Broadband dispersion mirror structure with high laser damage threshold

A laser damage threshold and dispersion mirror technology, applied in optics, mirrors, optical components, etc., can solve the problems of less and insufficient research on the femtosecond damage threshold of laser thin films, and achieve enhanced laser damage resistance and reduced peak electric field intensity , the effect of wide versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

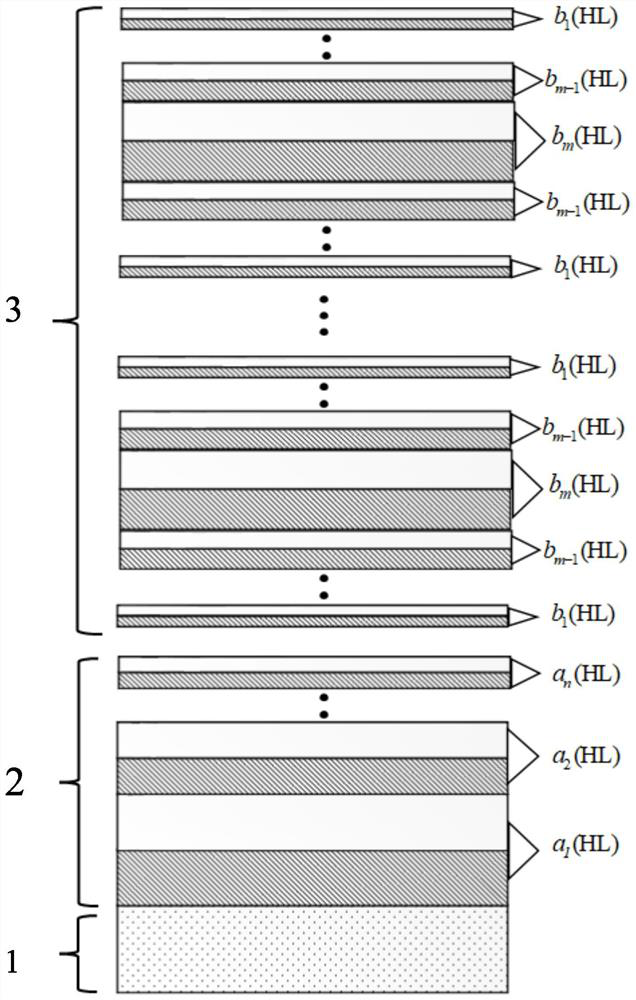

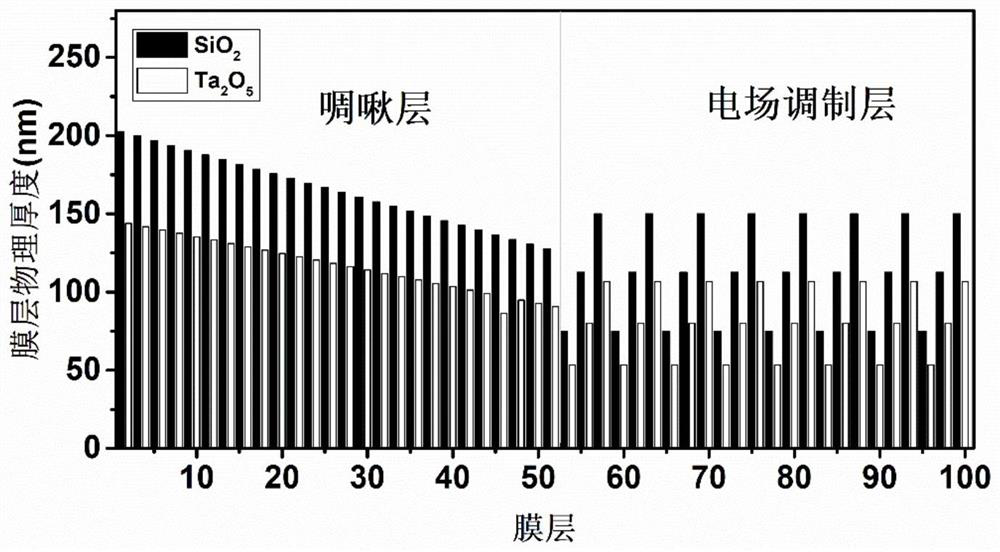

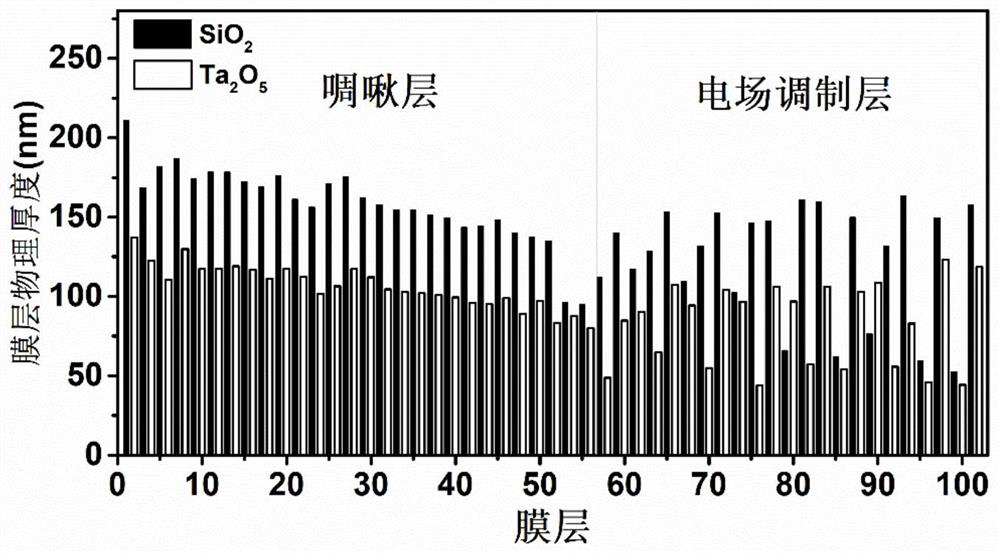

[0025] The invention provides a broadband high laser damage threshold dispersion mirror structure, such as figure 1 As shown, the substrate 1, the chirped layer 2 and the electric field modulation layer 3 are sequentially included from bottom to top. The substrate 1 is the substrate material of the dispersive mirror; the chirped layer 2 is a structural unit for realizing dispersion compensation and broadband high reflection, and its structure is a multi-layer dielectric film layer with a chirp gradient in film thickness; the electric field modulation layer 3 is used for A structural unit that optimizes the electric field to achieve a high laser damage threshold. Its structure is a multi-layer dielectric film layer whose film thickness changes periodically and is arranged repeatedly. The expression of the broadband high laser damage t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com