Micro-milling repair process for laser damage on the surface of large-diameter kdp crystal components

A technology of laser damage and crystal components, applied in the direction of fine working devices, manufacturing tools, stone processing equipment, etc., can solve the problems of poor repair surface quality, single repair contour, low efficiency, etc., to prolong service life, avoid interference, Effects of Growth-Slowing Behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

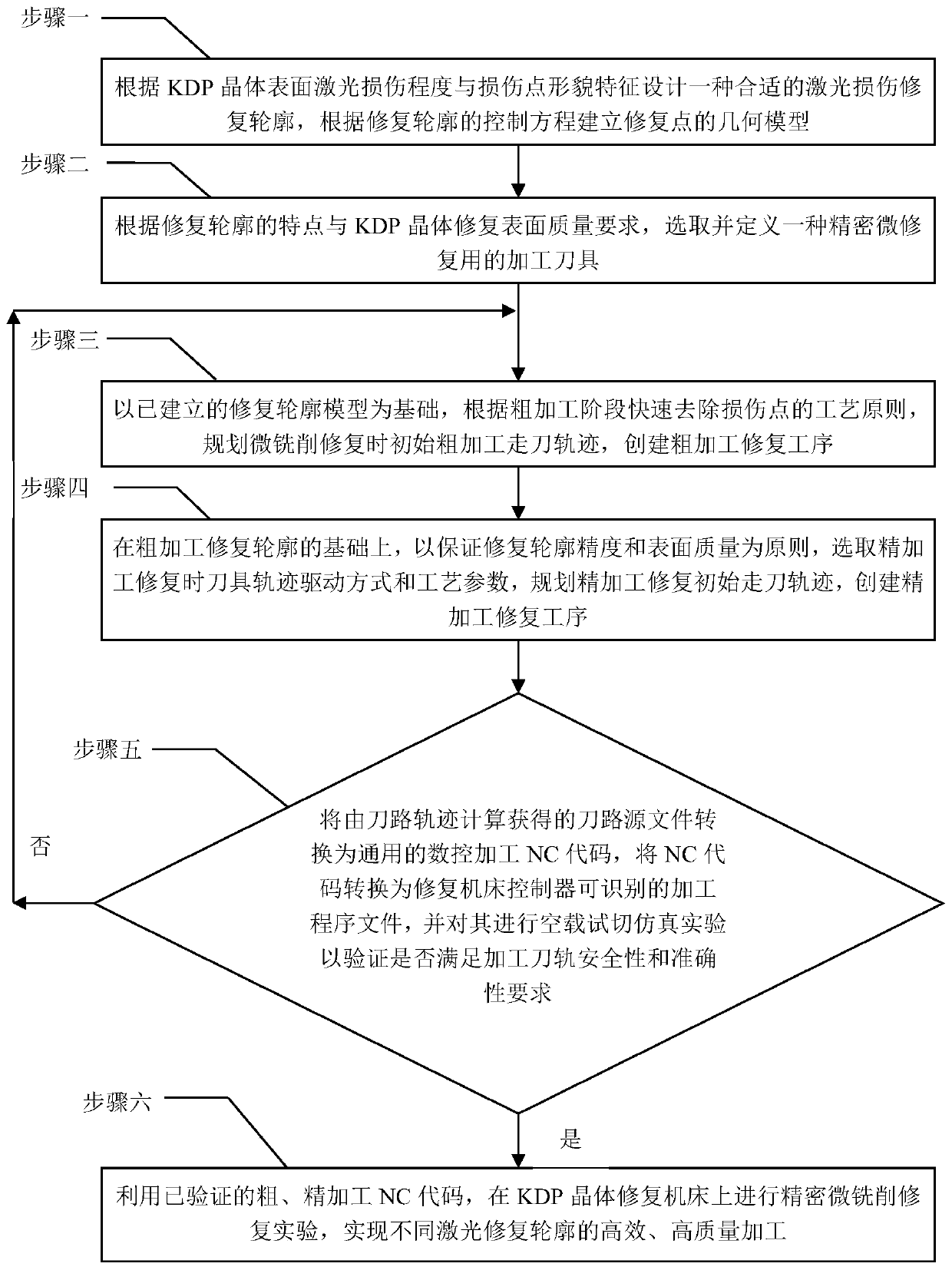

[0042] Specific implementation mode one: as Figure 1 to Figure 15 As shown, the implementation process of the micro-milling repair process method for laser damage on the surface of the large-diameter KDP crystal element described in this embodiment is:

[0043] Step 1. Design a suitable laser damage repair profile according to the laser damage degree on the KDP crystal surface and the shape characteristics of the damage point, and establish the geometric model of the repair point according to the control equation of the repair profile;

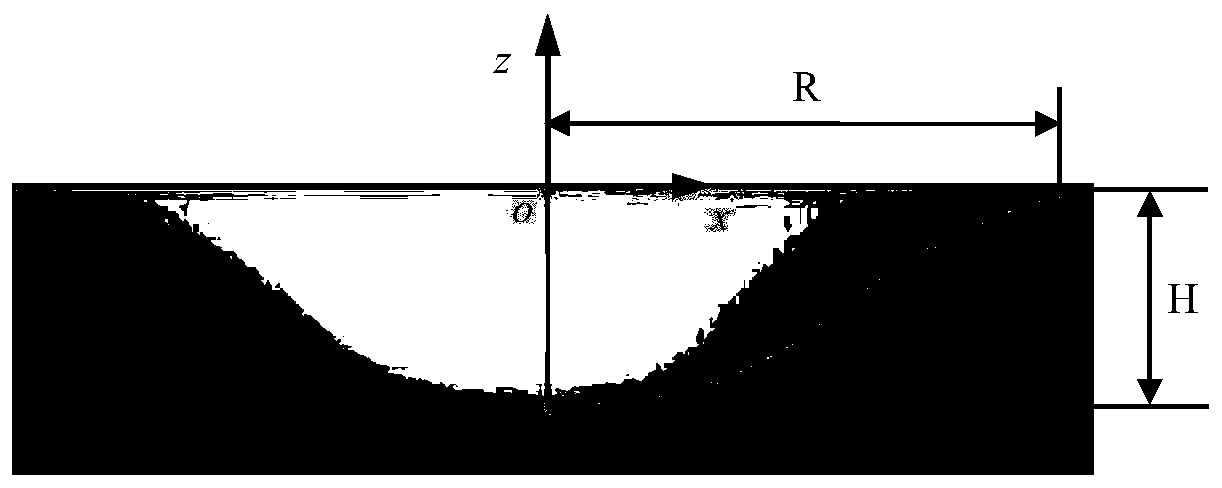

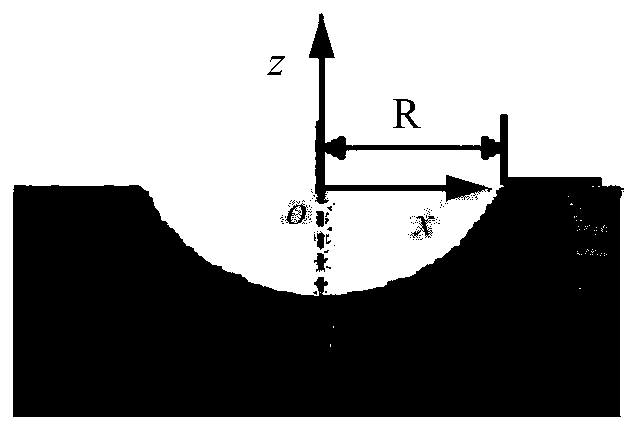

[0044] The laser damage repair profile described in step 1 mainly includes three forms: Gaussian, hemispherical and ellipsoidal. The repair profiles of these three forms are designed according to the morphology, size and distribution of laser damage points on the KDP crystal surface , for repairing the damaged surface with large damage area and small depth (ablation form), large damage point aspect ratio (pit, crack, etc.), and damage point l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com