Preparation method of quantum dot patterned film and patterned film

A patterned film and quantum dot technology, which is applied in the field of quantum dot luminescence, can solve the problems of quantum dot destruction, quantum dot destruction, and template method with high template requirements, and achieve the effects of chemical corrosion resistance, easy operation and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

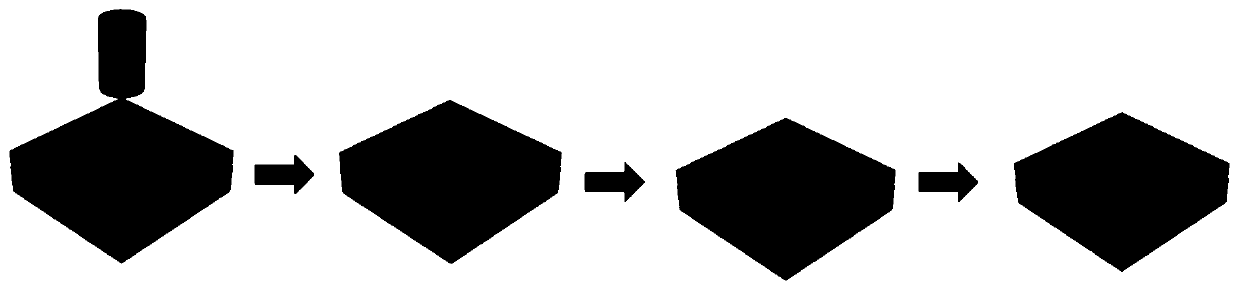

Method used

Image

Examples

Embodiment 1

[0173] a) 1gPAN was dissolved in 10gDMF as solution S1, 1mmolPbBr 2 , 2mmolMABr was dissolved in 10gDMF as solution S2;

[0174] b) Transfer S1 to a glass substrate for spin coating and evaporate to dryness into a film layer with a thickness of 10 μm;

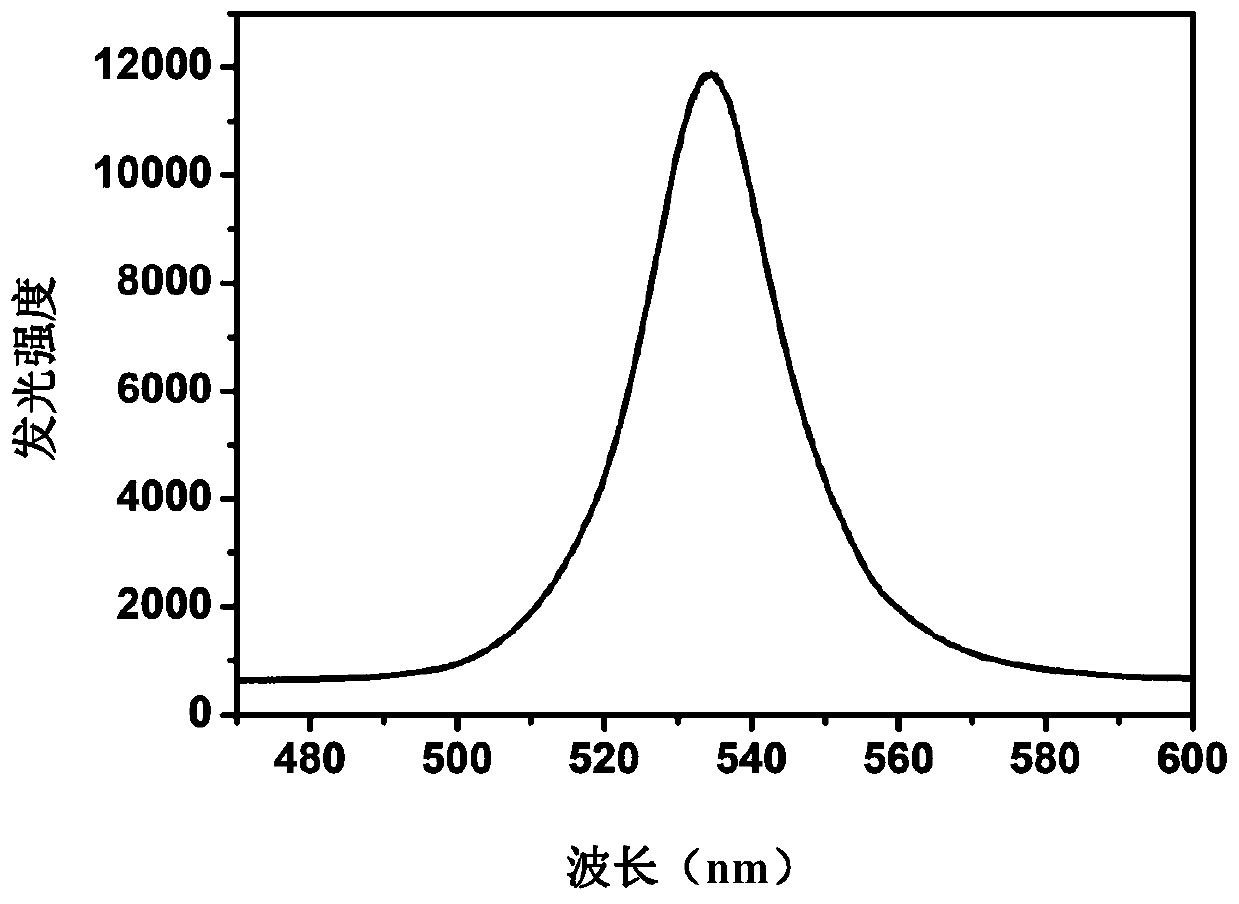

[0175] c) According to the pre-set pixelation pattern, the prepared solution S2 is transferred drop by drop to a specific position of the film layer by inkjet printing. The diameter of the nozzle hole of the printer is 35 μm, and then dried, and the place where the solution S2 drops forms a disk Shaped luminescent dots with a diameter of 150 μm have obvious green fluorescence under ultraviolet light, forming perovskite quantum dots and embedded in polymers. Denoted as sample 1#.

Embodiment 2

[0177] a) 1gPAN was dissolved in 10gDMF as solution S1, 1mmolPbBr 2 , 2mmolMABr, 0.1gPAN were dissolved in 10gDMF as solution S2;

[0178] b) Transfer S1 to a glass substrate for spin coating and evaporate to dryness into a film layer with a thickness of 10 μm;

[0179] c) According to the pre-set pixelation pattern, transfer the prepared solution S2 drop by drop to a specific position of the film layer by inkjet printing. The diameter of the nozzle hole of the printer is 21.5 μm, and then dry it. Disc-shaped light-emitting dots with a diameter of 100 μm have obvious green fluorescence under ultraviolet light, forming perovskite quantum dots and embedding them in polymers. Compared with Example 1, due to the addition of a small amount of PAN in solution S2, the viscosity Adjusted to 5cps, the ink output is more stable during the printing process, which is recorded as sample 2#.

Embodiment 3

[0181] a) 1gPAN was dissolved in 10gDMF as solution S1, 1mmolPbBr 2 , 2mmolMABr, 0.8gPAN were dissolved in 10gDMF as solution S2;

[0182] b) Transfer S1 to a glass substrate for spin coating and evaporate to dryness into a film layer with a thickness of 10 μm;

[0183] c) According to the pre-set pixelation pattern, the prepared solution S2 is transferred drop by drop to a specific position of the film layer by inkjet printing. The diameter of the nozzle hole of the printer is 10 μm, and then dried, and the place where the solution S2 drops forms a disk Shaped luminescent dots with a diameter of 50 μm have obvious green fluorescence under ultraviolet light, forming perovskite quantum dots and embedded in polymers. Denoted as sample 3#.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com