High-efficiency and low-consumption desulfurization method of molten iron mechanical stirring

A technology of mechanical stirring and molten iron, applied in the field of molten iron pretreatment, can solve the problems of poor adaptability of research results, complex problems of self-floating phase stirring, entrainment and dispersion, and few self-floating particle dispersion problems, so as to improve the reaction area and Desulfurization reaction efficiency, promotion of crushing, dispersion and entrainment circulation, and effect of overcoming changes in molten iron level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

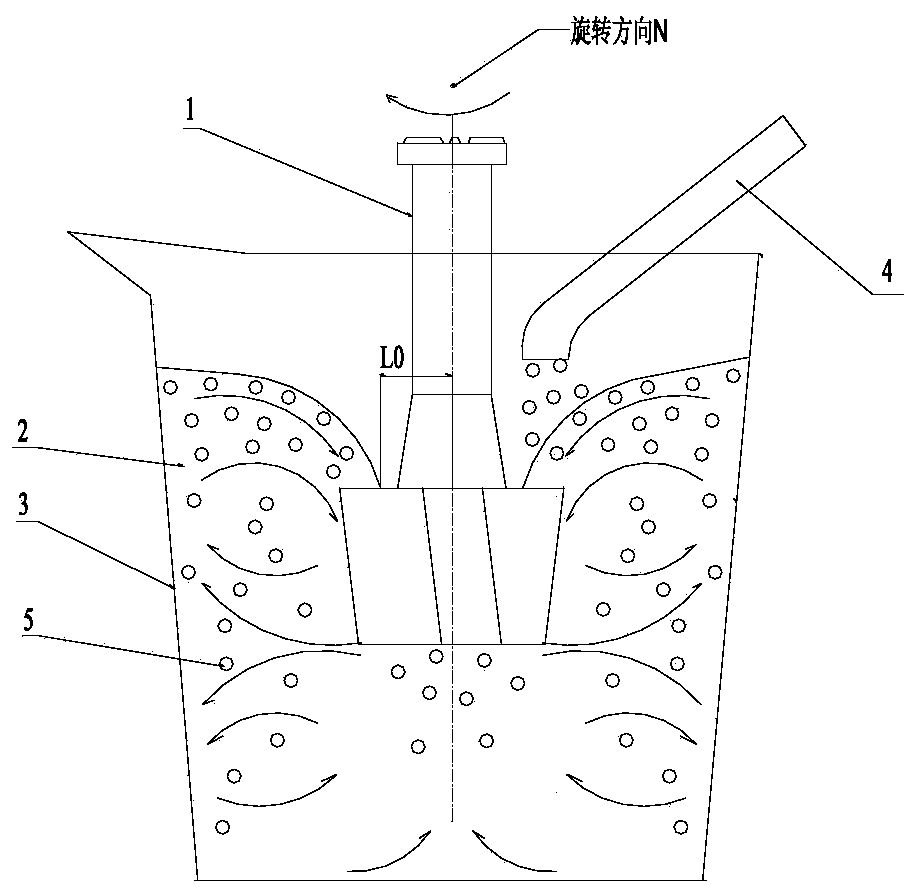

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

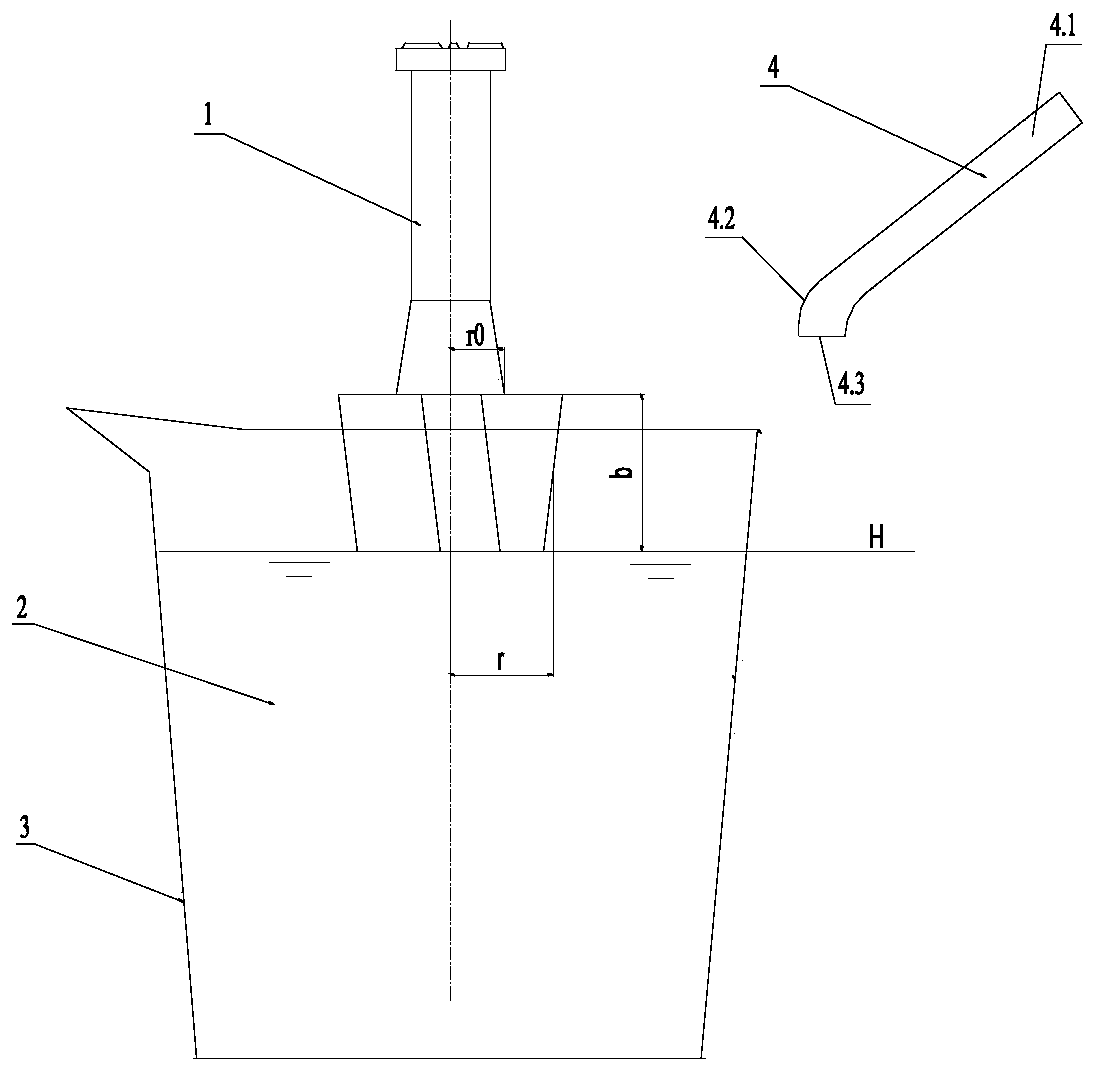

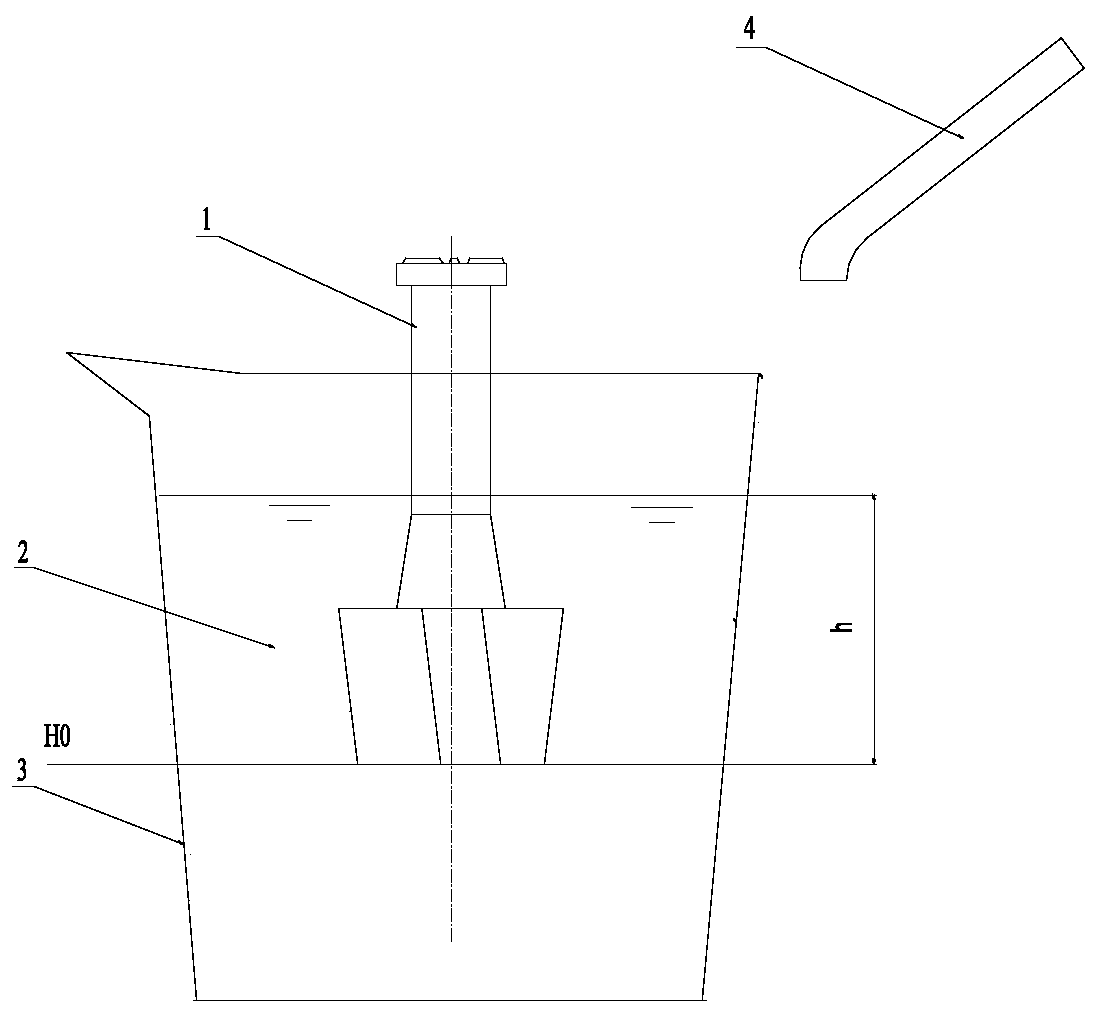

[0050] Such as Figure 1~4 As shown, the molten iron mechanical agitation high-efficiency and low-consumption desulfurization method of the present invention comprises the following steps:

[0051] 1) Open the molten iron tank 3 to the slag removal position, measure and sample the temperature of the molten iron 2, and carry out the slag removal before removal, until the exposed area of the molten iron 2 liquid surface reaches more than 60% (ordinary desulfurization with a target sulfur of more than 20ppm) or more than 80% (deep desulfurization with target sulfur below 10ppm); after the front slag is removed, the molten iron tank is opened to the desulfurization station;

[0052] 2) According to the analysis results of temperature measurement sampling and the amount of molten iron, calculate the desulfurization agent dosage W and st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com