Patents

Literature

31results about How to "Improved resistance to laser damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

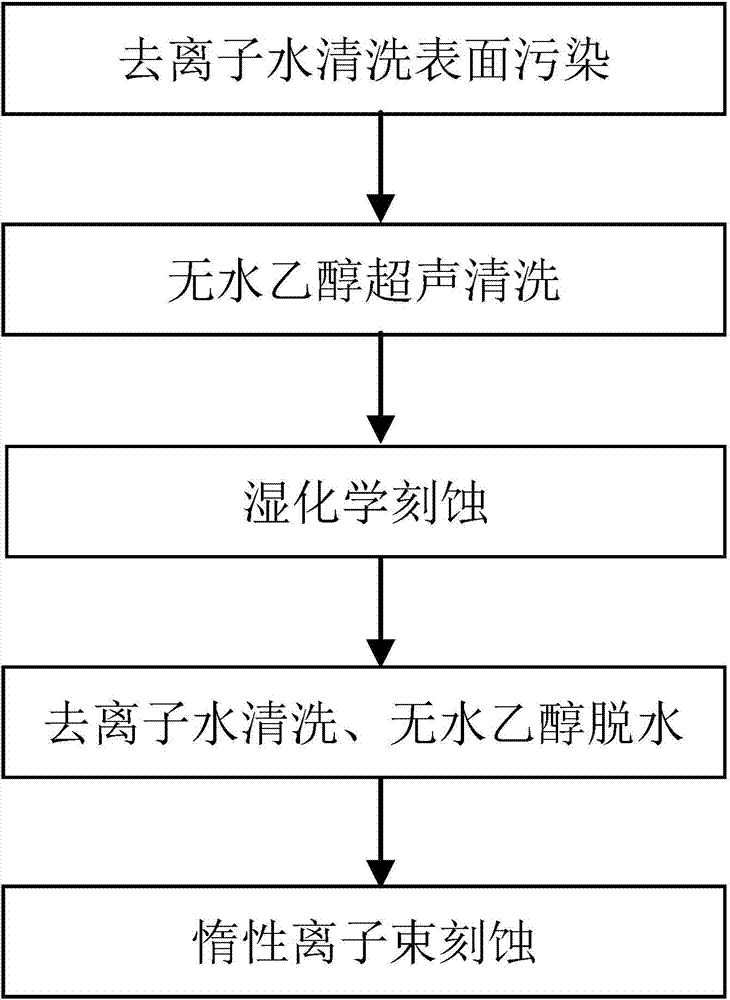

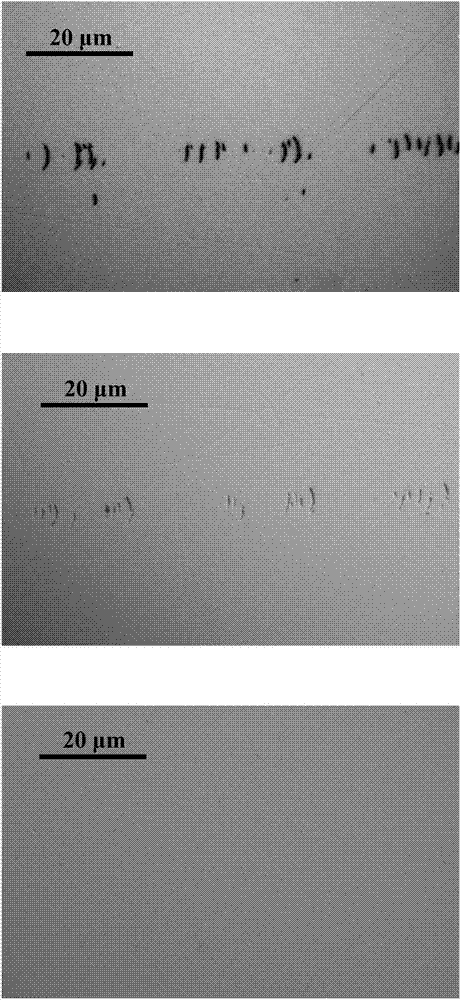

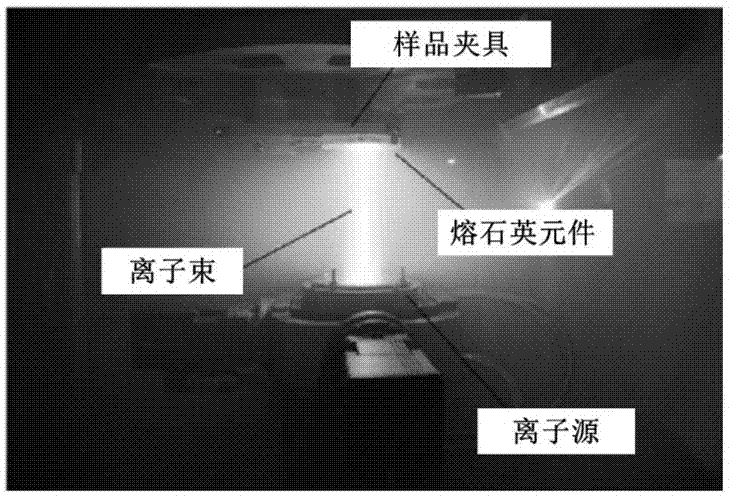

Surface treatment method for increasing fused silica element threshold value through wet etching-dry etching combination

InactiveCN103922601AIncreased Laser Damage ThresholdImproved resistance to laser damageHydrofluoric acidAlcohol

The invention discloses a surface treatment method for increasing a fused silica element threshold value through wet etching-dry etching combination, belongs to the technical field of optical materials and optical elements, and particularly relates to a surface treatment method for increasing a fused silica element laser damage threshold value. According to the surface treatment method, deionized water is adopted to wash the surface of a fused silica element processed by using the traditional grinding polishing process, dehydrated alcohol is adopted to carry out ultrasonic washing, the obtained fused silica element is subjected to an etching treatment by using a hydrofluoric acid solution, deionized water washing and dehydrated alcohol dehydration are performed, and finally an energetic inert ion beam is adopted to carry out surface polishing to remove the acid etching reaction product SiF6<2-> and improve the surface roughness. According to the present invention, the residual polishing powder on the fused silica element processed by using the traditional process can be removed, the defect can be subjected to passivation, and the good surface roughness can be obtained, such that the laser damage resistance of the fused silica element can be effectively increased.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

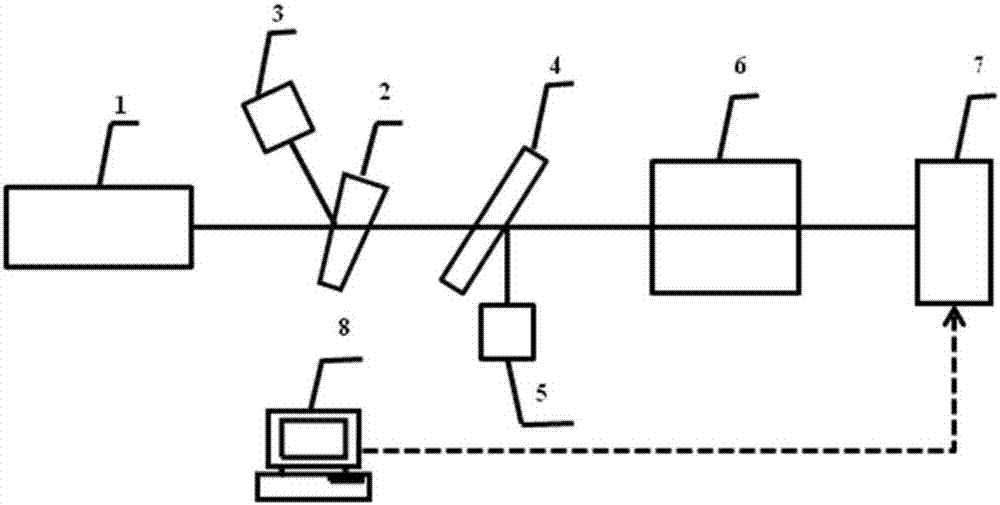

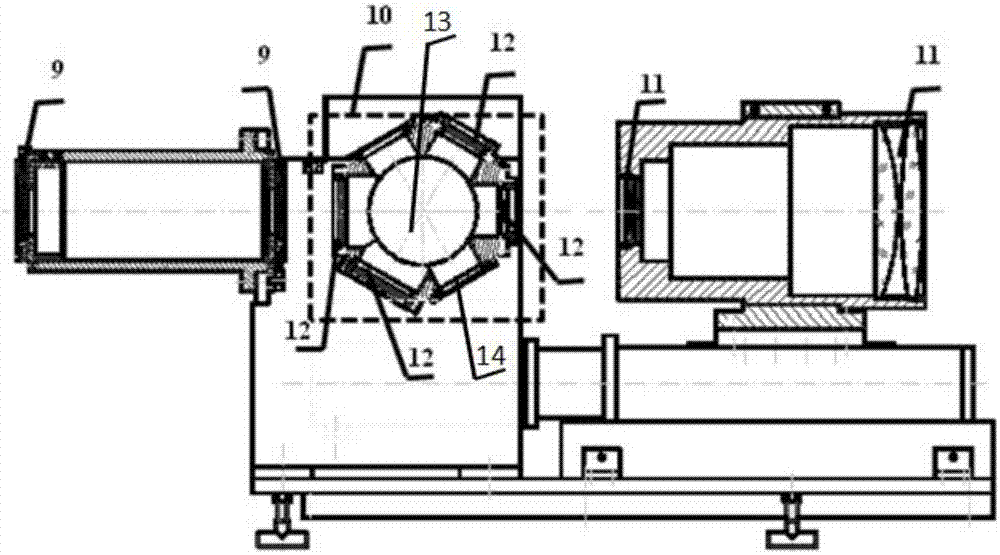

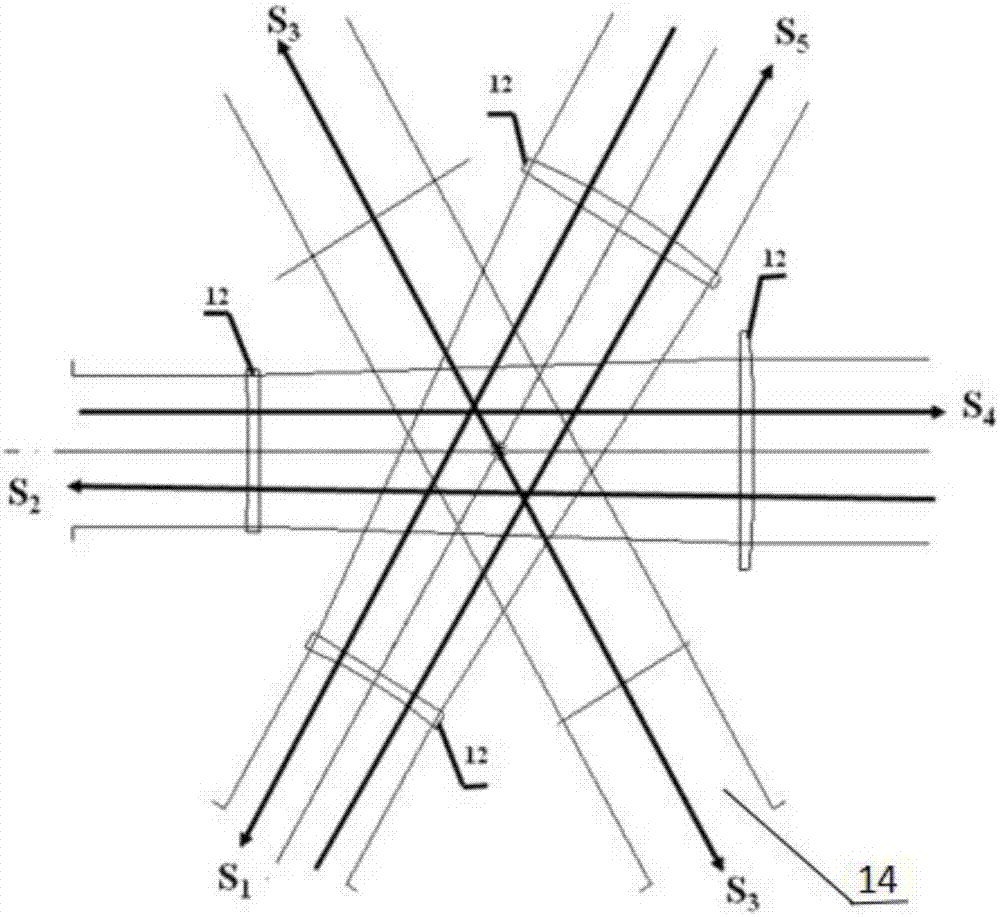

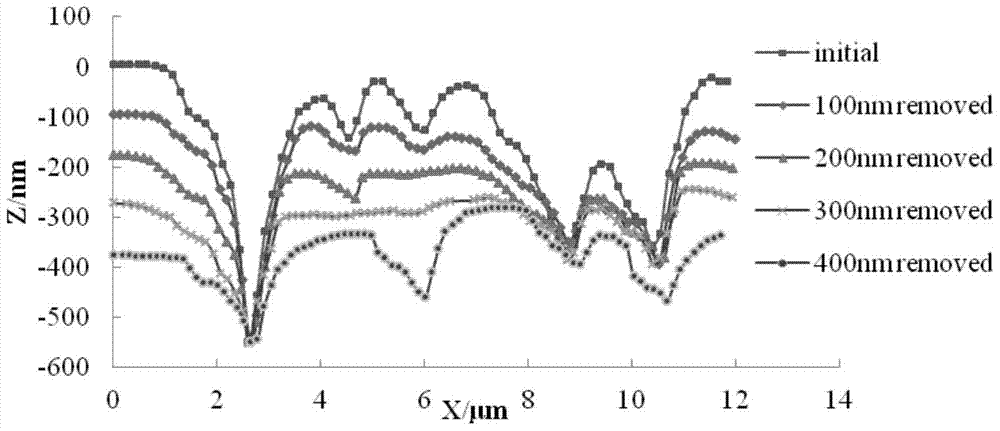

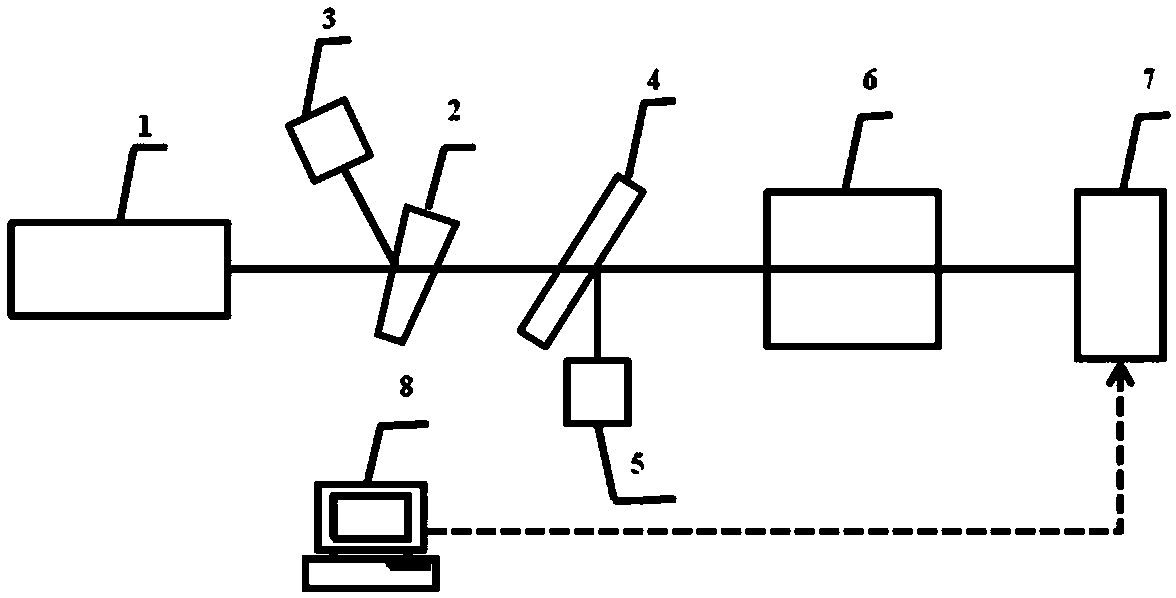

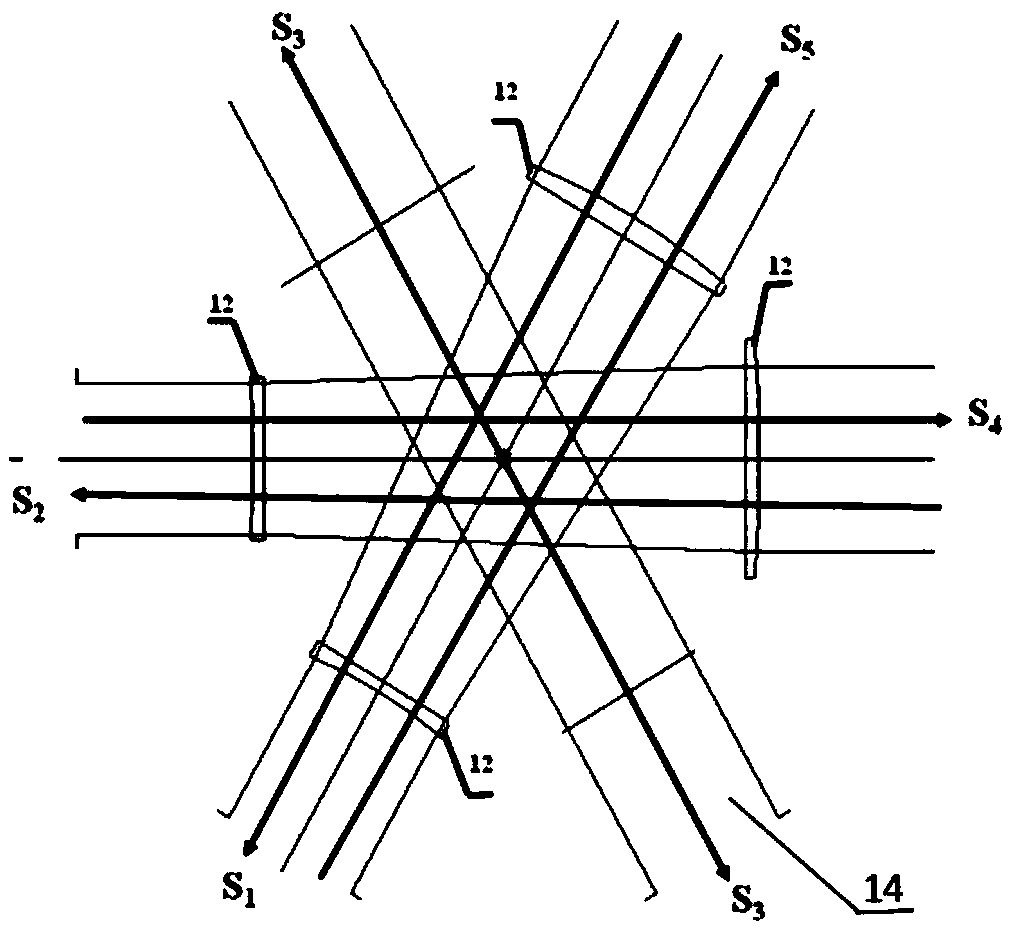

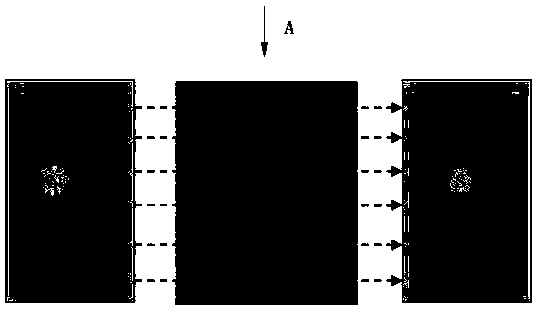

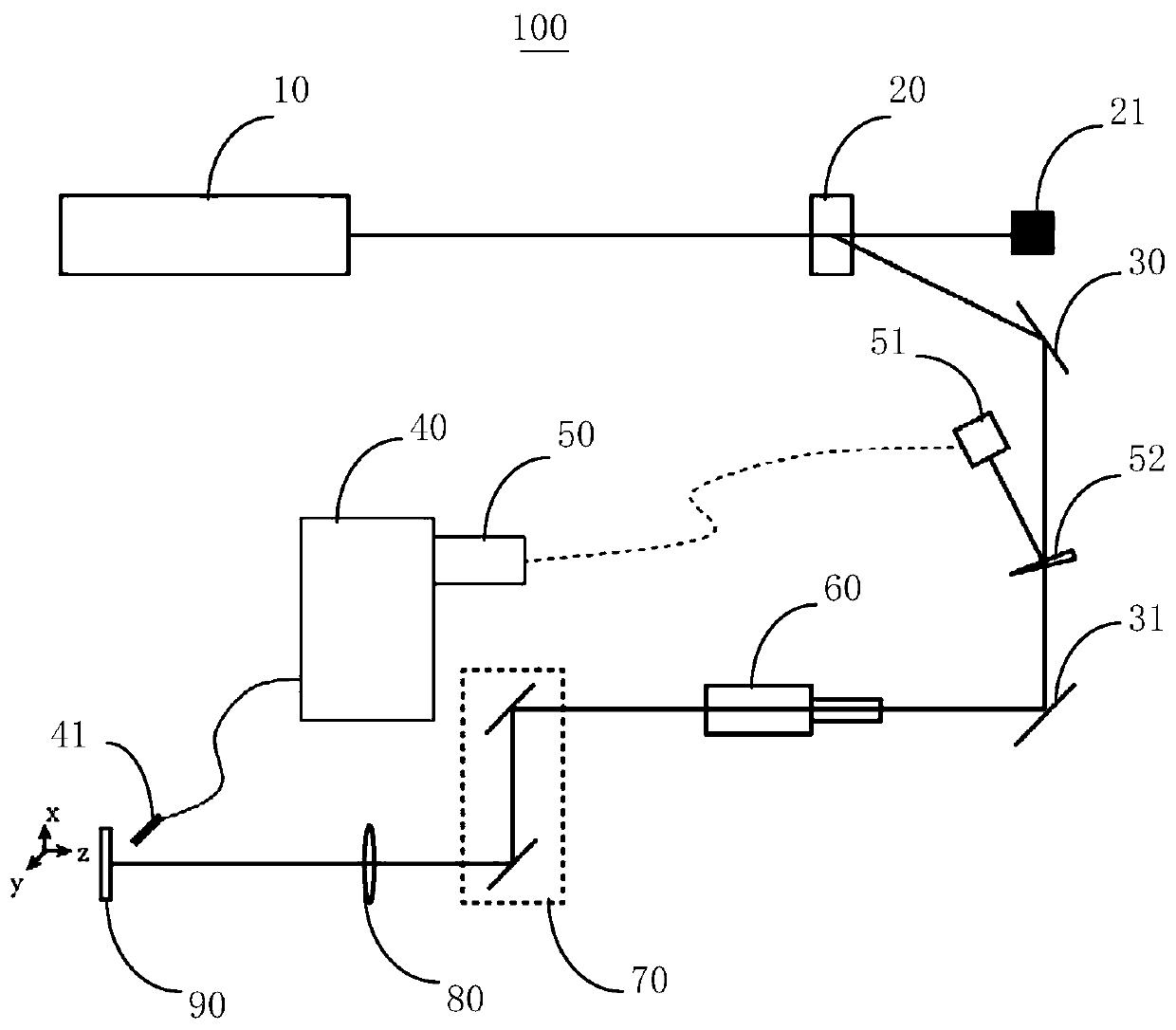

Laser preprocessing device and processing method used for optical element

InactiveCN106964893AImproved resistance to laser damageSolve the problem that uneven irradiation can easily cause damageLaser beam welding apparatusPower switchingLight beam

The invention discloses a laser preprocessing device and processing method used for an optical element. The laser preprocessing device comprises a laser light source used for emitting laser as well as a light-splitting chopping plate, a reflecting mirror, a light beam shaping system and an electric translation stage used for placing a to-be-processed optical element are sequentially arranged in the laser transmission direction, wherein laser emitted by the laser light source passes through the light-splitting chopping plate and then is transmitted to the light beam shaping system through the reflecting mirror; the light beam shaping system is used for performing light beam shaping on laser; laser spots which are in Gaussian distribution are shaped into square spots which are uniformly distributed flatly; and finally, the laser is irradiated to the surface of the optical element for performing laser preprocessing on the optical element. According to the laser preprocessing device disclosed by the invention, irradiation energy density of the whole preprocessing process is uniform through the uniform square laser pots which are flatly focused, and dimensions of the spots are easily regulated through a multiplying power switching structure, so that the purpose of regulating energy density of laser which reaches the surface of the optical element is achieved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

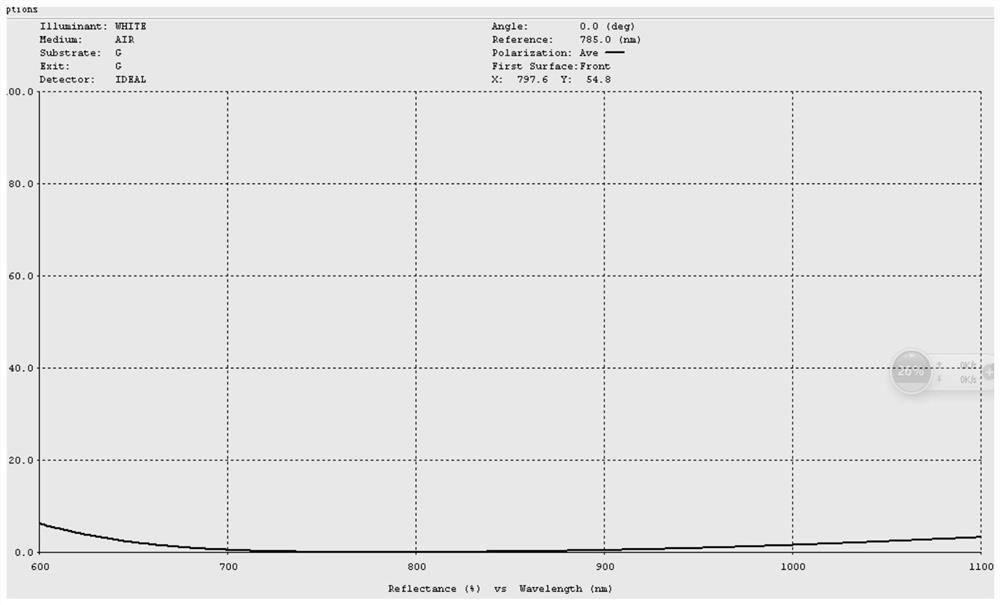

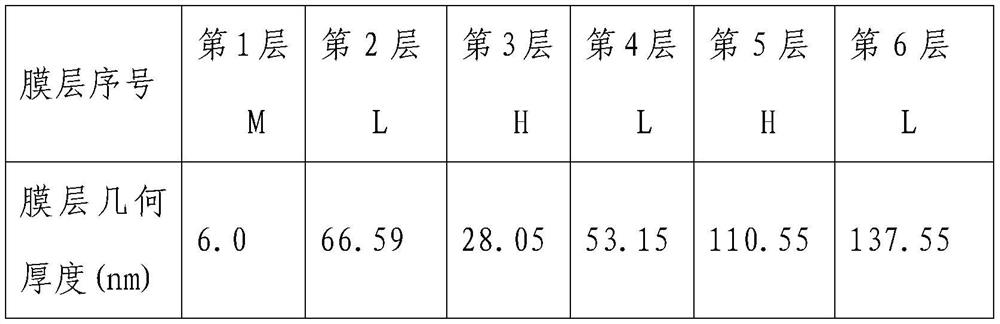

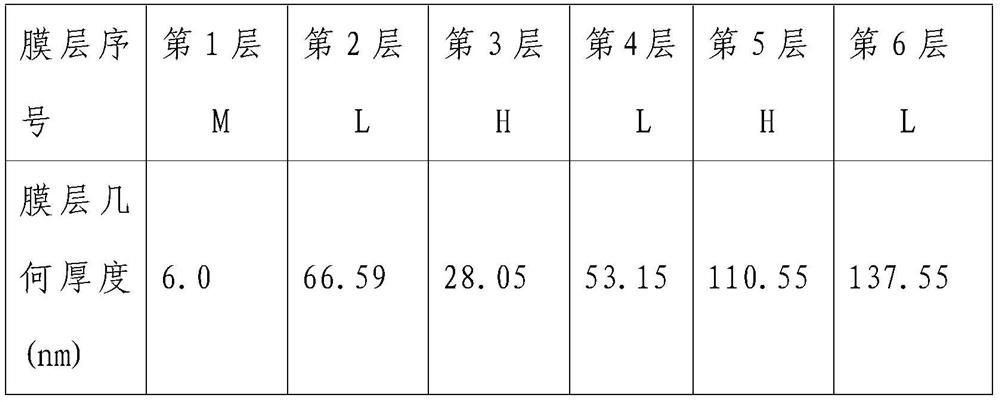

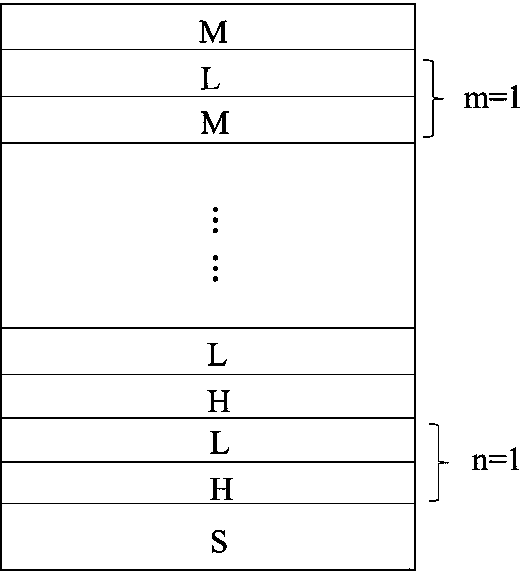

High-damage-threshold laser film process technical method

InactiveCN111679347AExcellent resistance to laser damageImprove permeabilityVacuum evaporation coatingSputtering coatingRefractive indexOptical thin film

The invention relates to a high-damage-threshold laser film technological method, and belongs to the field of optical film plating. The invention aims to overcome the defect that the laser damage resistance threshold of a laser film plated in visible light and near-infrared bands by a conventional laser film plating technology is relatively low. Quartz or K9 is used as a coating substrate, sapphire is used as a substrate film material M, HfO2 is used as a high-refractive-index film material H, SiO2 is used as a low-refractive-index film material L, and TFC is used for giving geometric thicknesses and film system sequence calculation results of all layers of film systems; ultrasonic cleaning and heating baking are carried out on the coating substrate; in an optical film layer bonding bottoming process and a stress matching process, three film materials are sequentially put into an electronic gun evaporation source crucible boat, and then a coating process is completed according to the geometric thickness of each layer of film system and the sequence of the film systems; and the coating substrate is bombarded by using an ion source before coating and in the coating process. The filmlayer is hard, firm, excellent in laser damage resistance and good in permeability, and can be used for a long time in a severe field environment.

Owner:SOUTH WEST INST OF TECHN PHYSICS +1

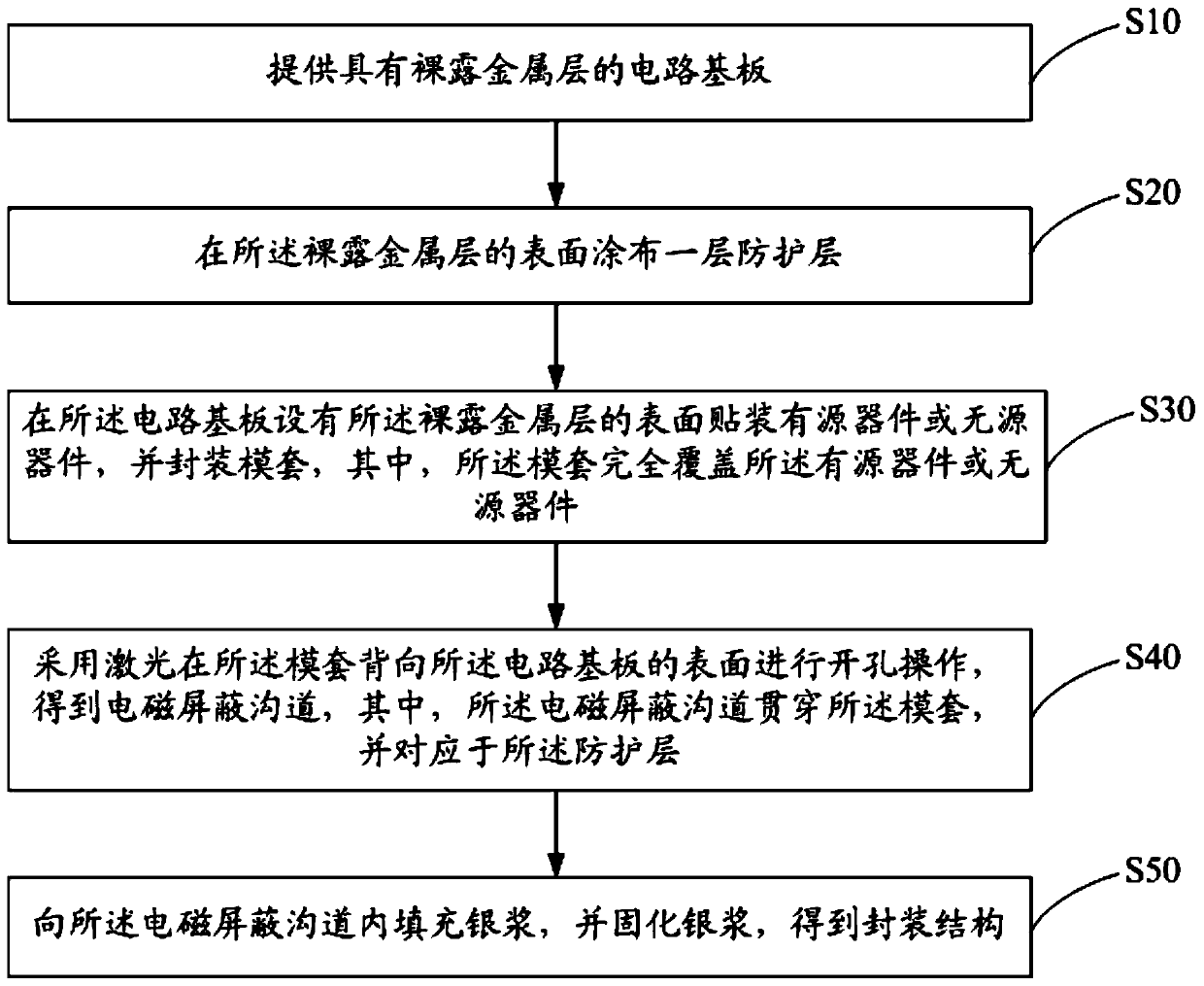

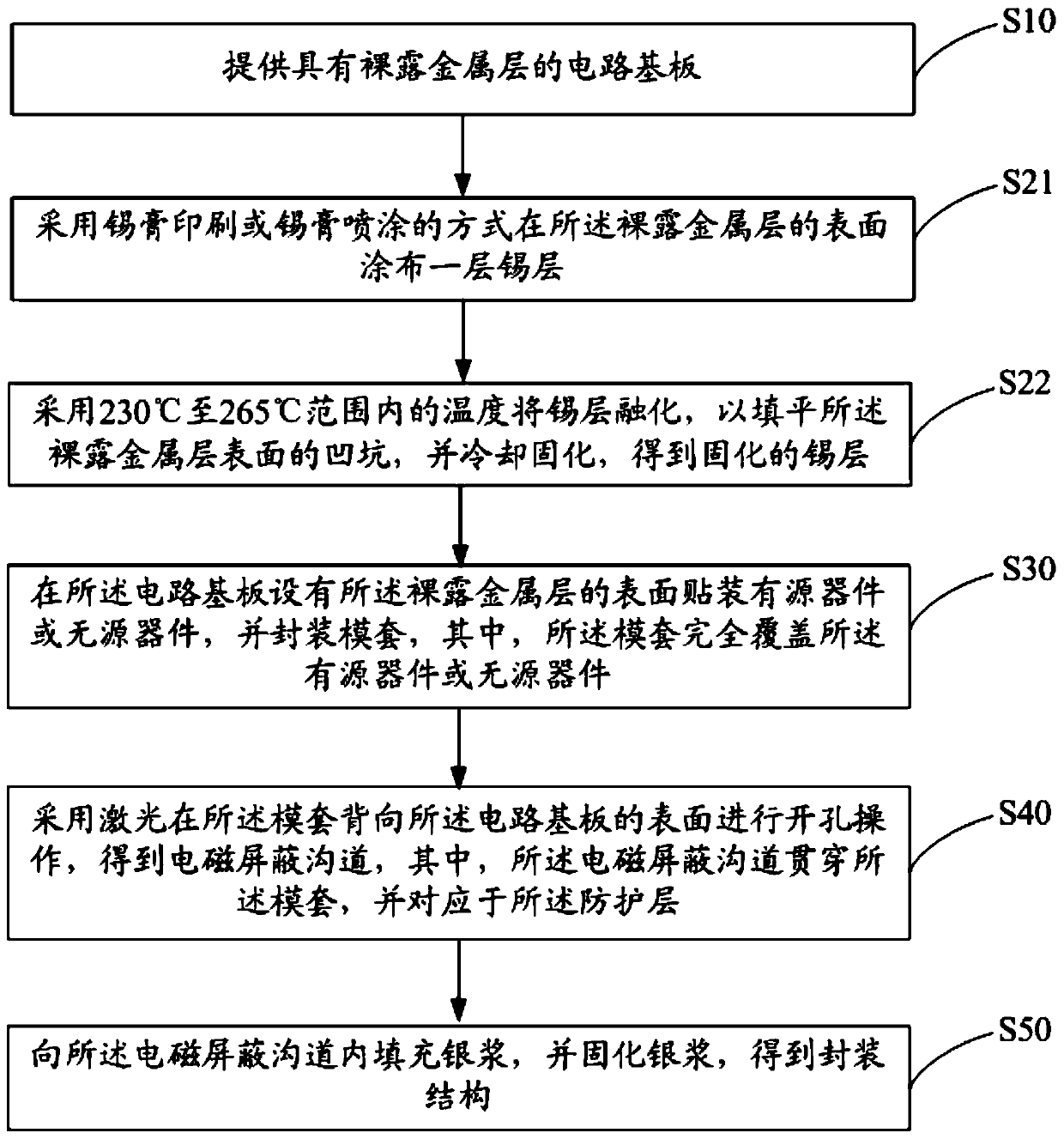

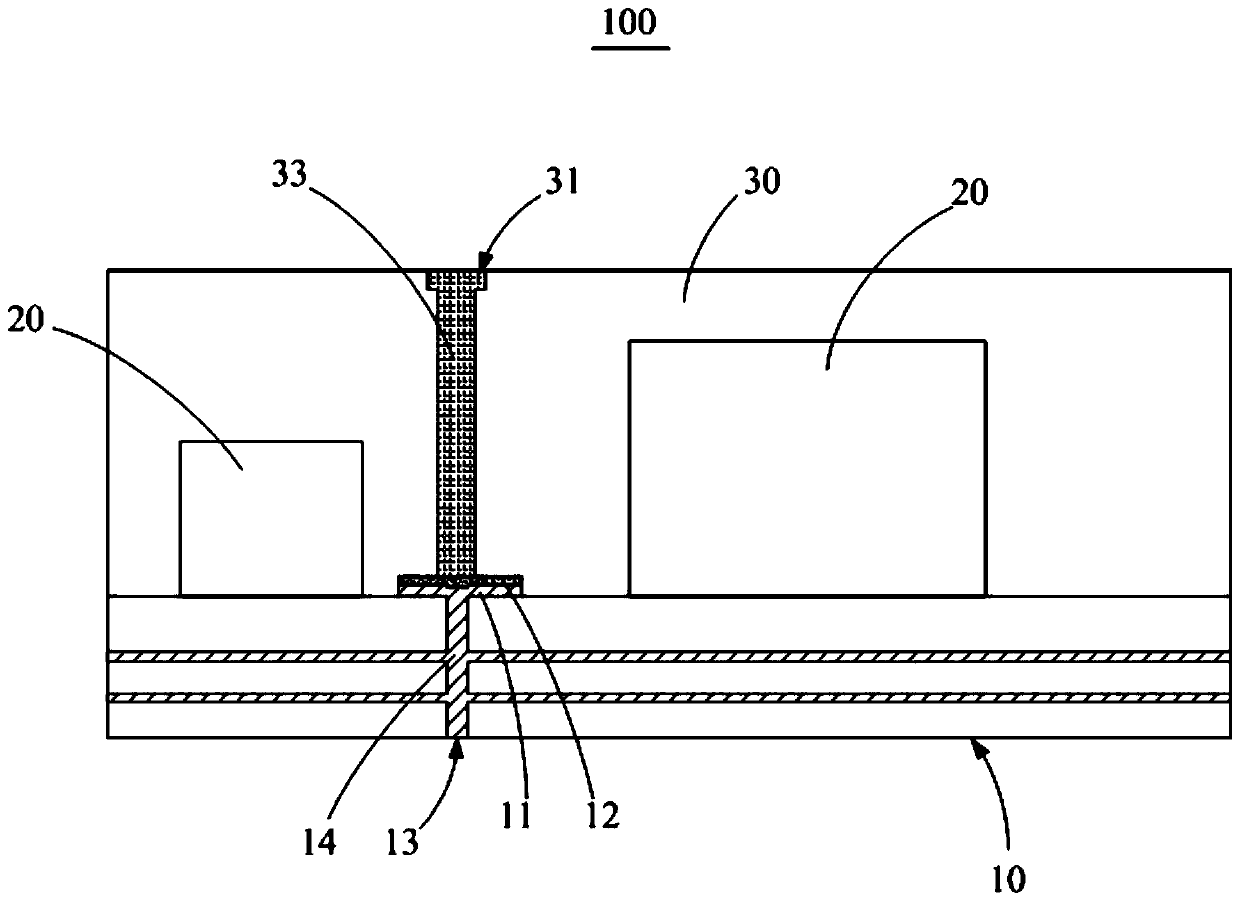

Packaging structure, manufacturing method thereof and electronic device

InactiveCN110993508AImproved resistance to laser damageImprove reliabilitySemiconductor/solid-state device detailsSolid-state devicesSilver pasteSurface mounting

The invention discloses a packaging structure, a manufacturing method thereof and an electronic device. The manufacturing method of the packaging structure comprises the following steps of providing acircuit substrate with an exposed metal layer; coating a protective layer on the surface of the exposed metal layer; mounting an active device or a passive device on the surface, provided with the exposed metal layer, of the circuit substrate in a surface-mounted manner, and packaging a die sleeve, wherein the active device or the passive device is completely covered by the die sleeve, the tapping operation is conducted on the surface, back on to the circuit substrate, of the die sleeve through laser, an electromagnetic shielding channel is obtained, and the electromagnetic shielding channelpenetrates through the die sleeve and corresponds to the protective layer; and filling the electromagnetic shielding channel with silver paste, and curing the silver paste to obtain a packaging structure. According to the technical scheme, the reliability of the packaging structure can be improved.

Owner:QINGDAO GOERTEK INTELLIGENT SENSOR CO LTD

High-reflection film for 10 kW semiconductor laser and preparation method thereof

InactiveCN110441844AReduce plating timeLow costMirrorsVacuum evaporation coatingOxygen ionsEvaporation

The invention discloses a high-reflection film for a 10 kW semiconductor laser and a preparation method thereof. A HfO2-TiO2-SiO2 multi-material film structure and the characteristic of large refractive index difference of aTiO2-SiO2 film combination are used to meet the requirement of high reflectivity under a few layers; the HfO2-SiO2 material has the characteristic of high laser damage resistance threshold, and a HfO2-SiO2 film stack is superimposed on the outermost part of the TiO2-SiO2 film stack, thereby improving the half-wave protection effect of laser damage resistance on TiO2-SiO2, achieving a few film layers, meeting the requirement of high reflectivity and improving the laser damage resistance of the film; the high-reflection film is prepared by ion beam assisted deposition, ametallic hafnium target, a metallic titanium target and a quartz glass sheet are used as coating materials, and the evaporation film is bombarded with an oxygen ion beam to obtain an oxide film, so that the compactness and stability of the film are improved.

Owner:DONGGUAN UNIV OF TECH +1

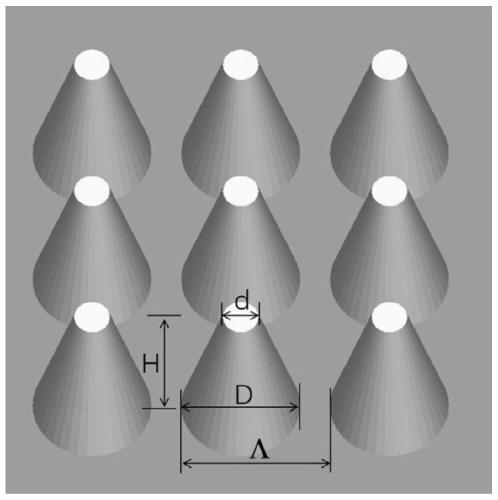

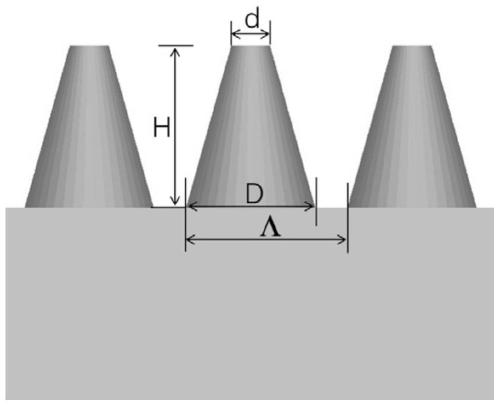

Lithium triborate crystal surface antireflective microstructure and preparation method thereof

InactiveCN110230096AImproved resistance to laser damageWith anti-reflection effectPolycrystalline material growthAfter-treatment detailsHigh power lasersMaterials science

The invention relates to a lithium triborate crystal surface antireflective microstructure, which has antireflective effect on ultraviolet, visible and near-infrared light. The microstructure parameters include period, depth, duty cycle, etc. All units of the microstructure are cuboid, cylindrical, conical or truncated cone structures. The microstructure parameters and the shapes of all the unitsare determined by specific use wavelength. The surface antireflective microstructure provided by the invention can effectively improve the transmittance of lithium triborate crystals at specific wavelength, and has very wide transmission bandwidth, well satisfies the requirements of high transmittance and bandwidth, and has very important practical significance for high power laser systems.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

High destructive threshold value semiconductor saturable absorbing mirror for mode locked laser

InactiveCN1622401AImproved resistance to laser damageImprove reflectivityLaser constructional detailsSemiconductor quantum wellsMode-locking

The present invention discloses one kind of saturable semiconductor absorbing mirror with high destruction threshold for mode locking laser, and belongs to the field of saturable absorbing mirror technology of mode locking laser. The saturable absorbing mirror includes silicon or Ga-As substrate, Bragg refection layer of metal film or Al-As / Ga-As, transparent Al-Ga-As or In-Al-Ga-As semiconductor layer, and saturable absorption layer of Ga-As or In-Ga-As quantum well. The present invention features that the surface of the saturable absorption layer has plated high reflectivity layer and the high reflectivity layer consists of at least three SiO2 film-ZrO2 film pairs in the optical thickness in one quarter of reflecting wavelength. The present invention has the obvious advantages of lowered transmitting light strength, raised capacity of resisting laser damage and the raised reflectivity of the mirror caused by the plated high reflectivity film.

Owner:TIANJIN UNIV

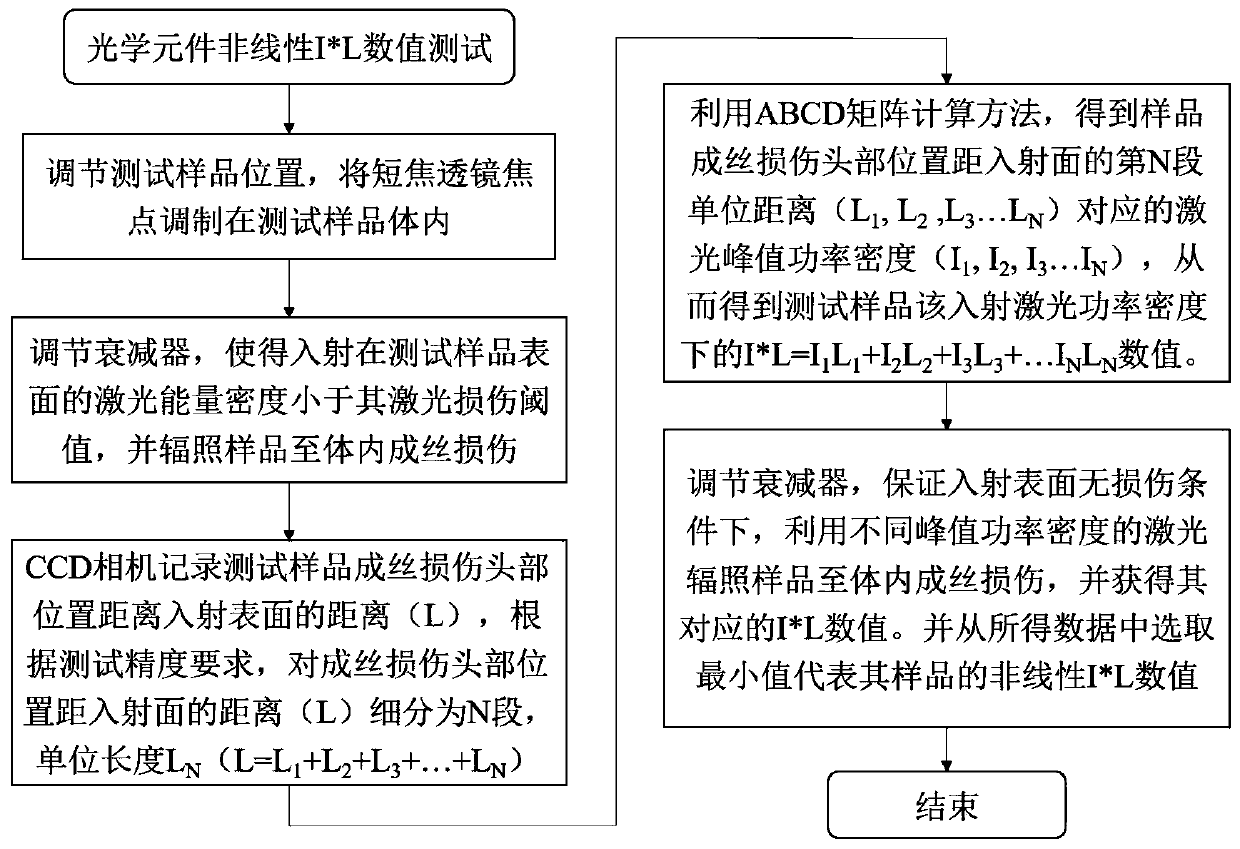

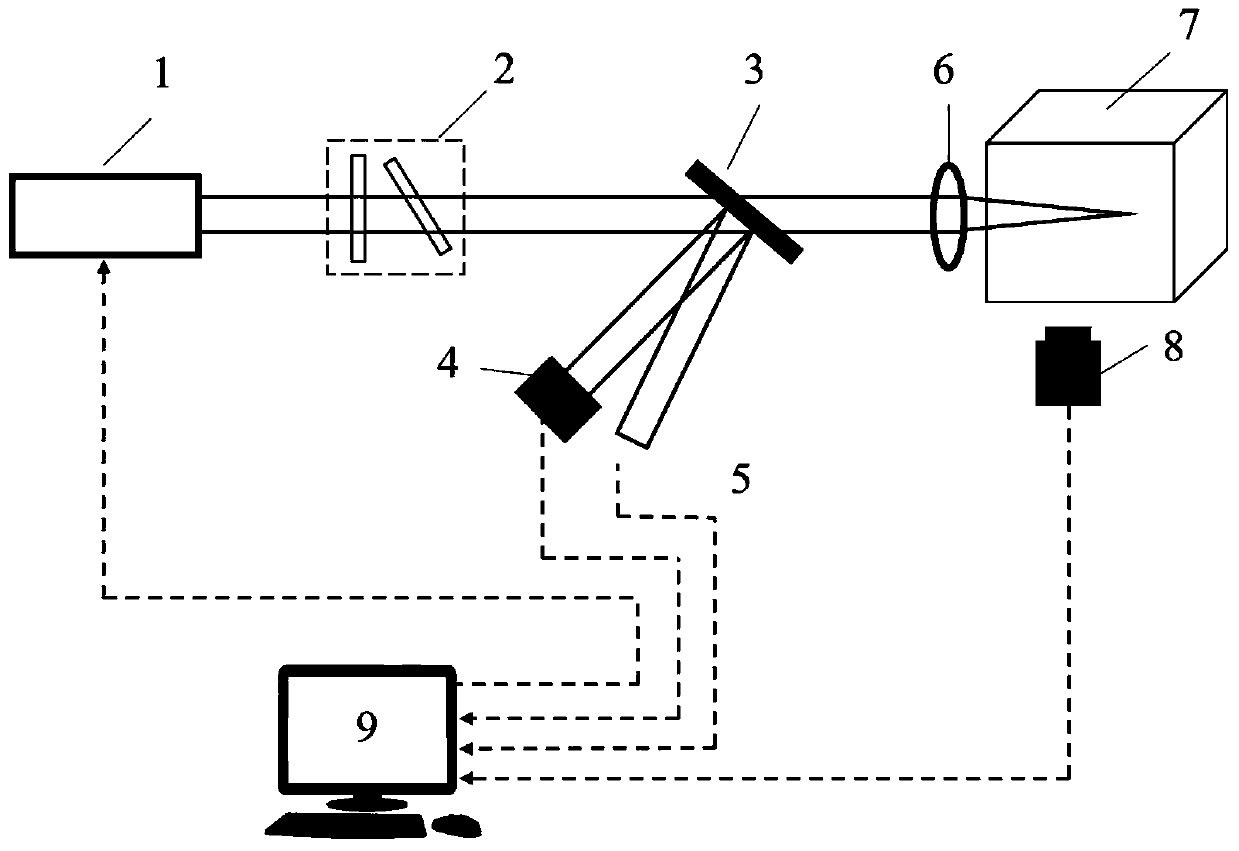

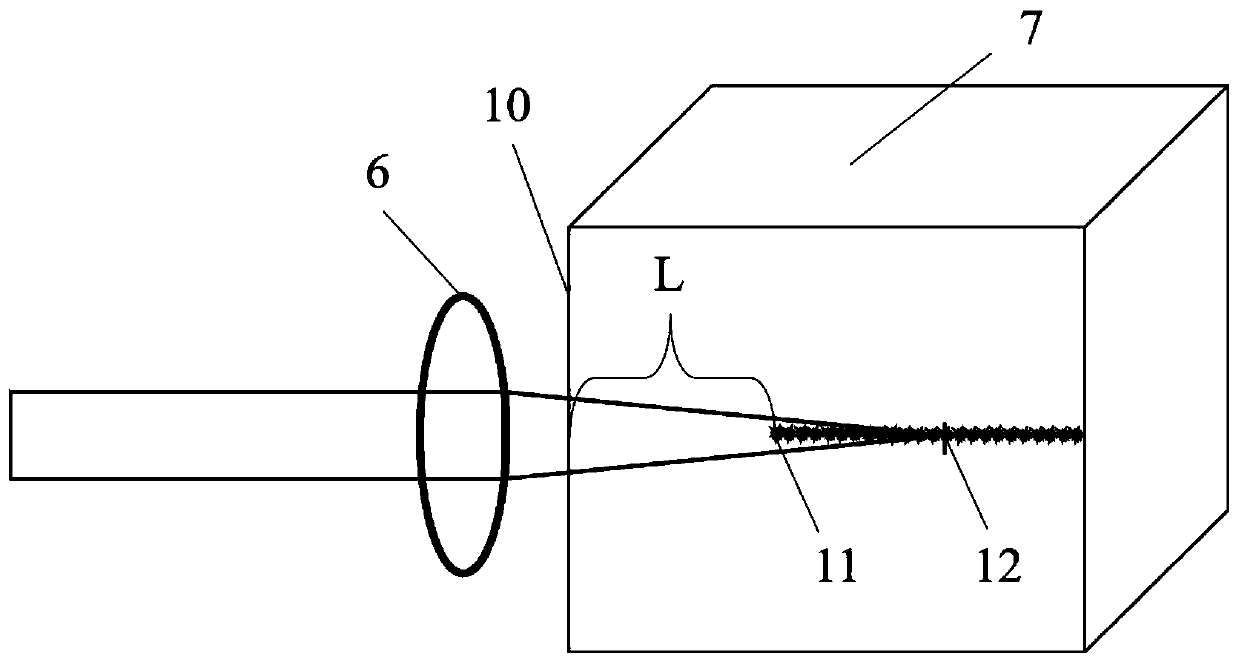

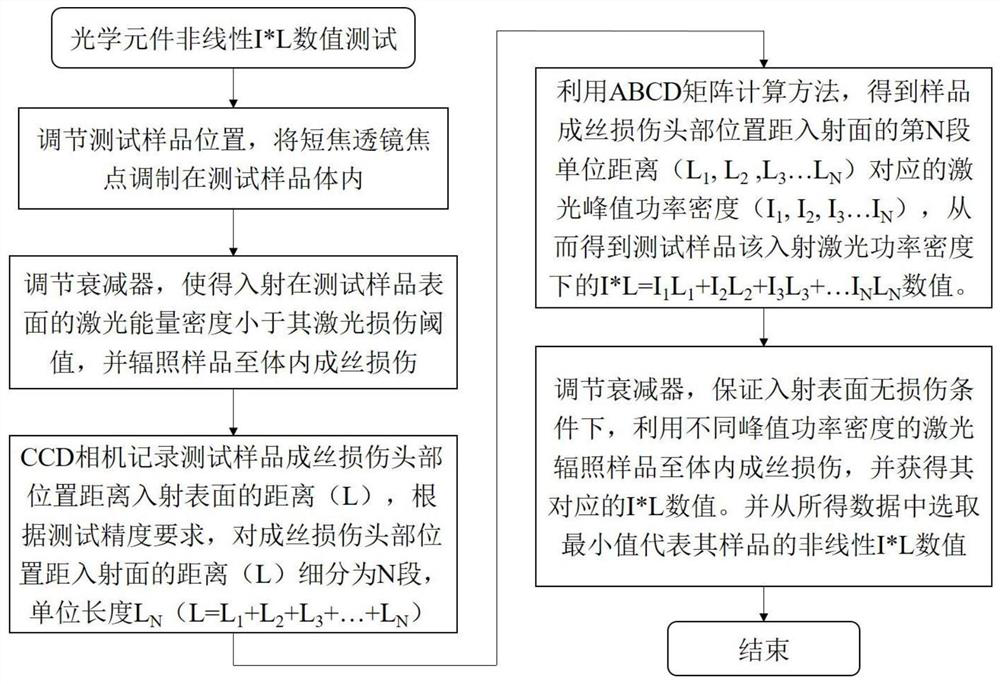

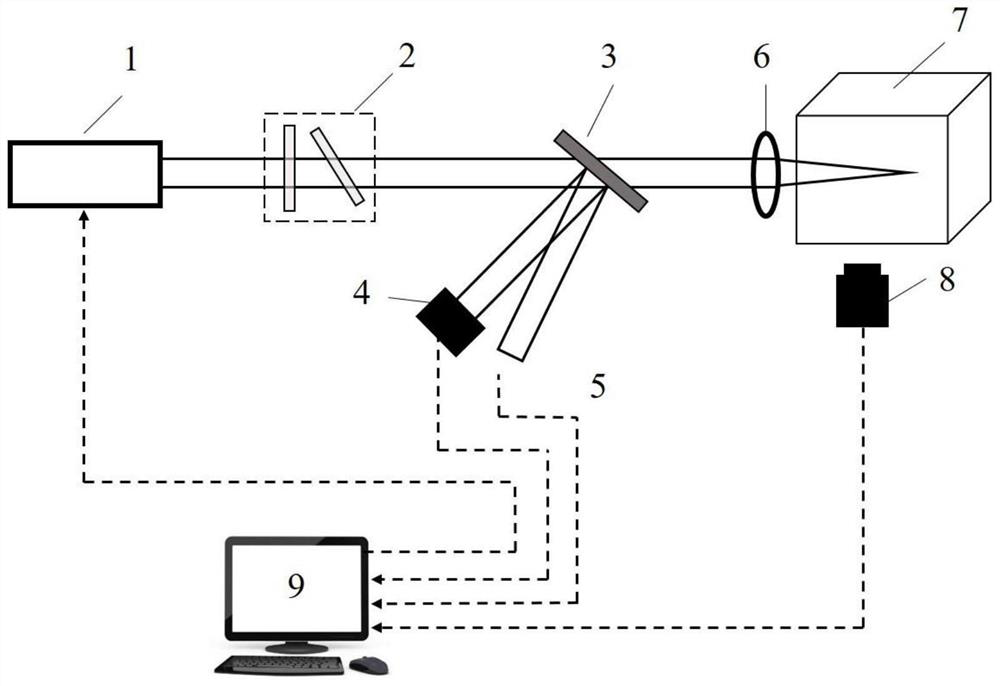

Method and device for testing nonlinear effect I * L value of optical element

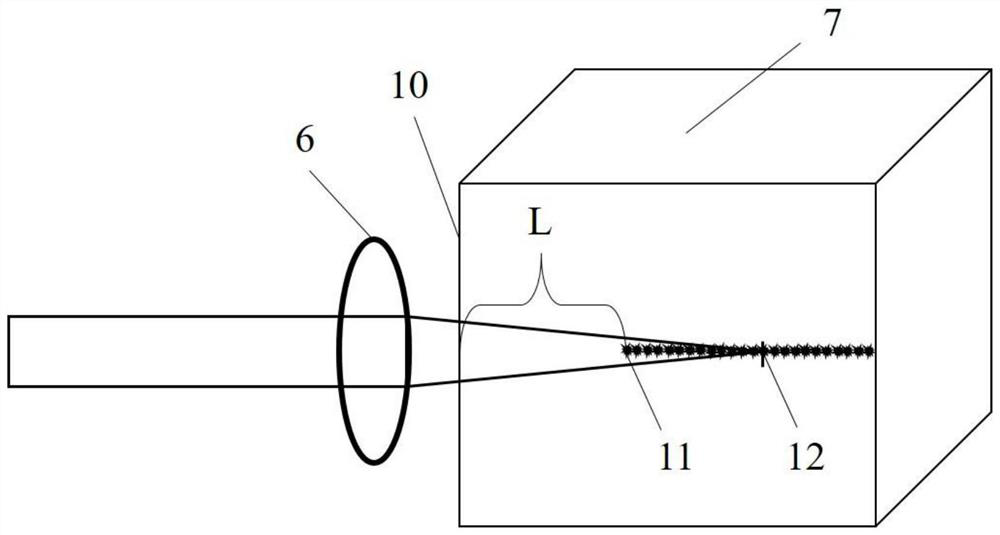

ActiveCN111579221AImproved resistance to laser damageResolve scatterGeometric properties/aberration measurementLaser damageLaser beams

The invention discloses a method and a device for testing a nonlinear effect I * L value of an optical element. According to the method, a laser beam is focused in an optical element body by using a lens of which the focal length is smaller than the thickness of the optical element and adjusting the position of the optical element; meanwhile, the laser energy density of laser irradiation on the incident plane of the optical element to be measured is adjusted to be smaller than the laser damage threshold value of the incident plane of the optical element to be measured; a disturbance-induced small-scale self-focusing effect under a non-focusing condition is simulated; in a traditional test method, an incident surface of an optical element is damaged before in-vivo self-focusing filamentation; therefore, the problems of scattering, defect absorption and other laser losses caused by the damage of the incident surface of the optical element are solved, the test precision is improved, and more help is provided for the safe use of the optical element in a high-power laser device and the improvement of the laser damage resistance of the material.

Owner:中国工程物理研究院上海激光等离子体研究所

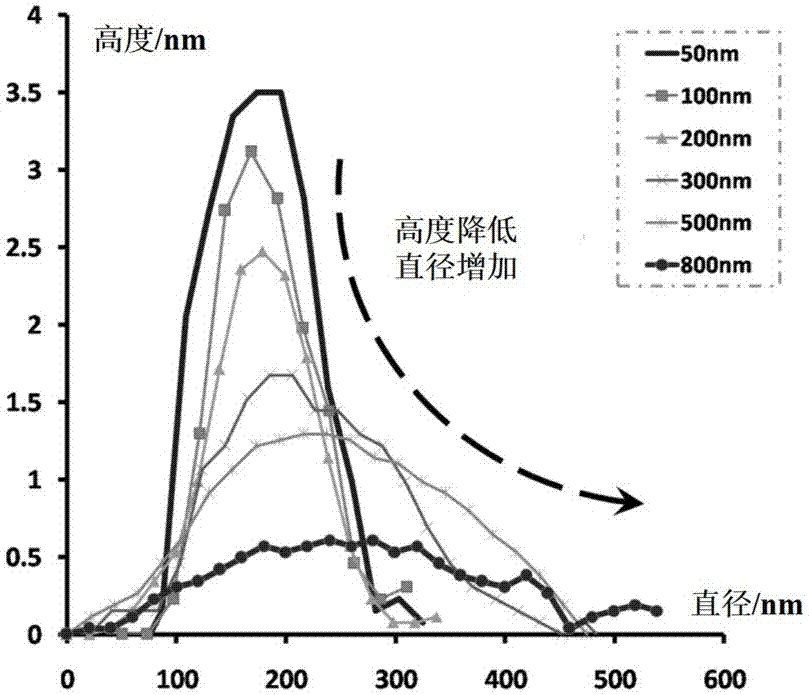

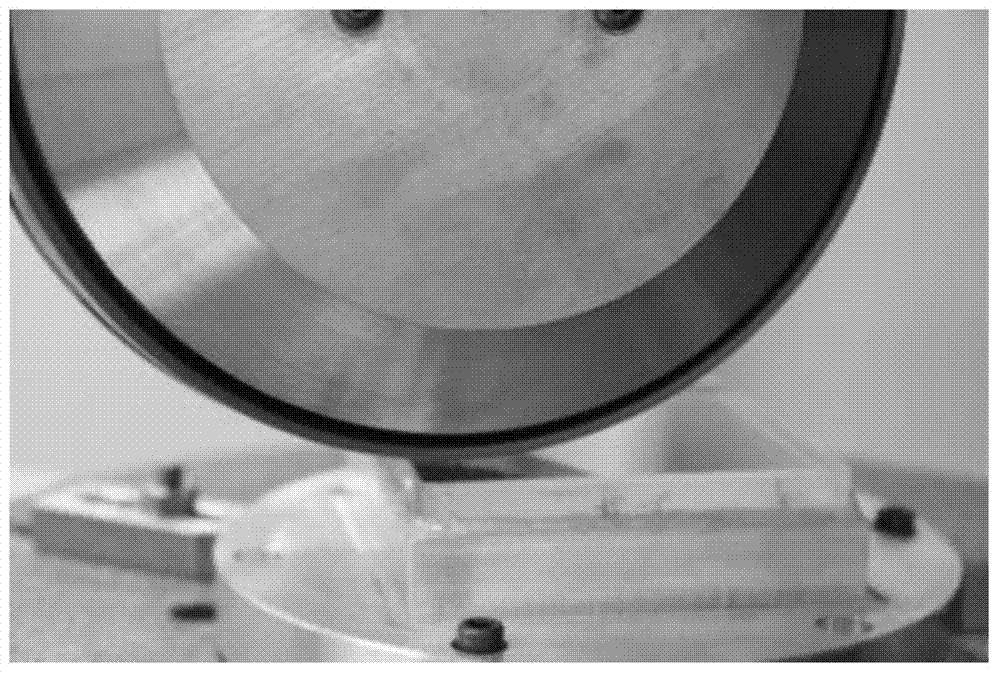

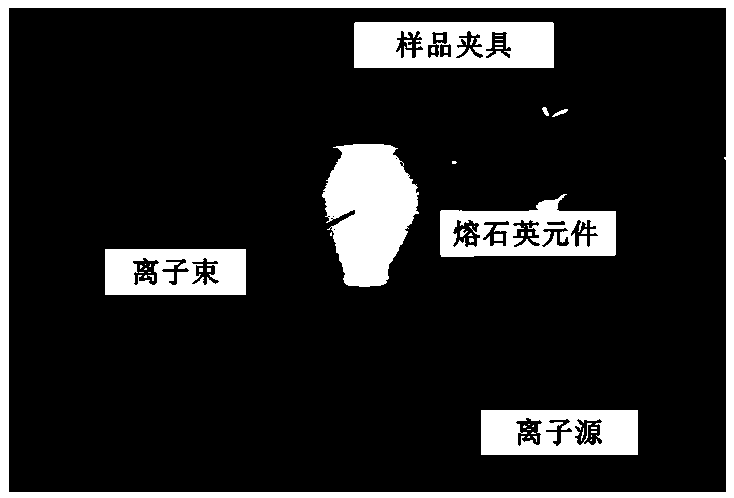

Method for increasing laser-damaged threshold through ion beam elastic domain etching

InactiveCN105252375APrevent foggingDeliquescence will notOptical surface grinding machinesCleaning using toolsWater basedEtching

The invention provides a method for increasing a laser-damaged threshold through ion beam elastic domain etching. Polishing of potassium dihydrogen phosphate (KDP) crystals is carried out through non-water-based magnetorheology, and ion beam elastic domain etching polishing is carried out on the surfaces of the polished crystals. By means of the method, it can be guaranteed that residual organic alcohol and iron powder on the surfaces of the crystals are removed, it can be ensured that scratches on the surfaces are avoided and the surface quality is not damaged in the iron powder removing process, meanwhile, subsurface defects which are generated in the ultraprecise turning process and not completely removed through magnetorheology polishing are overcome through elastic domain etching, and therefore the laser damage resistance capacity of the KDP crystals is effectively improved.

Owner:NAT UNIV OF DEFENSE TECH

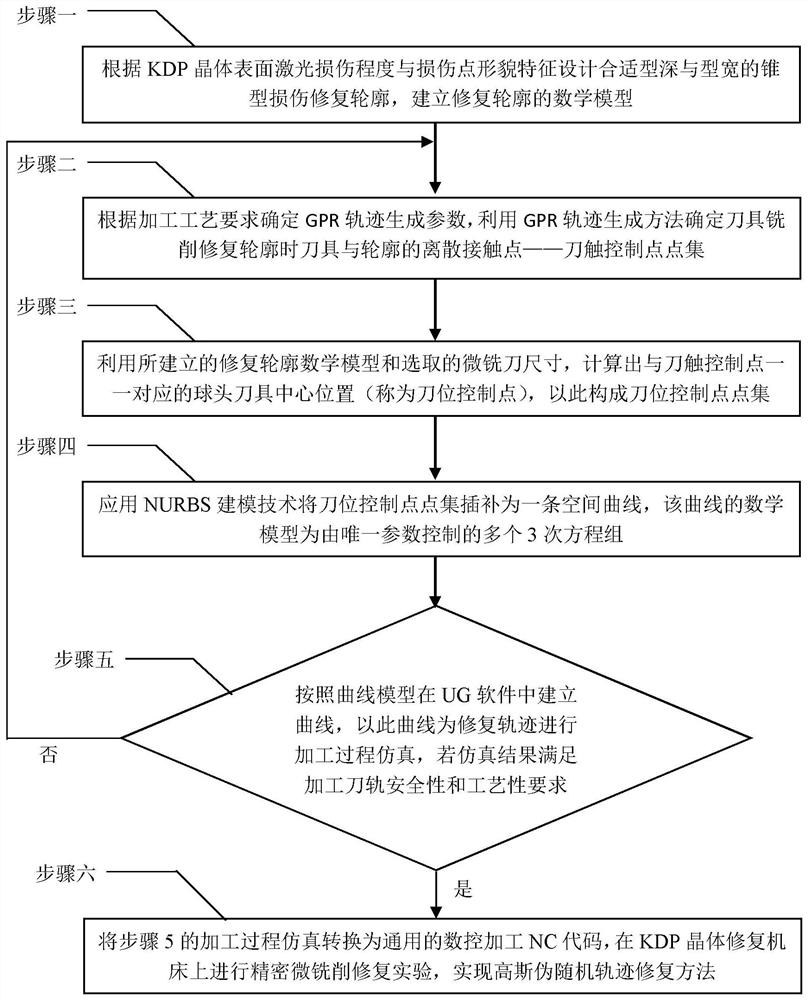

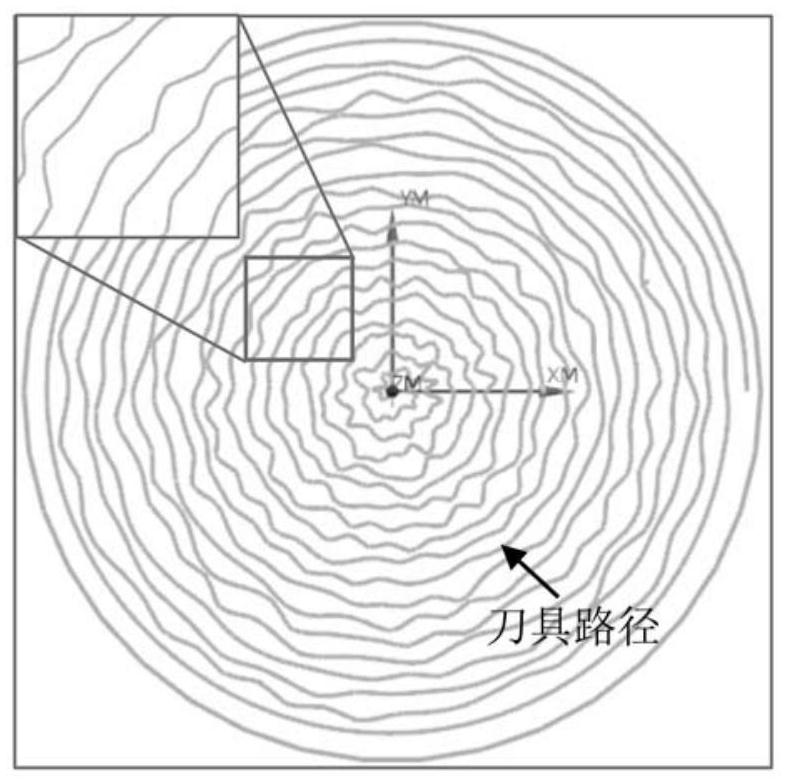

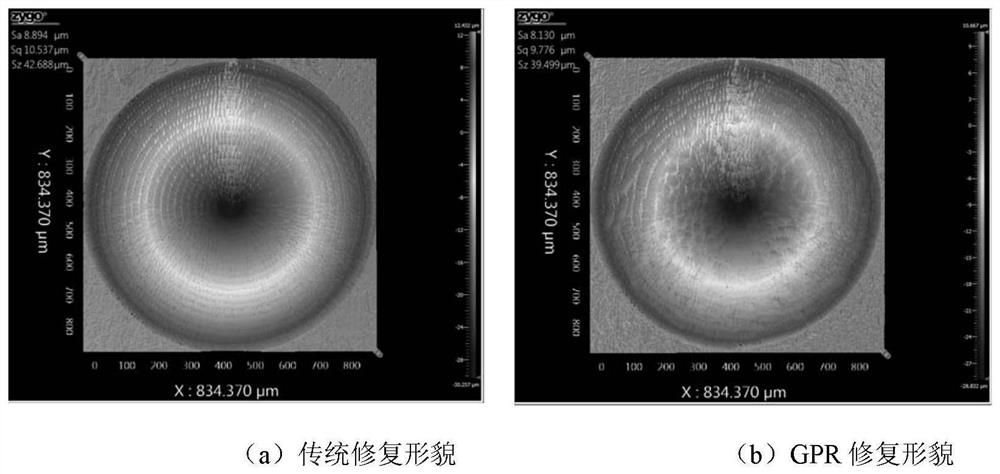

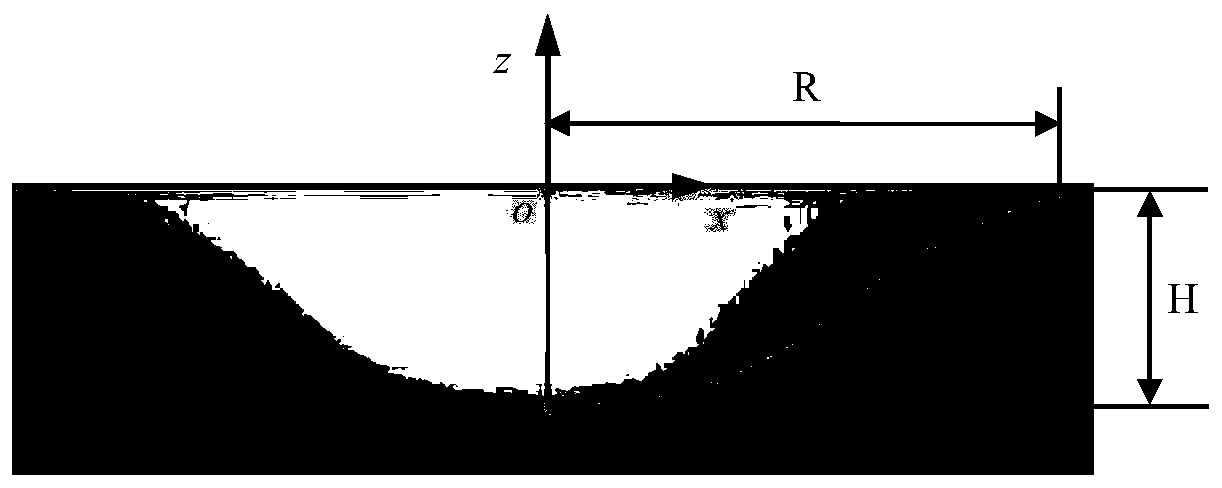

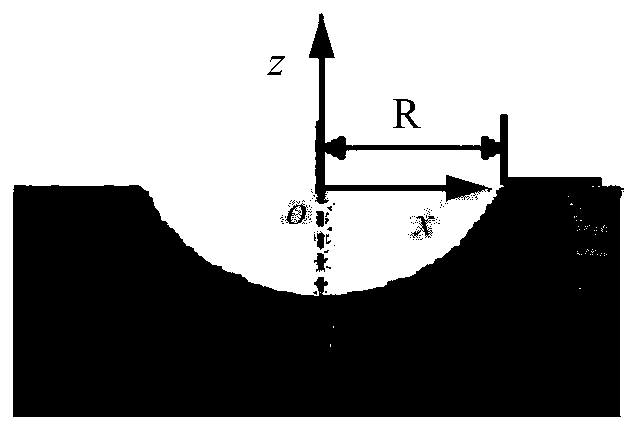

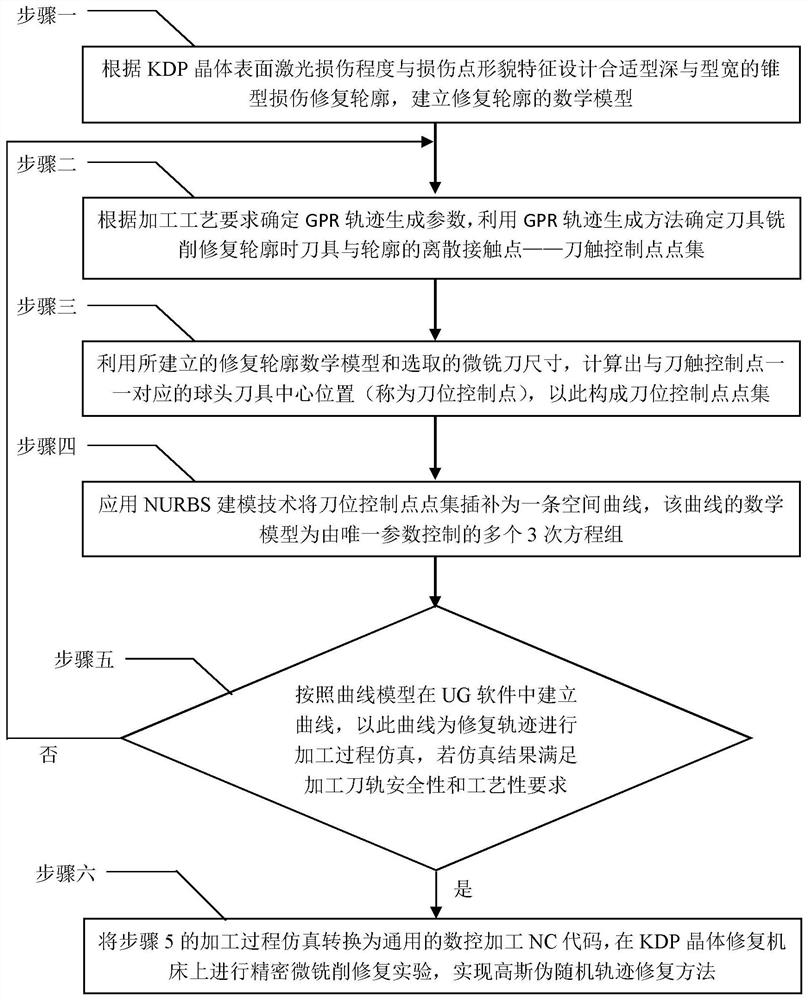

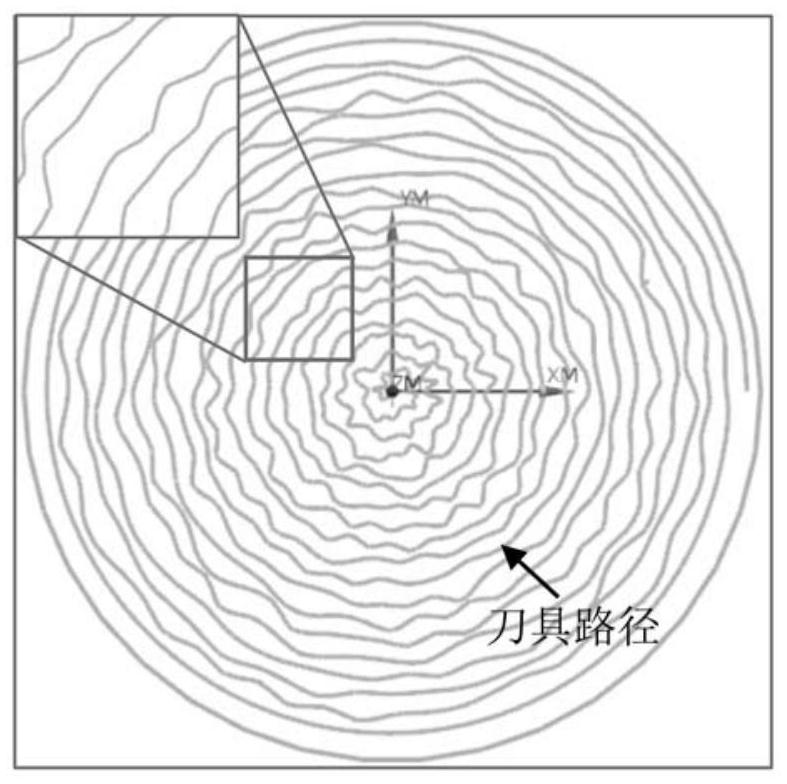

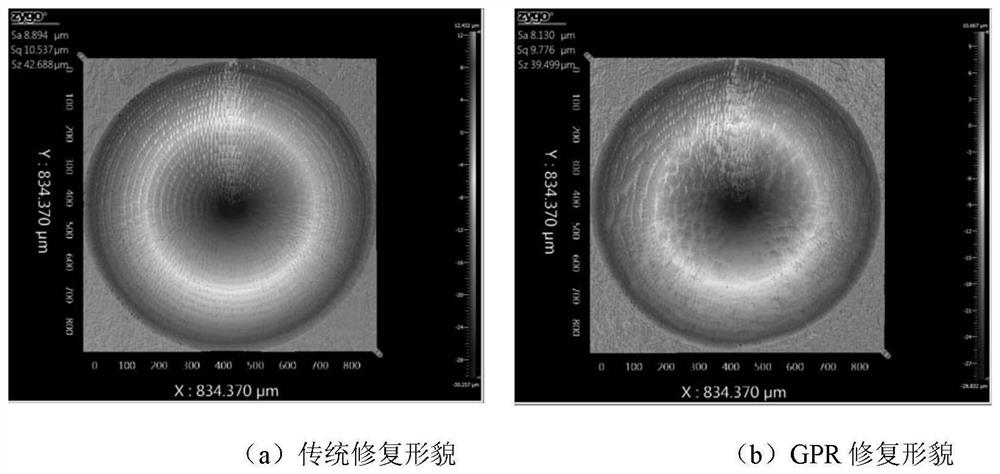

Variable-step-pitch micro-milling repair tool path generation method for optical crystal surface damage points

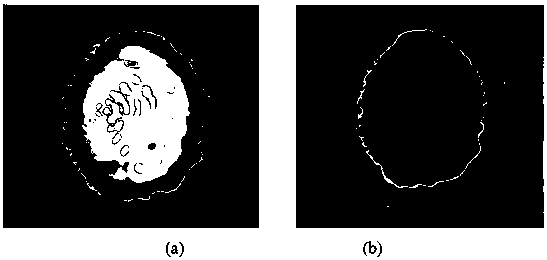

ActiveCN112379636AImprove elimination effectRealize modelingGeometric CADComputer controlMilling cutterMathematical model

The invention discloses a variable-step-pitch micro-milling repair tool path generation method for optical crystal surface damage points, and belongs to the technical field of optical material and optical element surface repair. The method aims to delay the modulation effect of a constant-period tool mark generated by a soft and brittle KDP crystal in micro-milling repair on incident laser, and achieve the purposes of improving the laser damage resistance of a KDP crystal element and prolonging the service life of the KDP crystal element. The method is characterized by: establishing a mathematical model of a repaired contour; determining discrete contact points of the cutter and the contour for controlling the motion trend of the pseudo-random trajectory when the cutter mills and repairs the contour by using a GPR trajectory generation method; utilizing the established repair contour mathematical model and the selected micro-milling cutter size; interpolating the cutter location control point set into a space curve by applying an NURBS modeling method; and establishing a curve in UG software according to the curve model, and performing machining process simulation by taking the curve as a repair track. It is verified that the method has a good elimination effect on the constant-period knife lines, and the strong laser damage resistance of the method is improved.

Owner:HARBIN INST OF TECH

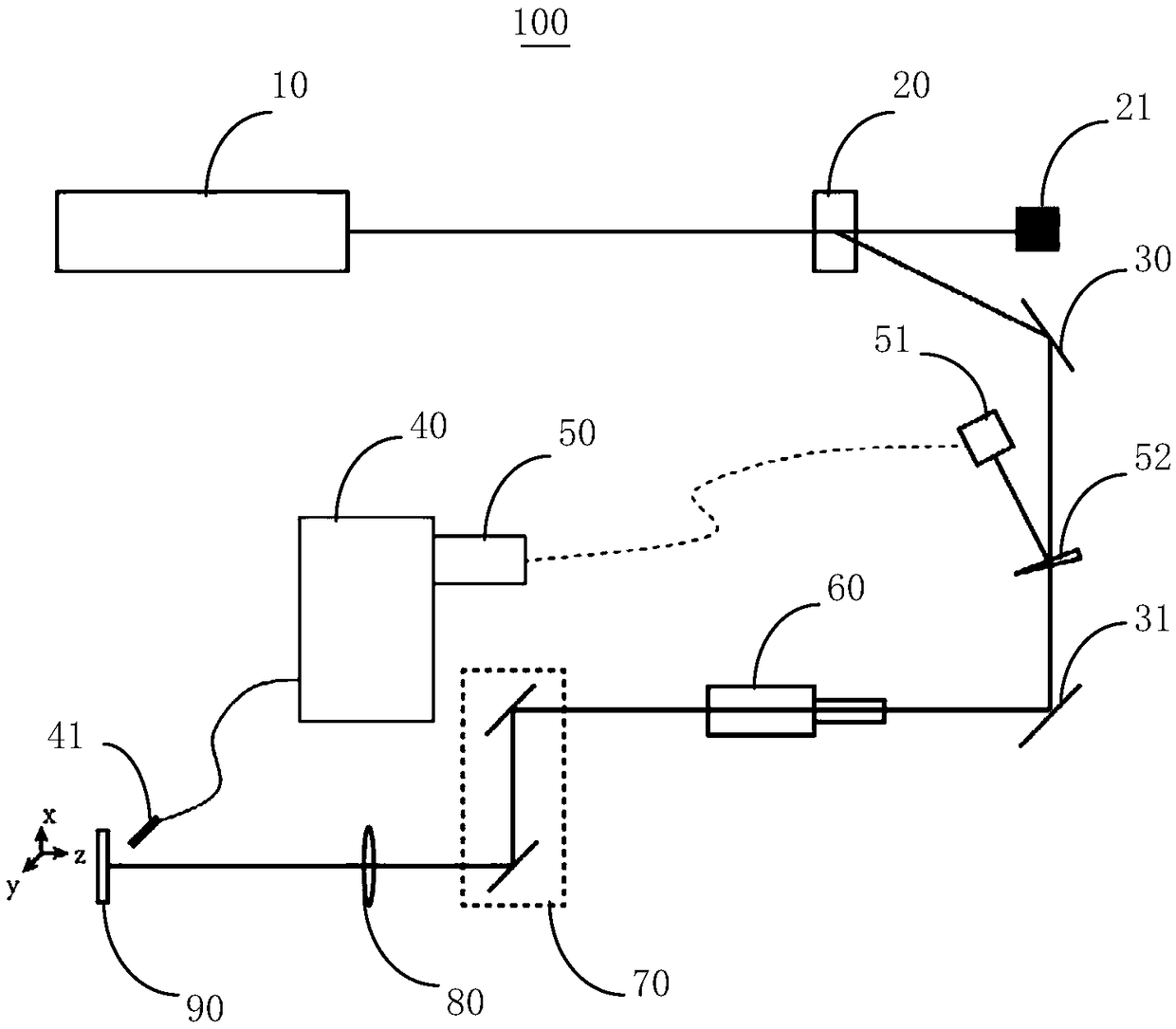

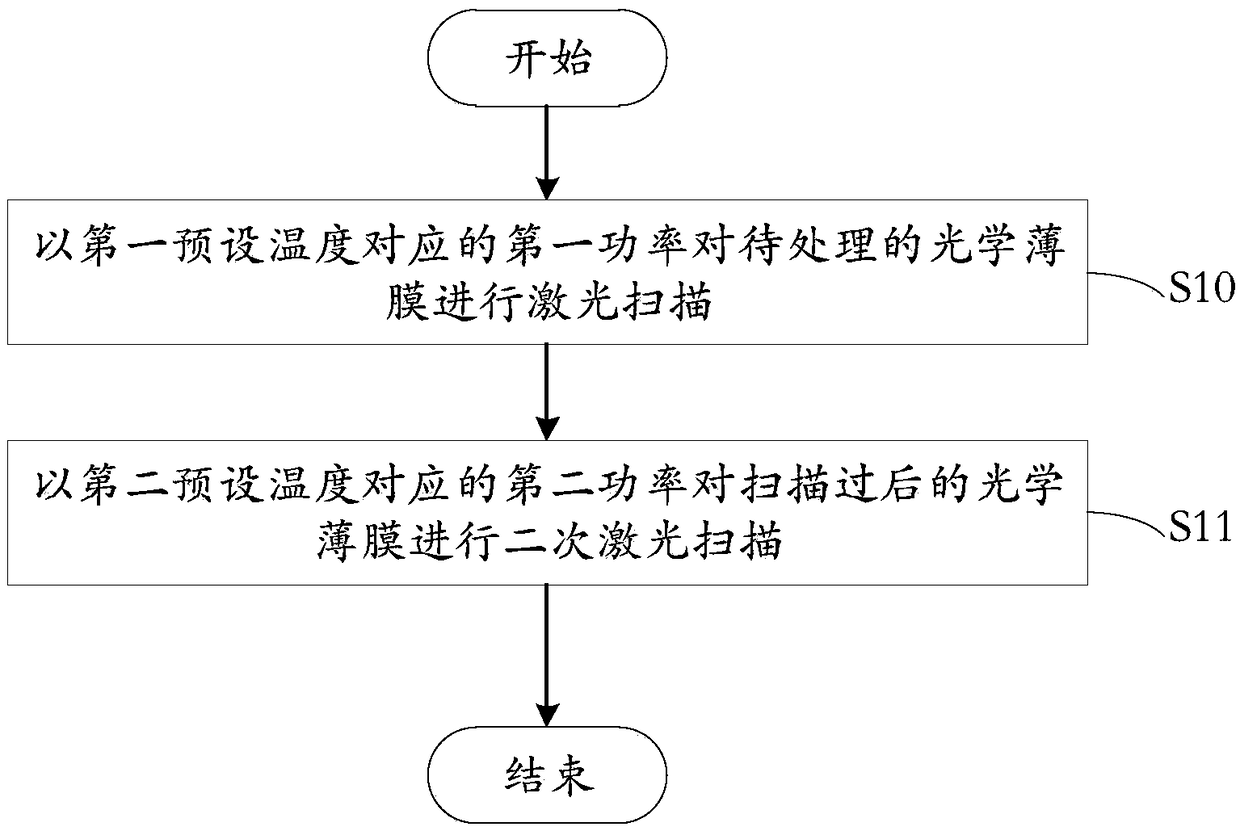

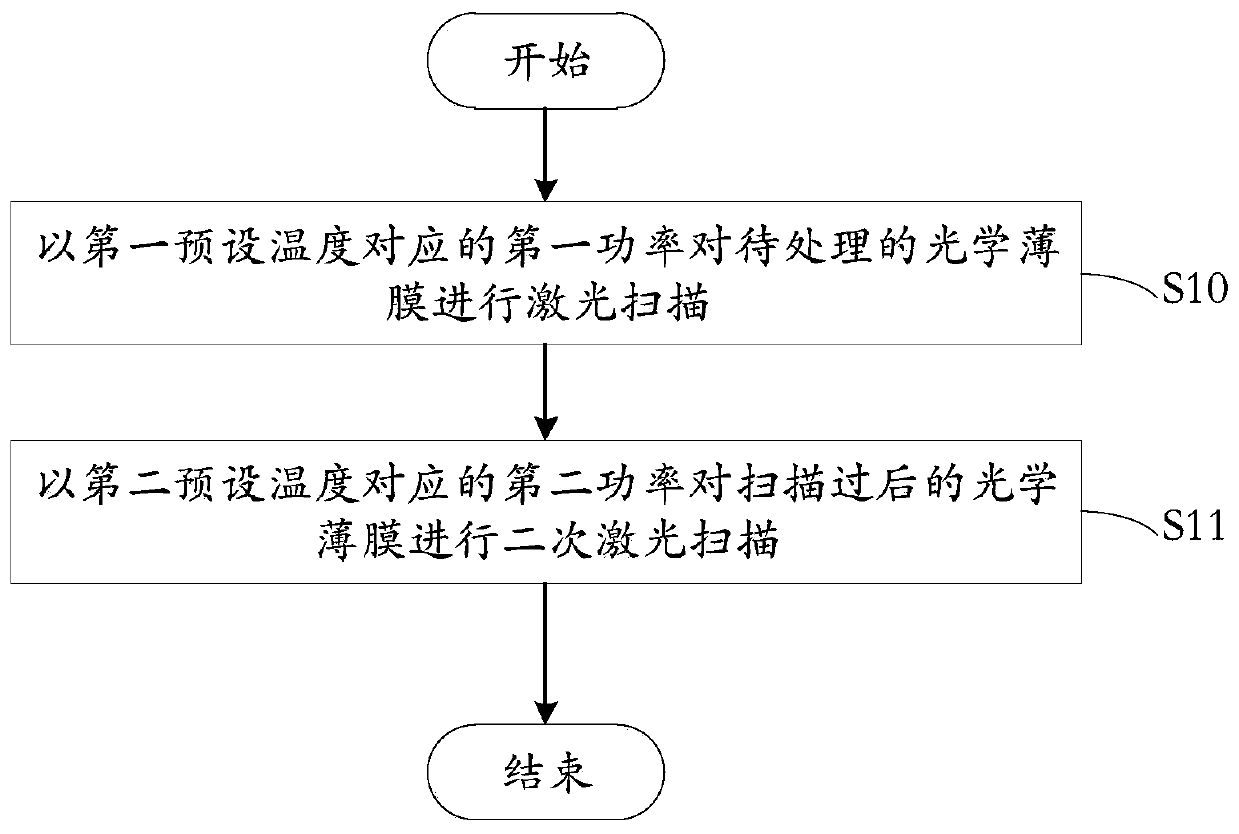

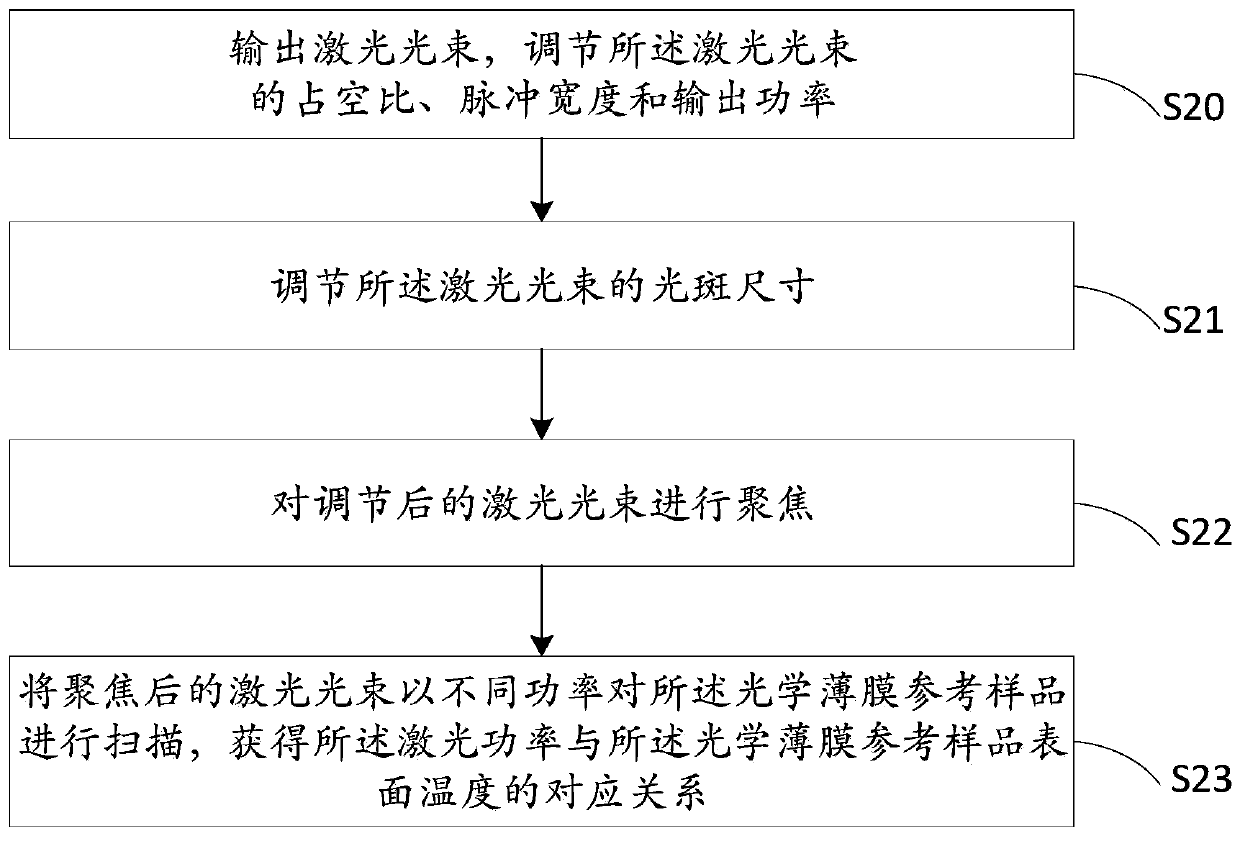

Optical film reinforcing method and laser reinforcing device

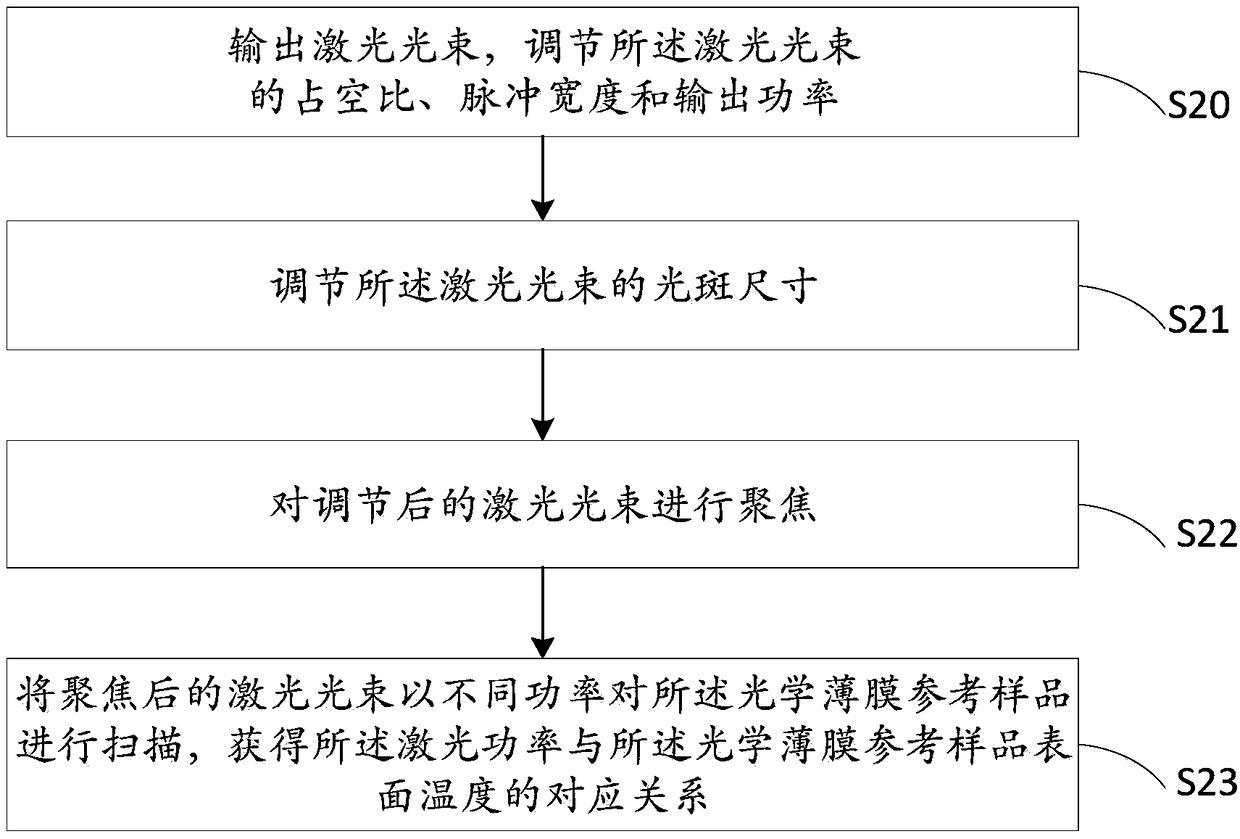

ActiveCN108761580AImproved resistance to laser damageReduce residual stressOptical elementsReference sampleLaser scanning

The invention provides an optical film reinforcing method and a laser reinforcing device, and relates to the technical field of laser. The optical film reinforcing method provided by the invention isapplied to the laser reinforcing device; the laser reinforcing device is prestored with a corresponding relation between the laser power and the surface temperature of an optical film reference sample; the optical film is prepared by an atomic layer deposition method; the optical film reinforcing method comprises the following steps: performing laser scanning on the optical film to be treated at the first power corresponding to the first preset temperature; after completion of the scanning, performing secondary laser scanning on the screened optical film at the second power corresponding to the second preset temperature, wherein the first preset temperature is higher than the second preset temperature. Through the optical film reinforcing method and the laser reinforcing device, laser scanning heat treatment is performed on the optical film prepared by the atomic layer deposition method, so that reliable reinforcement of the film is achieved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

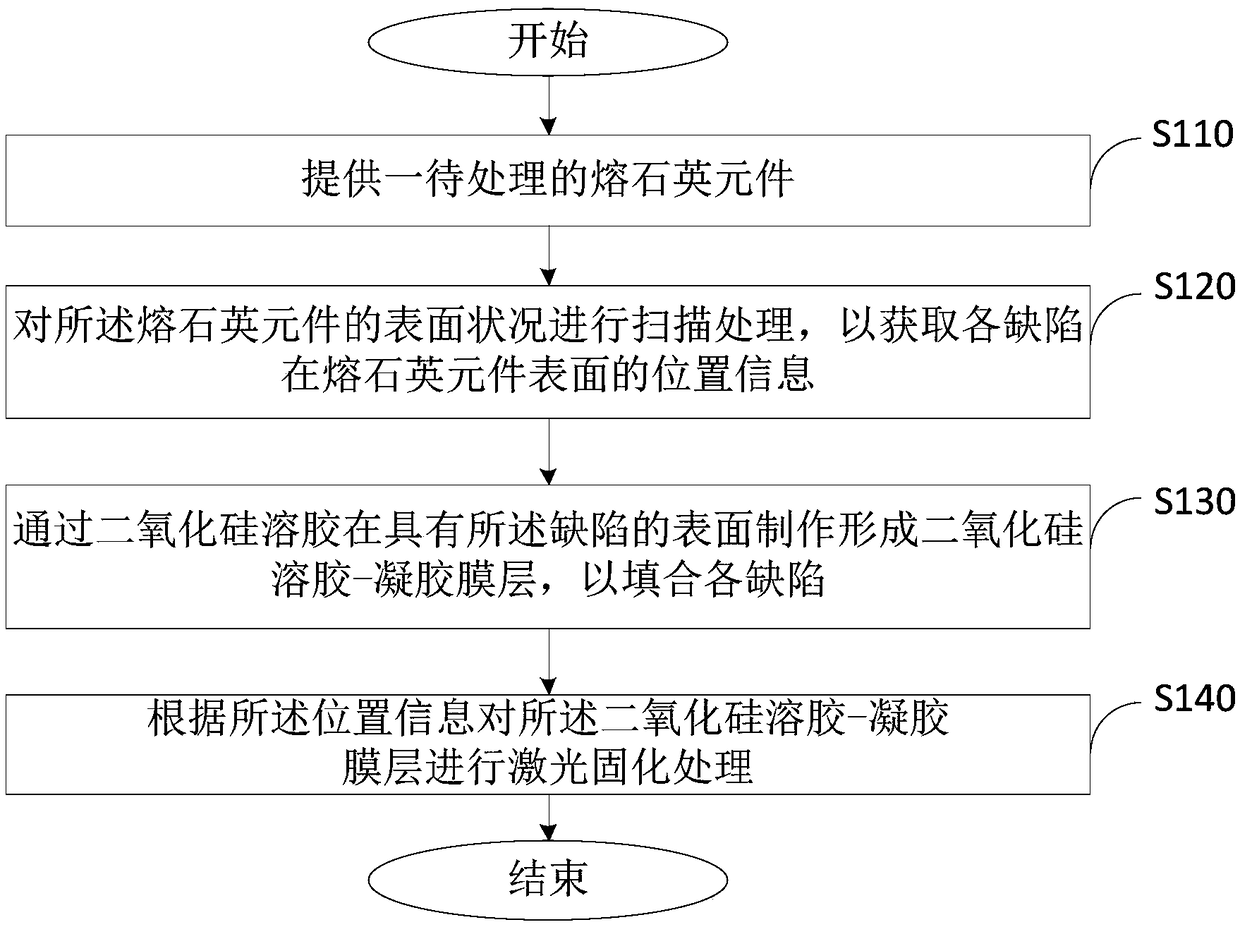

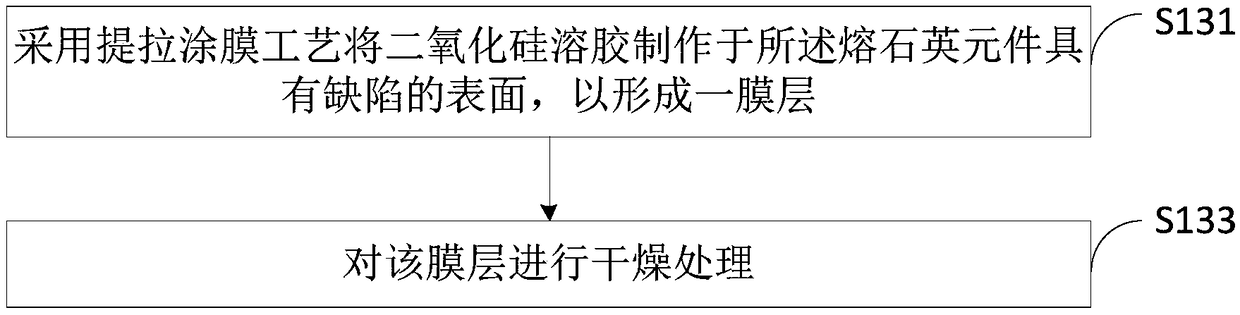

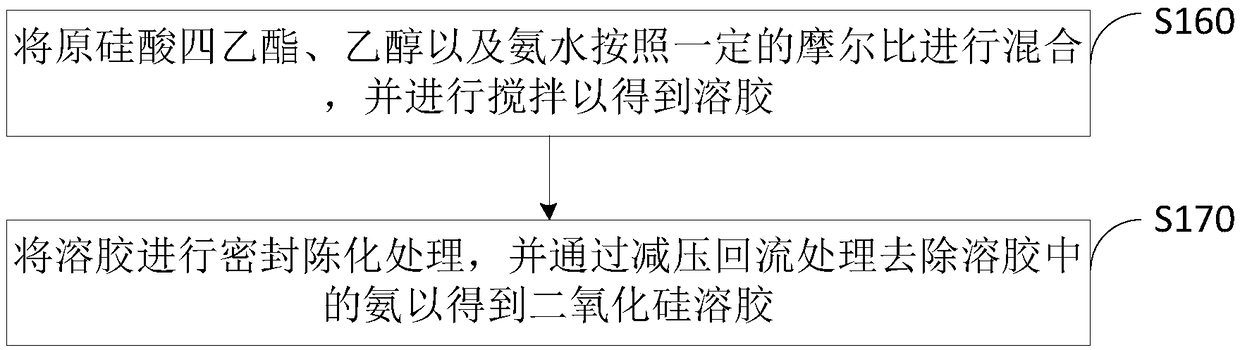

Surface defect processing method and laser curing processing system

InactiveCN109111123AImproved resistance to laser damageImprove the problem of low resistance to laser damageCoatingsLaser damageSilicon dioxide

The invention provides a surface defect processing method and a laser curing processing system, relating to the technical field of laser. The surface defect processing method comprises the steps of providing a to-be-treated fused quartz component; scanning the surface situation of the fused quartz component, so as to acquire position information of each defect on the surface of the fused quartz component; preparing and forming a silica sol-gel layer on the surface with the defect through silica sol, so as to fill each defect; and performing laser curing treatment on the silica sol-gel layer according to the position information. Through adoption of the method, a problem in the prior art that the fused quartz component cannot resist laser damage strongly is solved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

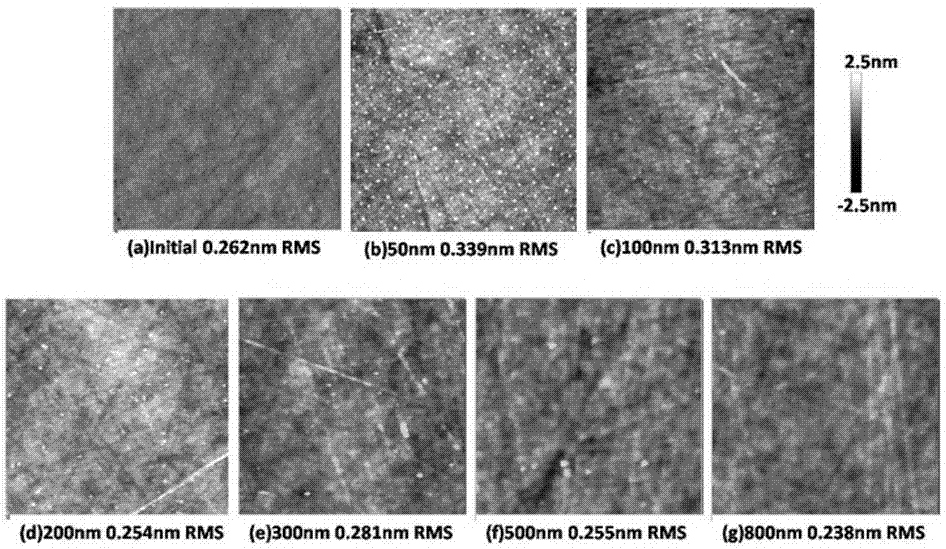

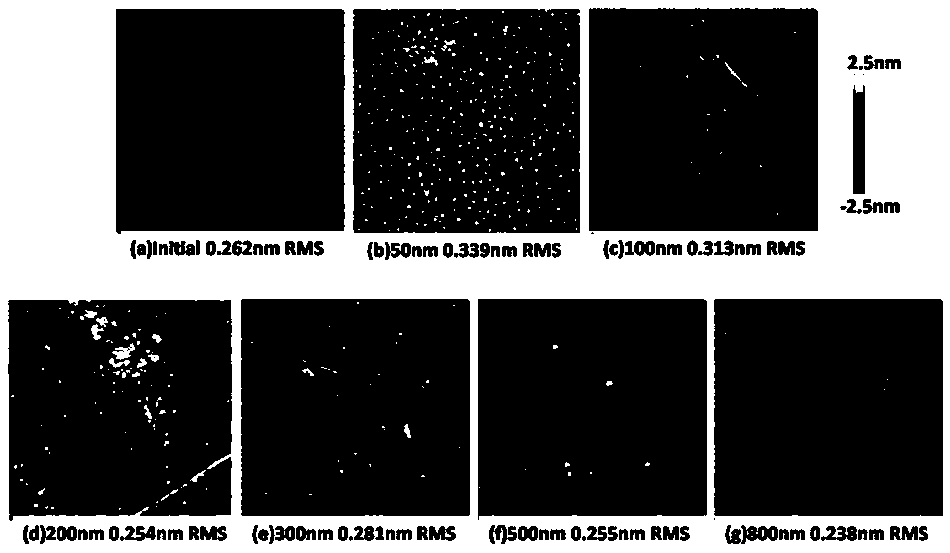

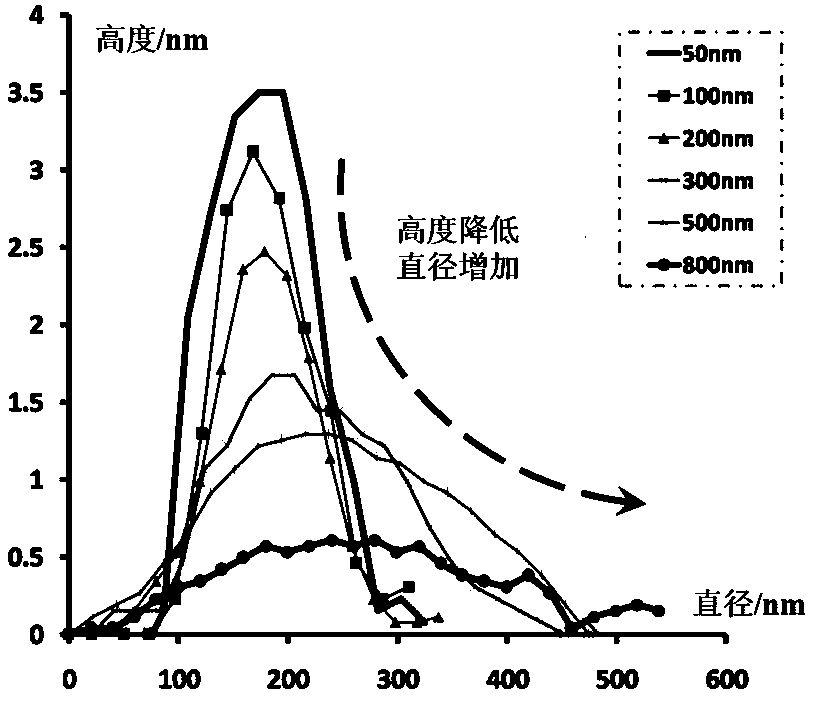

Fused quartz surface nanoscale damage precursor passivation technology

ActiveCN107088791ALaser Threshold RaisingImproved resistance to laser damageRms roughnessHigh surface

The invention discloses a fused quartz surface nanoscale damage precursor passivation technology. The passivation technology includes the following steps that (1) the surface of a fused quartz element with the RMS roughness Rq smaller than 0.5 nm is subject to plasma washing treatment to remove a hydrolysis layer on the surface of the fused quartz element, and a nanoscale damage precursor on the sub surface of the fused quartz element is exposed out; and (2) the surface of the fused quartz element treated in the step (1) is subject to plasma passivation treatment, and nanoscale damage precursor passivation is carried out. The technology has the beneficial effects that the technological process is simple, the maneuverability is high, the nanoscale damage precursor on the fused quartz surface can be removed, and secondary pollution of the surface of the element can be avoided; and by means of the technology, the optical element with the high accuracy and the high surface quality can be machined, and the laser damage resistant capacity of the fused quartz element is effectively improved.

Owner:NAT UNIV OF DEFENSE TECH

A kind of optical processing defect passivation process

ActiveCN105271791BImproved resistance to laser damageSimple processAfter treatmentOptical processing

Owner:NAT UNIV OF DEFENSE TECH

Laser pretreatment device and treatment method for optical components

InactiveCN106964893BImproved resistance to laser damageUniform energy densityLaser beam welding apparatusPower switchingLight beam

The invention discloses a laser preprocessing device and processing method used for an optical element. The laser preprocessing device comprises a laser light source used for emitting laser as well as a light-splitting chopping plate, a reflecting mirror, a light beam shaping system and an electric translation stage used for placing a to-be-processed optical element are sequentially arranged in the laser transmission direction, wherein laser emitted by the laser light source passes through the light-splitting chopping plate and then is transmitted to the light beam shaping system through the reflecting mirror; the light beam shaping system is used for performing light beam shaping on laser; laser spots which are in Gaussian distribution are shaped into square spots which are uniformly distributed flatly; and finally, the laser is irradiated to the surface of the optical element for performing laser preprocessing on the optical element. According to the laser preprocessing device disclosed by the invention, irradiation energy density of the whole preprocessing process is uniform through the uniform square laser pots which are flatly focused, and dimensions of the spots are easily regulated through a multiplying power switching structure, so that the purpose of regulating energy density of laser which reaches the surface of the optical element is achieved.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

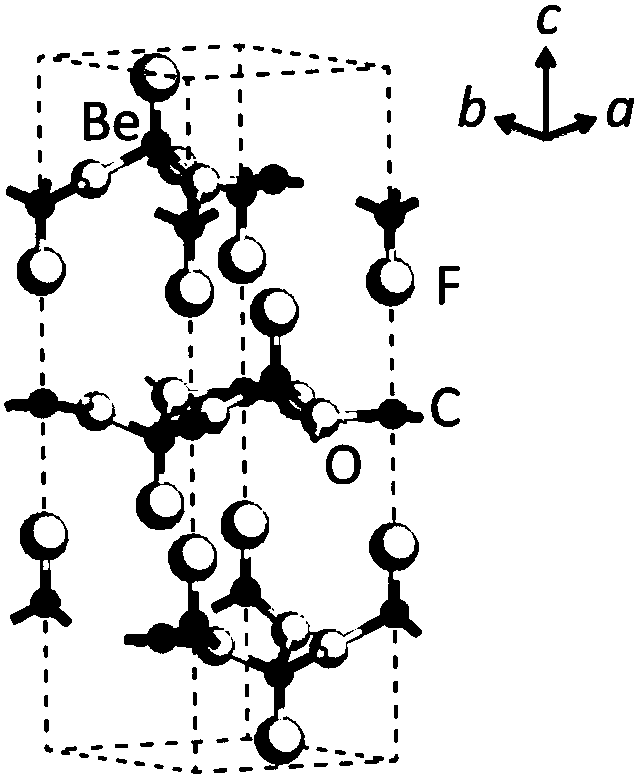

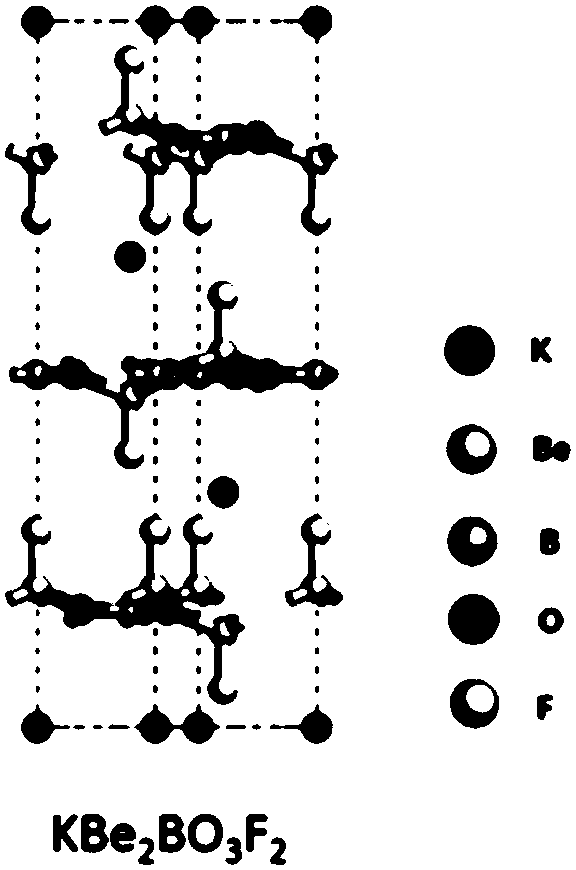

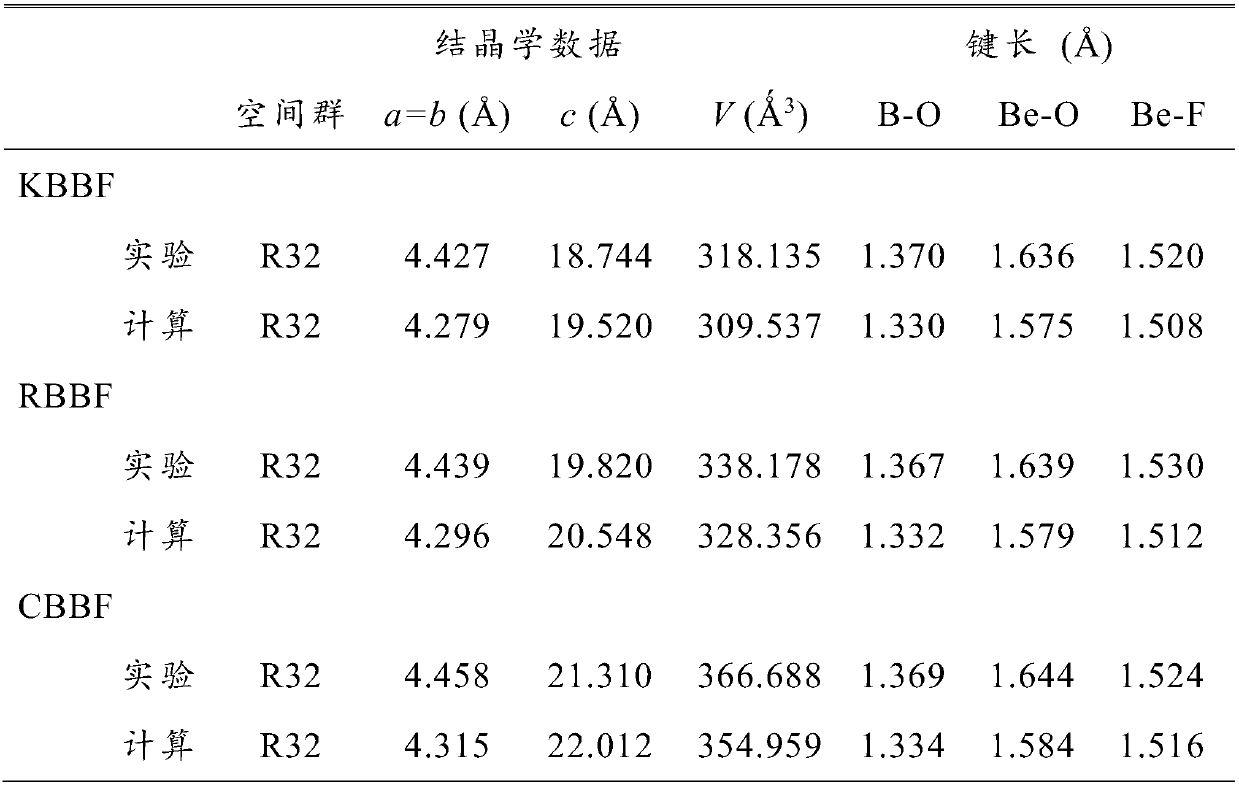

Nonlinear optical crystal fluorine beryllium carbonate, preparation method thereof and application of nonlinear optical crystal fluorine beryllium carbonate

InactiveCN107779952AReduce distanceStrong frequency doubling effectPolycrystalline material growthLaser detailsNonlinear optical crystalBirefringent crystal

The invention provides a nonlinear optical crystal beryllium fluorocarbonate with the chemical formula Be2CO3F2 (abbreviated as BCF). Research shows that the BCF crystal of the invention has stronger nonlinear optical effect and greater birefringence than the KBBF crystal. efficiency, higher frequency doubling conversion efficiency, higher deep UV output power, stronger mechanical properties, better machinability, and higher resistance to laser damage; it can be used as an excellent UV and deep UV nonlinear optics Crystals and birefringent crystals, and can be widely used in various nonlinear optical crystal materials and two-dimensional materials.

Owner:BEIJING COMPUTATIONAL SCI RES CENT

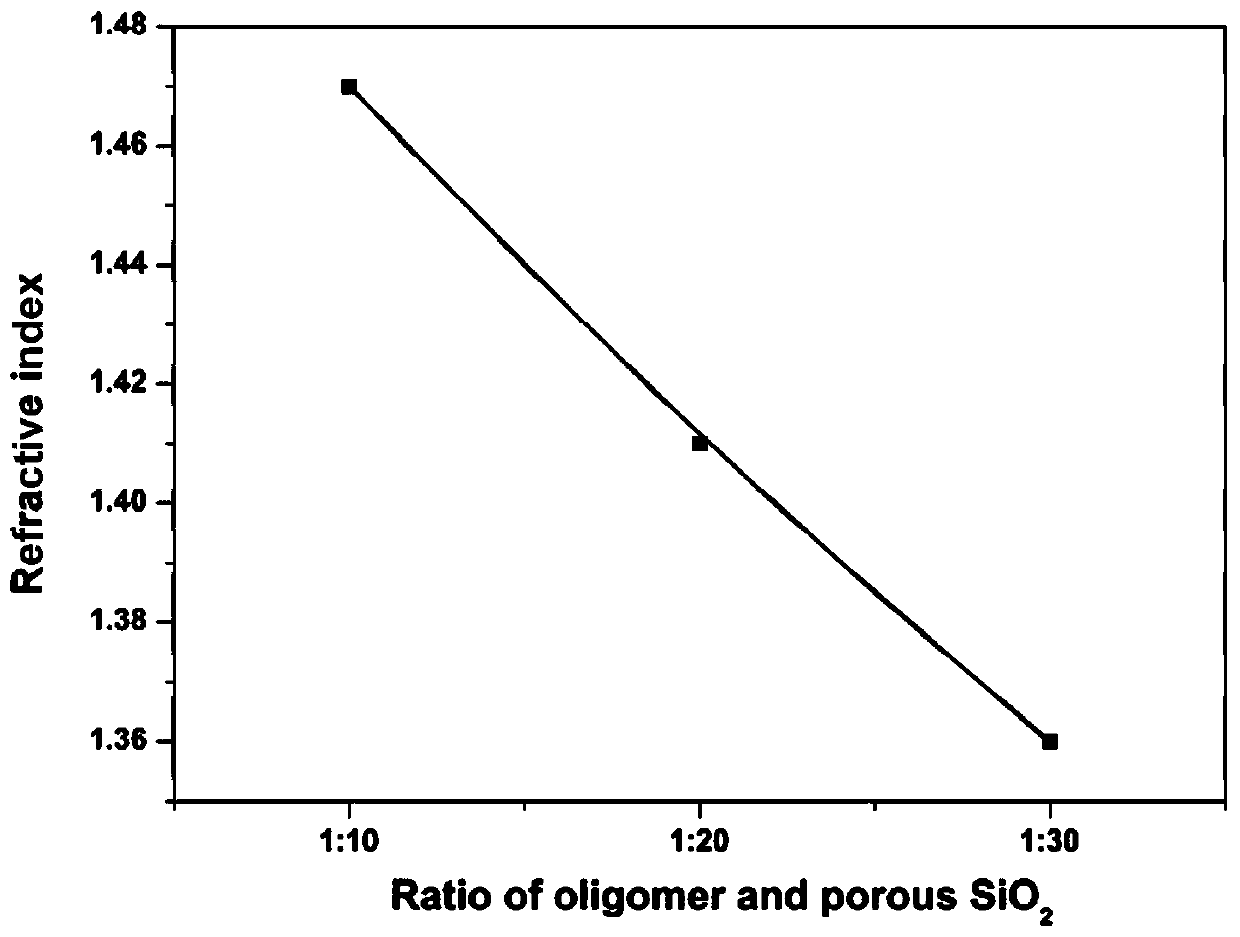

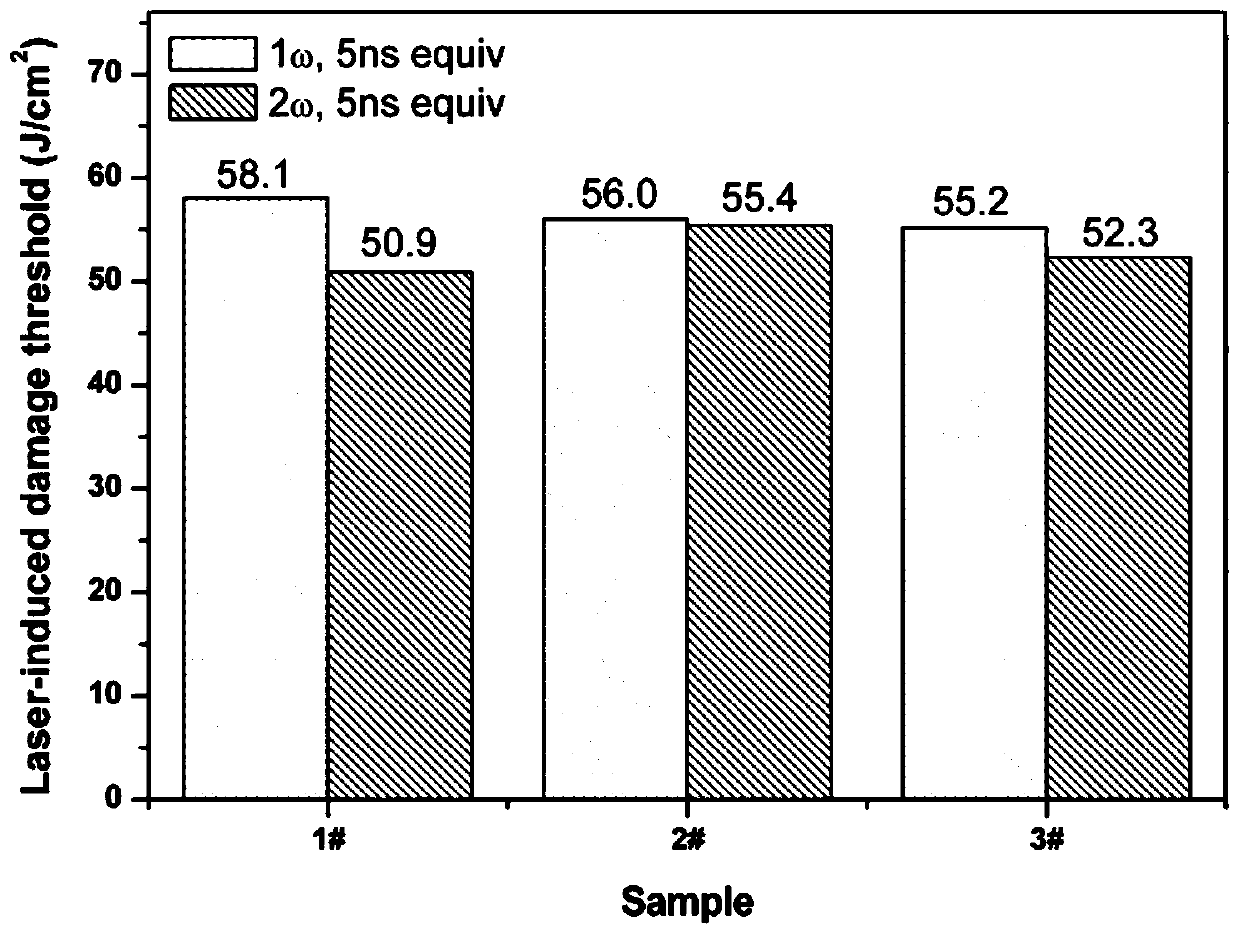

A kind of ultraviolet curing film with adjustable refractive index and preparation method thereof

ActiveCN108424537BWide range of refractive index controlLow refractive indexCoatingsMethacrylateSilicic acid

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

A method and device for testing the nonlinear effect i*l value of an optical element

ActiveCN111579221BImproved resistance to laser damageImprove test accuracyGeometric properties/aberration measurementEngineeringLaser damage

The invention discloses a method and device for testing the nonlinear effect I*L value of an optical element. The method focuses a laser beam in the body of the optical element by using a lens with a focal length smaller than the thickness of the optical element and adjusting the position of the optical element. At the same time, the laser energy density of the laser irradiated on the incident surface of the optical element to be tested is adjusted to be less than the laser damage threshold of the incident surface of the optical element to be tested, and the disturbance-induced small-scale self-focusing effect under non-focusing conditions is simulated, which solves the traditional In the test method, since the damage of the incident surface of the optical element occurs before the self-focusing filament damage in the body, the problems of laser loss such as scattering and defect absorption caused by the damage of the incident surface of the optical element not only improve the test accuracy, but also provide for the optical element in the test method. Safe use in high-power laser installations and improving the resistance of materials to laser damage provide additional assistance.

Owner:中国工程物理研究院上海激光等离子体研究所

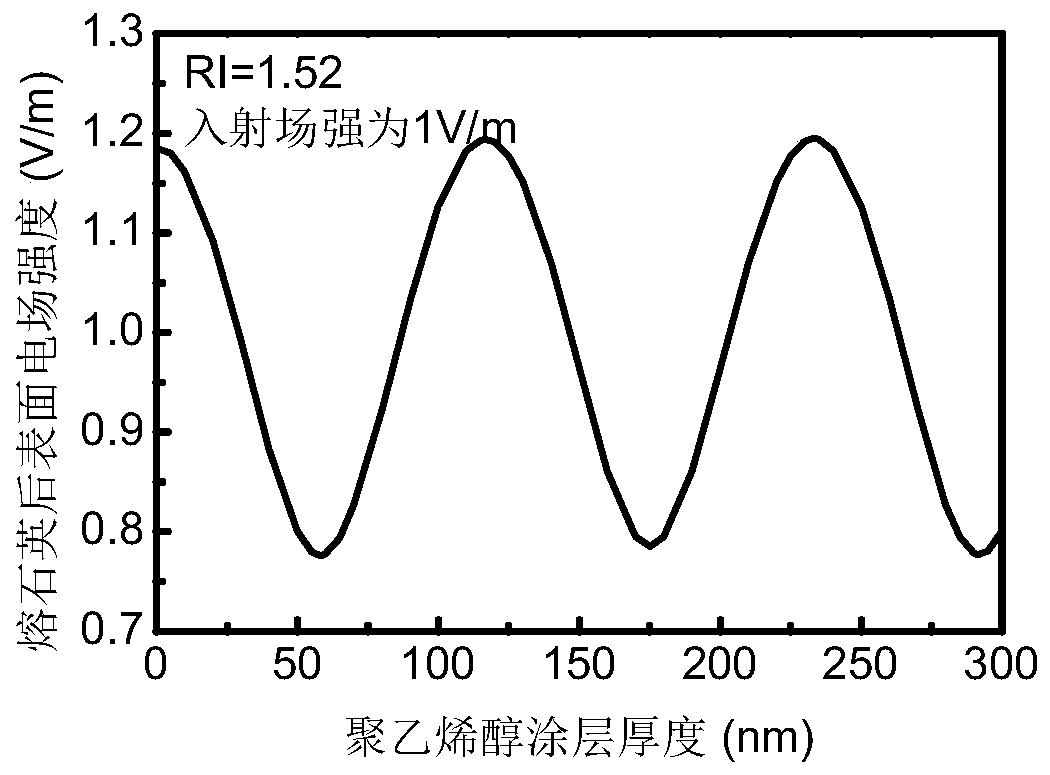

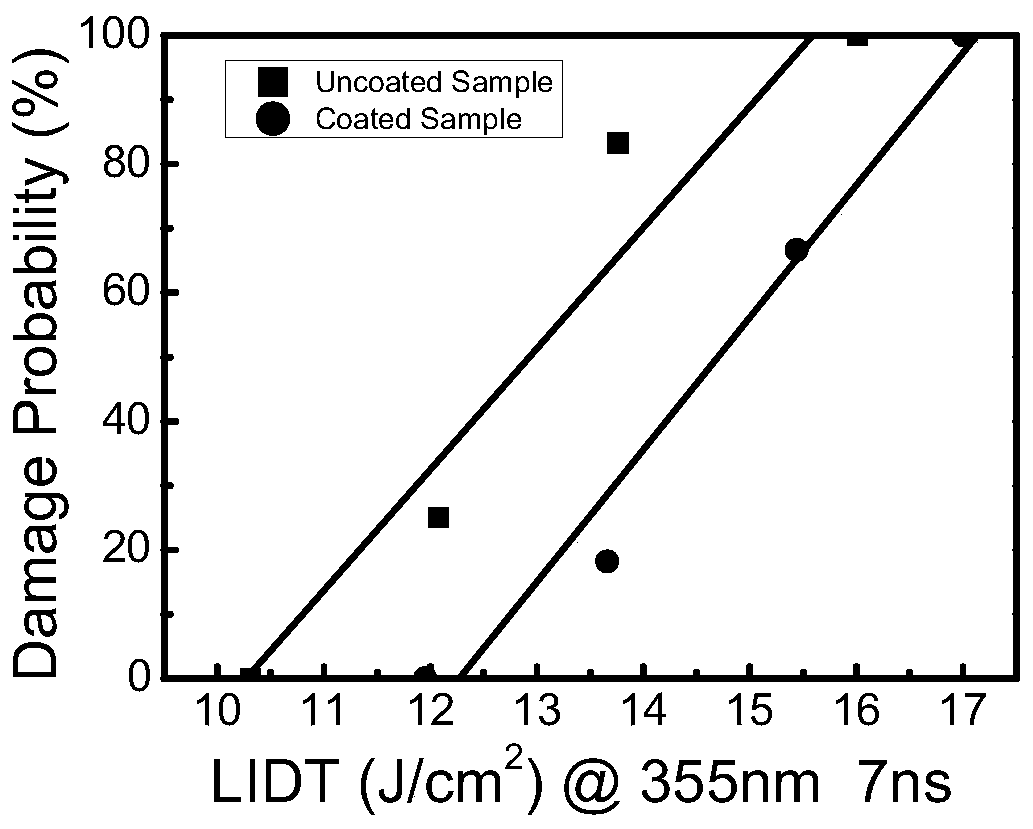

A kind of polyvinyl alcohol coating on the surface of fused silica, preparation method and application

ActiveCN108710163BReduce electric field strengthImproved resistance to laser damageCoatingsOptical elementsElectrical field strengthPolyvinyl alcohol

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

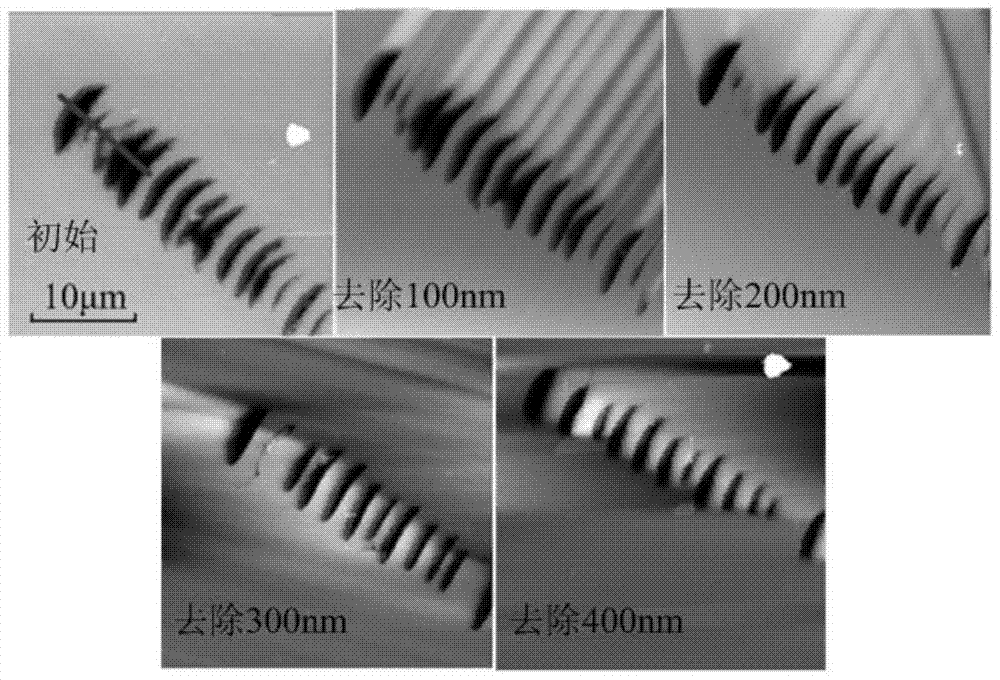

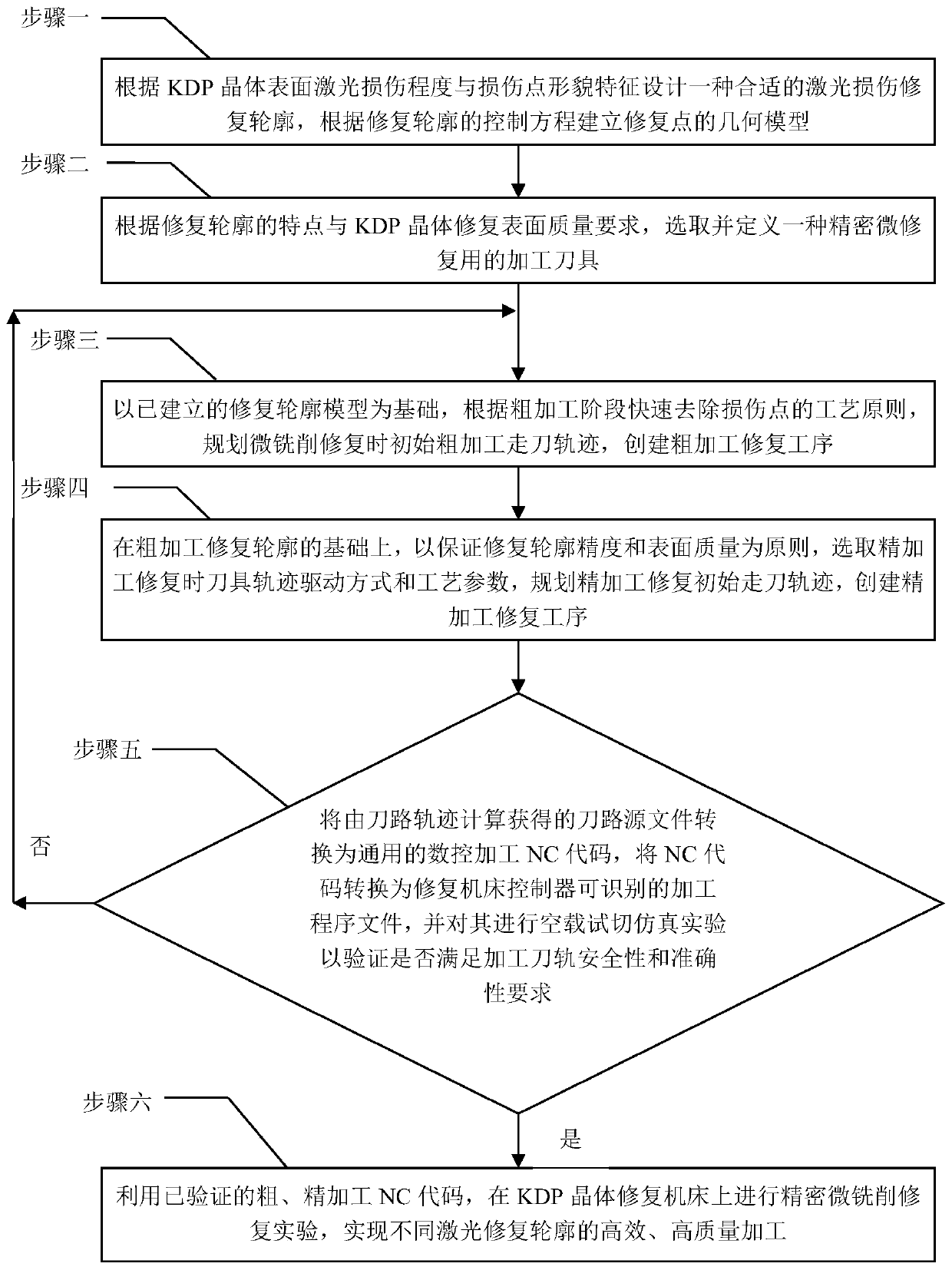

Micro-milling repair process for laser damage on the surface of large-diameter kdp crystal components

ActiveCN108705692BImproved resistance to laser damageReduced service lifeFine working devicesSpecial data processing applicationsNumerical controlGeometric modeling

The invention discloses a micro-milling repair technical method for the laser damage of the surface of a large-diameter KDP crystal element, and belongs to the technical field of repair machining of optical materials and optical elements in order to solve the problems that during repair of laser damage points of the surface of a soft and fragile KDP crystal element, the repair outline is simplex,the repaired surface quality is poor, and the efficiency is low. A geometric model of repairing points is built according to a control equation of the repair outline. A machining tool is selected. A rough machining repair procedure is built. A finish machining repair procedure is built. A tool path source file worked out according to the track of a tool path is converted into common numerical control machining NC codes, and the NC codes are converted into a machining program file capable of being recognized by a repair machine tool controller. A precise micro-milling repair experiment is carried out on a KDP crystal repair machine tool through the rough and finish machining NC codes, and efficient and high-quality machining of different laser friendly repairing outlines is realized. The increase behavior of laser damage points of the surface of the crystal element can be delayed, the laser damage resistance of the crystal element is improved, and the service life of the crystal elementis prolonged.

Owner:HARBIN INST OF TECH

A method and device for improving the ability of diamond-like carbon film to resist laser damage

ActiveCN105734523BImproved resistance to laser damageImprove heat accumulationVacuum evaporation coatingSputtering coatingCarbon filmThin membrane

The invention relates to a method and device capable of improving laser damage resistance capacity of a diamond-like thin film. The method and device aim at effectively improving the laser damage resistance capacity of a DLC thin film and a dielectric thin film on the basis of not affecting any optical constants and physical properties of the DLC thin film and the dielectric thin film. According to the technical scheme, through the method capable of improving the laser damage resistance capacity of the diamond-like thin film, magnetic continuity with a closed loop is formed on the surface of the DLC thin film and the dielectric thin film, and the magnetic flux of the closed loop has the maximum gradient. The device comprises a magnetic conductive outer frame. A pair of permanent magnets including a first permanent magnet and a second permanent magnet are arranged in the outer frame, and the distance between the first permanent magnet and the second permanent magnet is adjustable. Through the method, the damage threshold value of the DLC thin film is improved to 1.23 J / cm<2> from 0.57 J / cm<2>. For the dielectric thin film, the laser damage area is reduced by about 50%.

Owner:XIAN TECH UNIV

A tool trajectory generation method for micro-milling repair with variable step distance for damage points on the surface of optical crystals

ActiveCN112379636BImprove elimination effectRealize modelingGeometric CADComputer controlMilling cutterMathematical model

The invention discloses a method for generating a tool track for variable-step-pitch micro-milling repair aimed at damage points on the surface of optical crystals, belonging to the technical field of optical materials and optical element surface repair. The invention aims to delay the modulation effect of the constant-period knife marks produced in the micro-milling repair of the soft and brittle KDP crystal on the incident laser, so as to improve the anti-laser damage ability of the KDP crystal element and prolong its service life. Technical points: establish a mathematical model of the repair contour; use the GPR trajectory generation method to determine the discrete contact points between the tool and the contour when the tool mills the repair contour to control the movement trend of the pseudo-random trajectory; use the established mathematical model of the repair contour and the selected micro Milling cutter size; use NURBS modeling method to interpolate the tool position control point set into a space curve; establish a curve in UG software according to the curve model, and use this curve as the repair track to simulate the machining process. It has been verified that the invention has a good effect on eliminating constant-period knife marks and helps to improve its ability to resist strong laser damage.

Owner:HARBIN INST OF TECH

Optical film strengthening method and laser strengthening device

ActiveCN108761580BImproved resistance to laser damageReduce residual stressOptical elementsLaser technologyReference sample

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Passivation Process of Nanoscale Damage Precursor on Fused Silica Surface

ActiveCN107088791BLaser Threshold RaisingImproved resistance to laser damageRms roughnessHigh surface

The invention discloses a fused quartz surface nanoscale damage precursor passivation technology. The passivation technology includes the following steps that (1) the surface of a fused quartz element with the RMS roughness Rq smaller than 0.5 nm is subject to plasma washing treatment to remove a hydrolysis layer on the surface of the fused quartz element, and a nanoscale damage precursor on the sub surface of the fused quartz element is exposed out; and (2) the surface of the fused quartz element treated in the step (1) is subject to plasma passivation treatment, and nanoscale damage precursor passivation is carried out. The technology has the beneficial effects that the technological process is simple, the maneuverability is high, the nanoscale damage precursor on the fused quartz surface can be removed, and secondary pollution of the surface of the element can be avoided; and by means of the technology, the optical element with the high accuracy and the high surface quality can be machined, and the laser damage resistant capacity of the fused quartz element is effectively improved.

Owner:NAT UNIV OF DEFENSE TECH

A Method for Improving the Laser Damage Resistance of Optical Thin Film Components

ActiveCN111443406BImproved resistance to laser damageReduce defect densityOptical apparatus testingOptical elementsThin membraneOptical thin film

The invention provides a method for improving the laser damage resistance of an optical thin film element, comprising: first obtaining the functional damage threshold of the optical thin film element; then performing coating treatment and laser-induced plasma impact post-treatment of the optical thin film element: obtaining the The functional damage thresholds of all thin-film elements after laser-induced plasma post-treatment with different scanning parameters; the largest functional damage threshold is selected as the optimal functional damage threshold of optical thin-film elements, and the corresponding pulse width and scanning parameters are the most Optimum parameters; using the optimal parameters to perform laser-induced plasma post-treatment on the optical thin film elements to improve the ability of the optical thin film elements to resist laser damage. The invention can simultaneously reduce the defect density of structural and absorption defects in the film, and can improve the mechanical properties such as the bonding force between the film interfaces, solving the problem that the current post-processing technology is only effective for a small number of film element types and improves the effect There are also limited puzzles.

Owner:WENZHOU UNIV

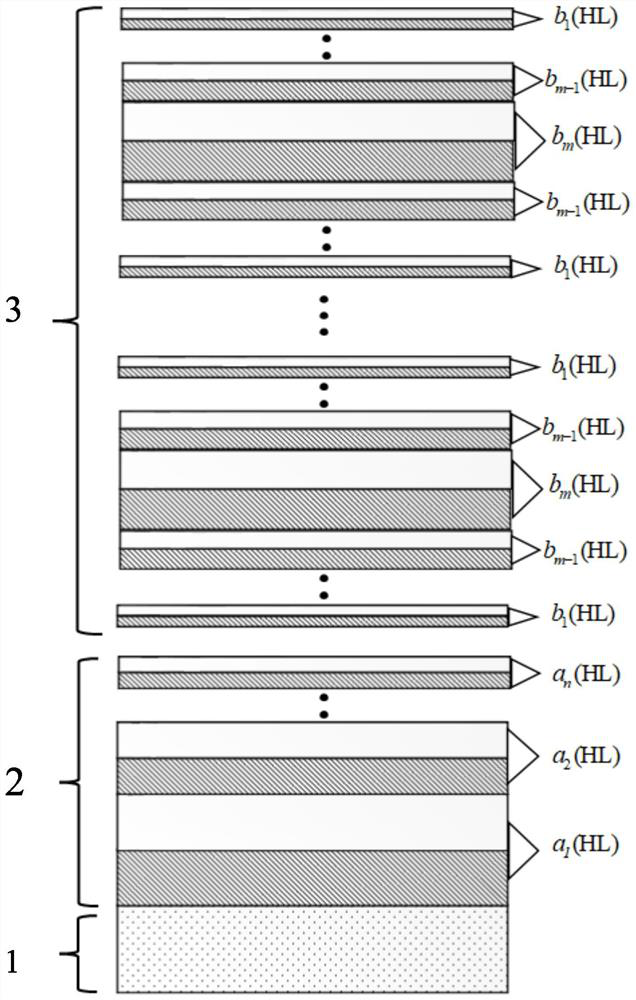

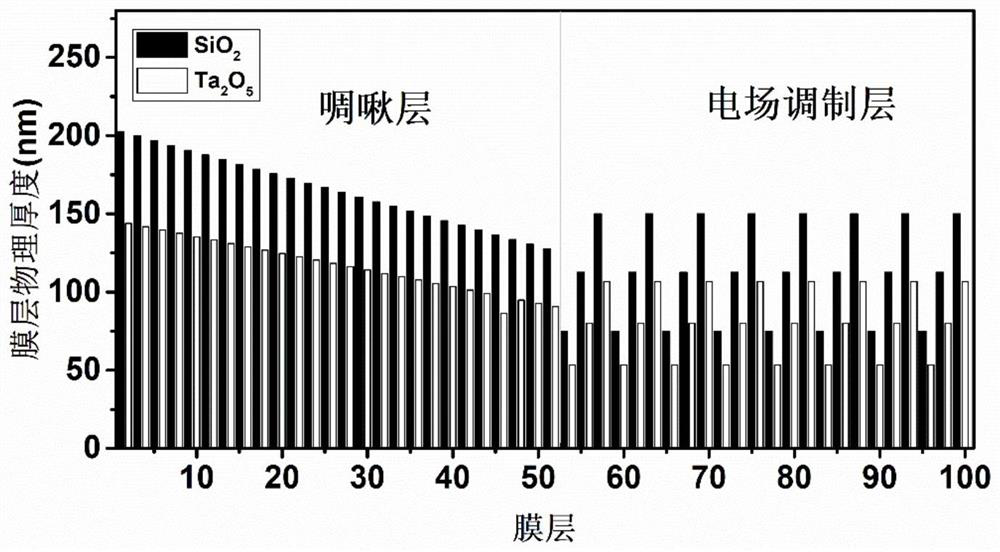

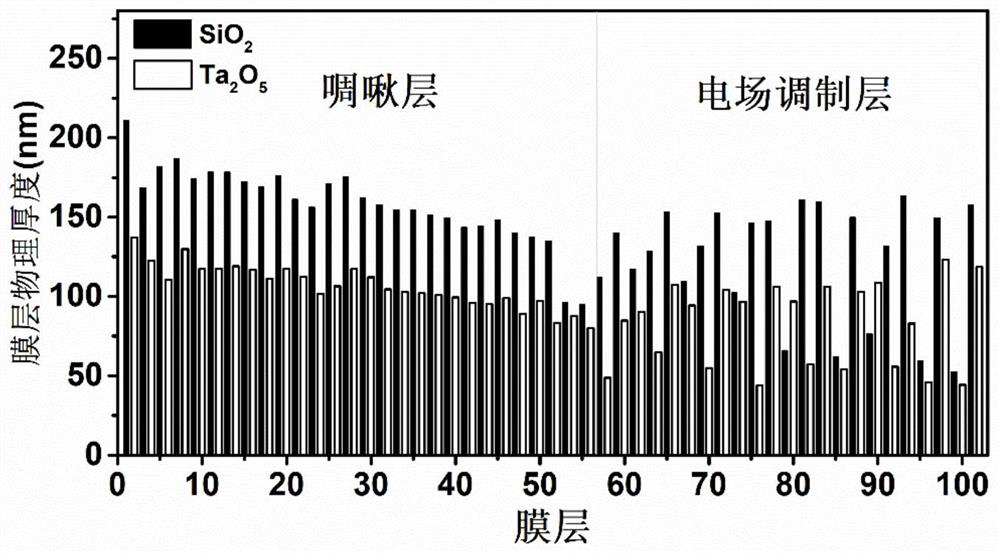

Broadband dispersion mirror structure with high laser damage threshold

ActiveCN113946005AReduce peak electric field strengthIncreased Laser Damage ThresholdMirrorsElectric field modulationElectrical field strength

The invention provides a broadband dispersion mirror structure with a high laser damage threshold. The broadband dispersion mirror structure sequentially comprises a substrate, a chirp layer and an electric field modulation layer from bottom to top; the substrate is a substrate material of the dispersion mirror; the chirp layer is a multi-layer dielectric film layer of which the film layer thickness is gradually changed in a chirp manner; the electric field modulation layer is a multi-layer dielectric film layer with the film layer thickness changing periodically and arranged repeatedly. The bottom of the broadband dispersion mirror structure with the high laser damage threshold is a traditional chirp structure, and the electric field modulation layer structure is creatively introduced into the top of the broadband dispersion mirror structure with the high laser damage threshold; according to the novel dispersion mirror structure, the electric field modulation layer is a multi-layer dielectric film layer of which the film layer thickness changes periodically and is arranged repeatedly, so that standing wave field peak values of wavelength components in the electric field modulation layer are mutually staggered, and the maximum peak electric field intensity is greatly reduced. The total peak electric field intensity is reduced by modulating the standing wave field distribution of all wavelengths in the dispersion mirror at the same time, and finally the laser damage threshold can be effectively improved.

Owner:WENZHOU UNIVERSITY

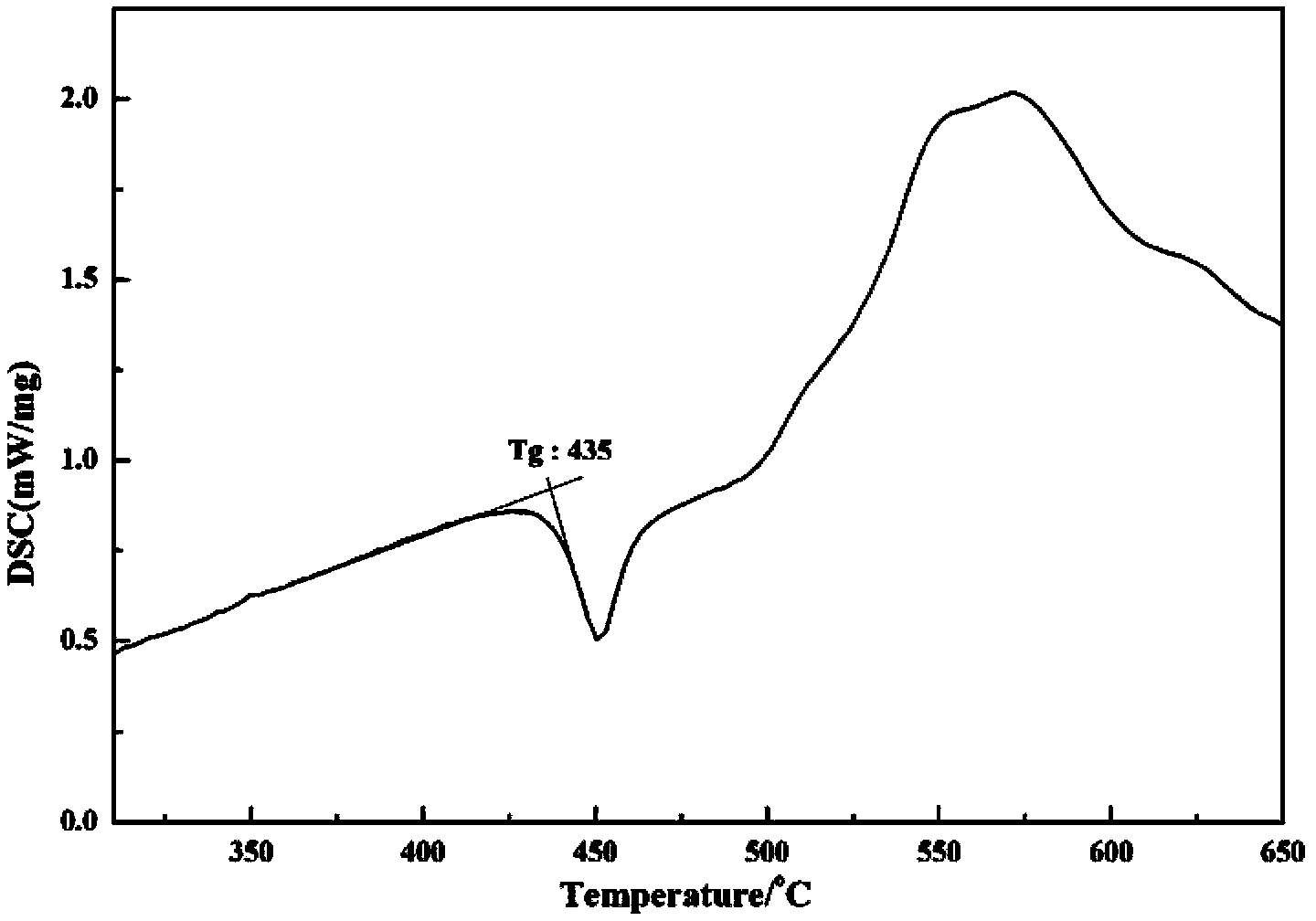

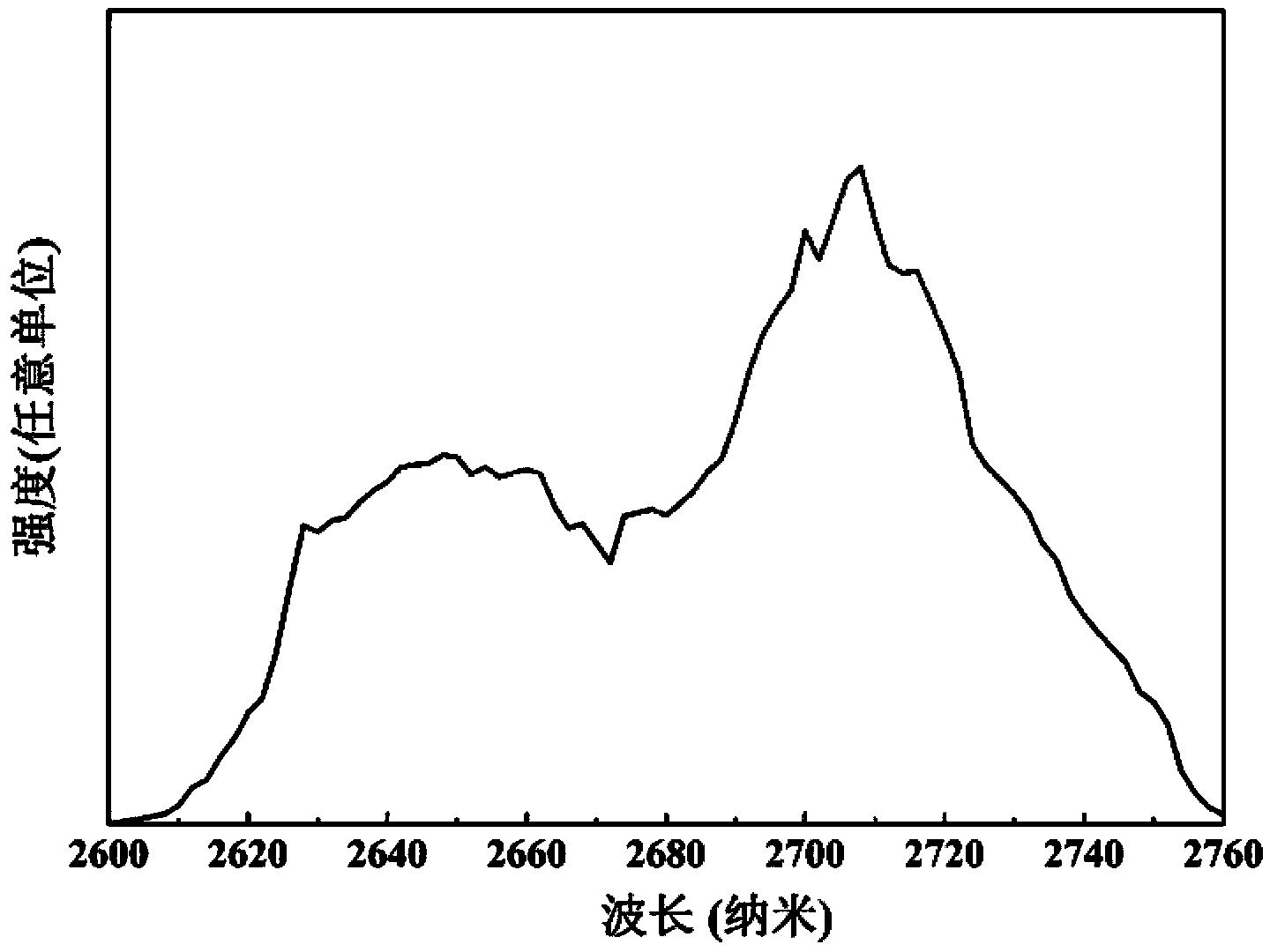

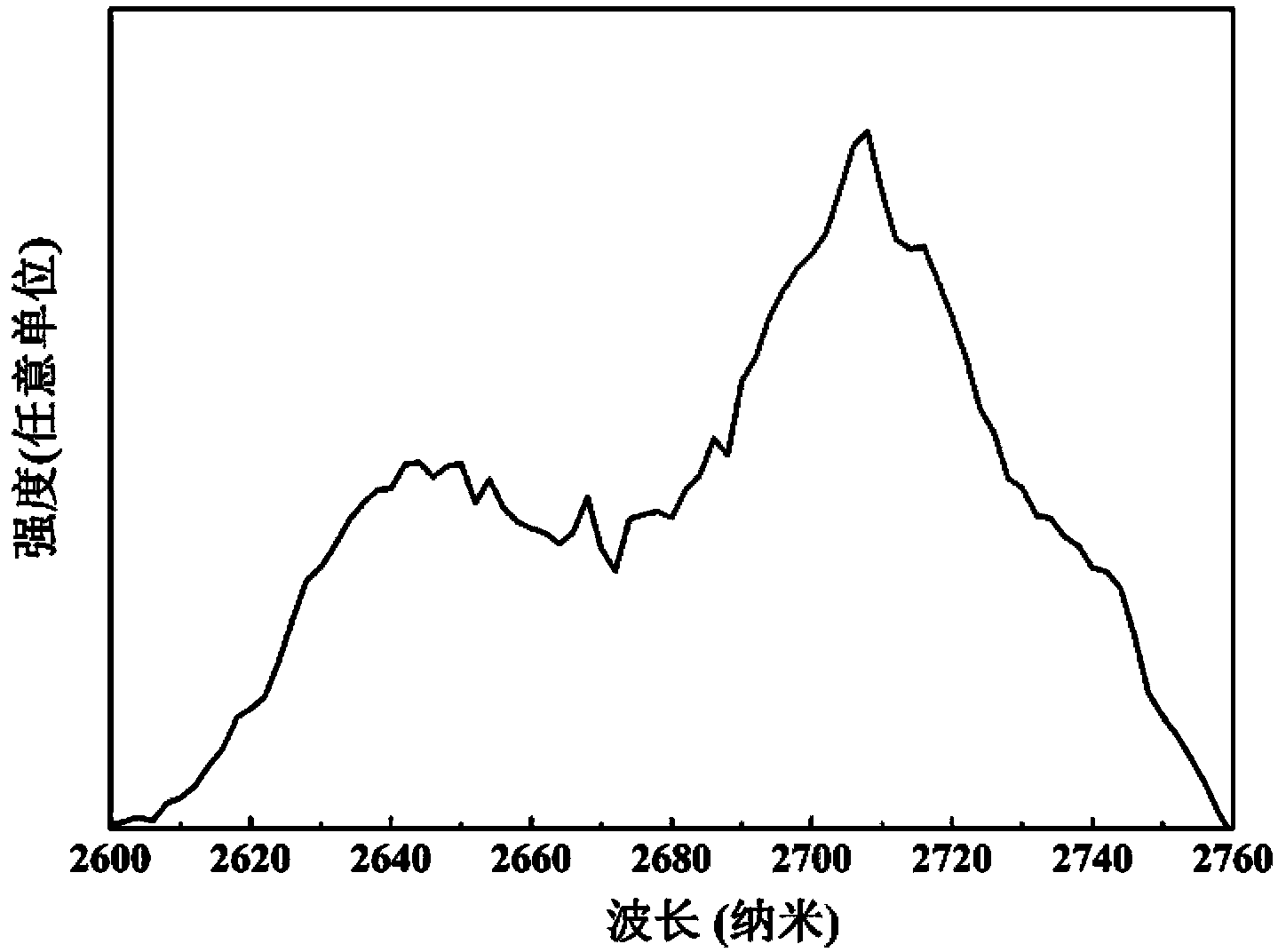

High erbium-doped lead-free fluoride (halide) tellurate laser glass, and preparation method and application thereof

ActiveCN103086600BImproved resistance to laser damageMeet practical requirementsGlass making apparatusTellurateErbium doping

The invention relates to high erbium-doped lead-free fluoride (halide) tellurate glass, and a preparation method and application thereof. The high erbium-doped lead-free fluoride (halide) tellurate glass is prepared from the following components in percentage by mol: 20-35% AlF3, 20-35% of BaF2, 10-20% of CaF2, 10-20% of ZnBr2, ZnCl2 and / or ZnI2, 15-30% of TeO2, 2-8% of YF3+LaF3 and 3-7% of ErF3, wherein the sum of the mol percents of all the components is 100%. The fluoride (halide) phosphate glass prepared by a fusion method is transparent, causes no crystallization, and has high infrared transmittance around 3mu m and fine physicochemical property. The glass can be used for a 3mu m fiber laser, and is hopefully used in the fields of national defense industry, military and civilian use.

Owner:CHINA JILIANG UNIV

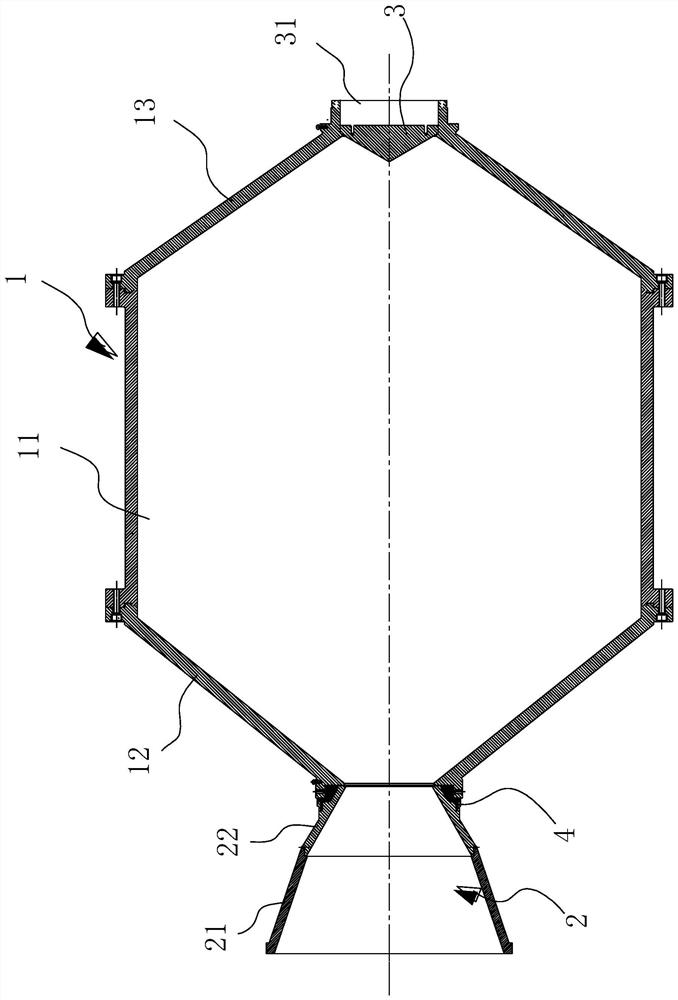

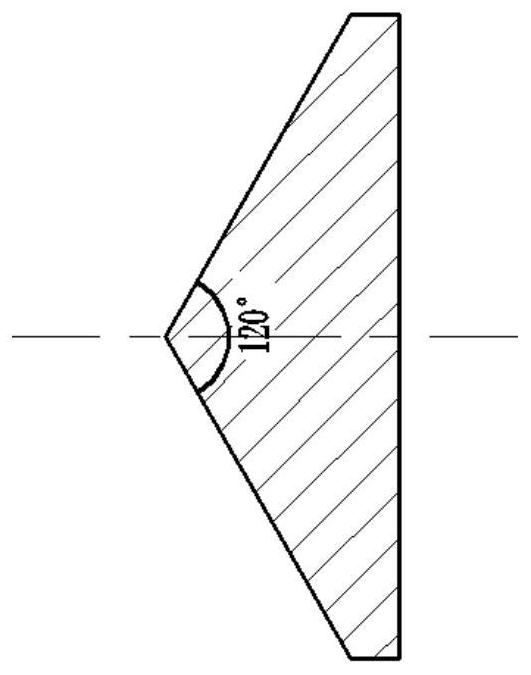

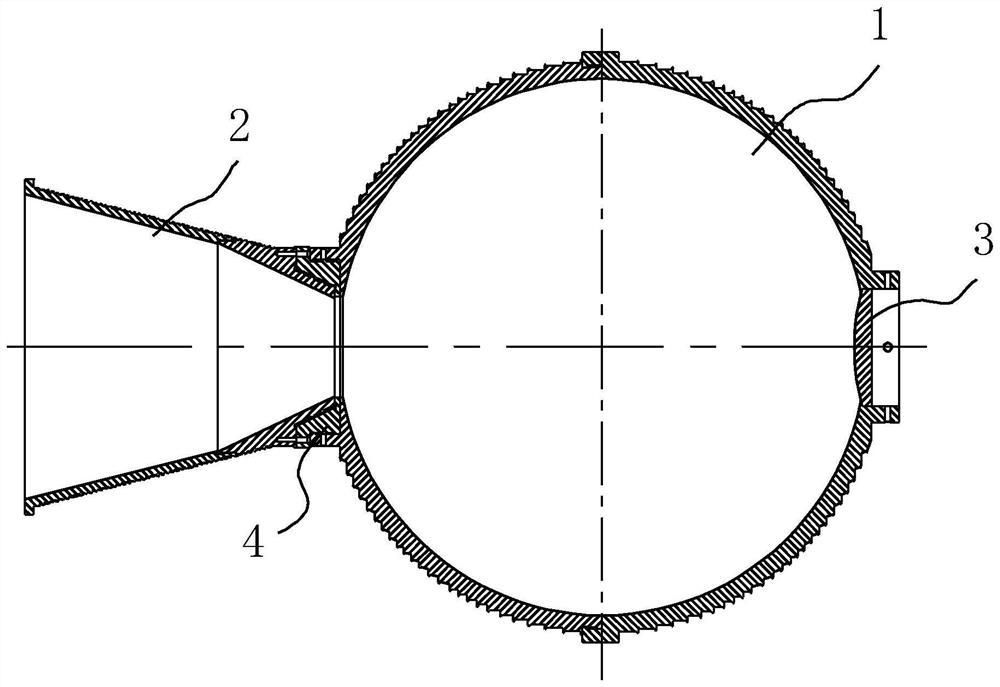

Composite absorber structure of total-absorption high-energy laser energy meter

PendingCN114235349AGuaranteed receiving caliberReduce escape lossPhotometryTesting optical propertiesHigh energy laser beamLaser damage

The invention discloses a composite absorber structure of a total-absorption high-energy laser energy meter. The composite absorber structure comprises a main absorber, a receiving cone and a reflector, the main absorber is a combined cavity, the receiving cone is movably connected with an opening of the main absorber, the receiving cone is composed of two sections of conical structures which are movably connected and have different cone angles, the reflecting mirror is located in the main absorber and at the bottom opposite to the opening of the main absorber, and the main absorber and the receiving cone are connected through a connecting transition piece with low thermal conductivity. A high-energy laser beam is incident in the direction parallel to the axes of the receiving cone and the main absorber, is reflected by the inner surface of the receiving cone, enters the main absorber, and is absorbed after being reflected on the inner surface of the main absorber for multiple times. According to the invention, the overall size of the laser energy meter is effectively controlled, the laser damage resistance of the energy meter is improved, the loss of energy escaping from an opening is reduced, and the measurement accuracy of the high-energy laser energy meter is improved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

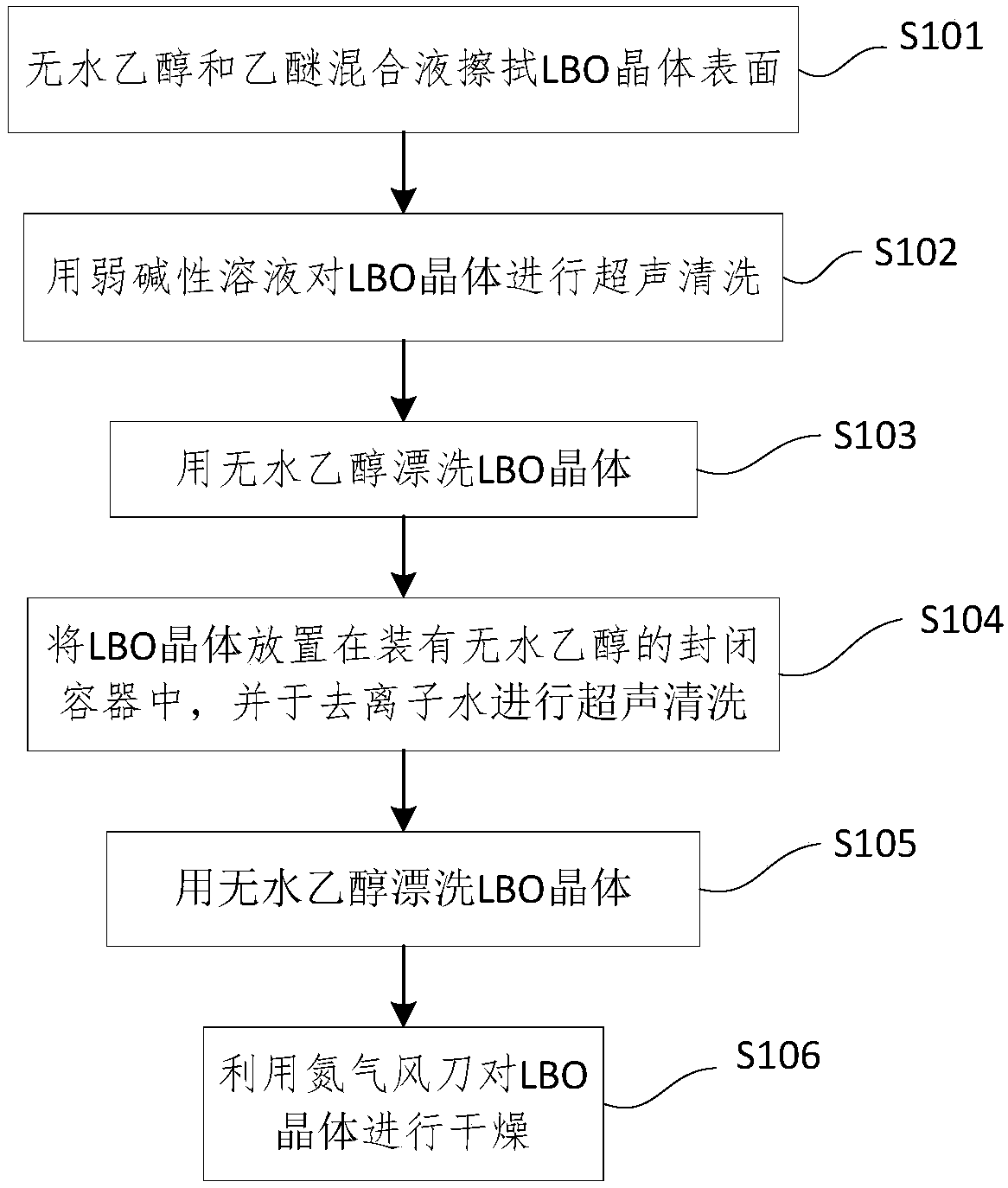

A kind of cleaning method before coating on lbo crystal surface

ActiveCN106862114BImproved resistance to laser damageImprove adhesionCleaning using toolsCleaning using liquidsAlkalinityAlcohol

The invention relates to a method for cleaning the LBO crystal surface before coating. The LBO crystal is subjected to the following steps in sequence: a mixture of absolute ethanol and ether is used to wipe the LBO crystal surface; a weak alkaline solution is used to ultrasonic clean the LBO crystal. The weakly alkaline solution includes NH4OH and H2O2, the volume ratio is NH4OH:H2O2:H2O=1:8:50; use absolute ethanol to rinse the LBO crystal; place the LBO crystal in a sealed container filled with absolute ethanol, and The LBO crystal is cleaned by ultrasonic heating; the LBO crystal is taken out and rinsed again; the LBO crystal is dried using a dry nitrogen air knife in a positive pressure container environment. Compared with the existing technology, the present invention has the advantages of good cleaning effect, can not only improve the laser damage resistance of the LBO crystal after coating, but also improve the film adhesion and crack resistance after coating.

Owner:TONGJI UNIV

Both-end composite growth type laser medium

InactiveCN101465510AImproved resistance to laser damageImprove cooling effectActive medium materialLaser constructional detailsMachiningMaterials science

The invention relates to a double-end equal compound growth form laser medium which is a crystal body of two single-end or three three-end similar crystal medium which grow in a compounding way; the crystal medium is selected from the following: 1) GdVO4+Nd:GdVO4; 2) GdVO4+Nd:GdVO4+GdVO4; wherein, the concentration of the Nd is between 0.1 percent to 3 percent (molar fraction). The invention has the beneficial effects: the single-end or double-end similar crystal medium is compounded by growth without thermal bonding or optical cement, thus completely realizing permanent growth among molecules; the optical character and transmission rate of a transition surface of the compound crystal is in line with the theory, therefore, the grown compound crystal can be processed by any optical and mechanical processing.

Owner:彭毅

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com