A Method for Determining the Grooving Ratio of Wall Panel in Wind Tunnel Test Section

A technology of wind tunnel test and test section, applied in aerodynamic test, test of machine/structural components, instruments, etc., can solve problems such as lack of theoretical basis, achieve good application prospects, improve the level of refinement, and good versatility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

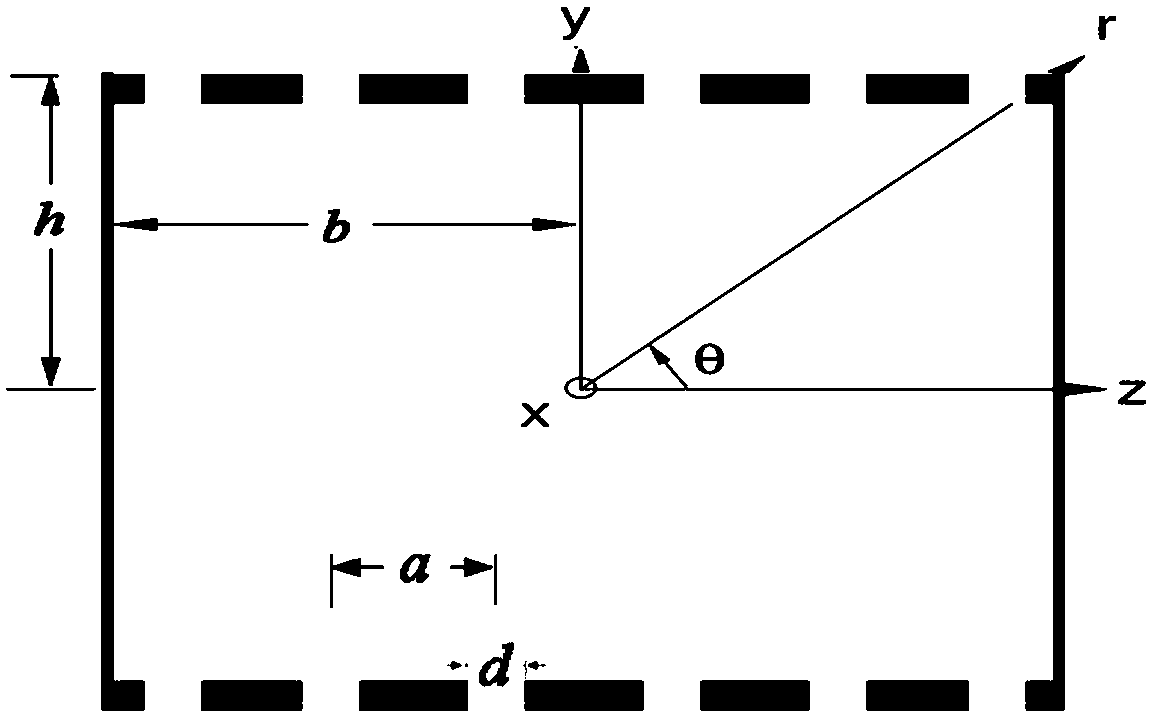

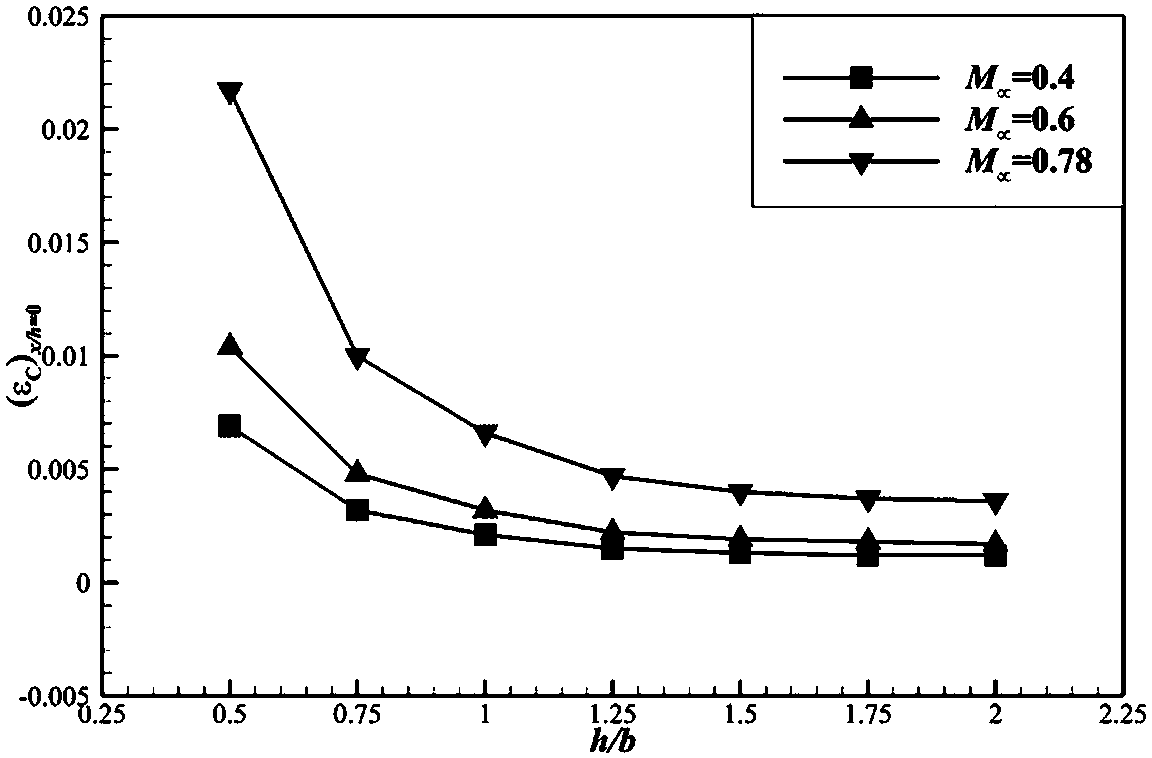

[0059] In this example, the method of the present invention is used to determine the reasonable grooving rate of a test section with a rectangular section, and the cross-sectional dimension of the test section is 2.4 meters (width, denoted as h) × 2.0 meters (height, denoted as b). The coordinate system is established with the center of the test model as the origin; the X-axis is along the axial direction of the test section; the Y-axis is perpendicular to the X-axis and points upward in the longitudinal symmetry plane of the model; the Z-axis is given according to the right-hand rule. figure 1 shown. The test section is in the form of upper and lower slots, left and right solid walls, and the number of slots is n=2b / a. A reasonable slotting ratio d / a is determined according to the method of the present invention to completely eliminate the blocking interference effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com