-dielectric color-changing film with Cr / polyurethane / Al three-layer structure prepared on polyester film (PET) ( figure 2 ).

[0031] A layer of aluminum film with a thickness of 80-100nm is grown by sputtering on the PET film, and then polyurethane colloid is coated on the aluminum film on a coating machine and dried to form a dielectric layer of 400-500nm. Finally, a chromium film with a thickness of 12-20nm is deposited on the dielectric layer by sputtering to obtain the multilayer color-changing film of the present invention which is golden yellow at normal incidence and blue at 45° incidence.

Embodiment 3

[0033] Prepare color shifting inks.

[0034] Coating a layer of release agent on the plastic film, then depositing 10-20nm chrome film absorbing layer on the release agent by sputtering, coating 250-400nm polyurethane colloid on the chrome film, and drying. Then a 100-200nm aluminum film reflective layer is deposited on the dielectric layer by sputtering, and then 250-400nm polyurethane colloid is coated on the aluminum film and dried. Finally, a 10-20nm thick chromium absorbing layer is deposited on the dielectric layer by sputtering to obtain a metal-dielectric color-changing film with a five-layer symmetrical structure. After demoulding, the base plastic is removed, and then crushed to prepare the photochromic raw material of the color-changing ink, which can be added to the ink to make the color-changing ink.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com