Composite absorber structure of total-absorption high-energy laser energy meter

A high-energy laser and energy meter technology, applied in the field of high-energy laser optical parameter measurement, can solve problems such as incorrect measurement results, energy loss, and increase the diameter of the integrating sphere, so as to improve the ability to resist laser damage and measurement accuracy, and improve the resistance to laser damage. The effect of laser damage capability, ease of processing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

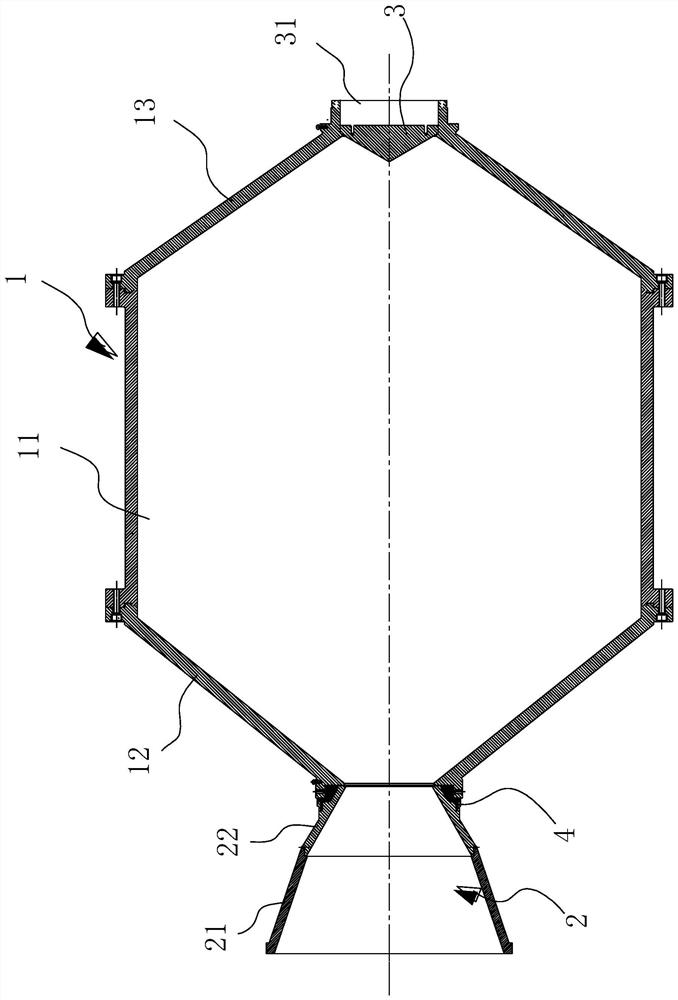

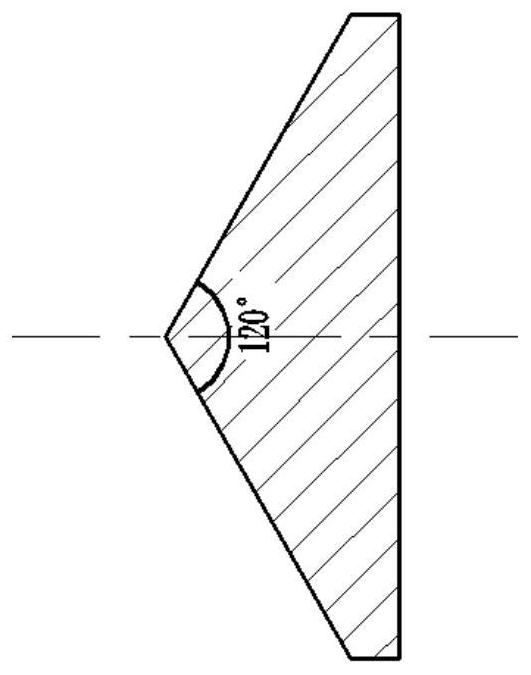

[0031] see figure 1 , a composite absorber structure of a total absorption high-energy laser energy meter, including a main absorber 1, a receiving cone 2, and a reflector 3. The main absorber 1 is a combined cavity, the receiving cone 2 is movably connected with the opening of the main absorber 3, the receiving cone 2 is composed of two conical structures with different cone angles that are movably connected, and the reflector 3 is located in the main absorber 1, the bottom opposite to the opening of the main absorber 1, the main absorber 1 and the receiving cone 2 are connected by a connecting transition piece 4 with low thermal conductivity. When the high-energy laser beam is incident in the direction parallel to the axis of the receiving cone 2 and the main absorber 1, it enters the main absorber 1 after being reflected by the inner surface of the receiving cone 2, and is absorbed by the main absorber 1 after multiple reflections on the inner surface of the main absorber 1...

Embodiment 2

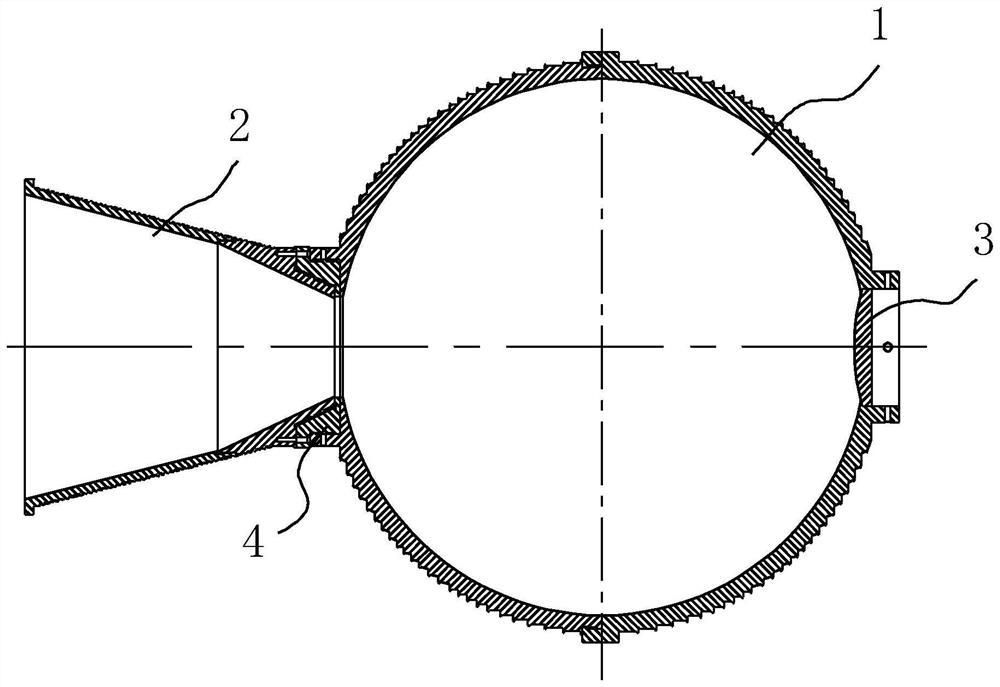

[0044] A composite absorber structure of a total absorption high-energy laser energy meter, comprising a main absorber 1, a receiving cone 2, and a reflector 3. In this example, see image 3 , the main absorber 1 is a spherical cavity connected by two hemispherical cavities.

[0045] The outer surfaces of the main absorber 1 and the receiving cone 2 are provided with spiral grooves or several linear grooves (shown in the figure), and temperature sensors are evenly distributed in the grooves for measuring the main absorber 1 and the receiving cone 2 before and after the laser incident. The measured value of the temperature increment can accurately characterize the overall average temperature rise of the absorber.

[0046] The reflector is a spherical mirror. The rest of the content is the same as that of Embodiment 1, and will not be repeated here.

[0047] The composite absorber structure of the present invention combines the advantages of the conical cavity and the integra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com