Field effect transistor device

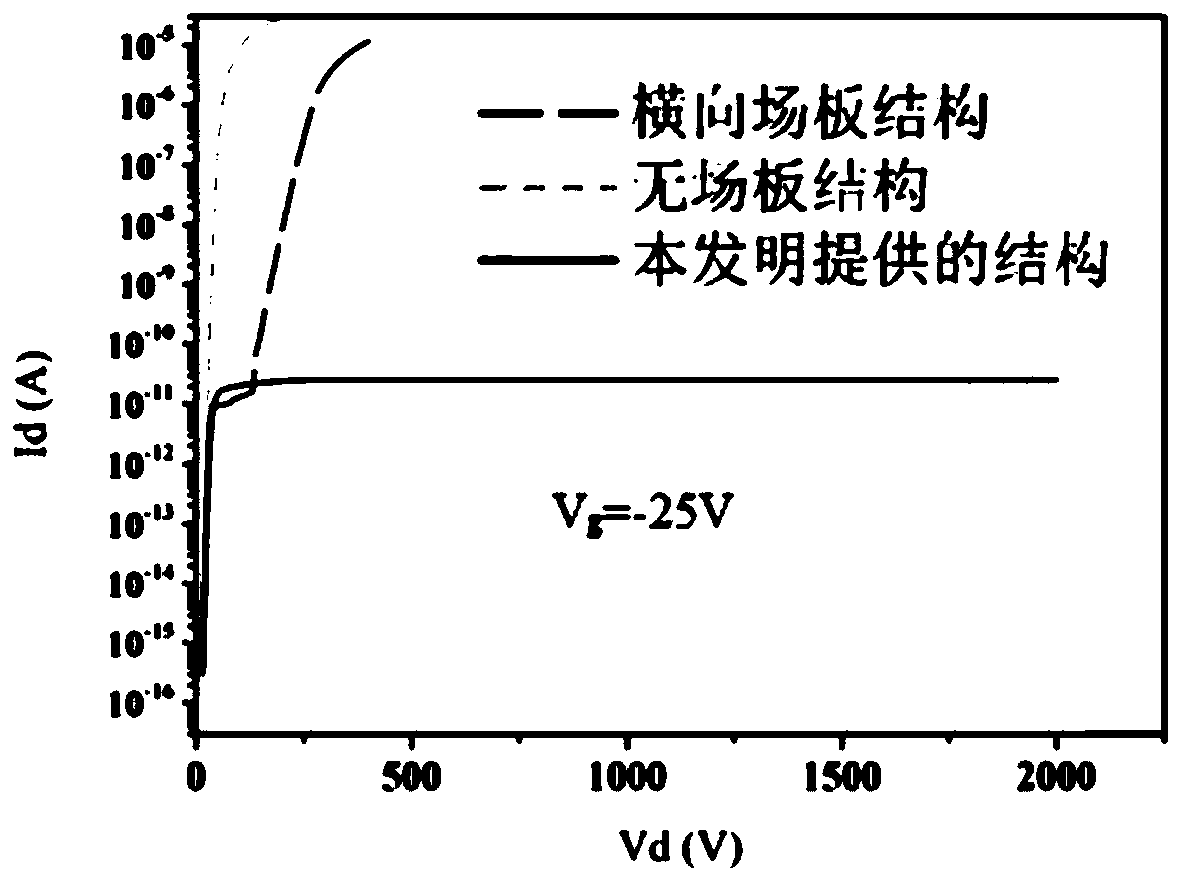

A technology of field effect transistors and devices, applied in the field of microelectronics, to achieve the effects of reducing leakage current, reducing peak electric field intensity, and reducing peak electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

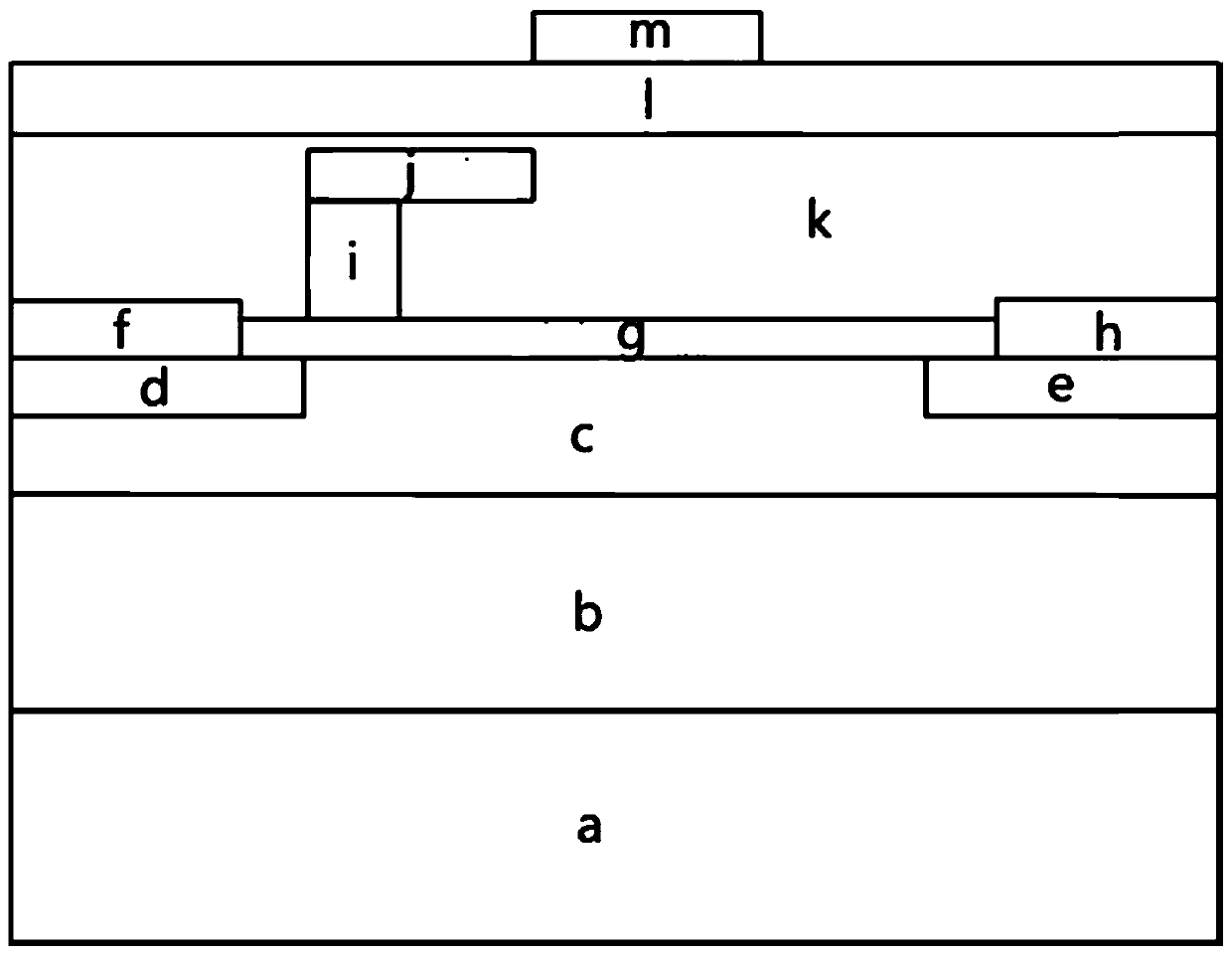

[0062] Specific implementation methods include:

[0063] A method for manufacturing a high-voltage-resistant field-effect transistor provided in this embodiment, the specific process is as follows:

[0064] (1) Clean the substrate: Ga 2 o 3 The semi-insulating substrate material was boiled with acetone and ethanol for 10 minutes, then washed with deionized water for 30 times, and finally dried with high-purity nitrogen;

[0065] (2) Epitaxial growth: put the cleaned substrate into MOCVD equipment, and grow Si-doped Ga of 100nm-300nm by controlling the process parameters. 2 o 3 channel layer;

[0066] (3) Ion implantation and annealing treatment: Firstly, photolithography is performed on the sample to form a pattern window of the source and drain regions, then ion implantation is performed on the source and drain ohmic contact regions, and then annealing treatment is performed at 950°C for 30 minutes in a nitrogen atmosphere. Then the sample is cleaned according to the met...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com