A kind of polyvinyl alcohol coating on the surface of fused silica, preparation method and application

A technology of polyvinyl alcohol and polyvinyl alcohol solution, which is applied in coatings, instruments, optics, etc., can solve the problems of reduced laser damage threshold of fused silica optical elements, easy damage to the back surface, and reduced laser energy, so as to improve the resistance Laser damage performance, improved laser damage resistance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] One aspect of the present invention provides a method for preparing a polyvinyl alcohol coating on the surface of fused silica, comprising: filtering the polyvinyl alcohol aqueous solution with a mass percentage of 0.5%-5% by using a PVDF filter head with a pore size of 0.15-0.30 μm , and finally cooled for later use;

[0032] The polyvinyl alcohol is plated on the rear surface of the fused silica substrate with a clean surface by spin coating or pull coating, and the polyvinyl alcohol coating is obtained after drying. For example, the mass percentage of the solute of the polyvinyl alcohol solution in the embodiment of the present invention can be set to 0.5%, 1.5%, 2.5%, 3.5%, 4.5%, 5.0%.

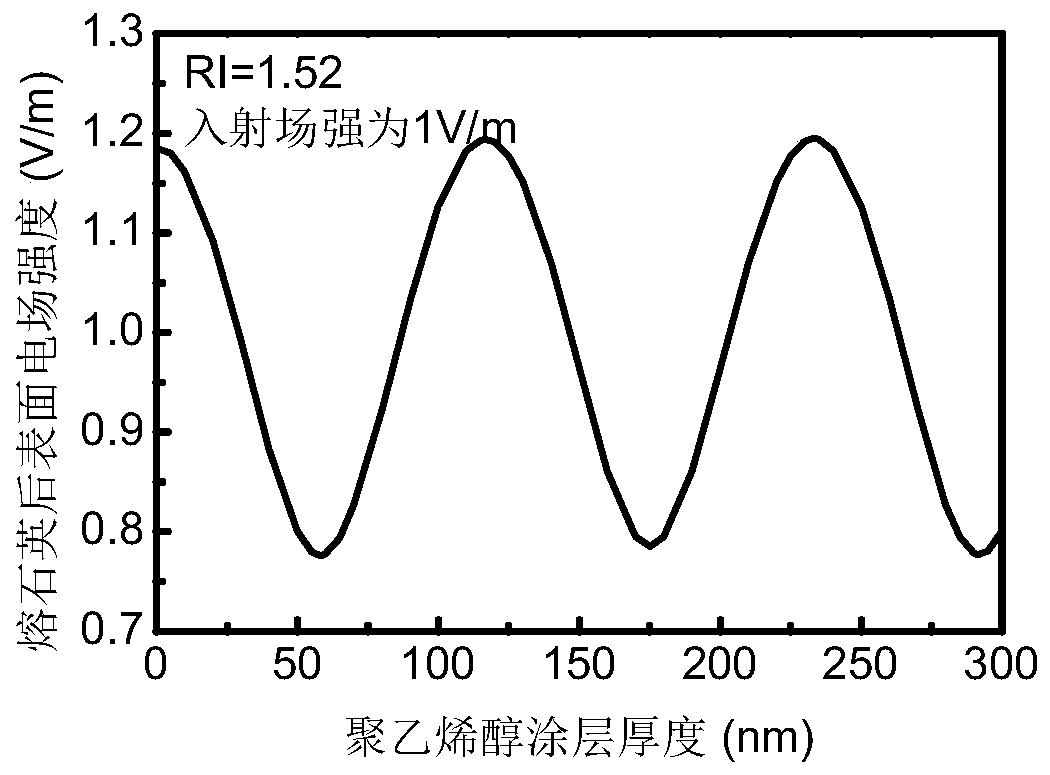

[0033] Preferably, the polyvinyl alcohol coating has a thickness ranging from 40-80 nm, 160-200 nm and 280-320 nm.

[0034] Preferably, the polyvinyl alcohol has a molecular weight of 80,000-150,000 and a degree of alcoholysis of 87-100%. For example, the molecular weight of polyv...

Embodiment 1

[0044] Add 0.4g of polyvinyl alcohol with a molecular weight of 80,000-90,000 and a degree of alcoholysis of 87-89% into a 100mL conical flask, then add 80mL of ultrapure water and a magnetic rotor, and stir at 200rpm in a water bath at 60°C for 4 hours. Until it is completely dissolved, the insoluble matter and impurity particles are filtered out with a PDVF filter head with a pore size of 0.15 μm, and finally a clear and transparent polyvinyl alcohol solution is obtained, which is cooled to room temperature for coating. Fix a 20mm x 20mm x 2mm clean fused silica substrate on the vacuum chuck of the spin coater, then add 0.1mL polyvinyl alcohol solution dropwise and spread evenly, then spin coat at 500rpm for 3 minutes, and then put it in 80 °C oven for 3.0 hours.

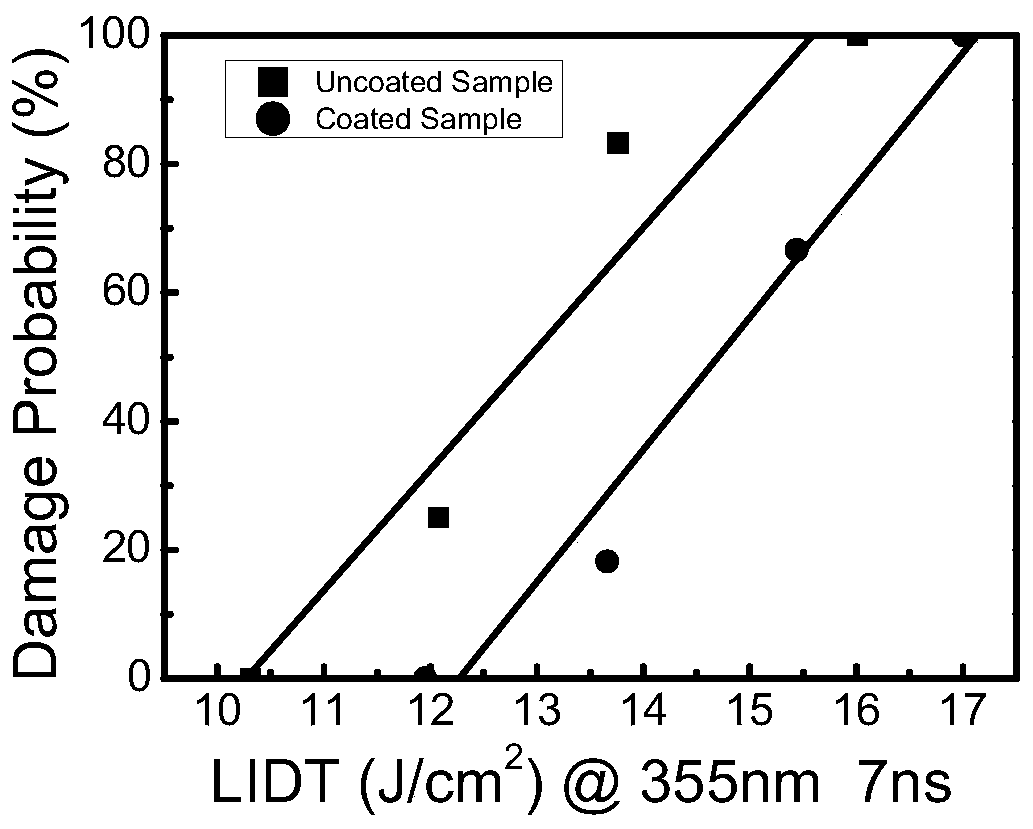

[0045] A polyvinyl alcohol coating with a thickness of about 300 nm was obtained. This polyvinyl alcohol coating can increase the laser damage threshold of fused silica at a laser wavelength of 355nm by about 15%...

Embodiment 2

[0047] Add 1.2g of polyvinyl alcohol with a molecular weight of 90,000-100,000 and a degree of alcoholysis of 89-91% into a 100mL conical flask, then add 80mL of ultrapure water and a magnetic rotor, and stir at 300rpm for 3 hours in a water bath at 65°C. Until it is completely dissolved, the insoluble matter and impurity particles are filtered out with a PDVF filter head with a pore size of 0.22 μm, and finally a clear and transparent polyvinyl alcohol solution is obtained, which is cooled to room temperature for coating. Fix a 20mm x 20mm x 2mm clean fused silica substrate on the vacuum chuck of the spin coater, then drop 0.40mL of polyvinyl alcohol solution and spread it evenly, then spin coat at 1000rpm for 2.5min, and then put it in an oven at 90°C Dry in medium for 2.5 hours.

[0048] A polyvinyl alcohol coating with a thickness of about 200 nm was obtained. This polyvinyl alcohol coating can increase the laser damage threshold of fused silica at a laser wavelength of 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com