Crack performance measurement and optimization solution method for composite material glue joint structure

A composite material and bonding technology, applied in the field of aerospace materials and materials science, can solve problems such as incomplete material properties, poor precision, and difficulty in solving parameters, and achieve clear physical meaning, fast speed, and high calculation accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better understand the crack performance measurement and optimization solution method of the composite material bonding structure according to the scheme of the present invention, a preferred embodiment of the crack performance measurement and optimization solution method of the composite material bonding structure of the present invention will be further elaborated below. .

[0028] The purpose of the present invention is achieved through the following technical solutions: a crack performance measurement and optimization solution method of a composite material adhesive structure comprises the following steps:

[0029] S1: Establish a crack propagation constitutive relation model;

[0030] S2: Model adjustment for parameter optimization algorithm;

[0031] S3: Design and carry out the interface crack growth test of composite bonded structure;

[0032] S4: Use test data to optimize and solve performance parameters.

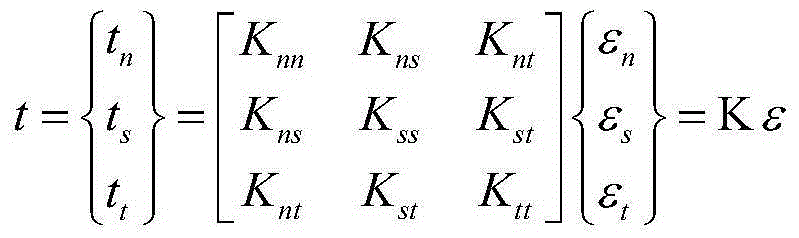

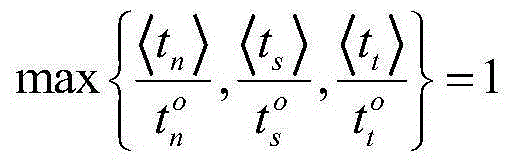

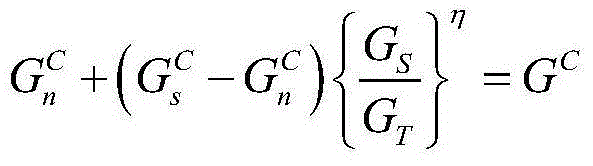

[0033] Preferably, in S1, the ductile ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com