Patents

Literature

33 results about "Incorrect Measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

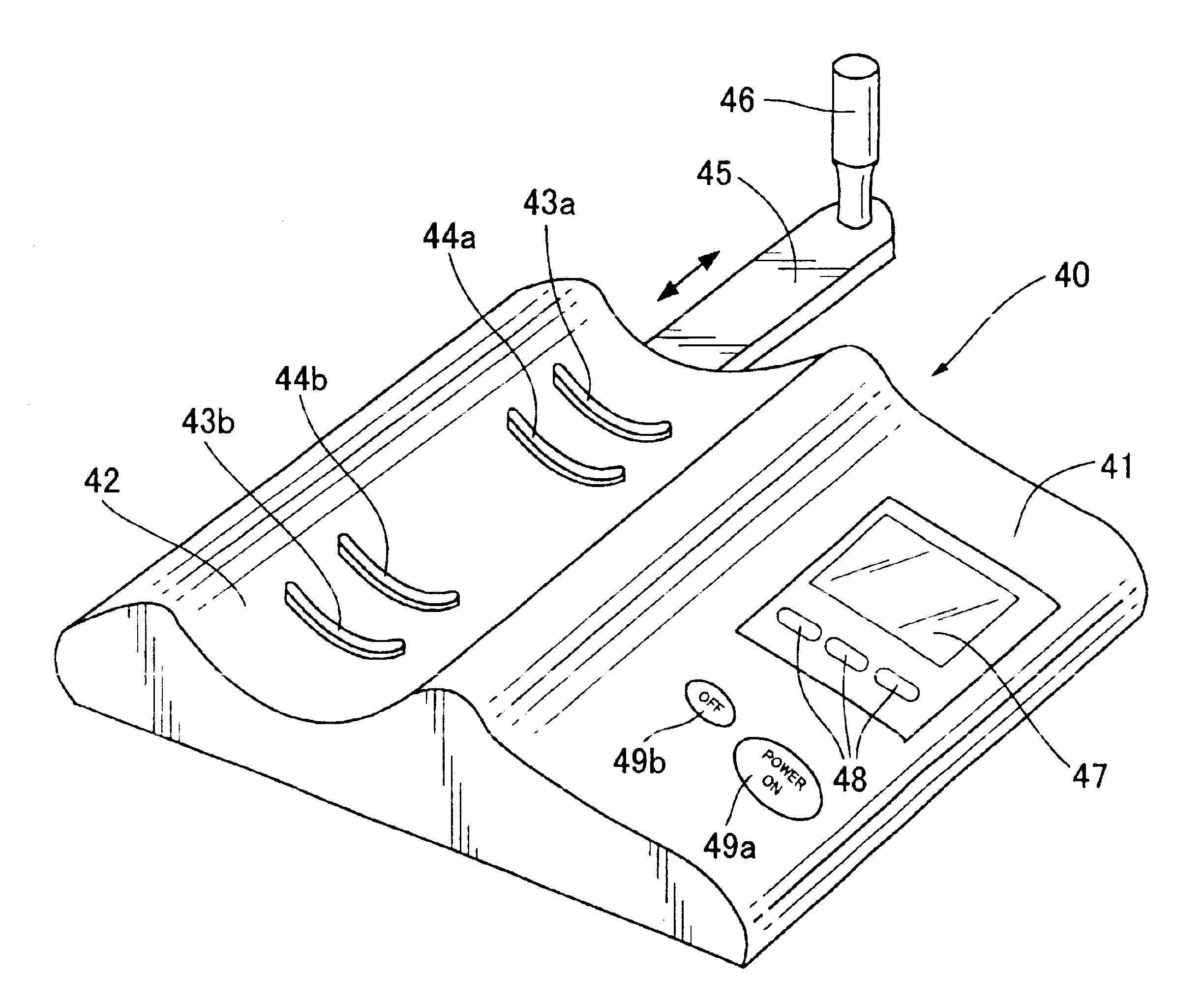

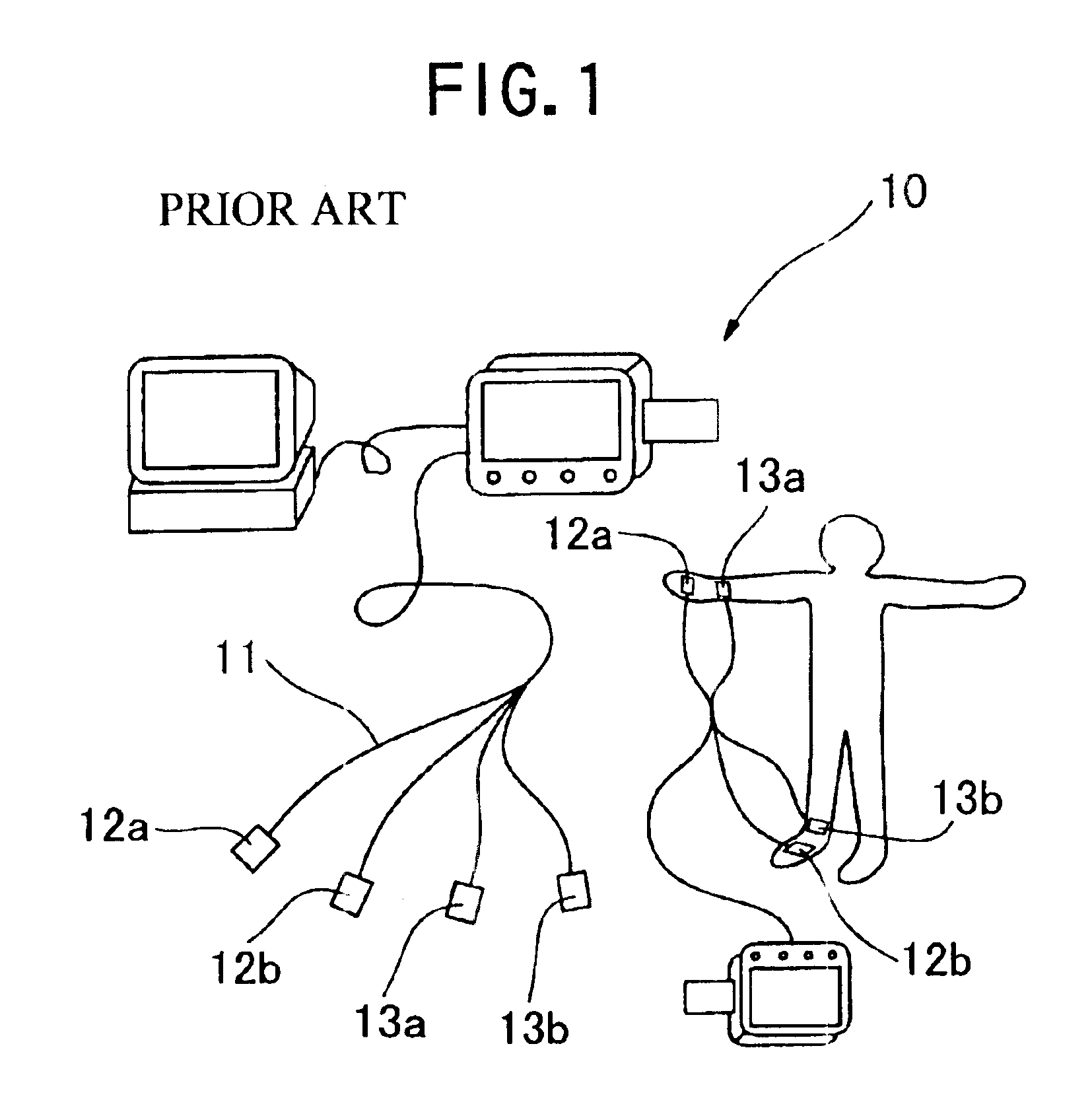

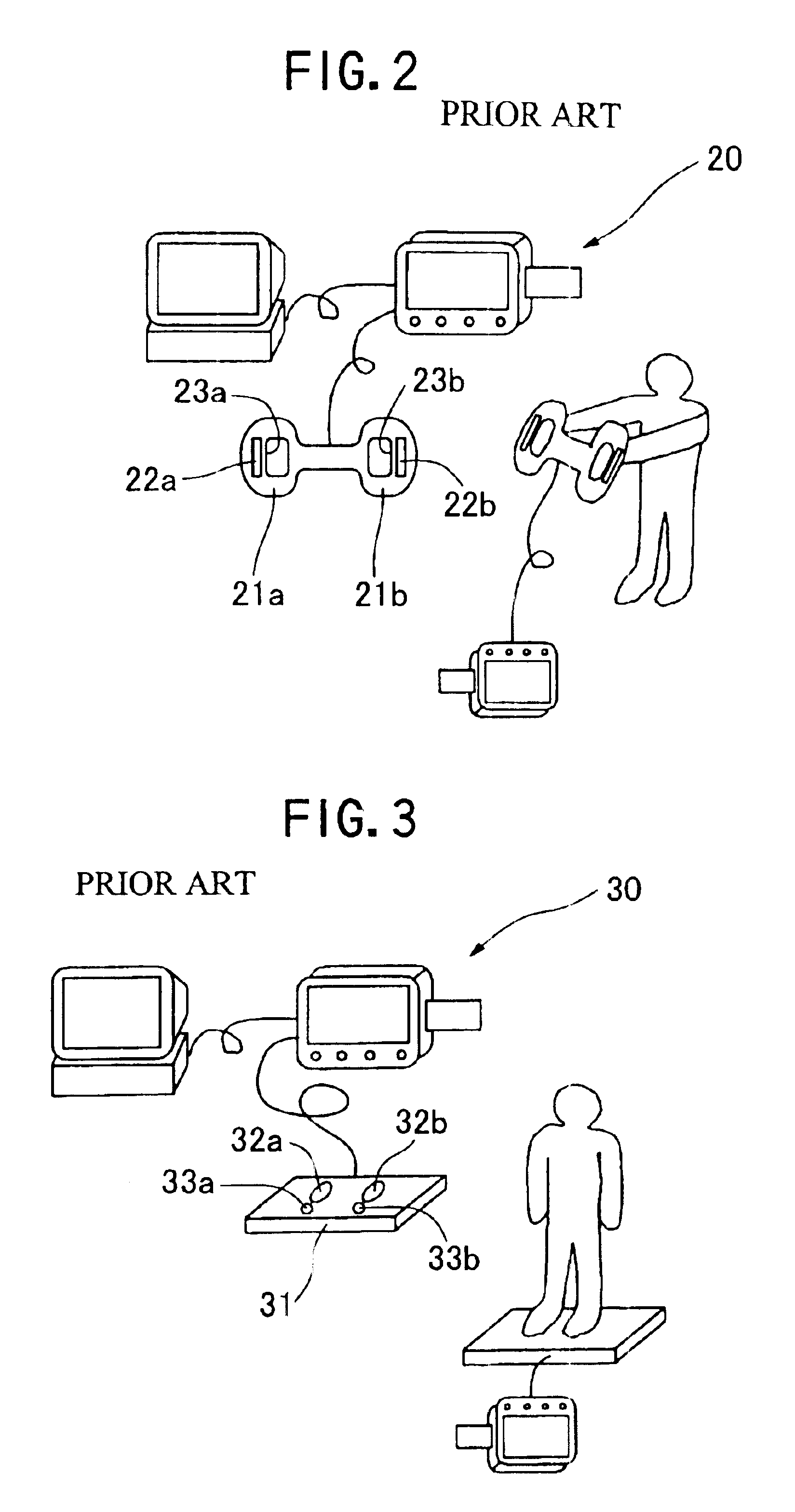

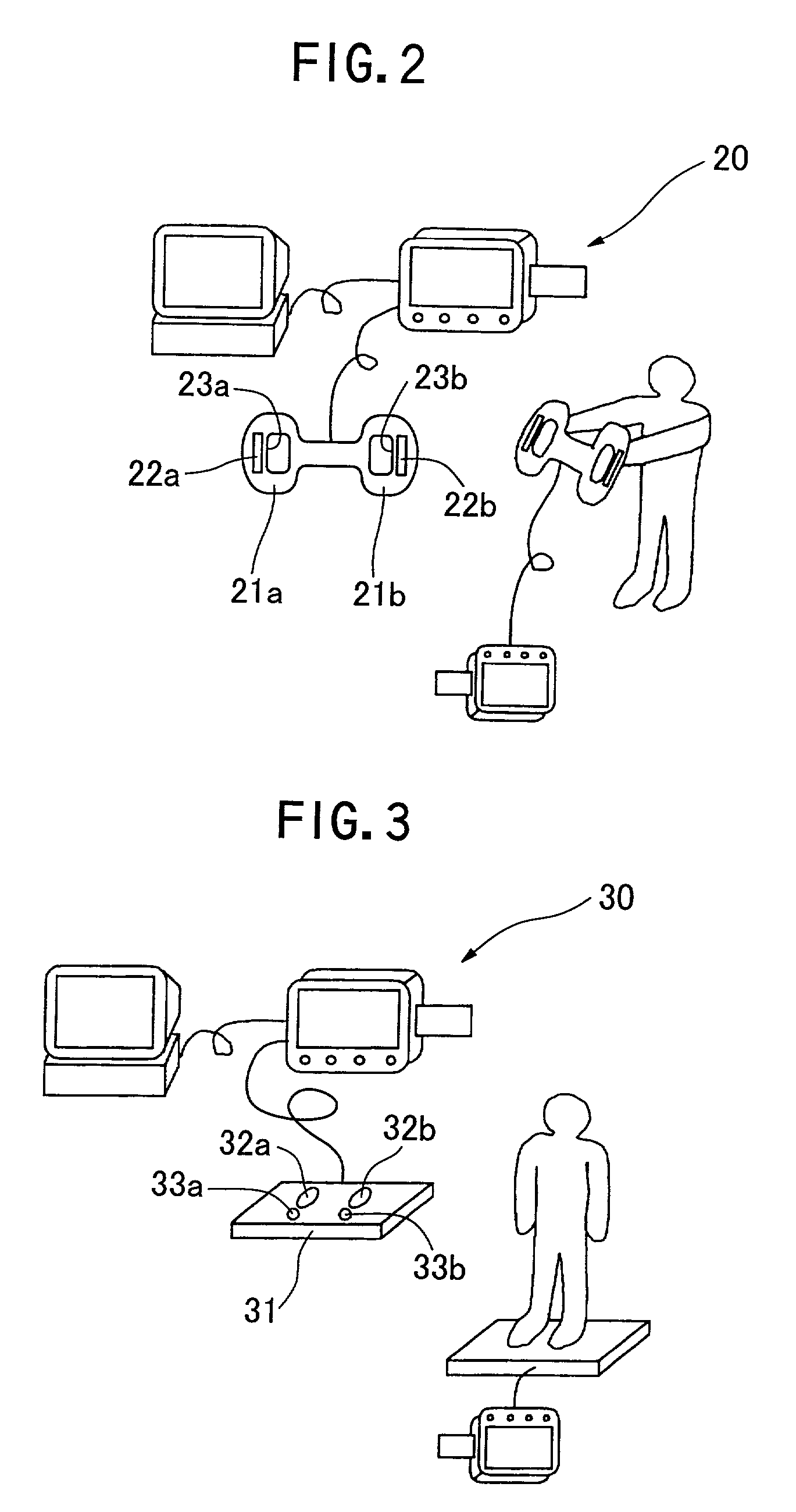

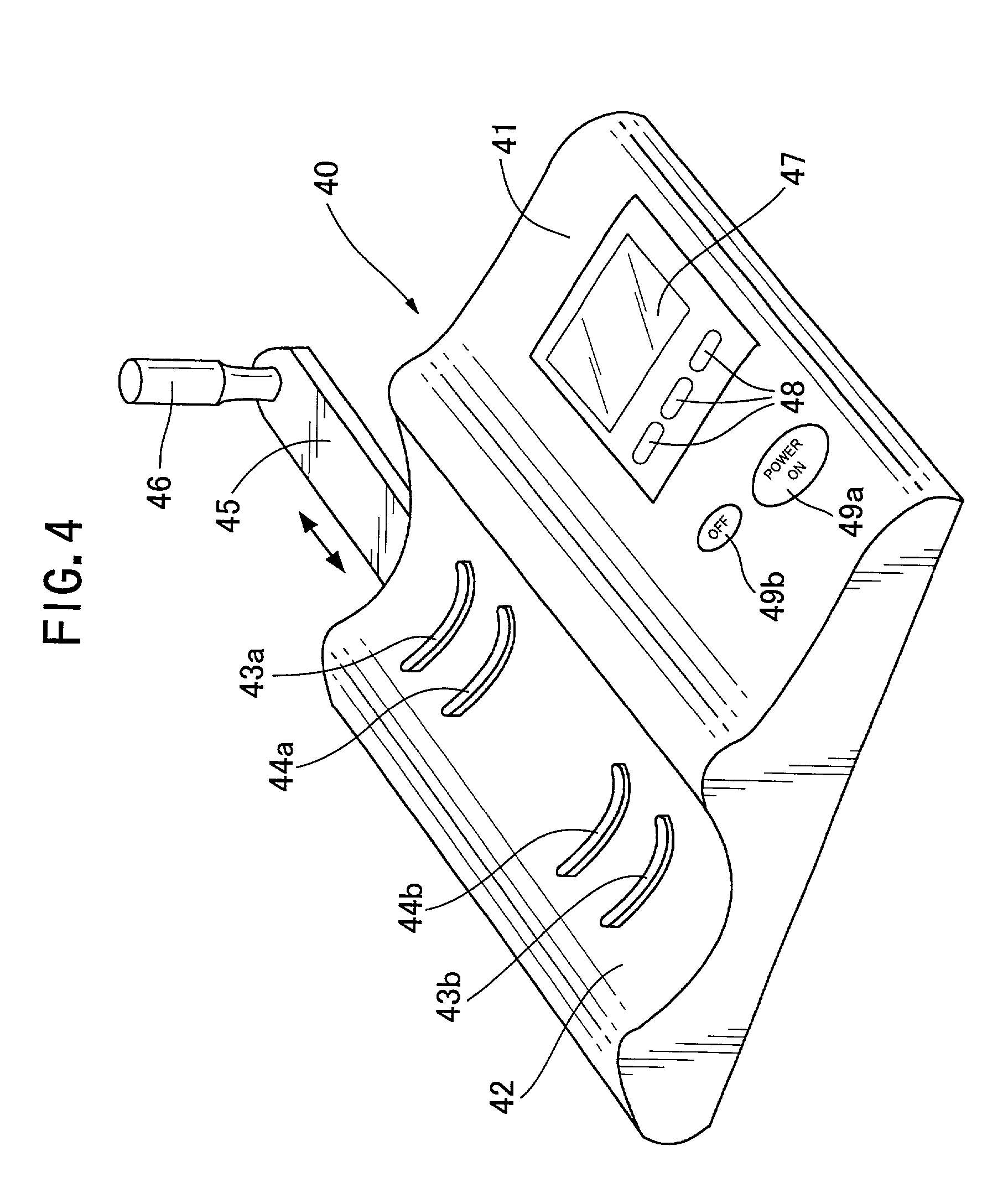

Bioelectrical impedance measuring apparatus

InactiveUS6714814B2Facilitates holdingDevices for locating reflex pointsResistance/reactance/impedenceBioelectrical impedance analysisEngineering

Disclosed is a impedance measuring apparatus which is easy to use, and which is guaranteed to be free of incorrect measurement caused by some joints appearing in the current flowing passage intervening between two selected body parts and by the indefinite length between two selected body parts. The measuring apparatus of the present invention limits the place of the body under measurement to "one body region", i.e. a selected joint-to-joint body portion or joint-free body portion such as the forearm extending from the wrist to the elbow or the portion extending from the ankle to the knee, and comprises a housing having a contact surface to be applied to one selected body region; a first pair of measurement current supplying electrodes so placed on the contact surface that the one selected body region may be put in contact with the current electrodes; and a first pair of voltage measuring electrodes so placed on the contact surface between the pair of current electrodes that the one selected body region may be put in contact with the voltage electrodes.

Owner:TANITA CORP

Bioelectrical impedance measuring apparatus

InactiveUS20010030546A1Facilitates holdingDevices for locating reflex pointsResistance/reactance/impedenceBioelectrical impedance analysisEngineering

Disclosed is a impedance measuring apparatus which is easy to use, and which is guaranteed to be free of incorrect measurement caused by some joints appearing in the current flowing passage intervening between two selected body parts and by the indefinite length between two selected body parts. The measuring apparatus of the present invention limits the place of the body under measurement to "one body region", i.e. a selected joint-to-joint body portion or joint-free body portion such as the forearm extending from the wrist to the elbow or the portion extending from the ankle to the knee, and comprises a housing having a contact surface to be applied to one selected body region; a first pair of measurement current supplying electrodes so placed on the contact surface that the one selected body region may be put in contact with the current electrodes; and a first pair of voltage measuring electrodes so placed on the contact surface between the pair of current electrodes that the one selected body region may be put in contact with the voltage electrodes.

Owner:TANITA CORP

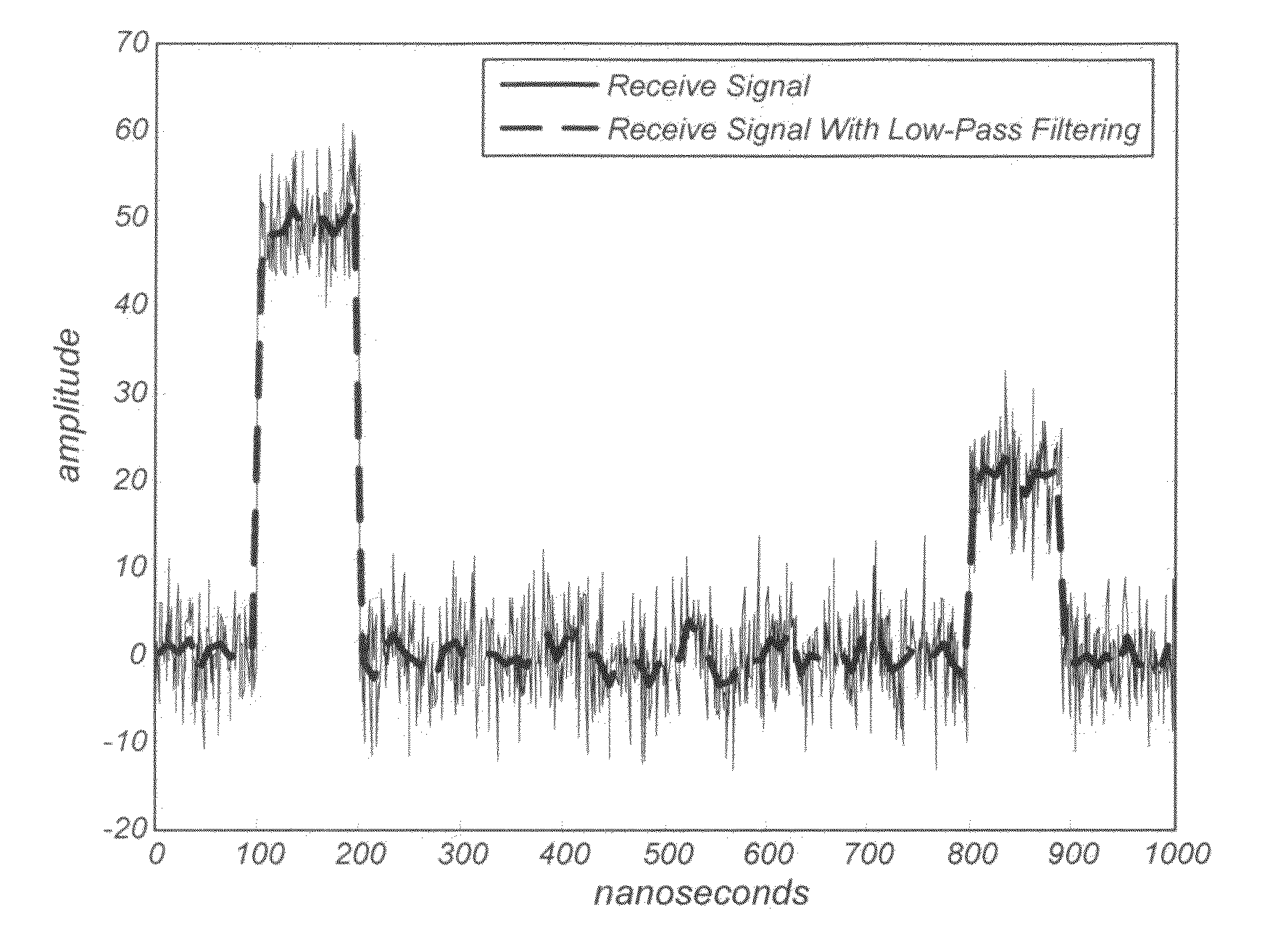

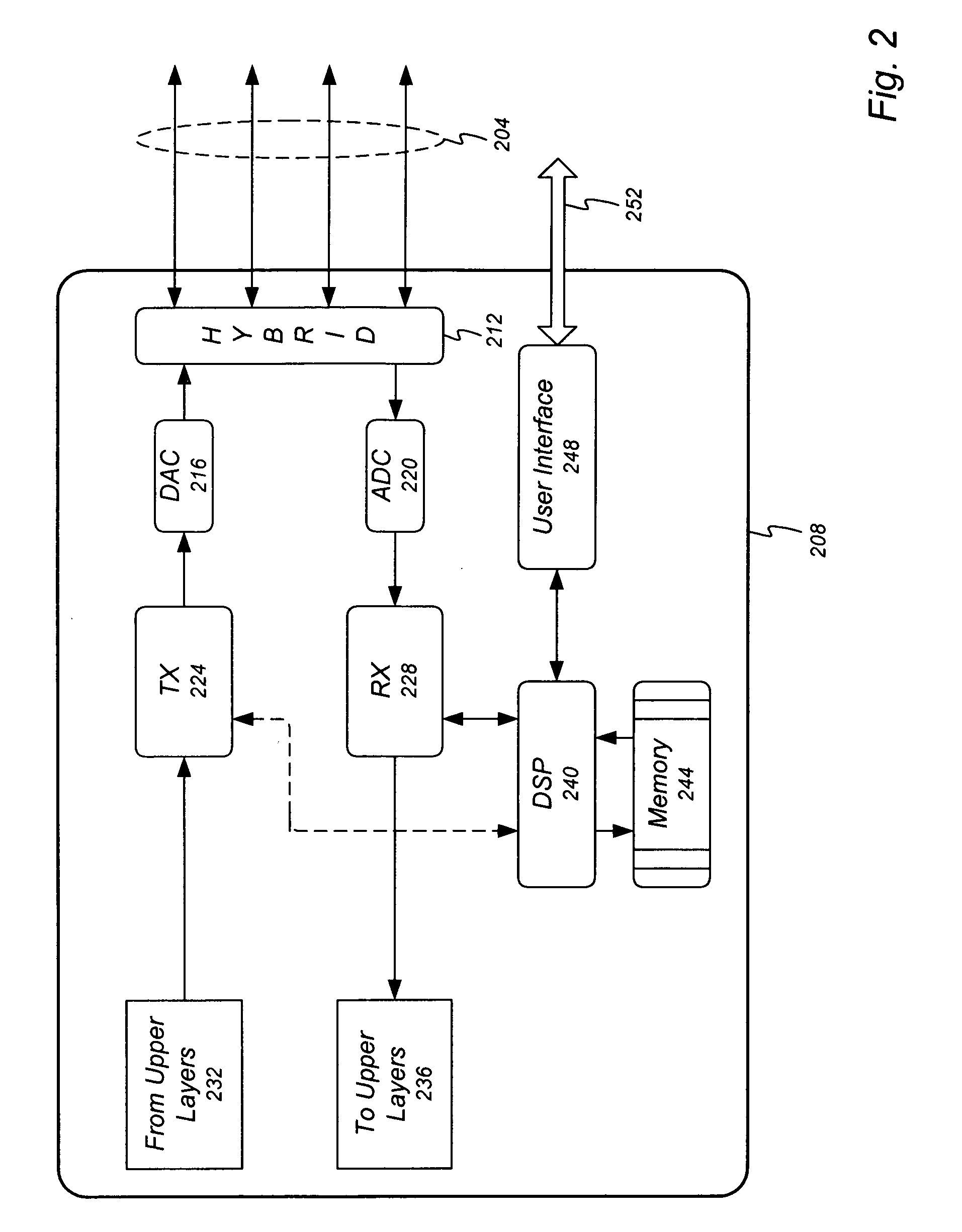

Cable diagnostics for base-T systems

ActiveUS20100164505A1Reduce complexityLow costFault location by pulse reflection methodsLine-transmission monitoring/testingNonlinear filterCommunications system

An apparatus and method for cable diagnostics is disclosed for deployment as part of an Ethernet communication system to conduct diagnostics. The system transmits one or more pulses which are Ethernet compatible and of finite duration. Reflections are detected and through processing and measurement of the amplitude and round-trip delay of the pulse's reflection, cable faults are located. In one embodiment, this innovation uses an IEEE 802.3 compliant transmit pulse, such as an auto-negotiation signal (AN pulse), to conduct cable diagnostics. The benefits of a standard compliant allow for use with any vendor on the far-end and the signal requires no special hardware or software to produce and, therefore, reduces system complexity and cost. To reduce incorrect measurements, the apparatus measures cable length and termination with multiple AN pulses. It then applies non-linear filters to redundant measurements in such a way that it produces accurate cable diagnostics information.

Owner:MARVELL ASIA PTE LTD

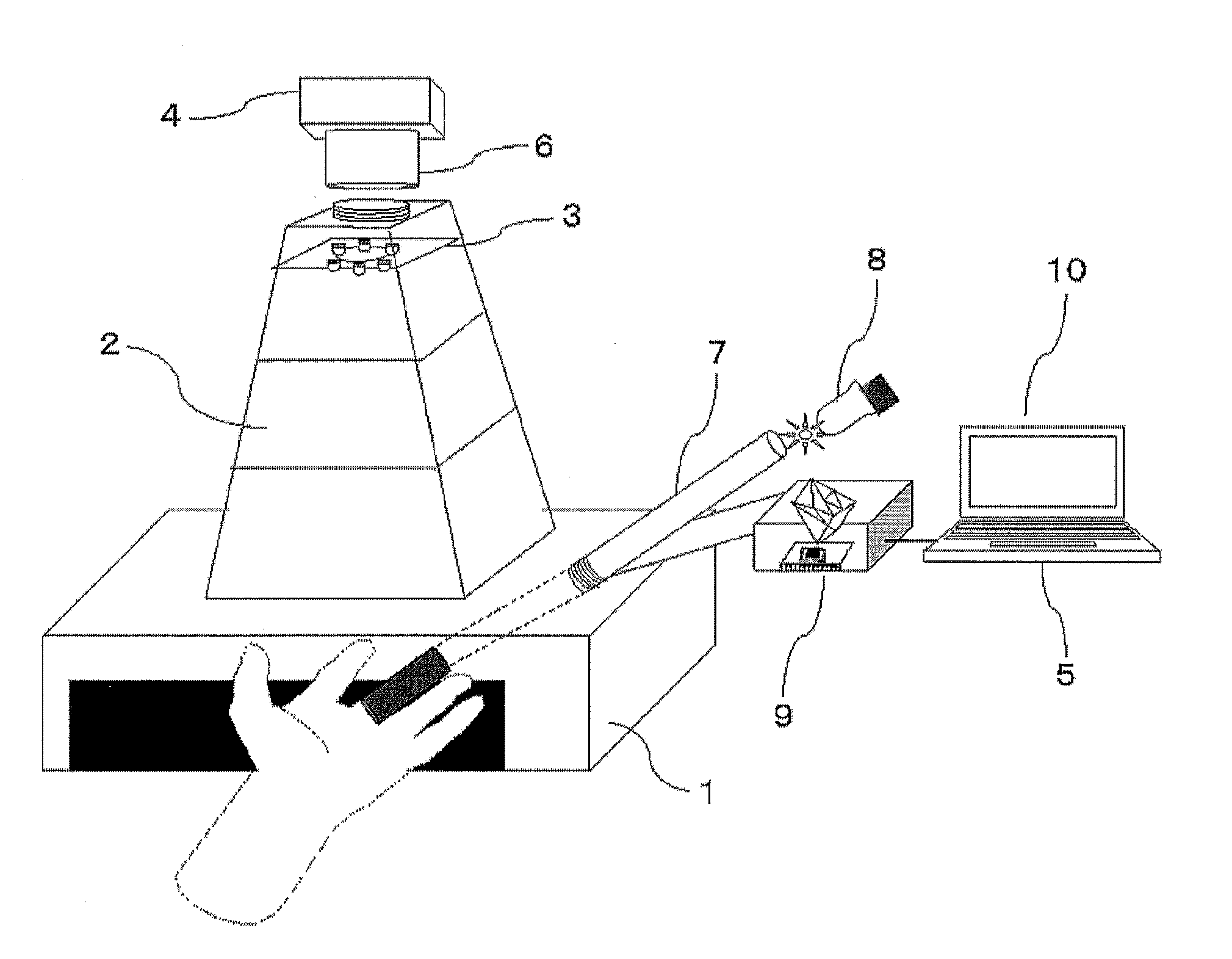

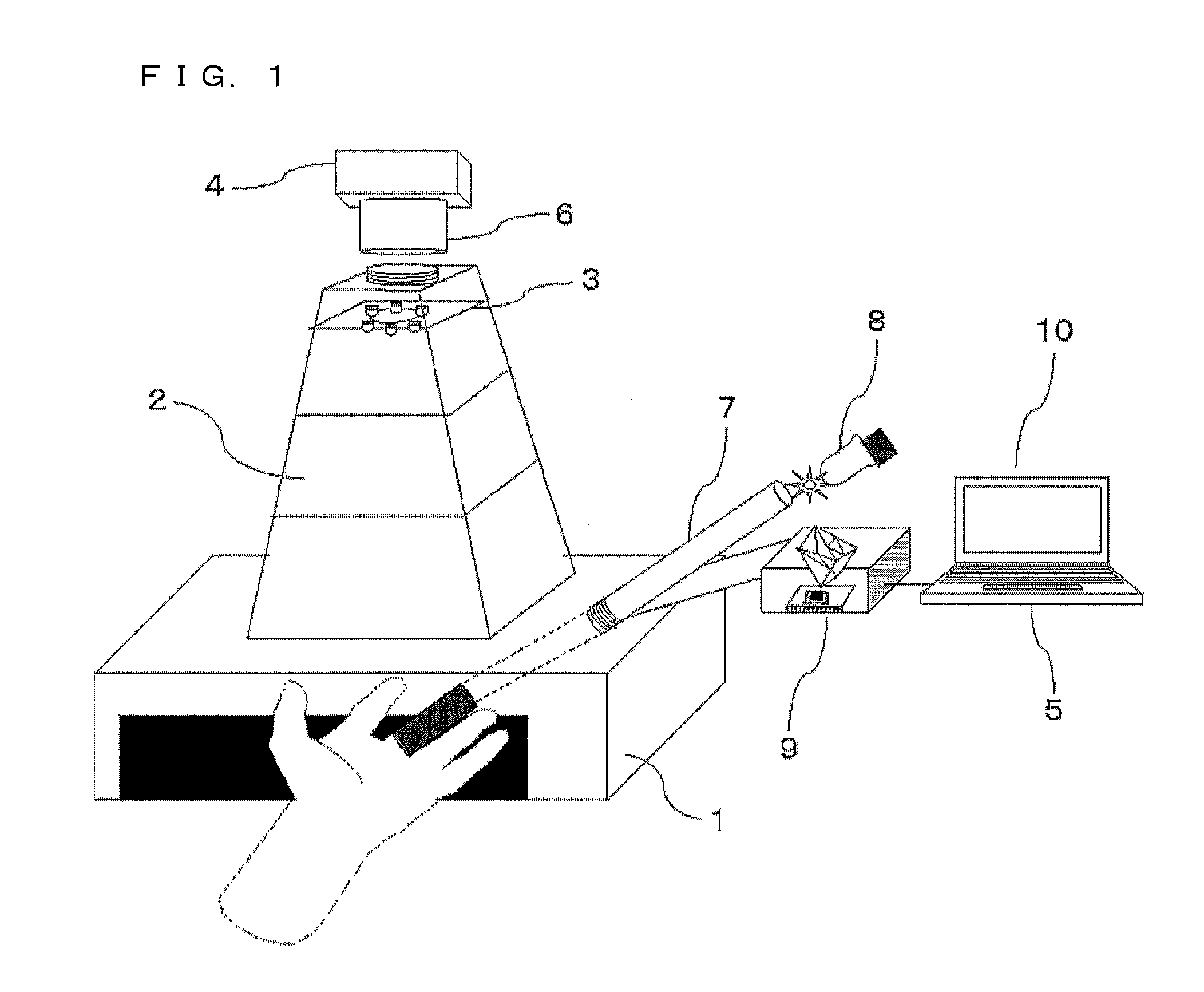

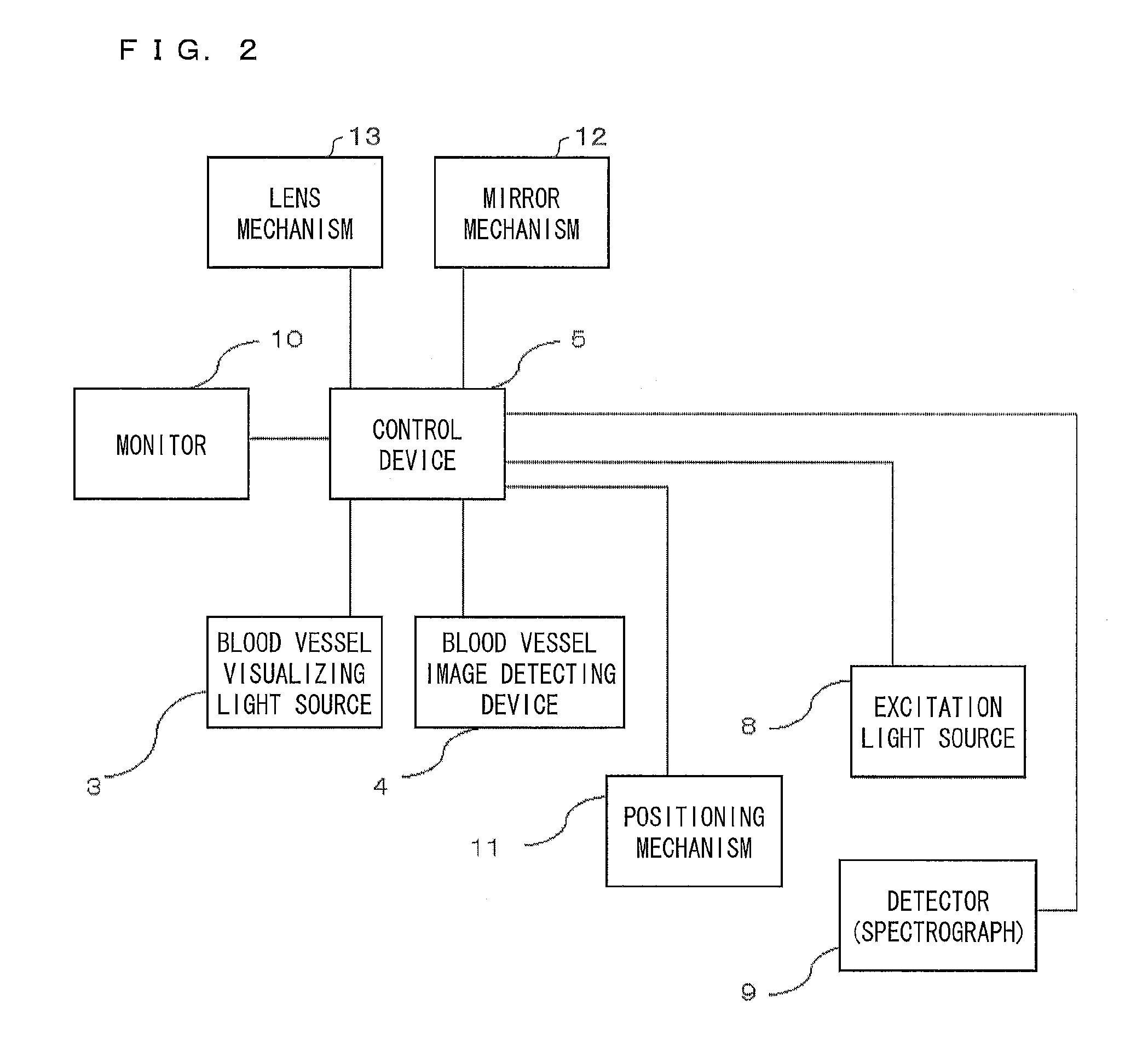

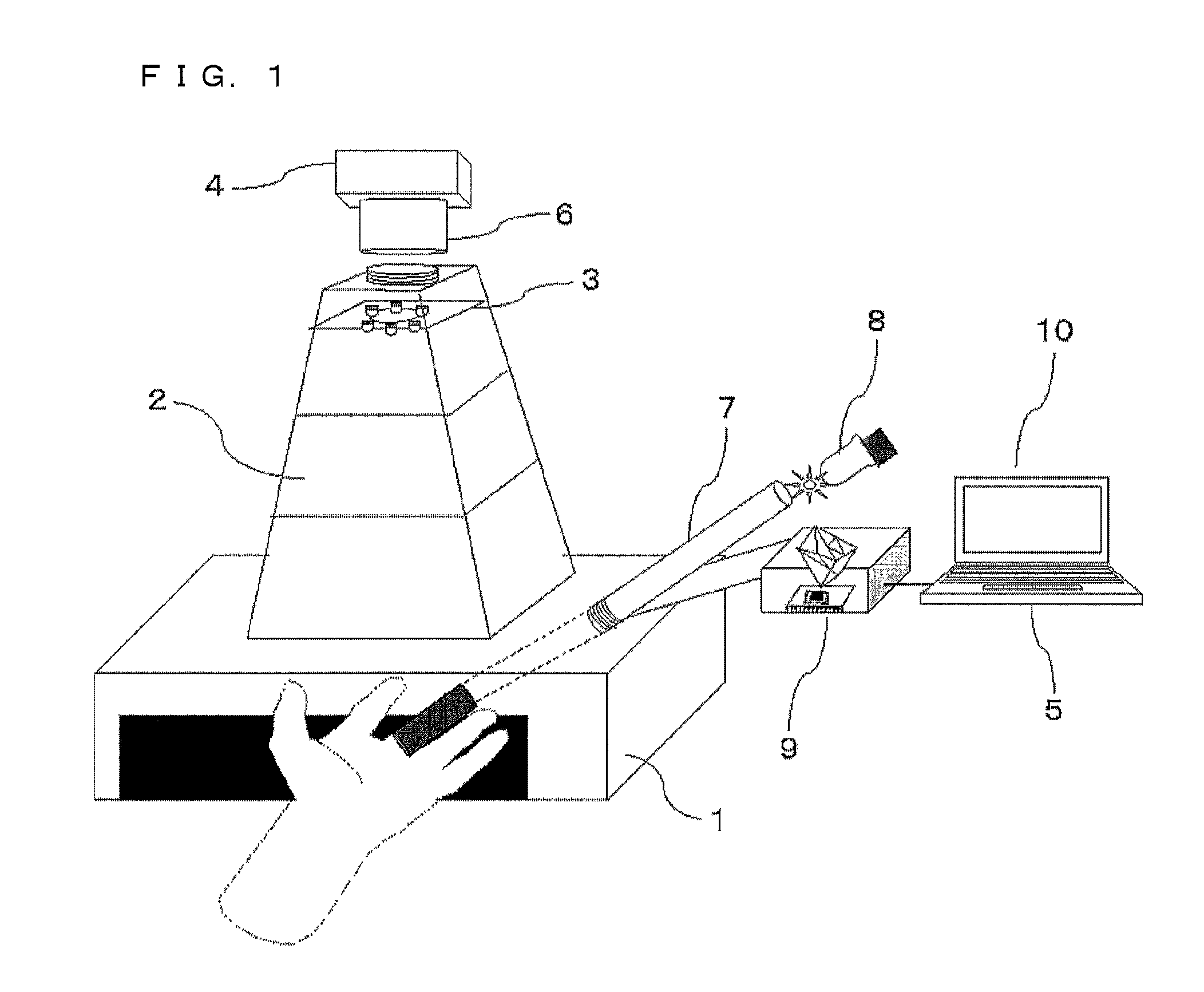

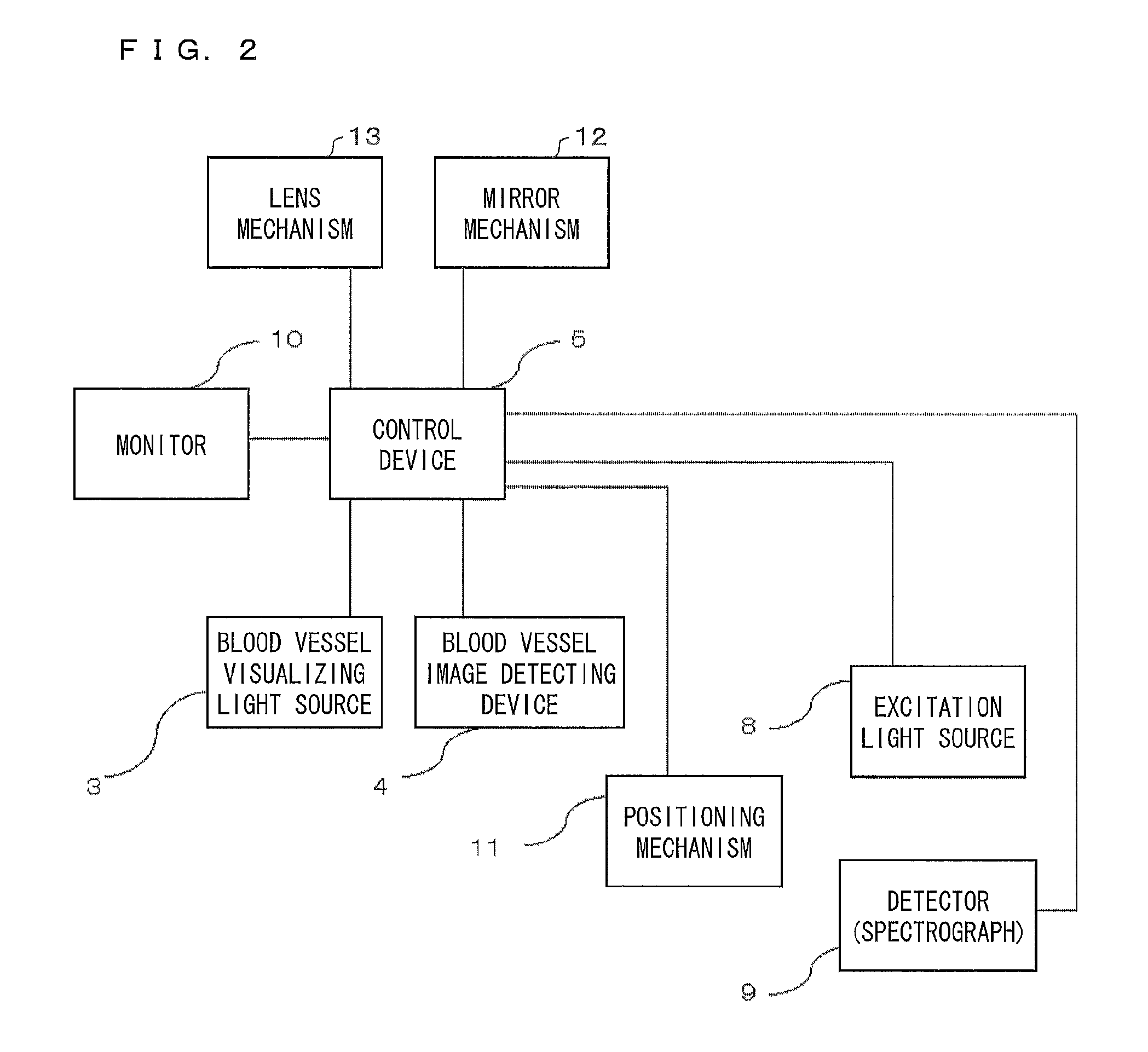

Device for monitoring blood vessel conditions and method for monitoring same

ActiveUS20120190945A1Easily and daily monitorDiagnostics using lightDiagnostics using fluorescence emissionMedicineBlood Vessel Tissue

The present invention detects a fluorescent signal from AGEs at a blood vessel tissue of an individual to determine the condition of the tissue of the individual. This solves a problem that in measurement of AGEs used in diagnosis of diabetes, data indicative of fluorescent spectrum from AGEs at the skin of a forearm varies depending on where to measure on skin of even the same forearm, which results in variations in measurement values, leading to unreliable data and incorrect measurement result.

Owner:SHARP LIFE SCI CORP

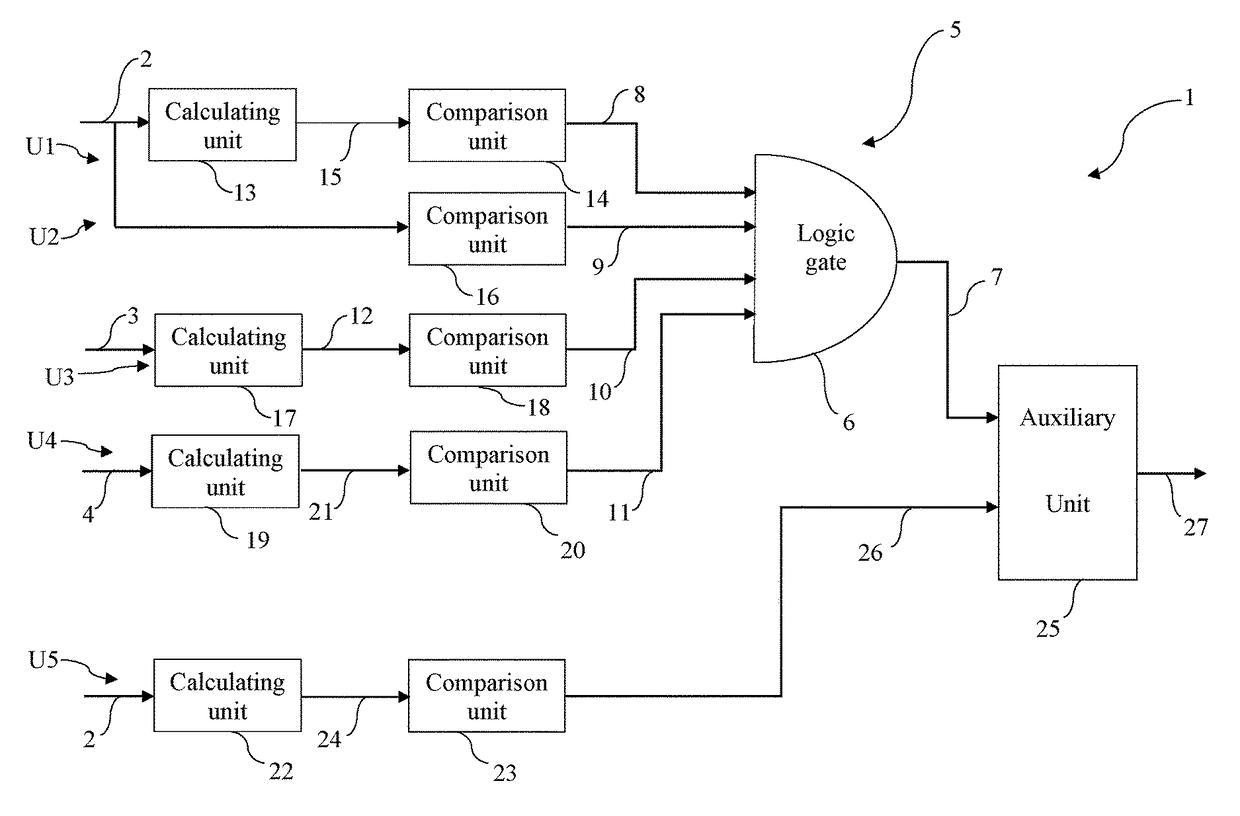

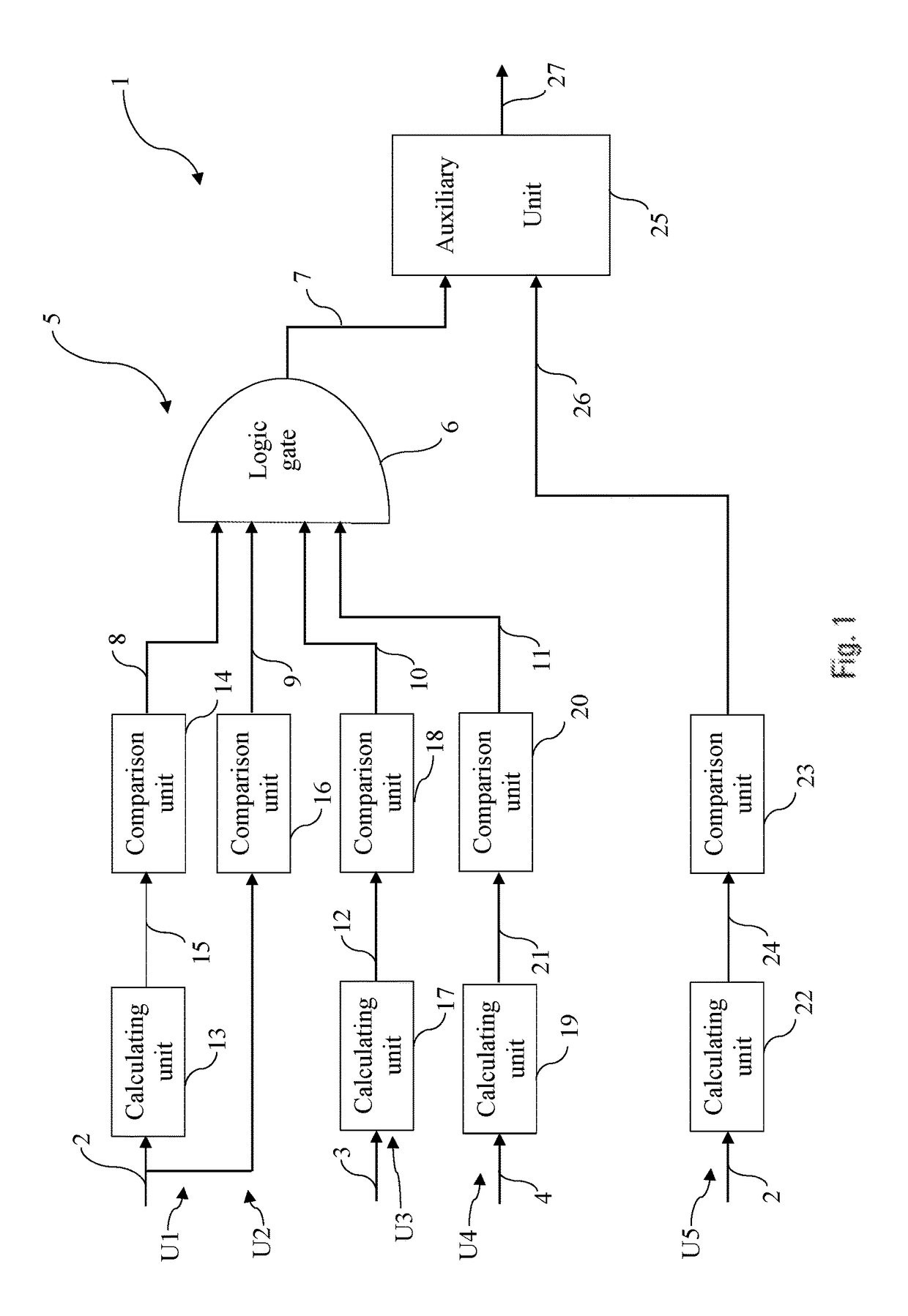

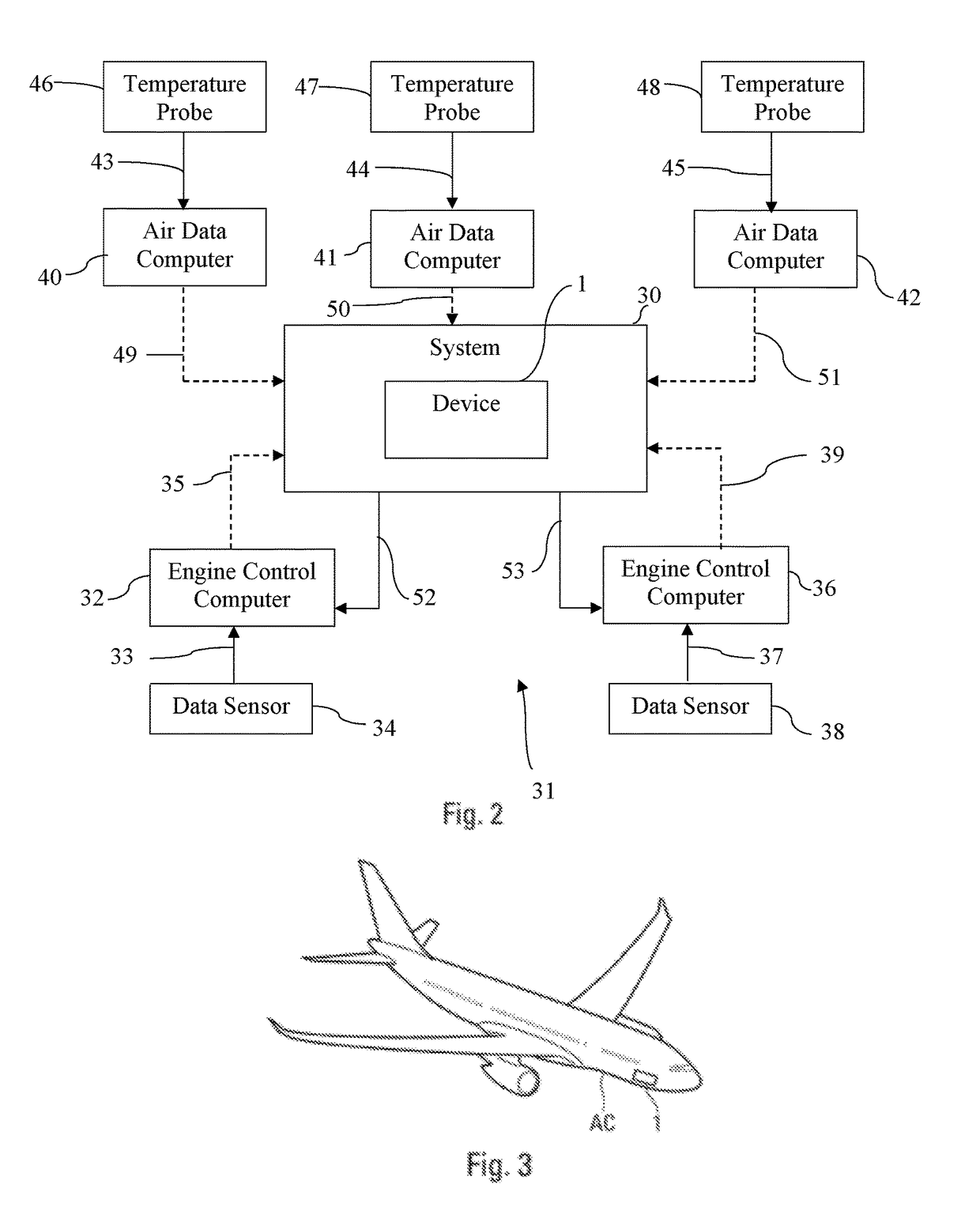

Method and device for automatically detecting an incorrect measurement of a total temperature on an aircraft

A method and a device for automatically detecting an incorrect measurement of a total temperature on an aircraft. The detection device comprises several monitoring units configured to monitor the variations of the measured total temperature, provided by a temperature probe, and current values of the Mach number and of the altitude of the aircraft over a predetermined monitoring period of time, and a detection unit configured to detect an incorrect measurement of the total temperature when said monitoring units simultaneously detect particular conditions relative to said variations.

Owner:AIRBUS OPERATIONS (SAS)

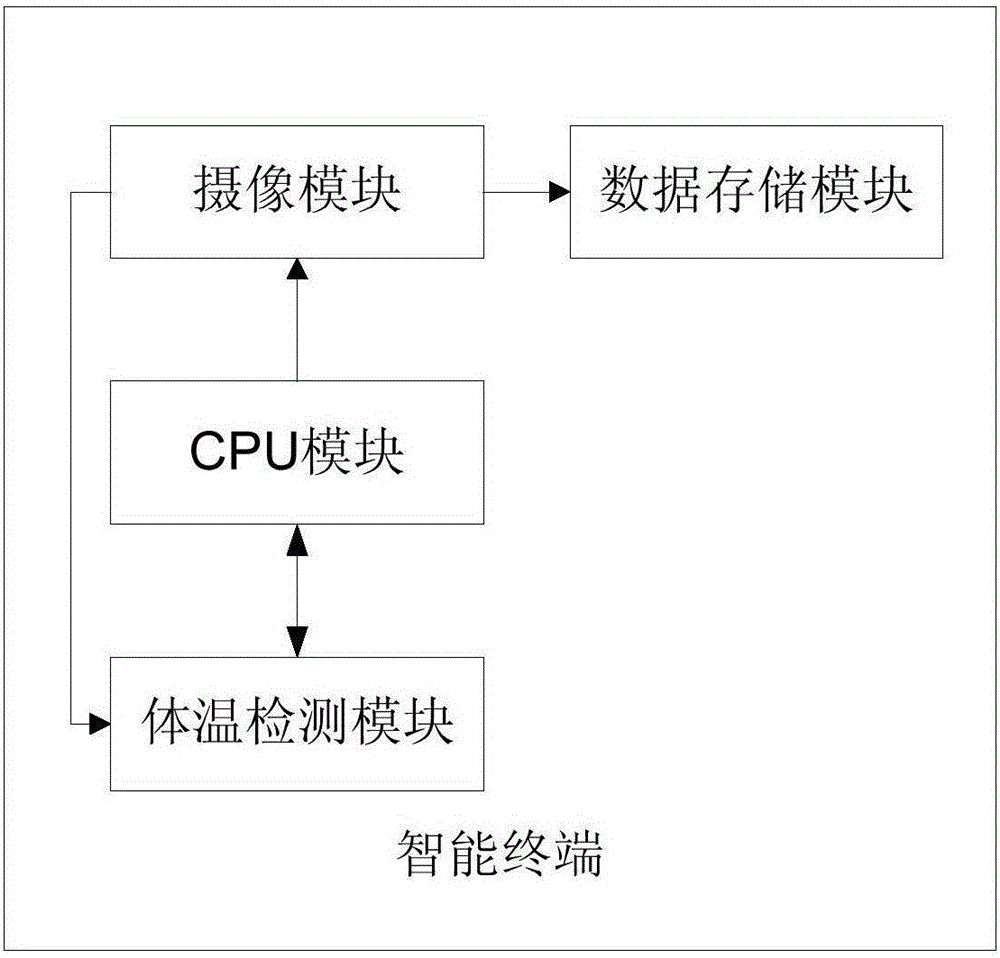

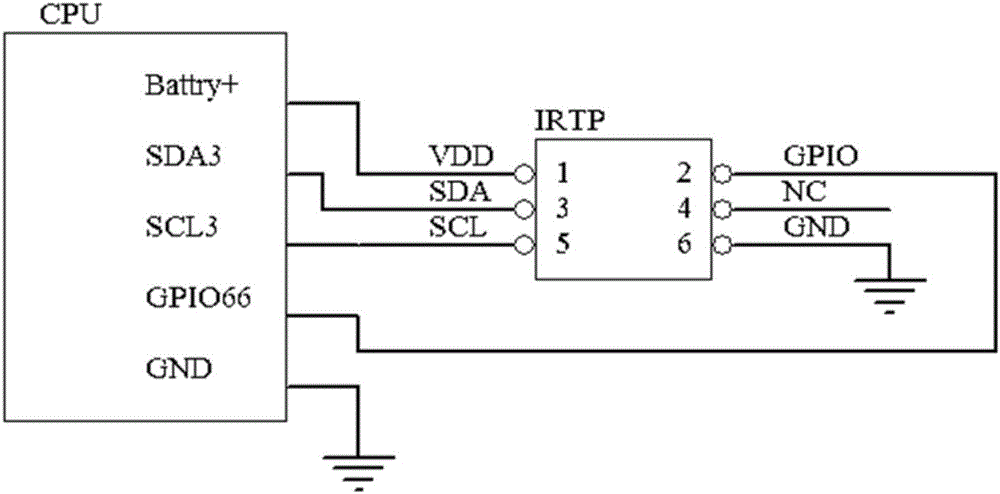

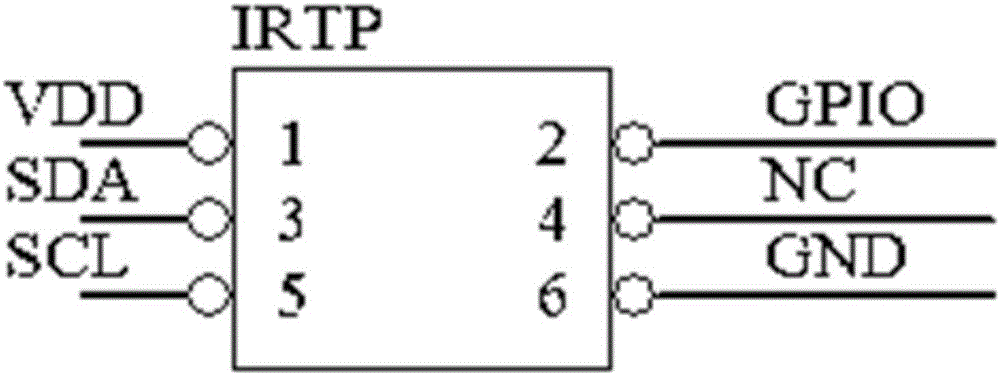

System and method for detecting body temperature

InactiveCN105816158AEasy to viewEasy to carryDiagnostics using lightSensorsComputer scienceHigh body temperature

The invention relates to the field of detection techniques for body temperatures, and particularly relates to a system and a method for detecting a body temperature. The system for detecting the body temperature comprises an intelligent terminal, a CPU (central processing unit) module, a shooting module and a body temperature detecting module, wherein the CPU module, the shooting module and the body temperature detecting module are arranged in the intelligent terminal respectively; the CPU module is used for controlling the on and off of the body temperature detecting function of the body temperature detecting module; the shooting module is used for aiming at a to-be-detected object; the body temperature detecting module is used for detecting the surface temperature of a human body of the to-be-detected object and displaying the detected surface temperature of the human body in a shooting preview interface of the shooting module. The system and the method for detecting the body temperature are simple to operate, a measurement of the body temperature can be completed so long as a mobile phone is at hand, a thermometer is not needed to be sought everywhere, the problem of an inaccurate measurement caused by an incorrect measurement technique does not need to be worried, so that the temperature measurement is convenient and quick, and further, the carrying is convenient.

Owner:LETV HLDG BEIJING CO LTD +1

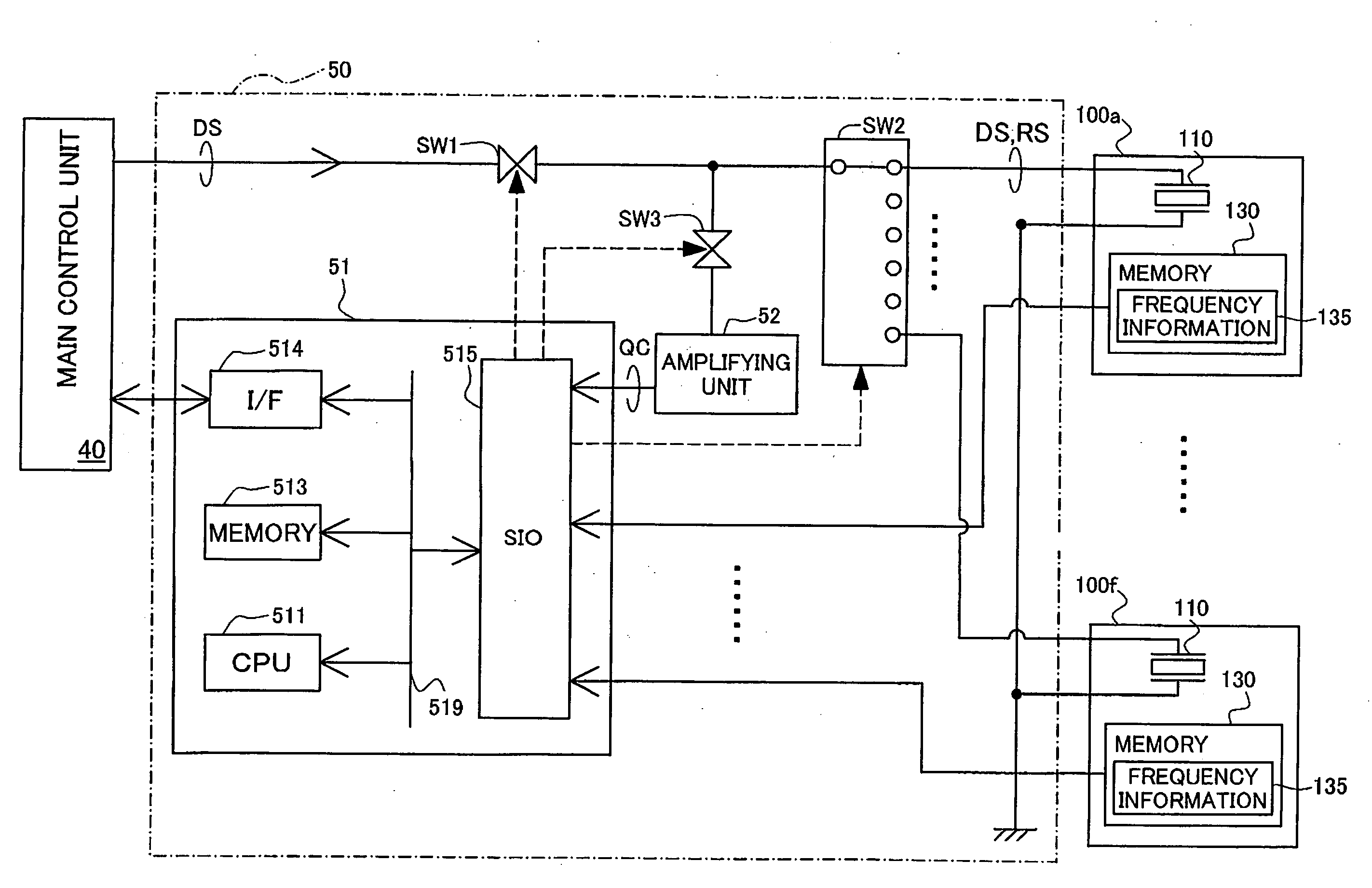

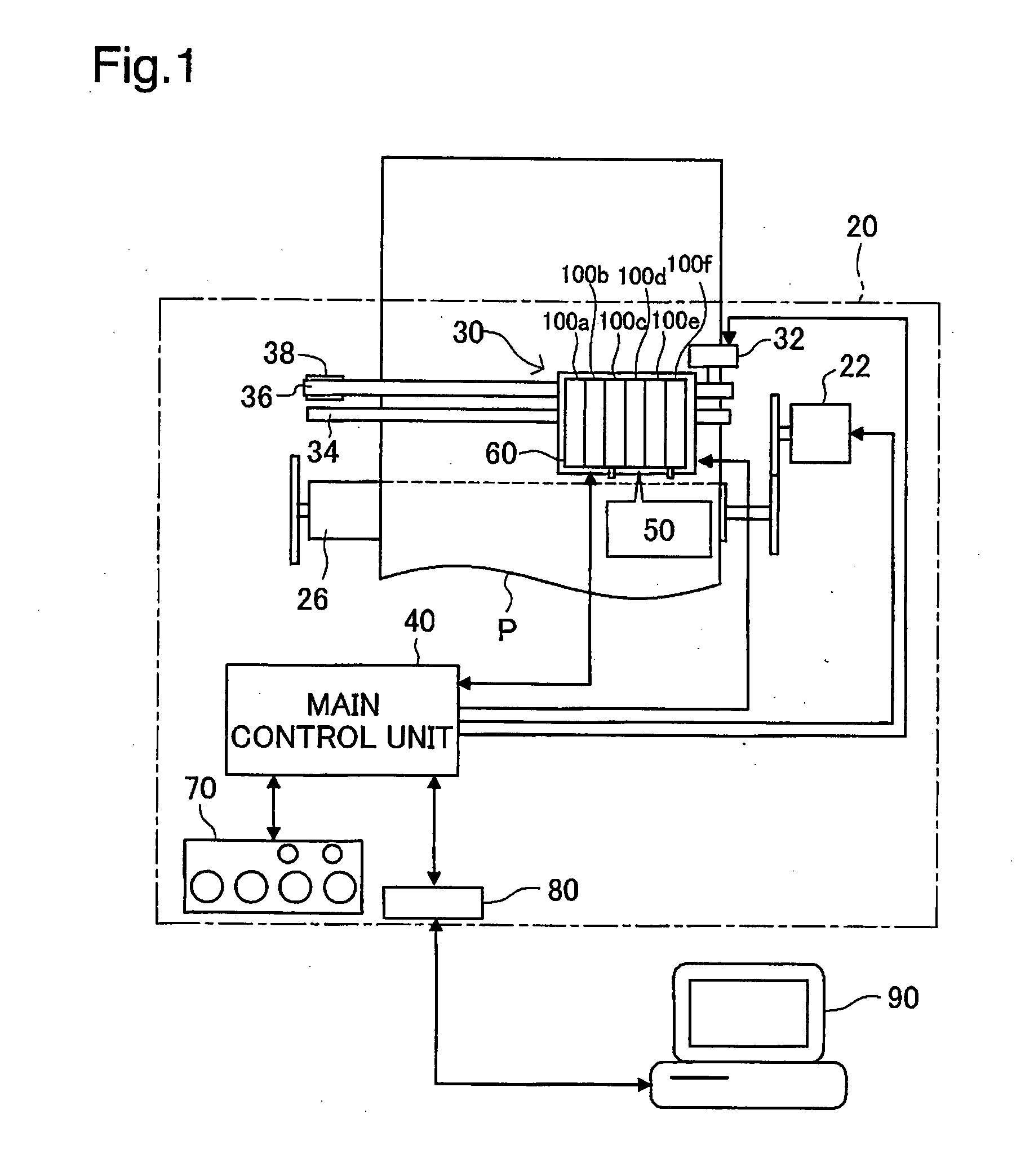

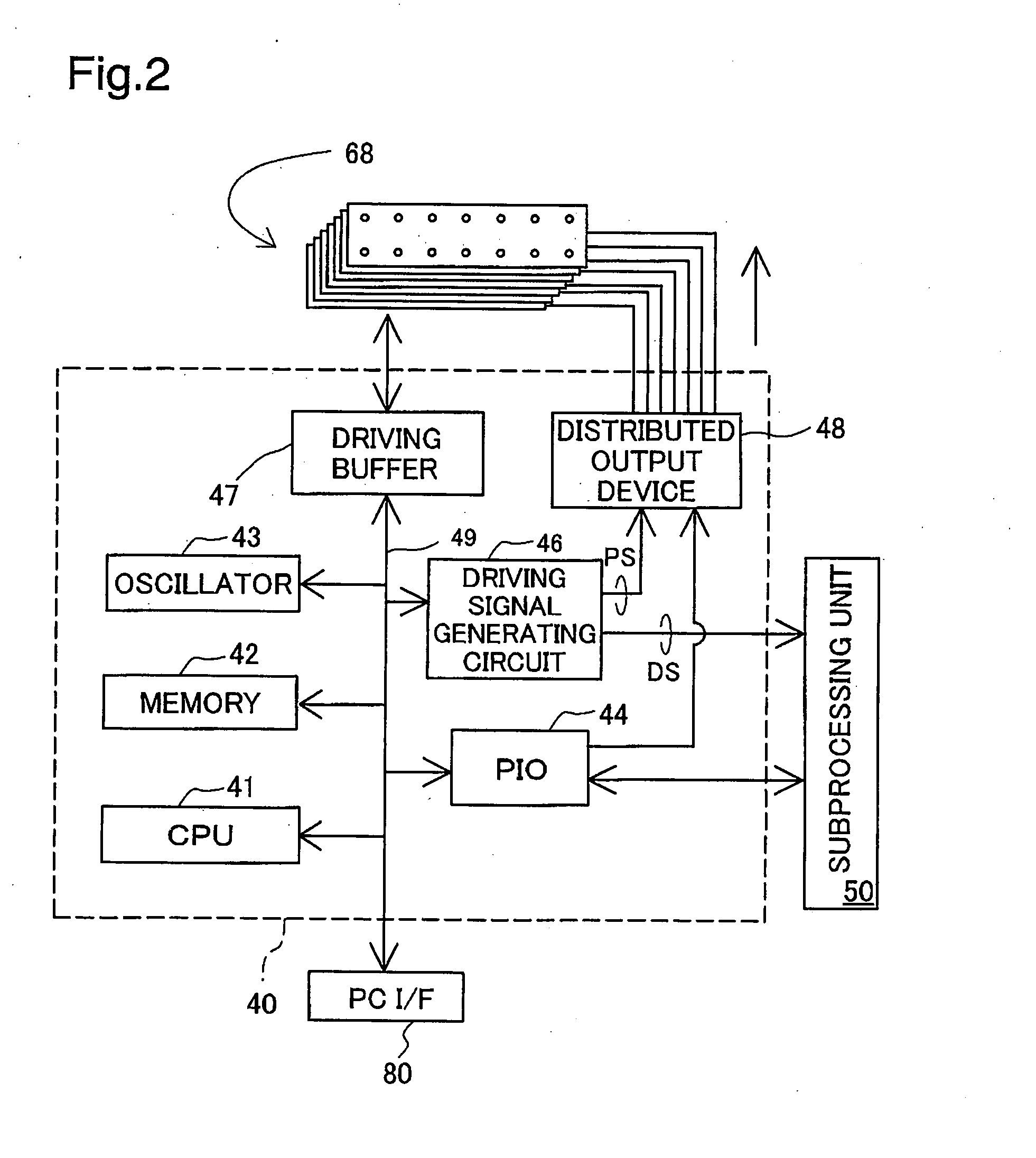

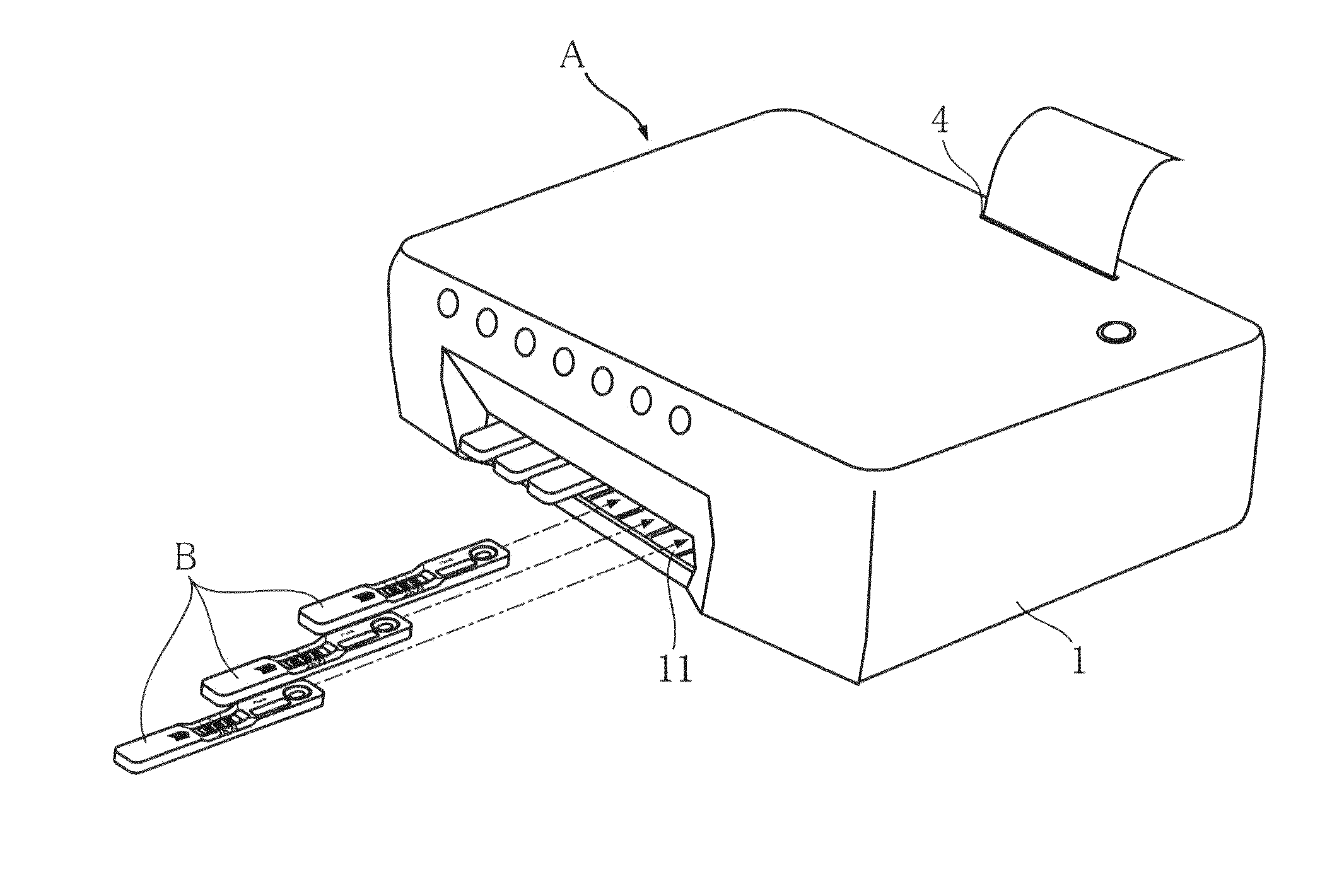

Method for detecting printing material amounts in printing material container attached to printer

InactiveUS20080007577A1Improve accuracySimple structureOther printing apparatusEngineeringIncorrect Measurement

The amount of ink is determined using both a first vibration frequency VF1 that is measured when a driving signal DS1 of a first frequency is provided to a sensor, and a second vibration frequency VF2 that is measured when a driving signal DS2 of a second frequency F2, which is less than the first vibration frequency by a specific ratio, is provided to the sensor. When there is an incorrect measurement of either the first vibration frequency VF1 or the second vibration frequency VF2, the natural frequencies to which the vibration frequencies are near will be different, as shown in the combination numbers “2” and “3” in the Ink Amount of Determining Table 600. Because the cases wherein the vibration frequency is measured incorrectly are the cases wherein there is no ink, when the first vibration frequency VF1 and / or the second vibration frequency VF2 is near to the target natural frequency H2 (combination numbers “2” through “4”), it is determined that the amount of ink is stored in the cartridge being processed is less than a specific amount.

Owner:SEIKO EPSON CORP

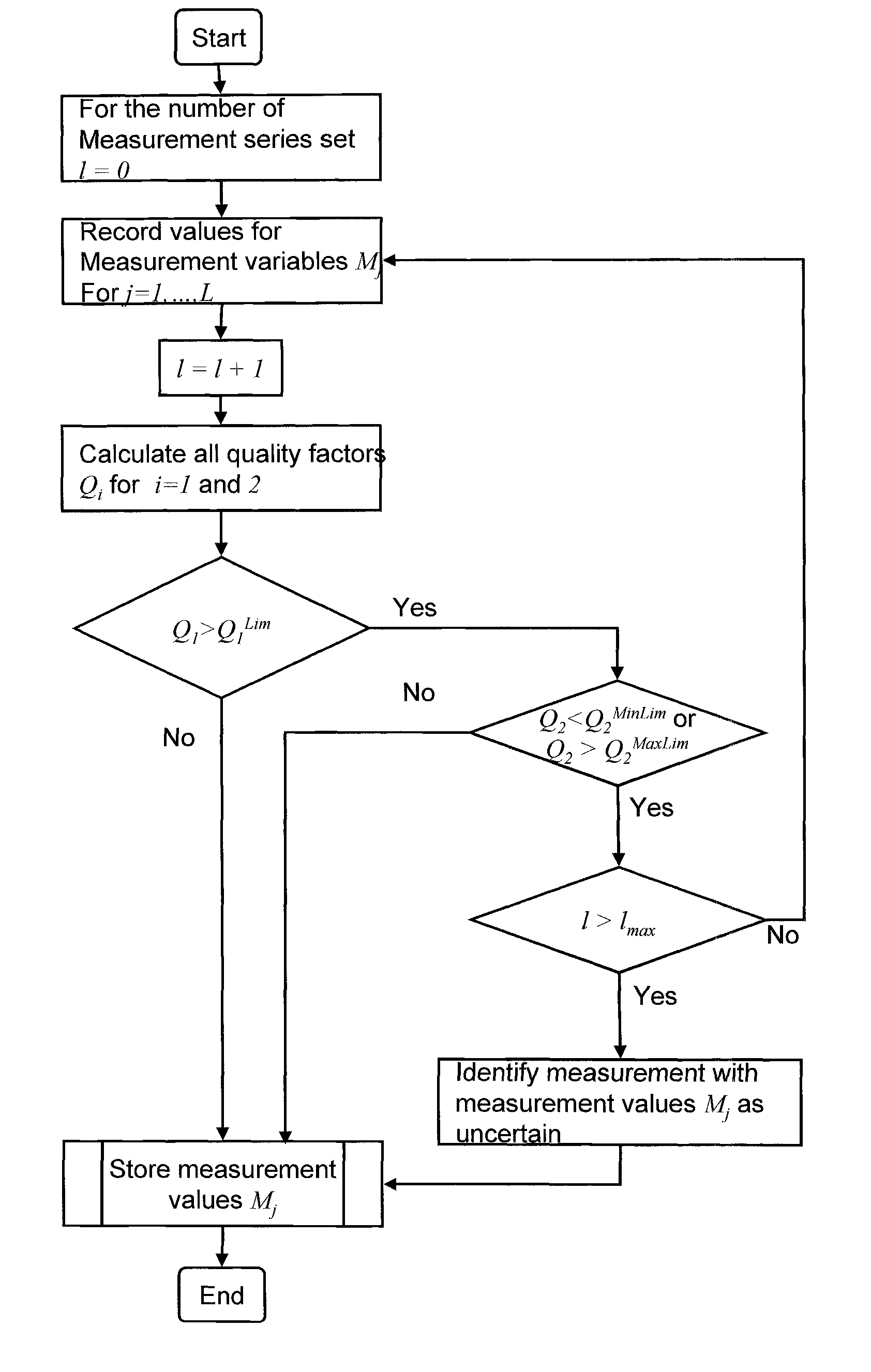

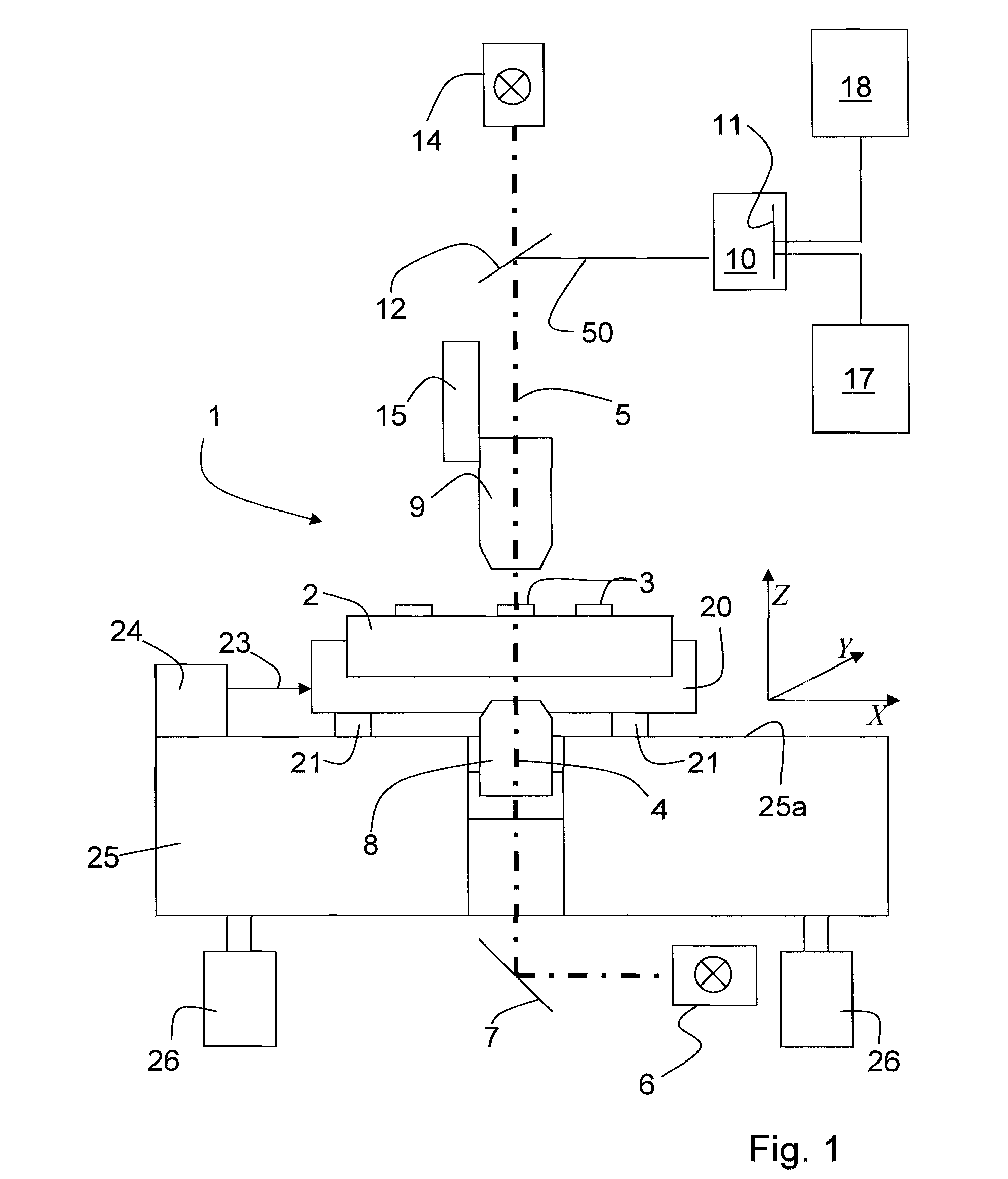

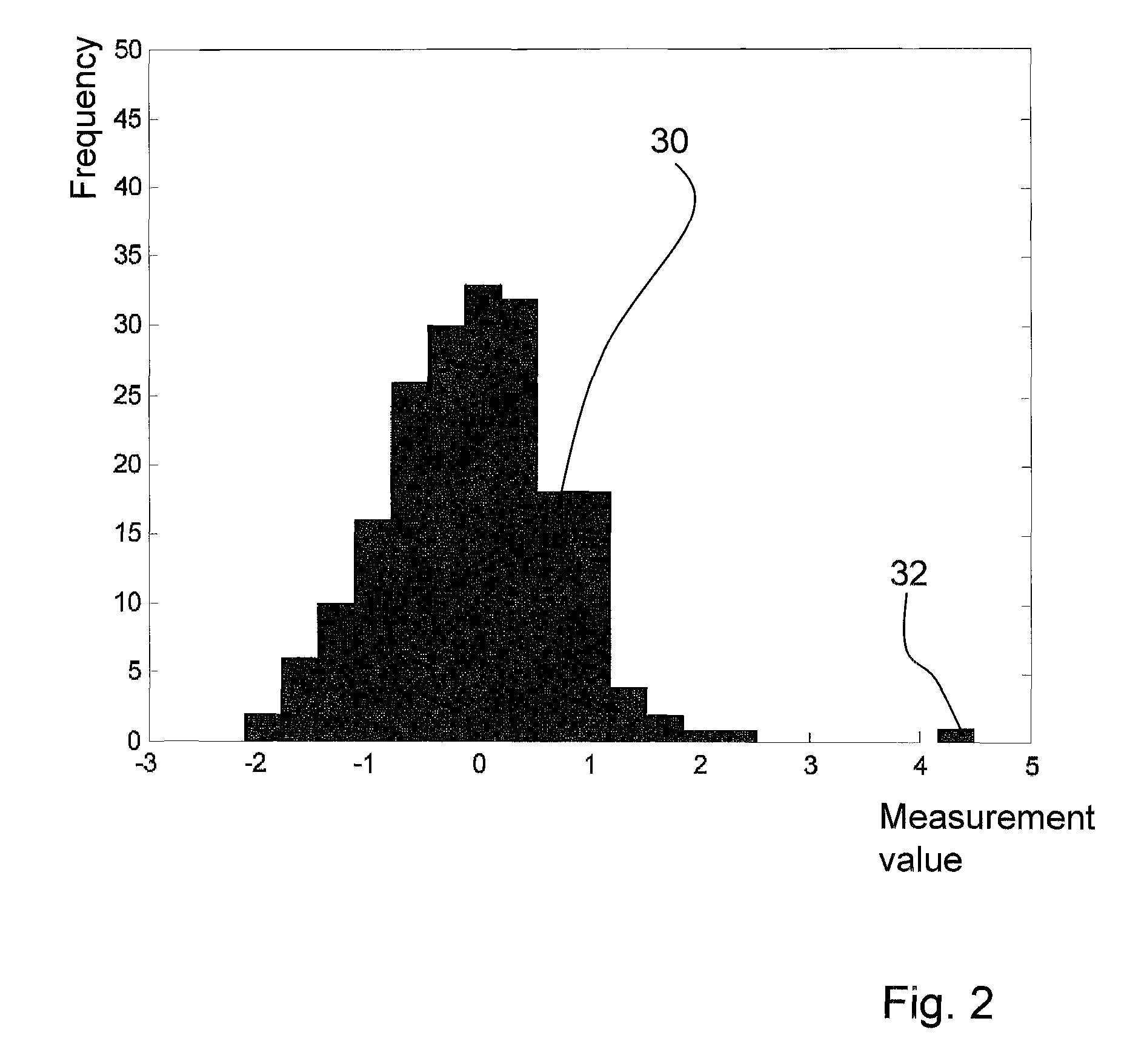

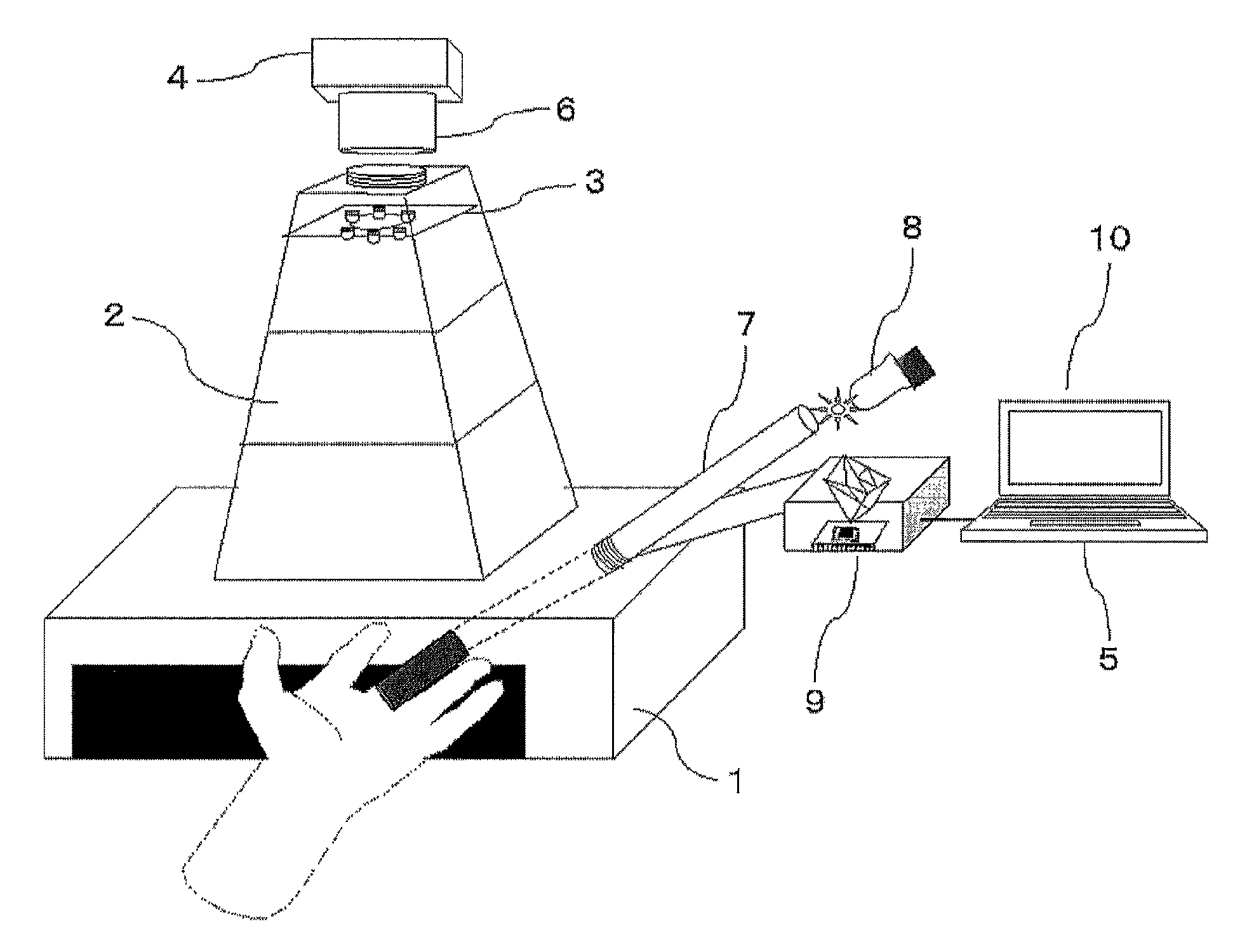

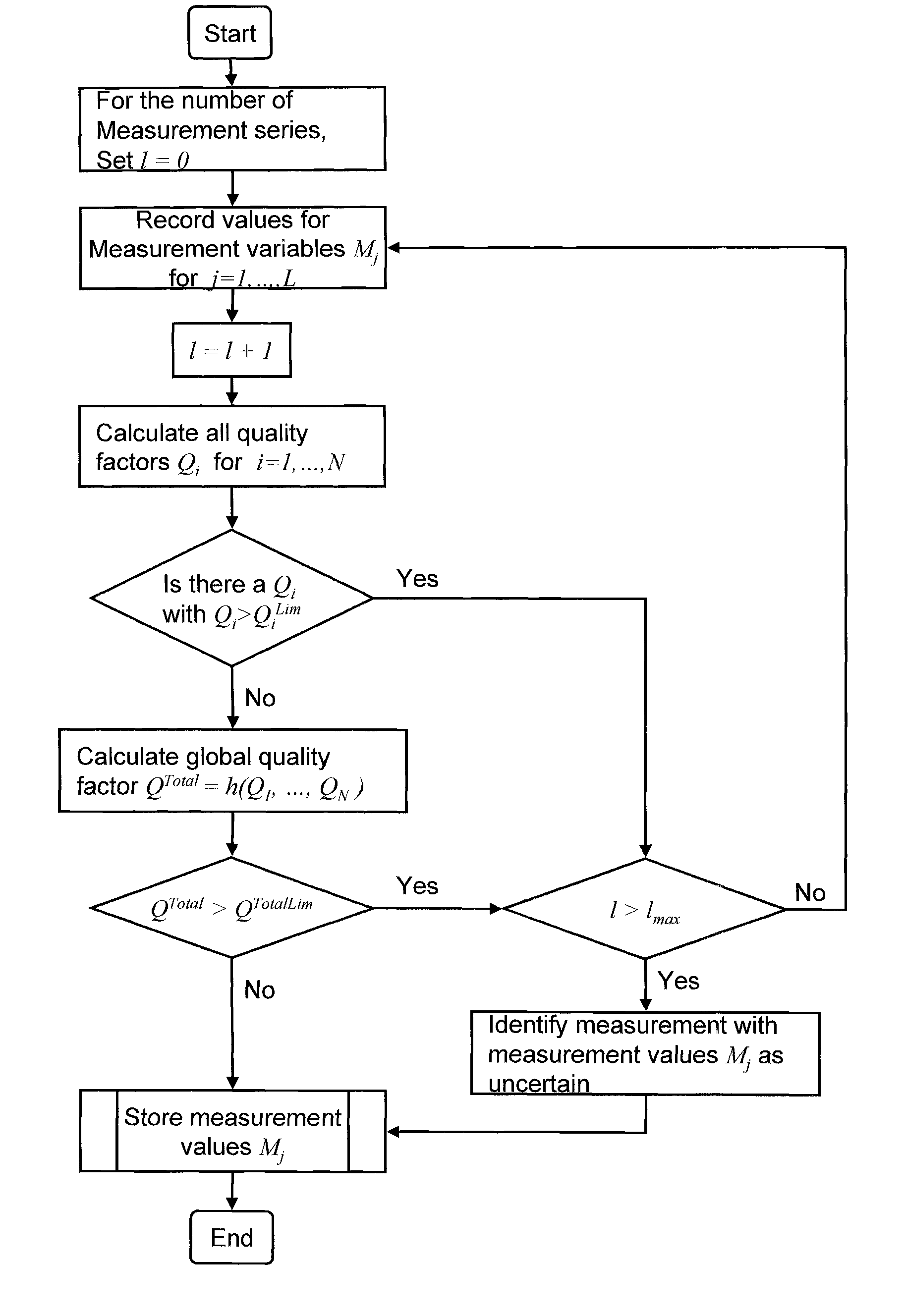

Device and method for automatic detection of incorrect measurements by means of quality factors

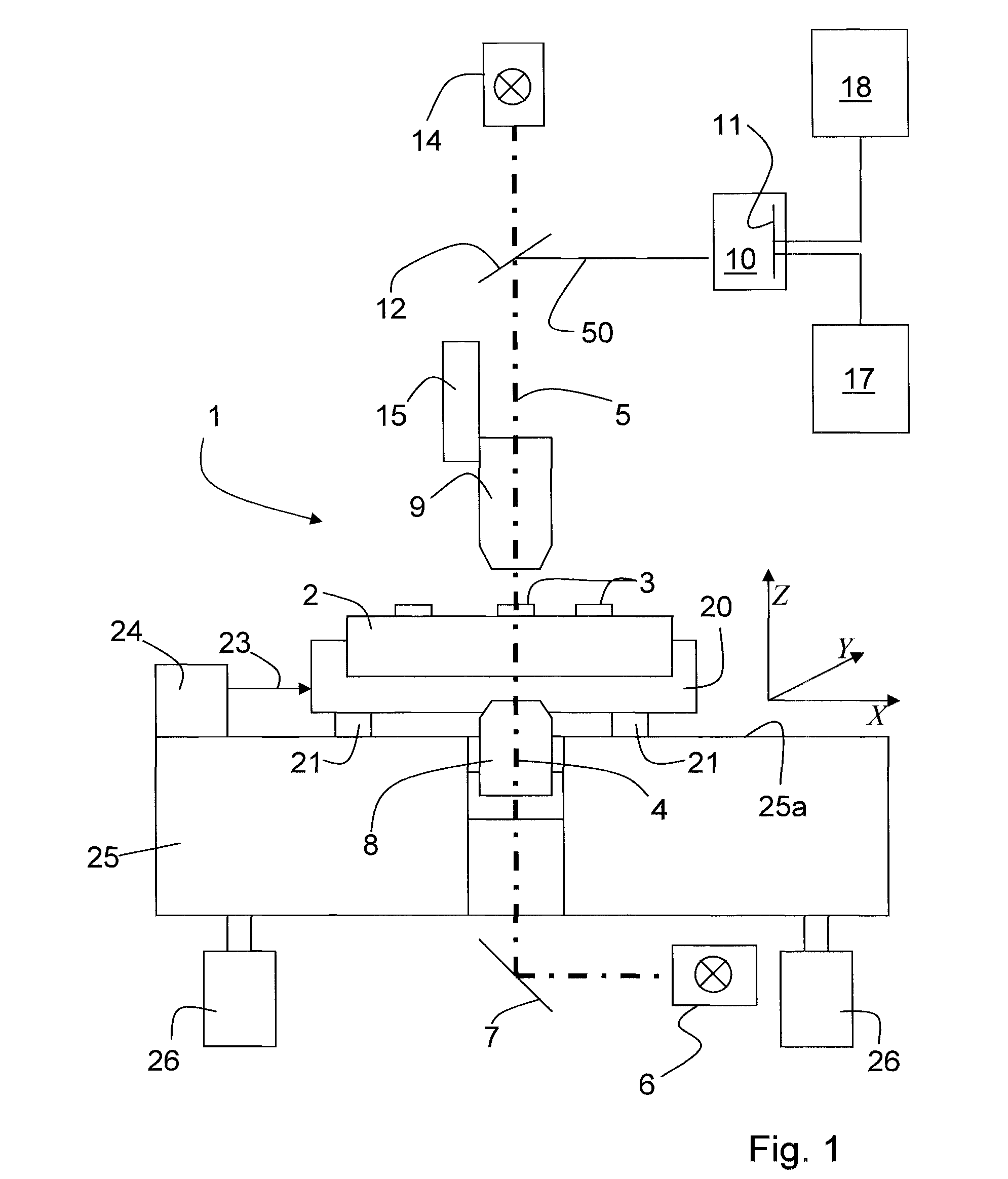

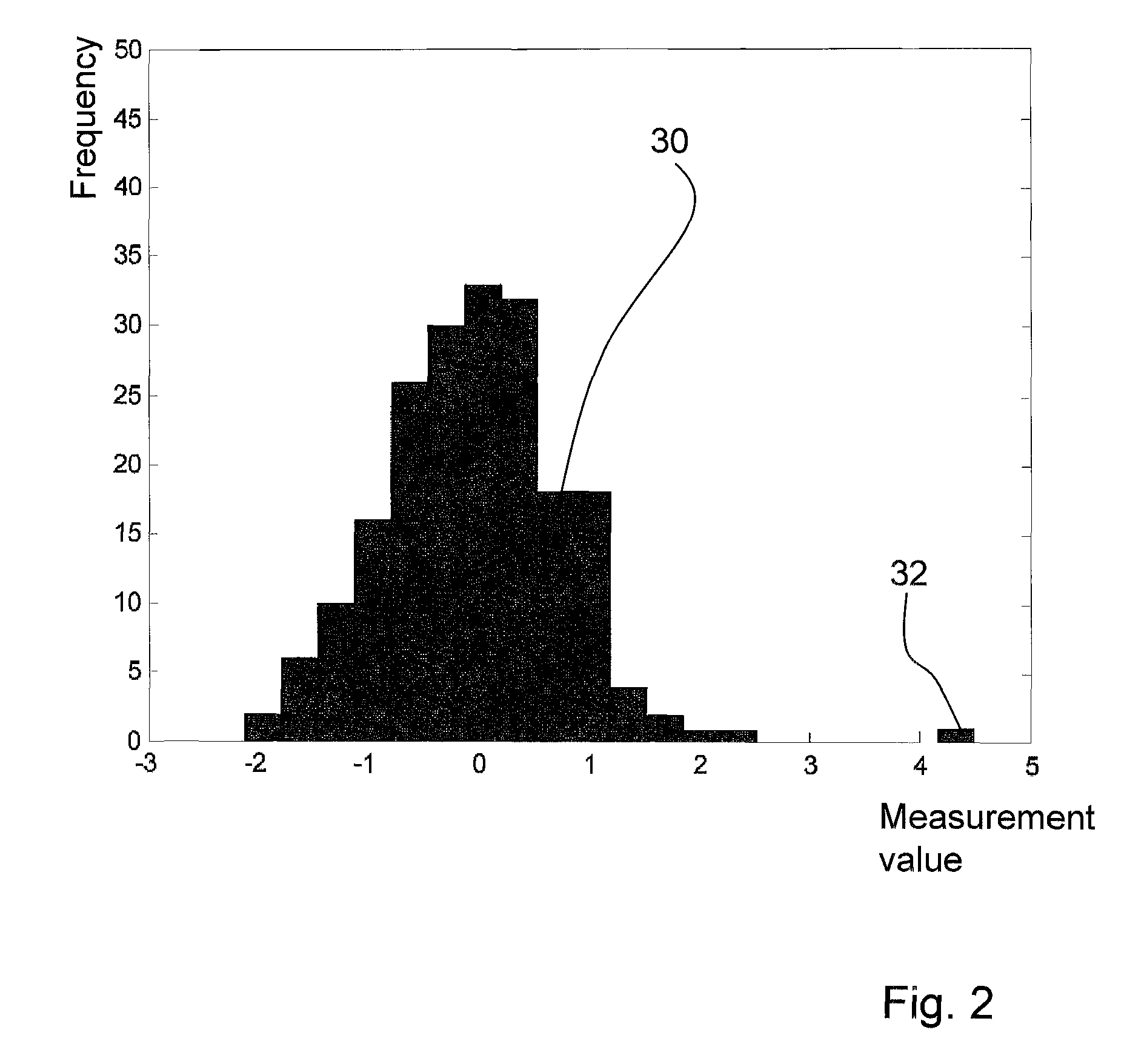

ActiveUS20080202201A1Solving precise measurementsReduce throughputElectric discharge tubesMaterial analysis by optical meansImage structureAutomatic testing

What is disclosed is a device (1) for automatic detection of a possible incorrect measurement, wherein the device (1) comprises at least one reflected light illumination apparatus (14) and / or a transmitted light illumination apparatus (6) and at least one imaging optical system (9) and one detector (11) of a camera (10) for imaging structures (3) on a substrate (2), wherein a first program portion (17) is linked to the detector (11) of the camera (10), said detector being provided for determining the position and / or dimension of the structure (3) on the substrate (2), wherein the device (1) determines and records a plurality of measurement variables Mj, j ε {1, . . . , L}, from which at least one variable G can be determined, wherein a second program portion (18) is linked to the detector (11) of the camera (10), said program portion calculating an analysis of the measurement variables Mj with regard to a possible incorrect measurement. Also disclosed is a method for automatic detection of a possible incorrect measurement wherein an analysis of the measurement variables Mj with regard to a possible incorrect measurement is calculated with a second program portion (18) which is linked to the detector (11) of the camera (10).

Owner:VISTEC SEMICON SYST JENA

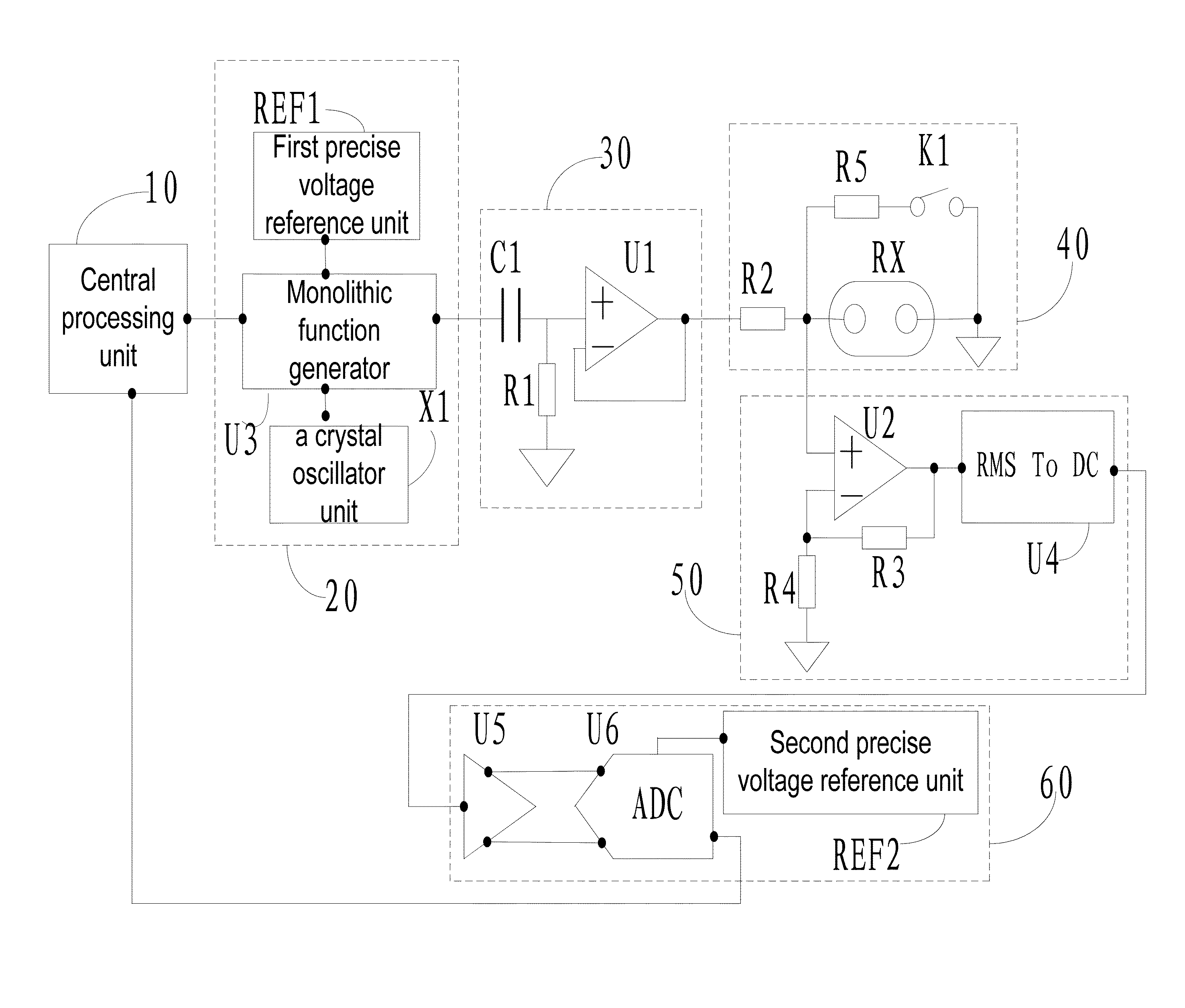

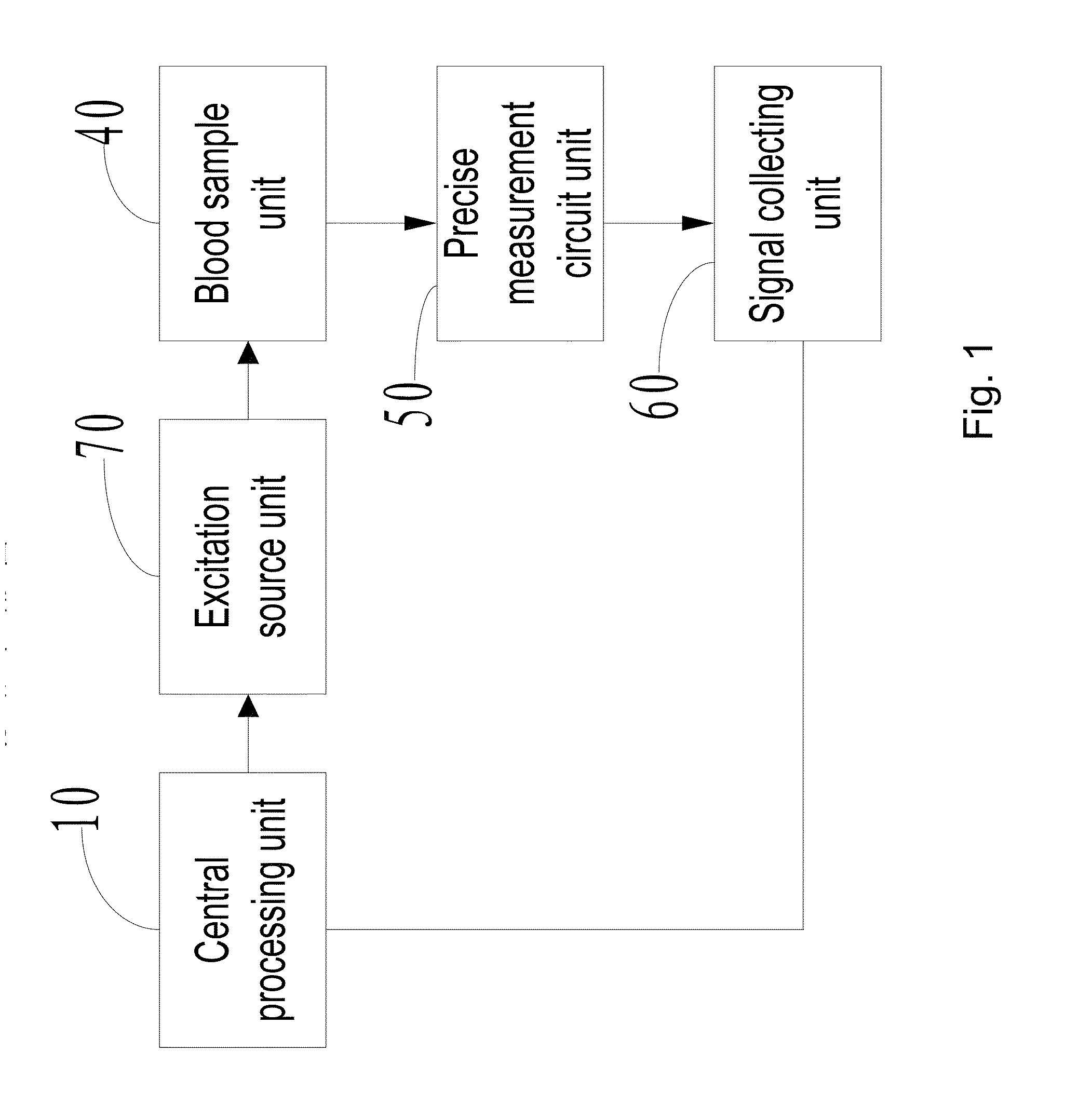

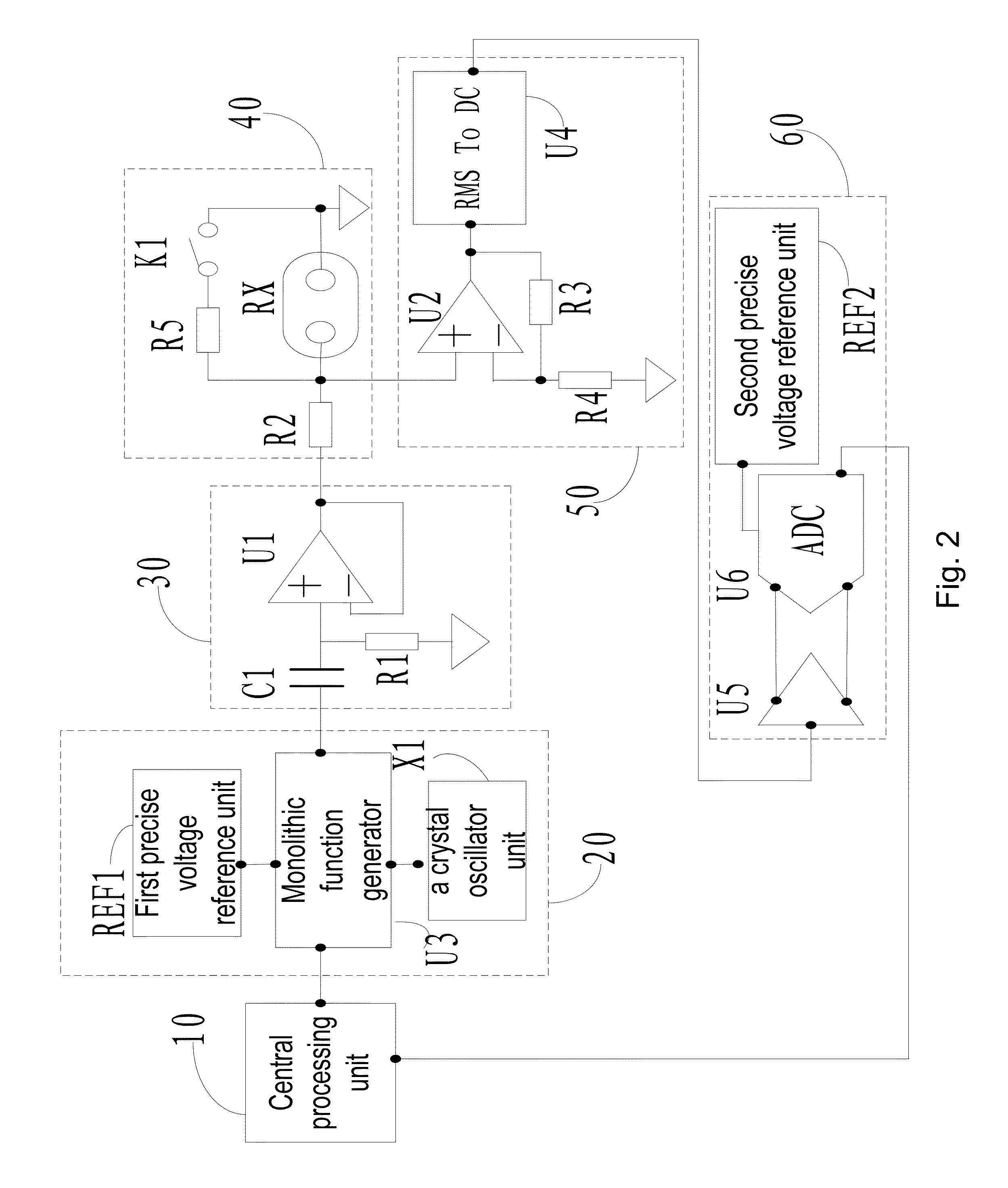

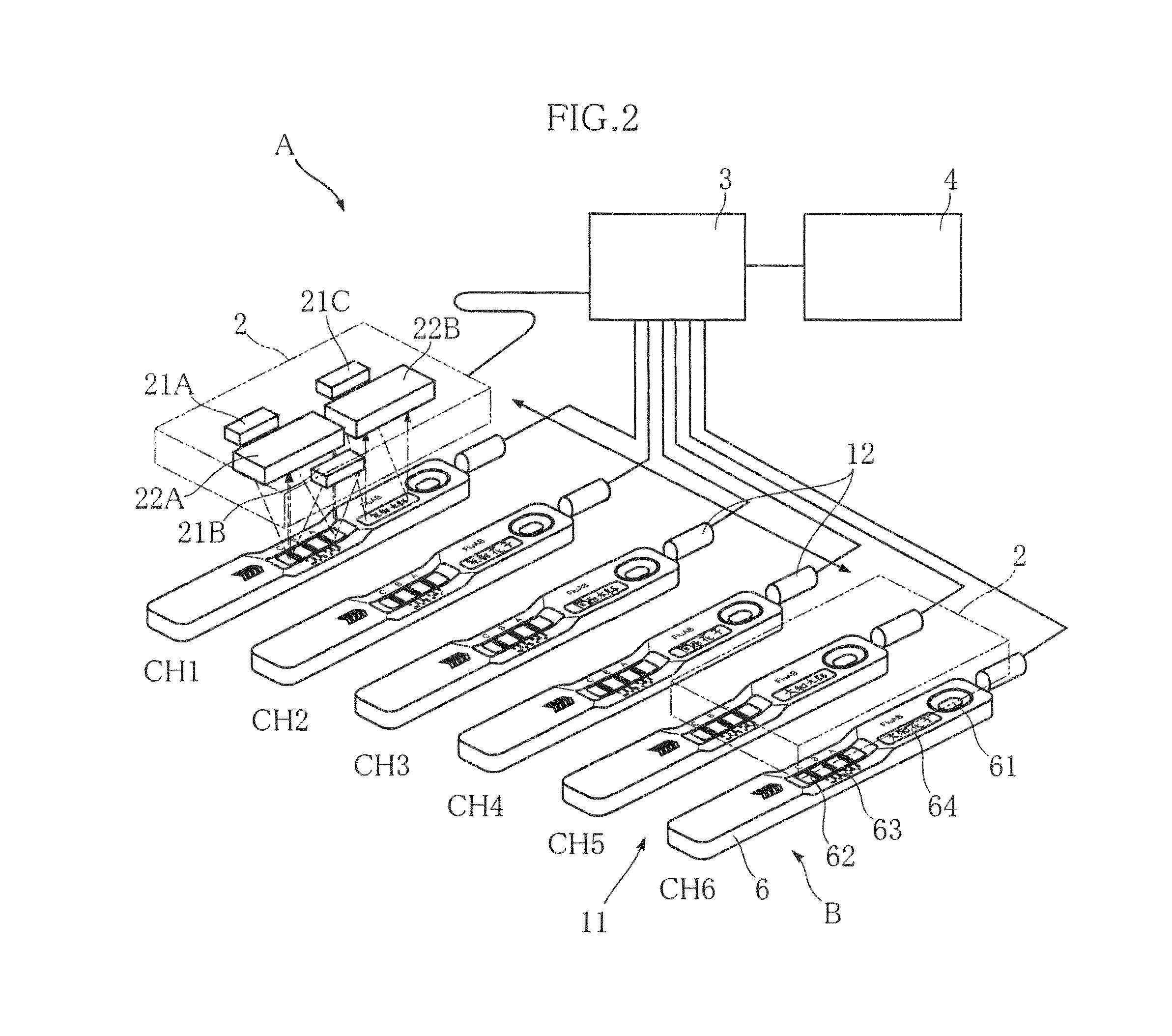

Detection system for improving accuracy of hematocrit measurement and operation control method

InactiveUS20160091408A1Accurate measurementEasy to measureResistance/reactance/impedenceDiagnostic recording/measuringHematocrit MeasurementEngineering

The present invention relates to a detection system for improving accuracy of hematocrit measurement and an operation control method. The detection system for hematocrit measurement comprises a central processing unit, an excitation source unit, a blood sample unit, a precise measurement circuit unit and a signal collecting unit. The present invention has the beneficial effects that the HCT measurement precision is improved by generating a sine wave by the excitation source unit and performing control by the central processing unit; the detection system of the present invention is simple and reliable, and implements precise measurement; and the measurement precision in the present invention is far greater than that of a conventional measurement technology and can be within 0.2%. Furthermore, due to a self-detection function, the measurement is quite reliable without the risk of resulting incorrect measurement data from a circuit failure.

Owner:EDAN INSTR

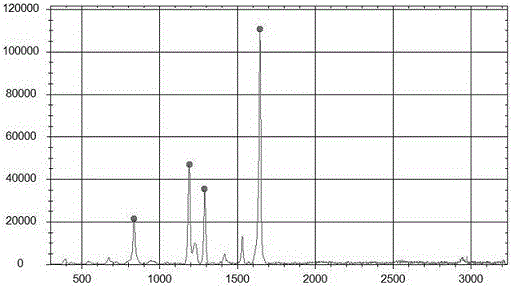

Method for rapidly detecting paraquat by utilizing Raman spectrometry

The invention relates to a method for rapidly detecting paraquat by utilizing Raman spectrometry and in particular relates to application to rapid detection of environments and foods. Specifically, the method comprises the following steps: taking silver nano-sol as a Raman detection enhancing agent; mixing one volume of the silver nano-sol with four volumes of a solution to be detected; rapidly determining a Raman signal under low power; realizing qualitative and quantitative detection on the paraquat according to preferable characteristic peak positions and strength. Photochemical reaction is effectively avoided under preferable testing conditions of low-power laser effect and no chlorine addition, so that the content of the residual paraquat in actual environment water bodies and foods is rapidly, accurately and conveniently determined; meanwhile, incorrect measurement is effectively avoided through a preferable characteristic peak combination; the method is especially suitable for being matched with a realization scene of a handheld Raman analyzer and outdoor real-time analysis.

Owner:南京简智仪器设备有限公司

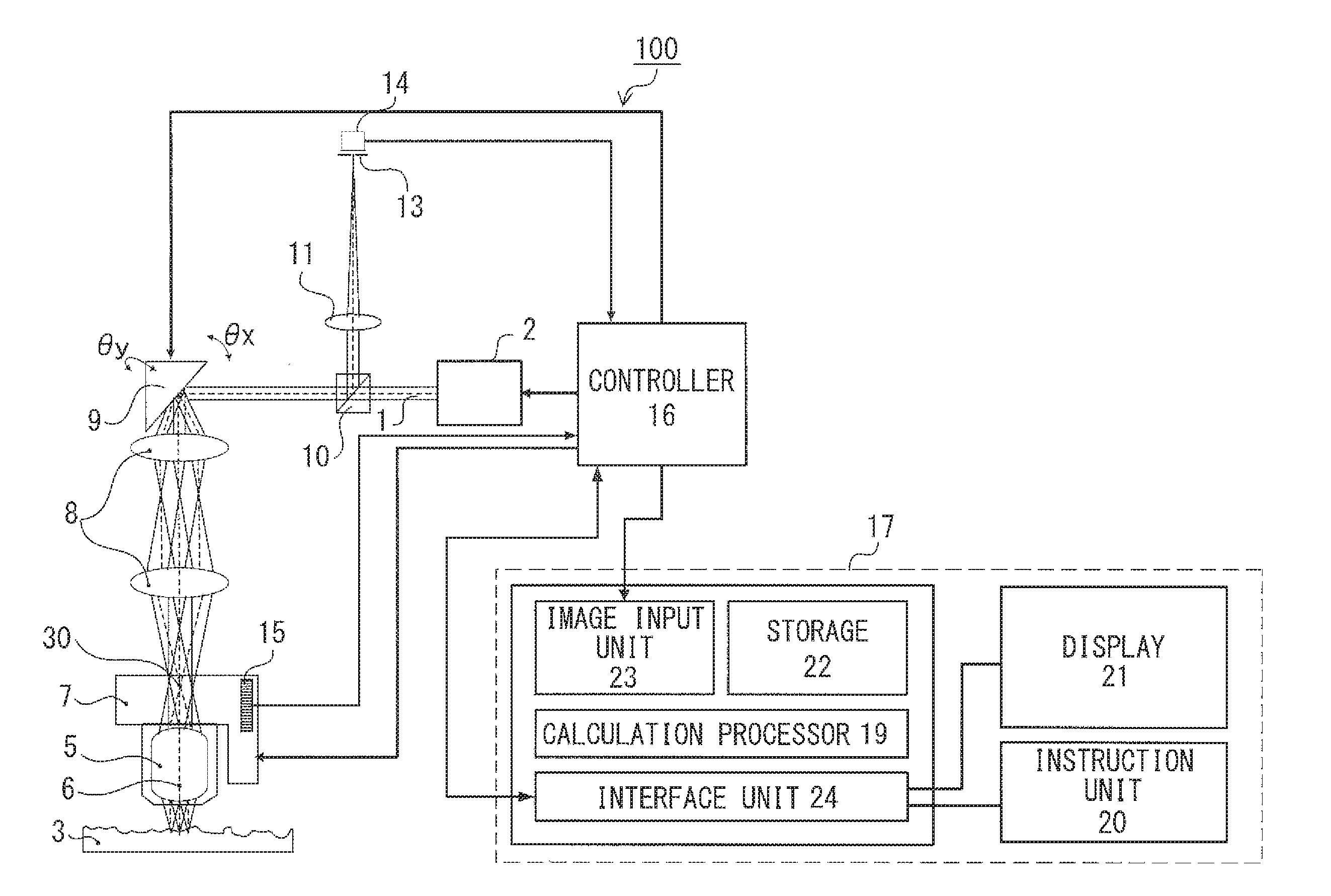

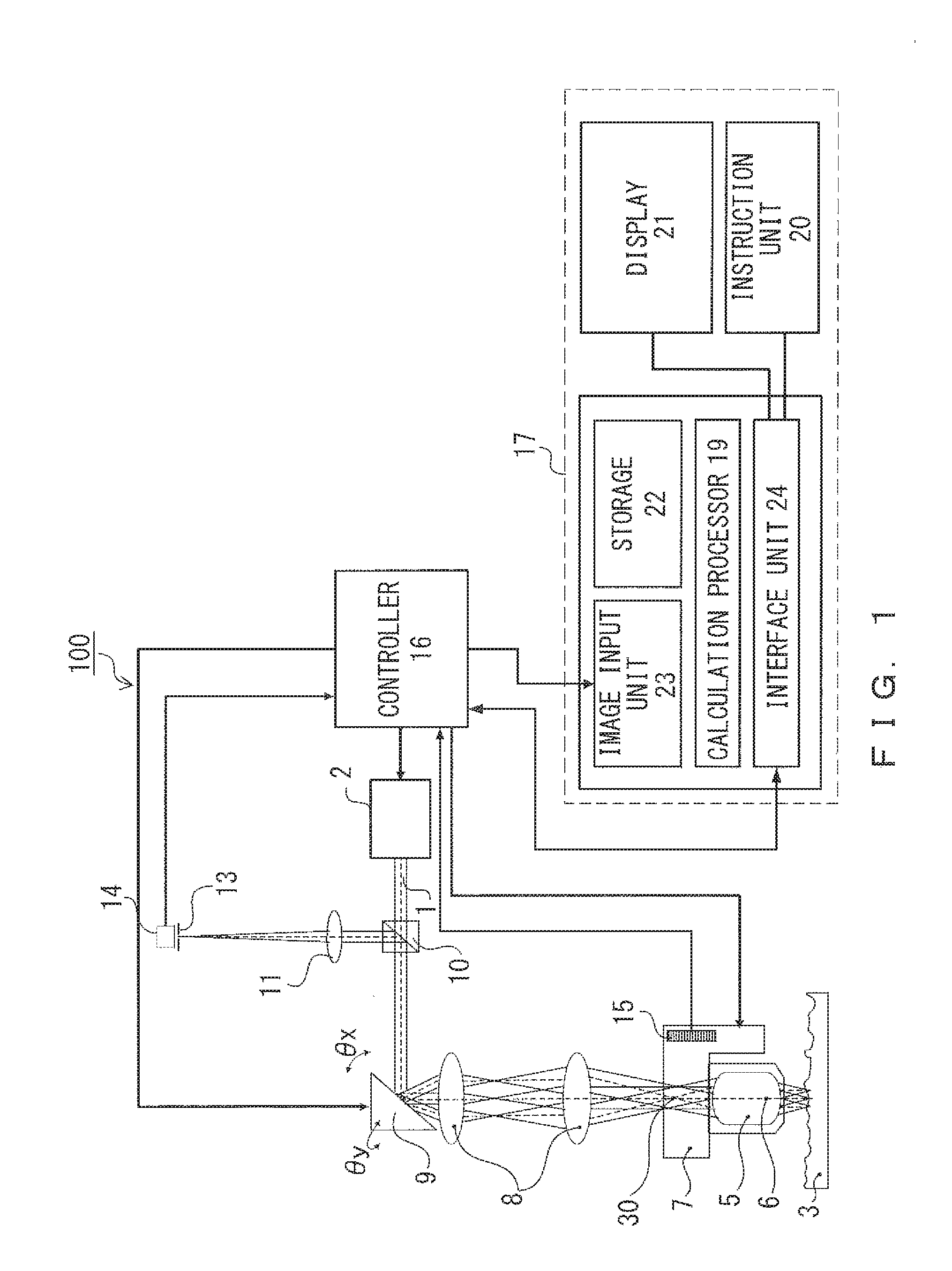

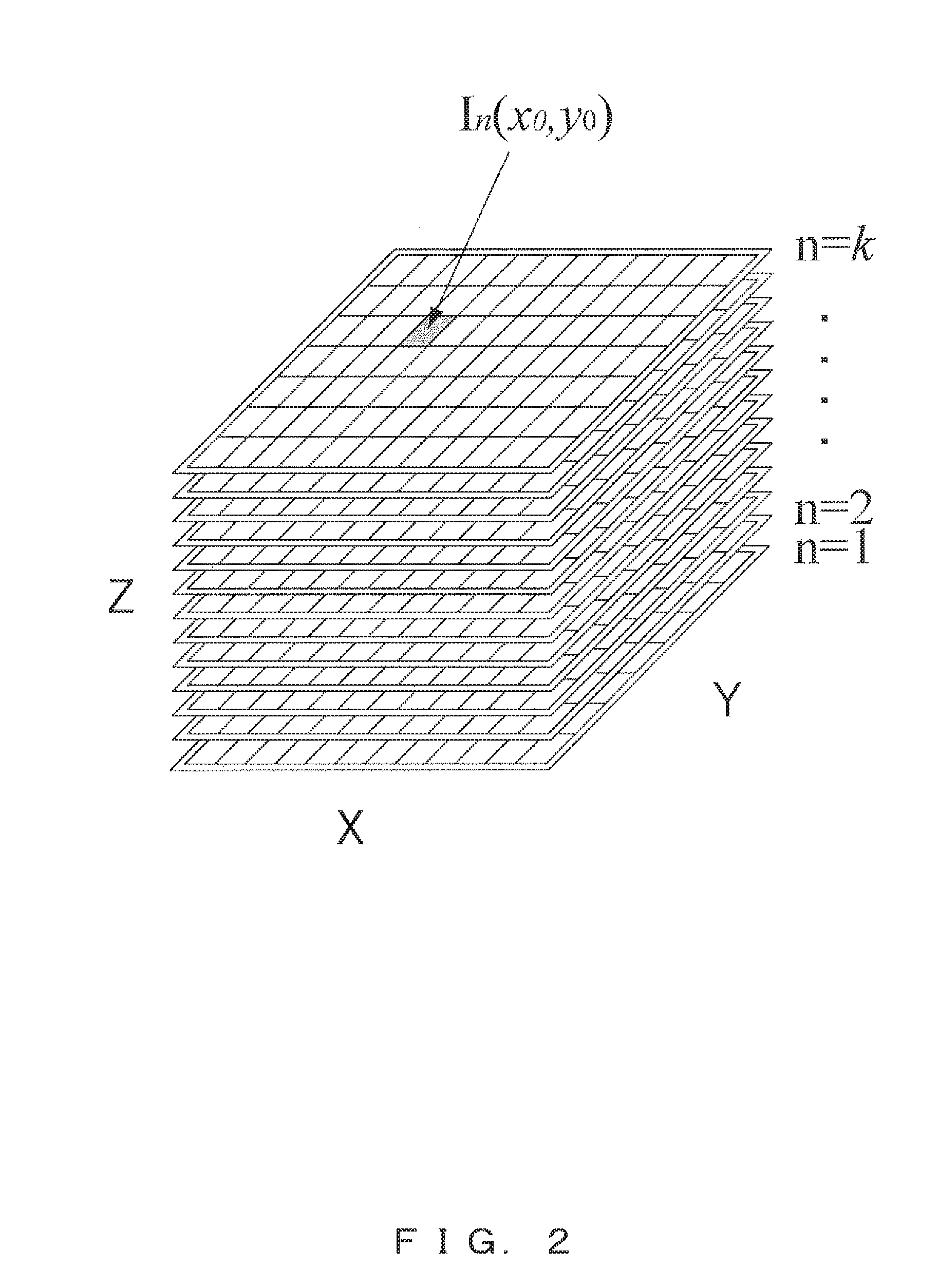

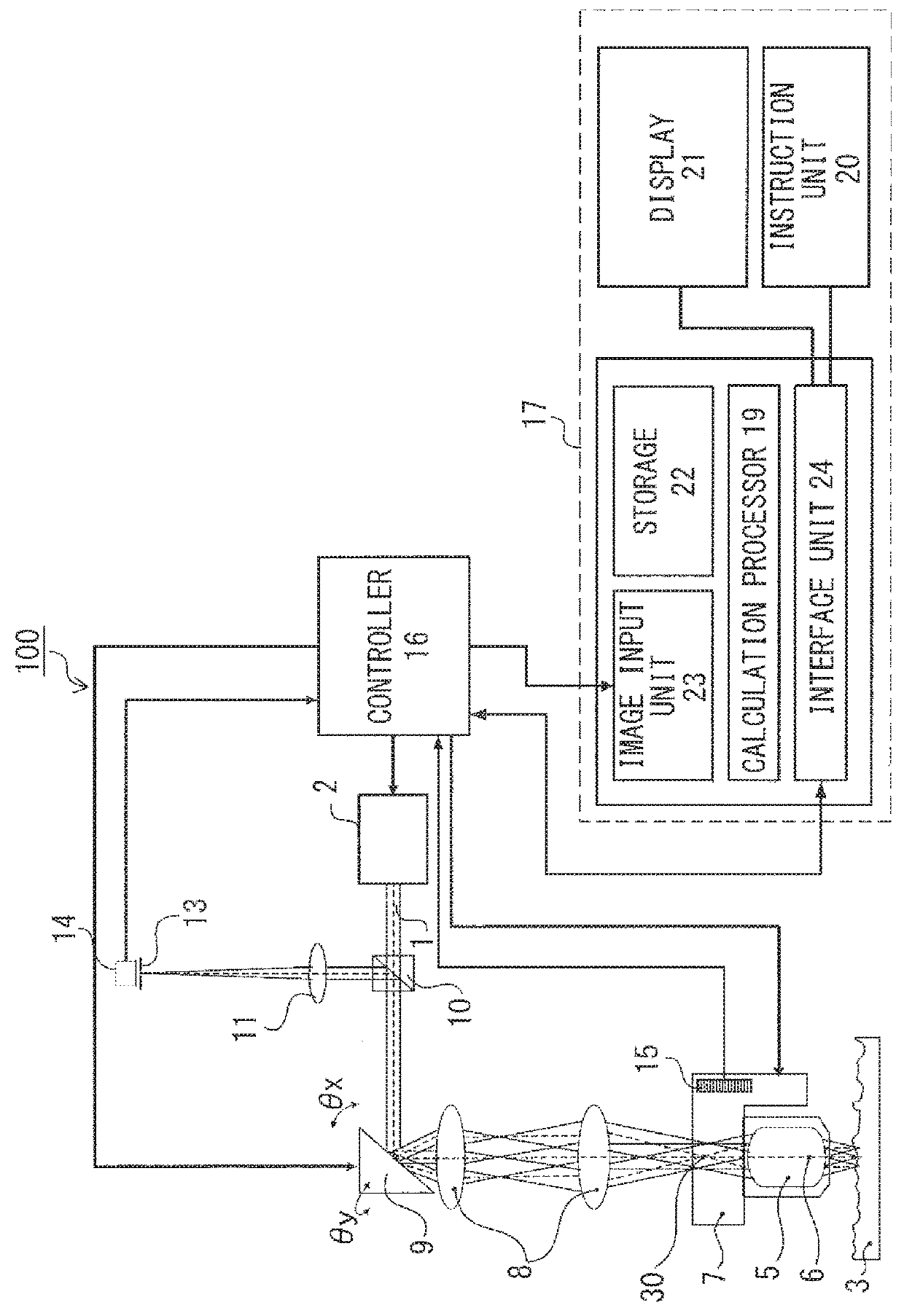

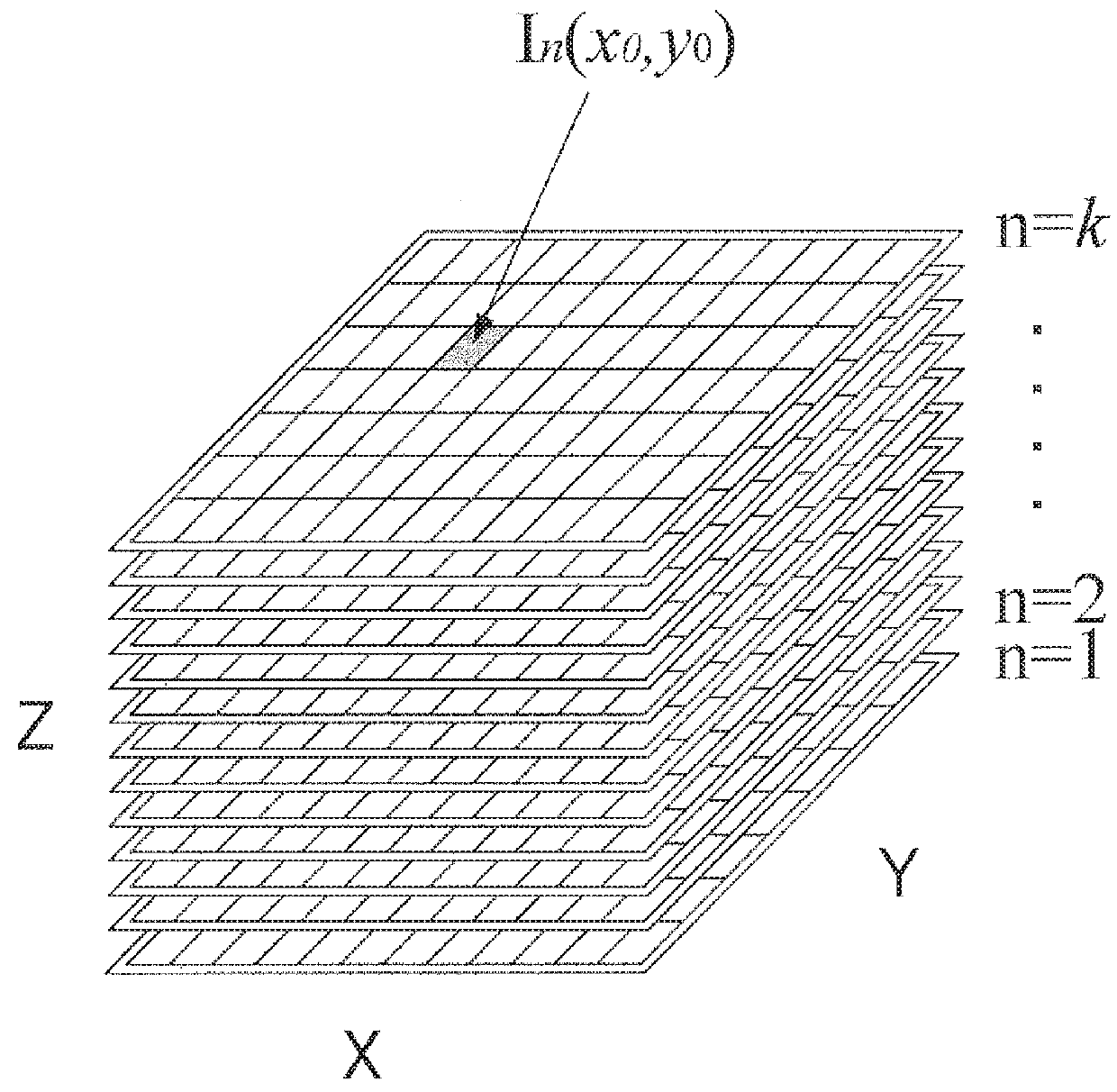

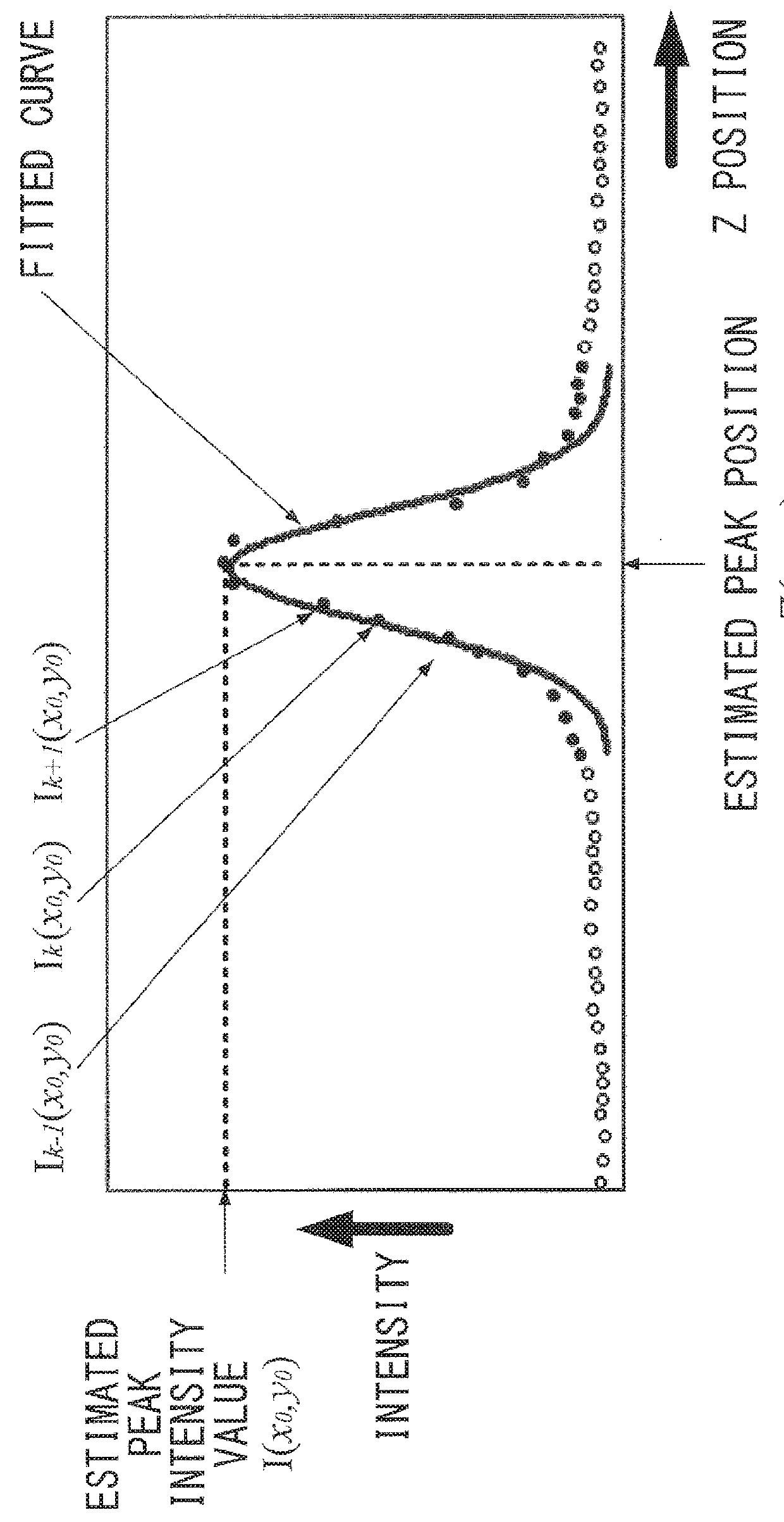

Three-dimensional shape measurement apparatus

A technology is provided that makes it possible for even a beginner to determine whether a measurement result is correct, to thereby prevent the use of incorrect measurement data, and to improve the reliability of an analysis result. In a three-dimensional shape measurement apparatus 100 that measures a three-dimensional shape of a specimen 3 in a non-contacting manner, a score that evaluates the reliability of measurement data is calculated for each measurement point by use of information obtained during a process of estimating the height of the specimen 3 or the estimated height. Measurement data is processed according to a result of evaluating the measurement data for each measurement point by use of the score.

Owner:EVIDENT CORP

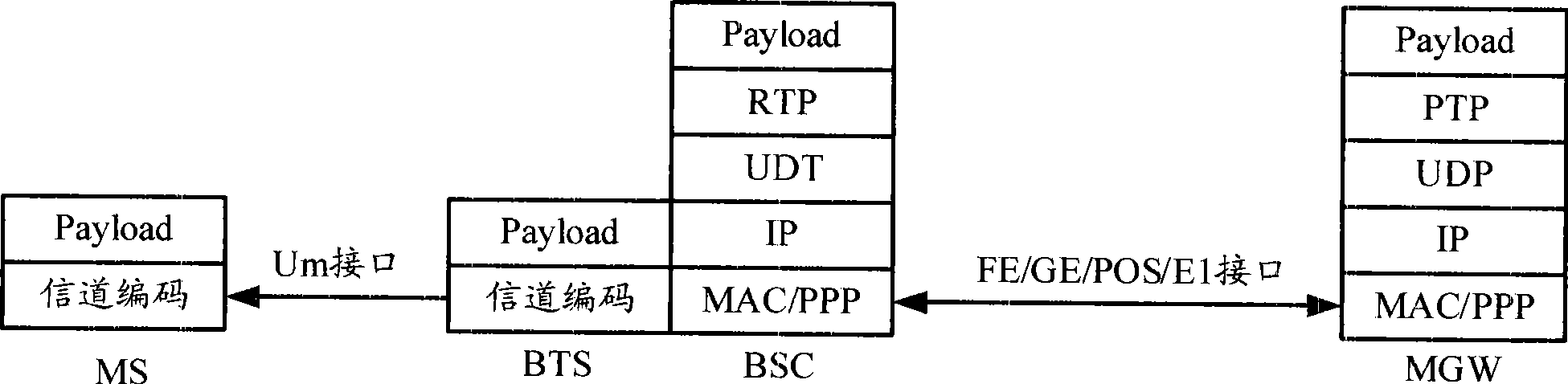

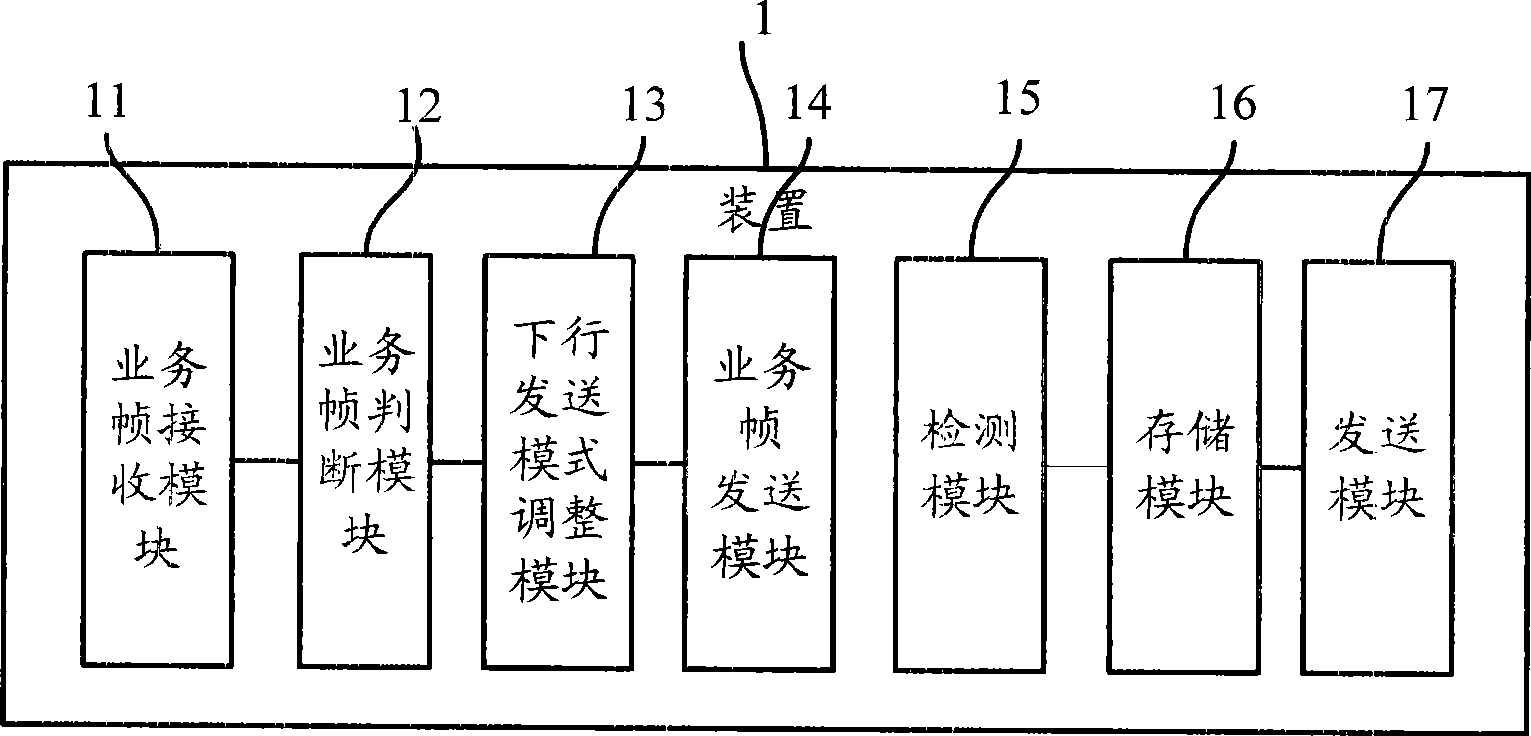

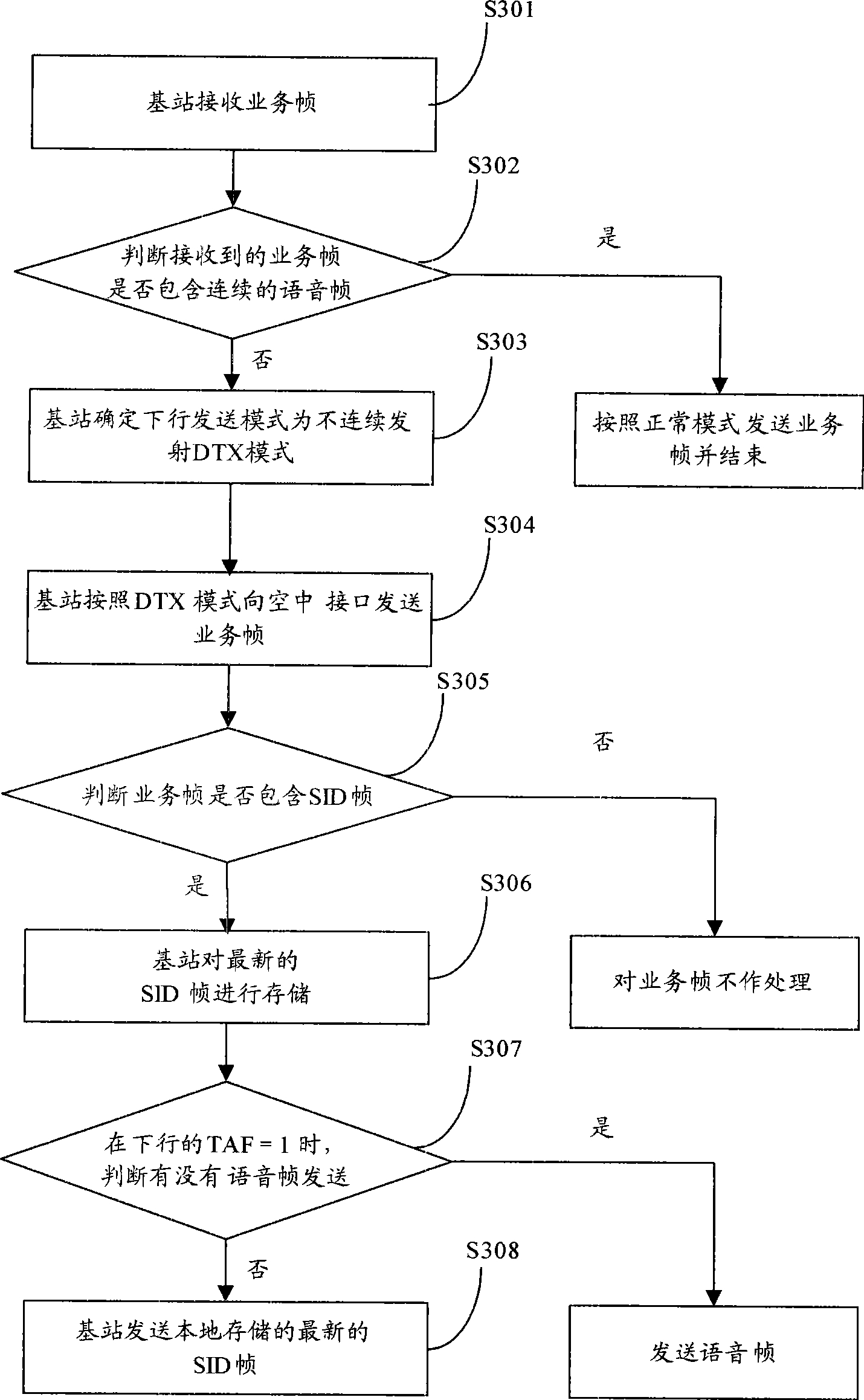

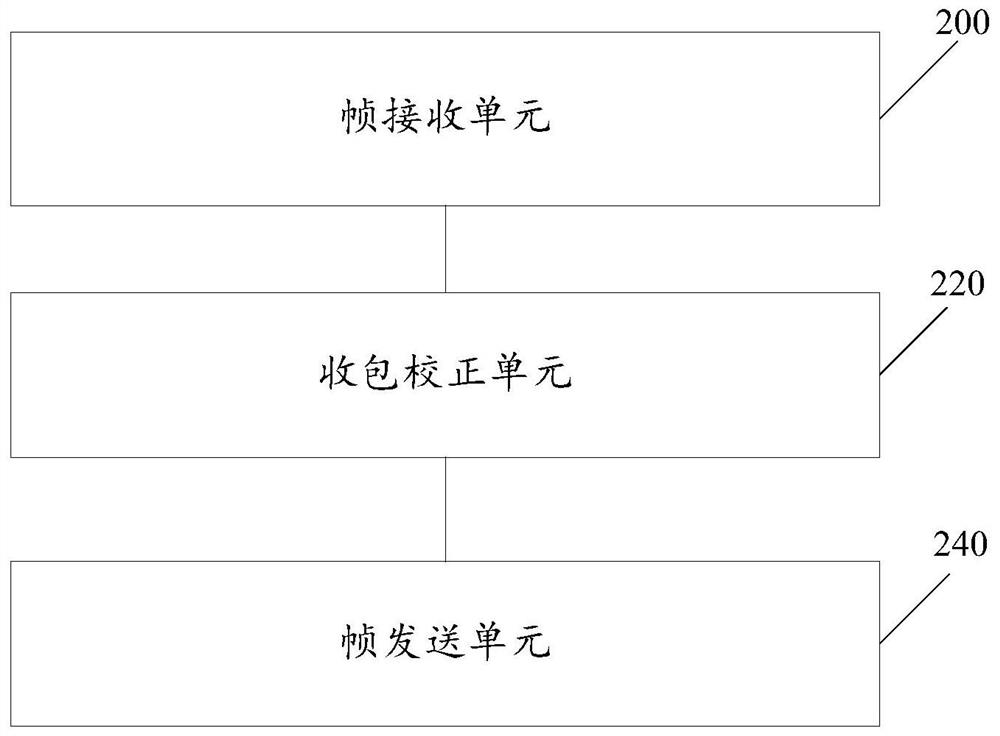

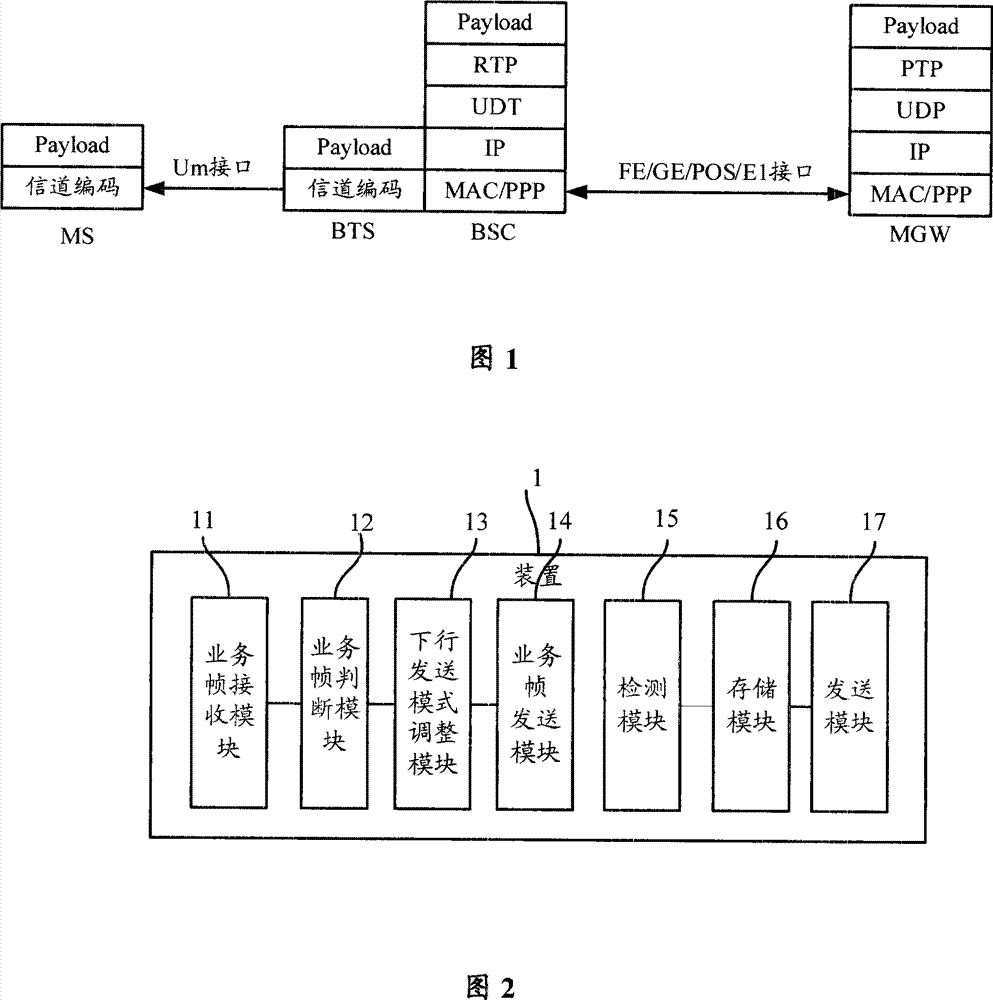

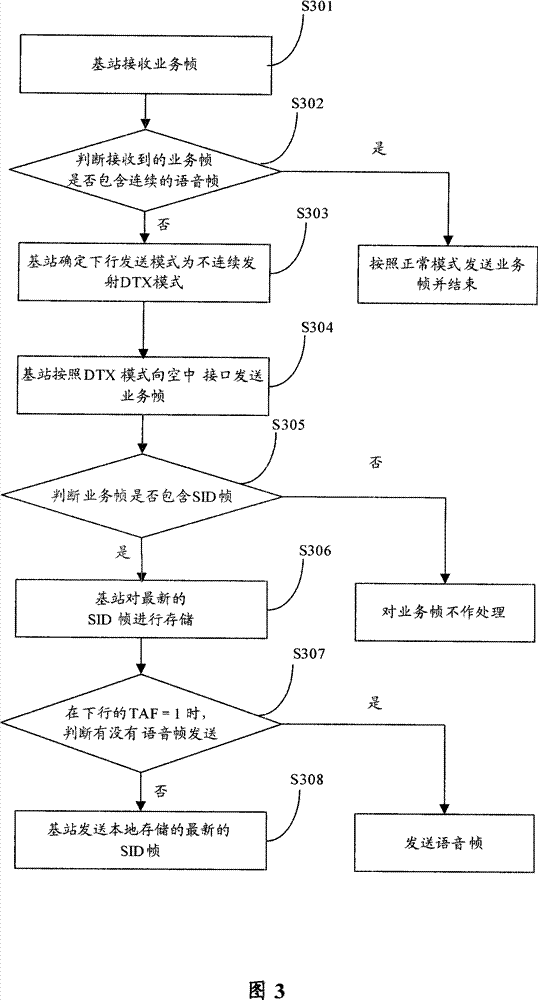

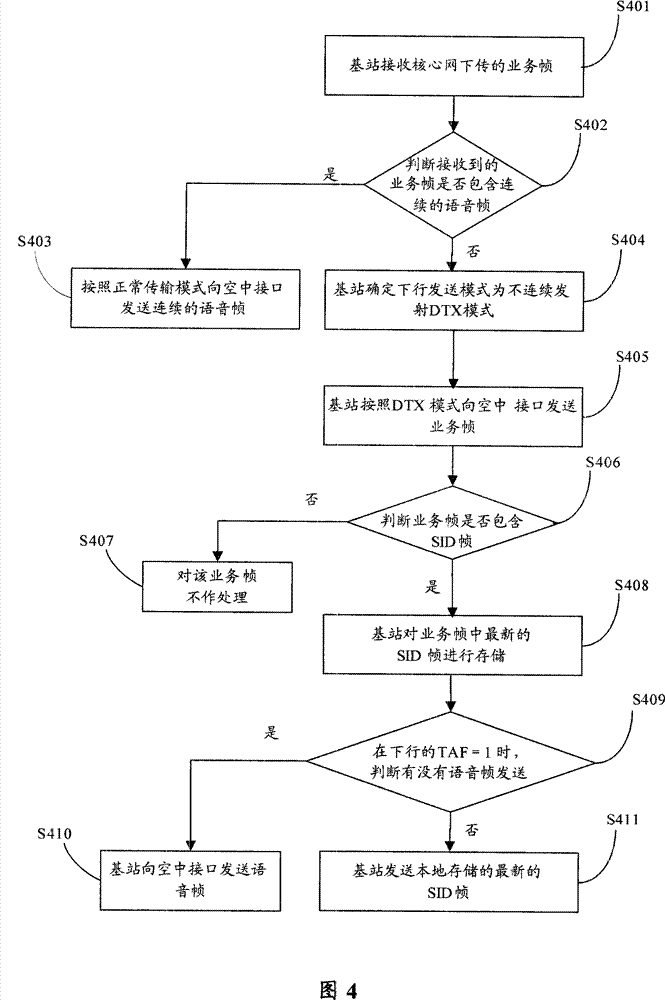

Service frame sending method and device

InactiveCN101394224AInterconnection arrangementsRadio transmission for post communicationComputer scienceIncorrect Measurement

The invention discloses a method for sending service frames, which comprises the following steps: a home terminal base station receives the coming service frame; and the home terminal base station stores the SID frame when the service frame includes a mute-described SID frame, and the home terminal base station sends the latest stored local SID frame when that no voice frame is sent at the pre-set time is determined. By applying the method provided by the embodiment of the invention, the latest local SID frame stored in the base station can be sent even when no voice frame is sent at the timethat the downlink TAF is 1 when an interface A carries out the voice transmission by utilizing an IP protocol, thereby solving the problems that MS downlink measurement is incorrect and the mute can not be recovered timely.

Owner:HUAWEI TECH CO LTD

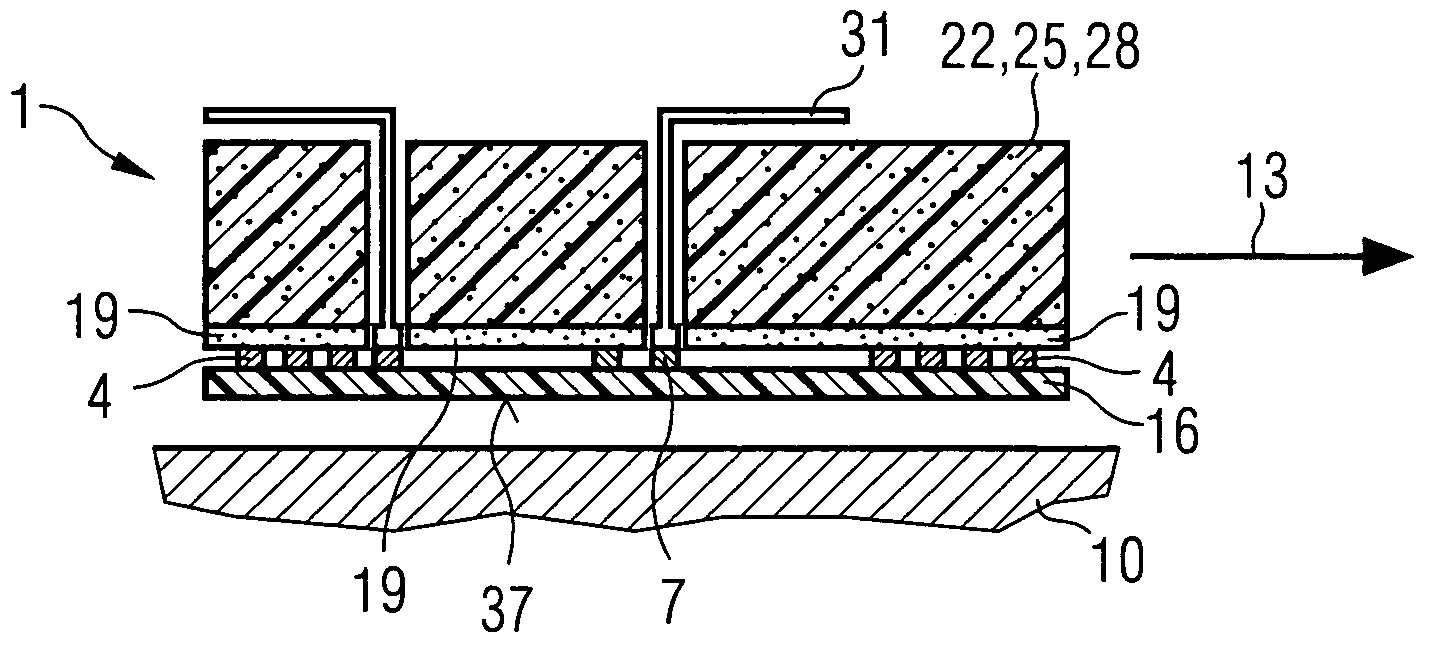

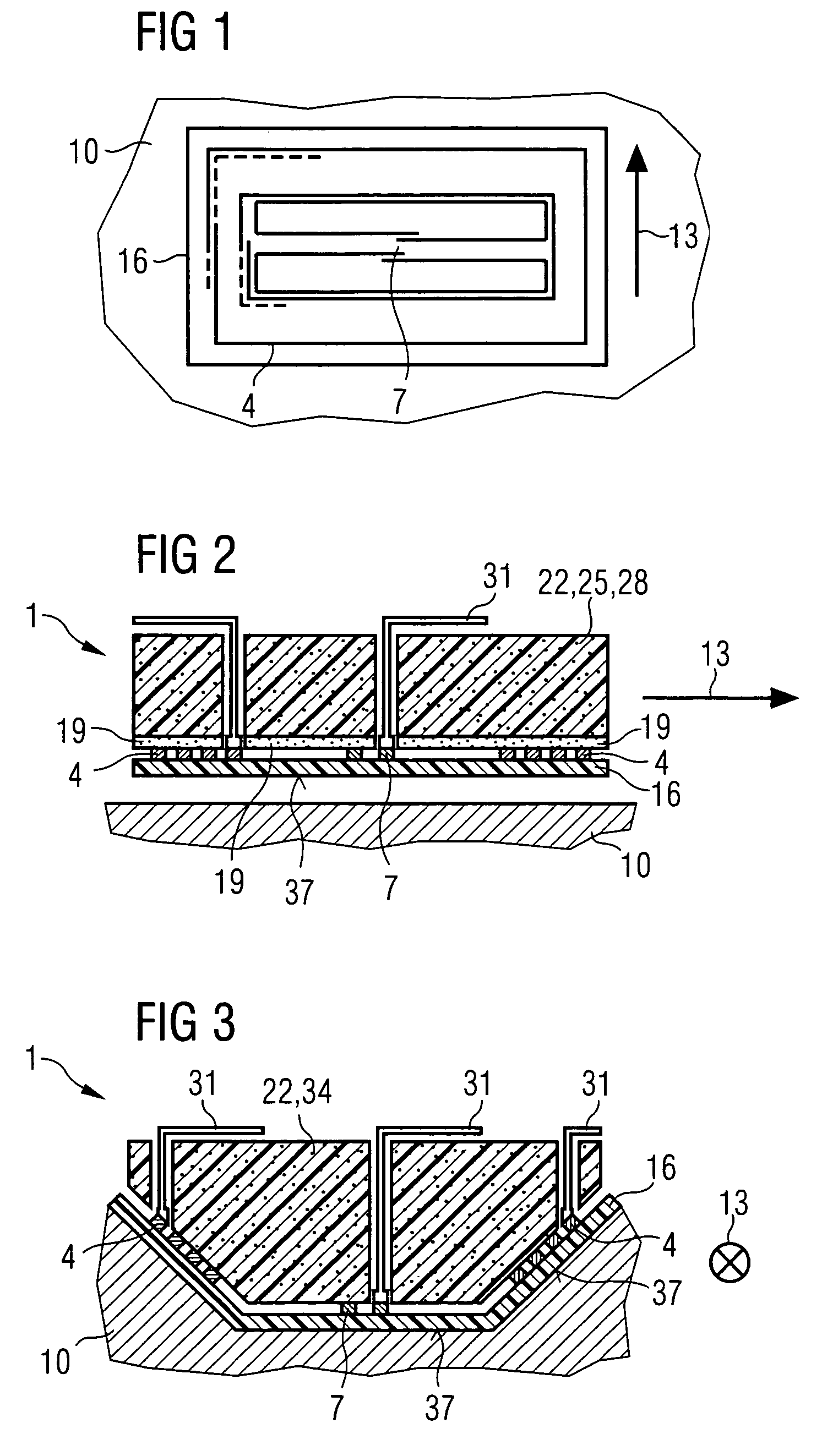

Probe for electrical measurement methods, especially eddy current measurements

InactiveUS7463039B2Resistance/reactance/impedenceElectrical testingEddy currentBiomedical engineering

When using a rigid substrate eddy current probe to measure a non-planer test piece, the probe must be adapted to the test piece shape in order to avoid incorrect measurement values. Disclosed is a probe which is configured in a flexible manner via a flexible substrate so as to be adjustable to different radii of curvature of a test piece. Furthermore the probe lining is also embodied in an elastic manner.

Owner:SIEMENS AG

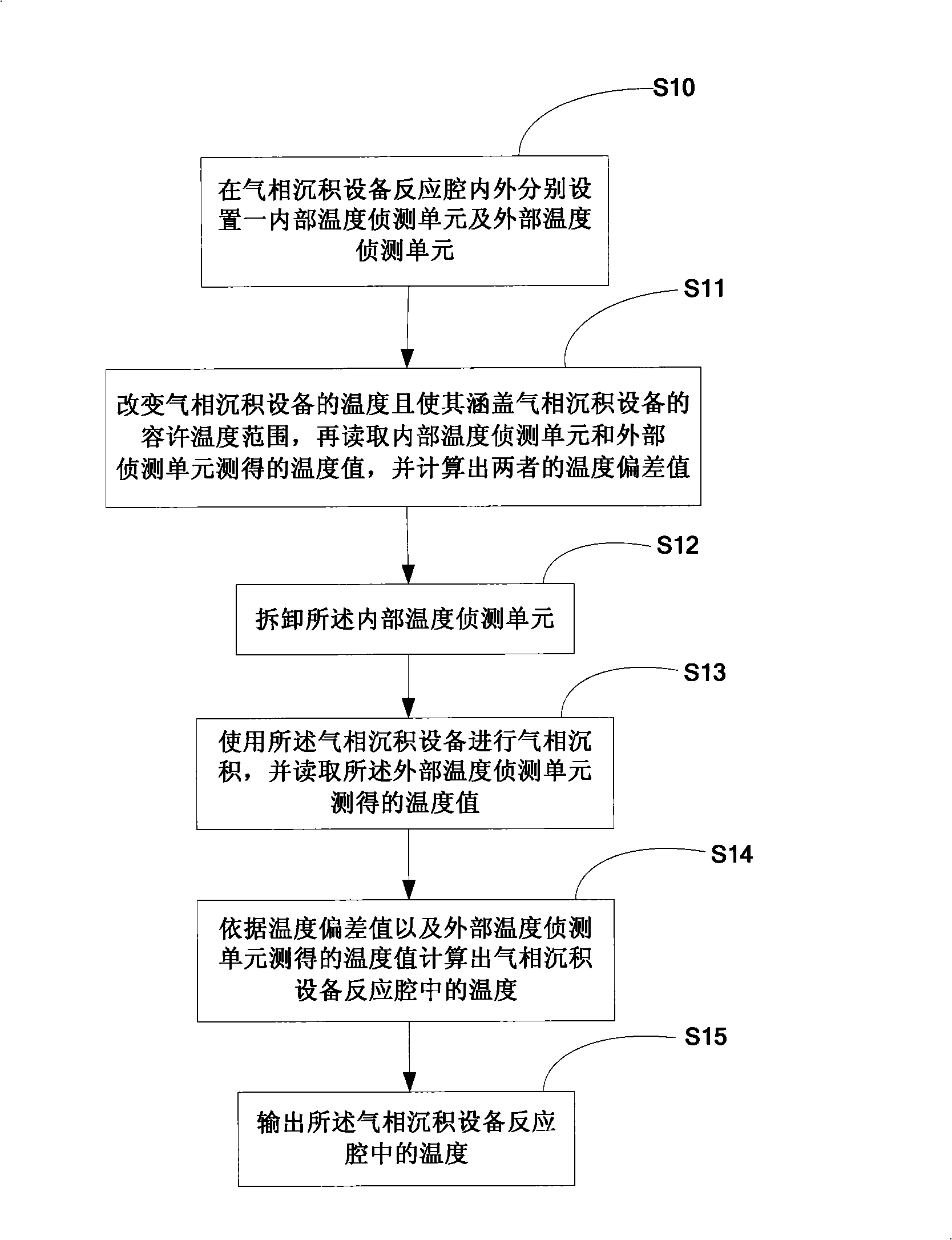

Process for measuring temperature of reaction chamber of vapor deposition equipment

InactiveCN101311304AAvoid events such as chipped wafersAccurate temperature measurementThermometer applicationsChemical vapor deposition coatingGas phaseEngineering

The invention provides a method for measuring the temperature of a reaction chamber of a vapor deposition device. The temperature of the reaction chamber is measured by arranging temperature detecting units inside and outside the reaction chamber respectively in the prior art, which has the problems of cost waste, incorrect measurement and hidden danger. The invention provides a temperature measuring method which includes that: an inner temperature detecting unit and an outer temperature detecting unit are respectively arranged inside and outside the reaction chamber of the vapor deposition device; then the temperature of the vapor deposition device is changed to cover the permitted temperature range of the vapor deposition device; then the temperature detected by the inner and outer temperature detecting units is read and the temperature deviation value of the inner temperature and the outer temperature is calculated; then the inner temperature detecting unit is dismounted, vapor deposition is carried out again by the vapor deposition device, and then the temperature detected by the outer temperature detecting unit is read; finally, the temperature of the reaction chamber of the vapor deposition device is calculated according to the temperature deviation value and the temperature detected by the outer temperature detecting unit. The method of the invention can measure the temperature of the reaction chamber safely and accurately with low cost.

Owner:SEMICON MFG INT (SHANGHAI) CORP

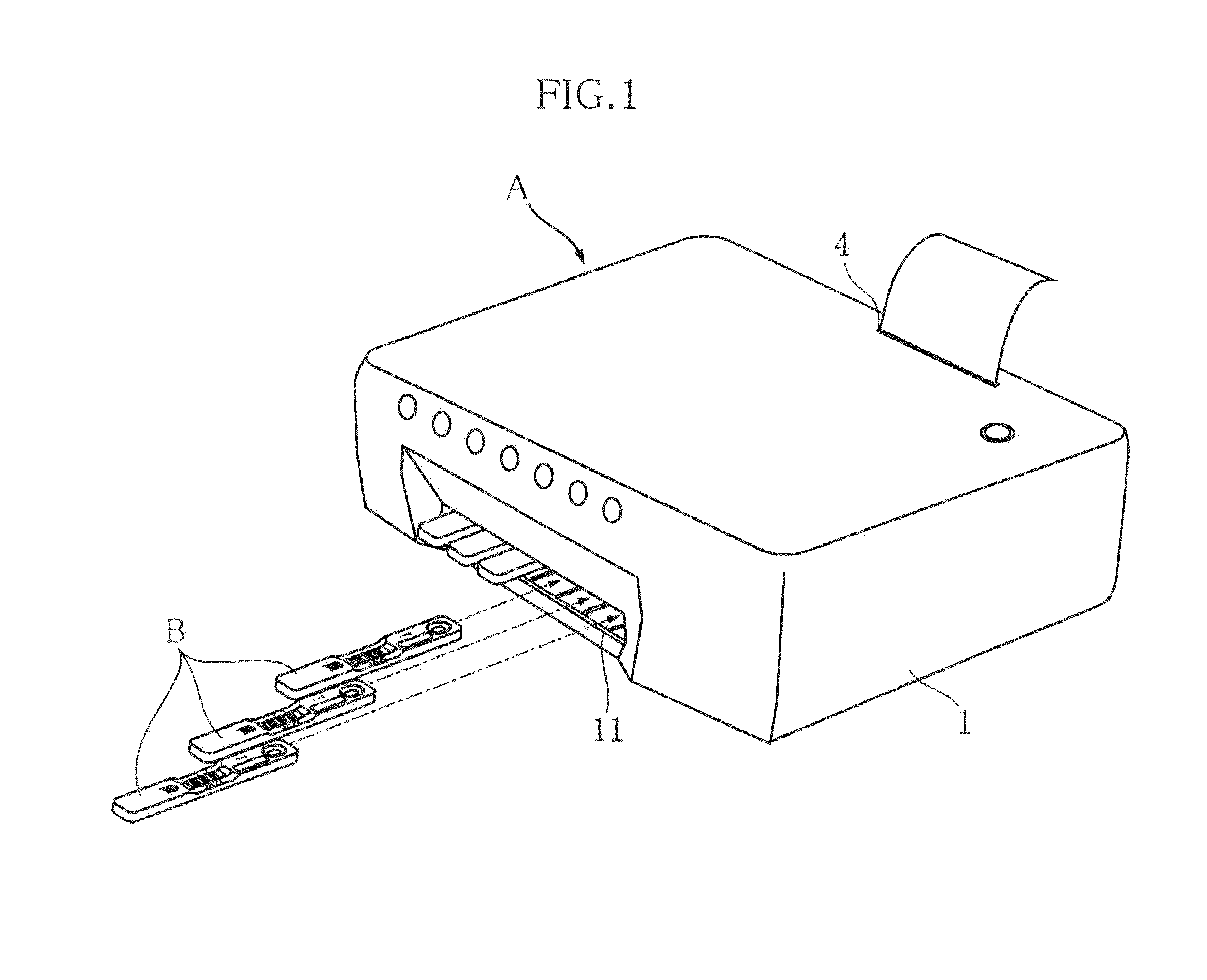

Optical measurement apparatus

ActiveUS9417235B2Effective performance testingAvoid testingBioreactor/fermenter combinationsBiological substance pretreatmentsMeasurement deviceEngineering

An object is to provide an optical measurement apparatus for performing an efficient test by optical measurement without incurring incorrect measurements.To this end, the measurement apparatus utilizes a test instrument mounted thereto and including a carrier with a reagent retaining portion for application of a sample. The measurement apparatus includes a reader for color development at the reagent retaining portion, and a controller for driving control of the reader and for required determination. The controller performs the determination by utilizing the data obtained by reading the color development of the reagent after a reaction completion period Tr1-Tr6 depending on the reagent and starting from the mounting of the test instrument. When detecting that the color development at the reagent retaining portion is completed before the lapse of the reaction completion period Tr1-Tr6 after the mounting of the test instrument, the controller stops the test for the test instrument.

Owner:ARKRAY INC

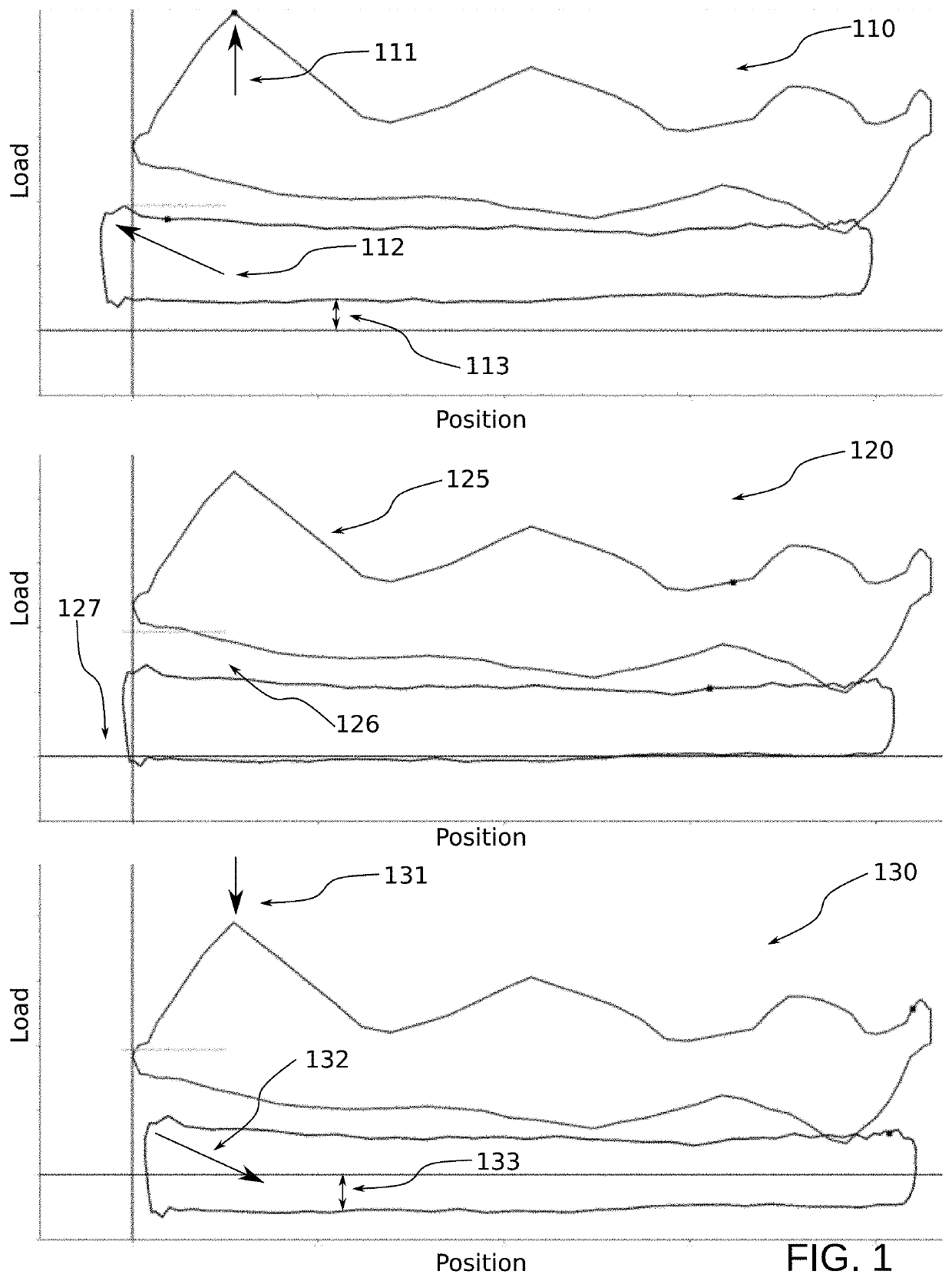

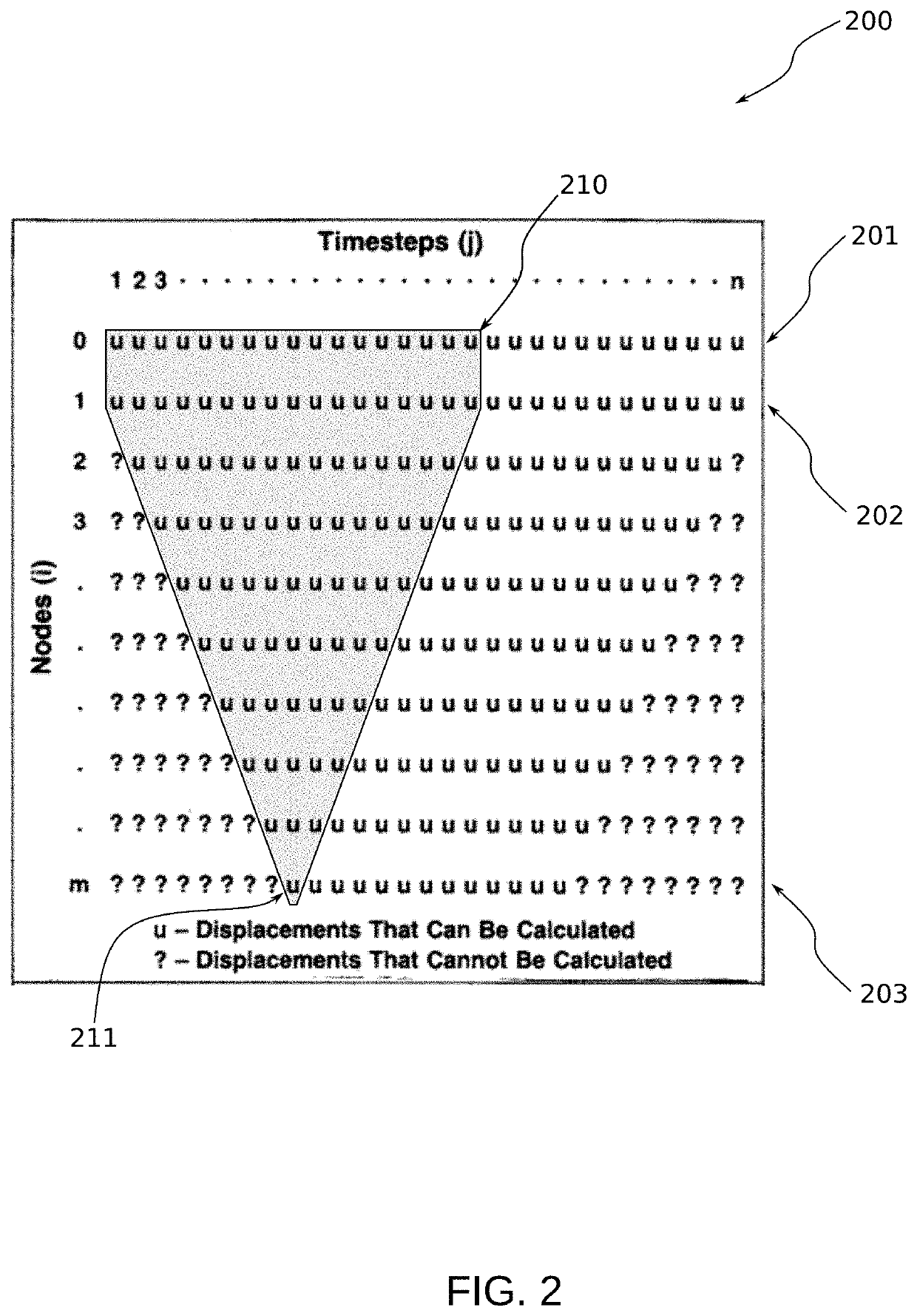

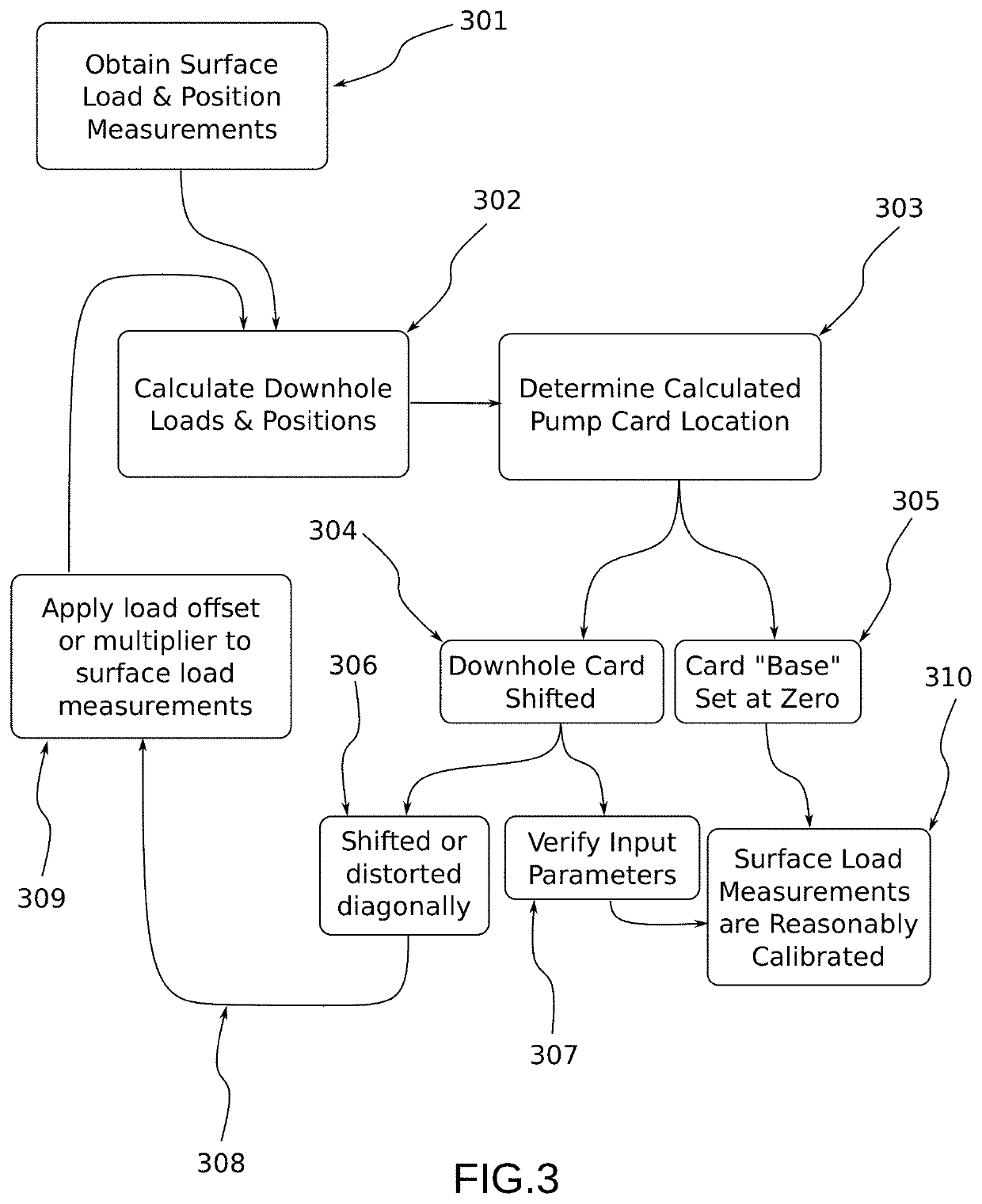

Dynamic Pumpjack Load Verification

ActiveUS20200386092A1Accurate measurementEasy to diagnose fluid densityConstructionsFluid removalSimulationControl theory

A properly calibrated load-cell is critical for the safe operation of a rod-pumping system. Load readings are utilized for shutdown thresholds, and incorrect measurements can cause those safe load limits to be exceeded. Correct surface load, combined with position measurement, is also important for the diagnosis of the complete pumping system. The diagnostic method for calculating down-hole conditions presents an interesting opportunity to validate surface load measurements, even from the incorrect load measurements themselves. The calculated down-hole dynamometer card will be transposed on a distinct diagonal with respect to both load and position, if the input surface load measurements are incorrect. A load offset can then be identified from this shifting and the surface load measurements can be corrected. Calculated pump cards have been traditionally aligned with the surface dyno card position, and so this diagonal pump card shifting correlation with incorrect, or unexpected, surface load has not been realized.

Owner:PHILLIPS WALTER

Device for monitoring blood vessel conditions and method for monitoring same

ActiveUS9060687B2Easily and daily monitorDiagnostics using lightDiagnostics using fluorescence emissionDiabetes mellitusMedicine

The present invention detects a fluorescent signal from AGEs at a blood vessel tissue of an individual to determine the condition of the tissue of the individual. This solves a problem that in measurement of AGEs used in diagnosis of diabetes, data indicative of fluorescent spectrum from AGEs at the skin of a forearm varies depending on where to measure on skin of even the same forearm, which results in variations in measurement values, leading to unreliable data and incorrect measurement result.

Owner:SHARP LIFE SCI CORP

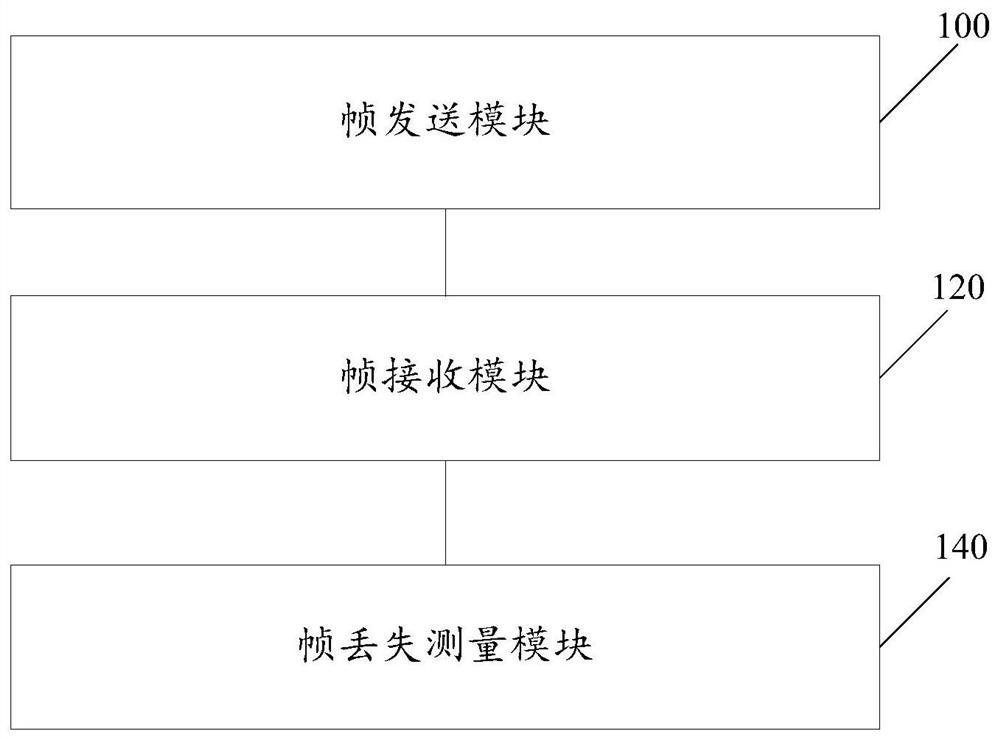

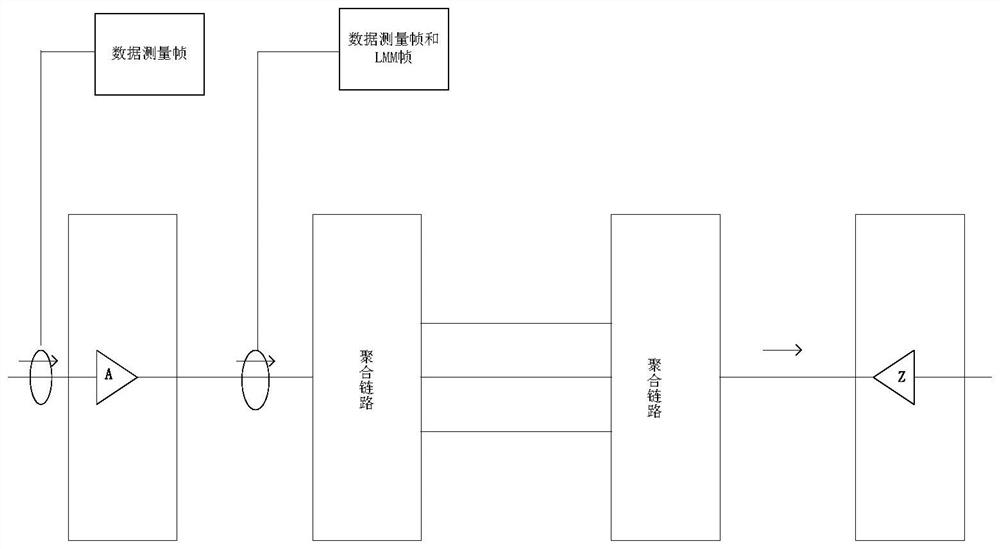

Aggregation link frame loss measuring device and method

ActiveCN107864026BTroubleshoot missing measurement inaccuraciesImprove accuracyTransmitted data organisation to avoid errorsControl theoryComputer science

Owner:ZTE CORP

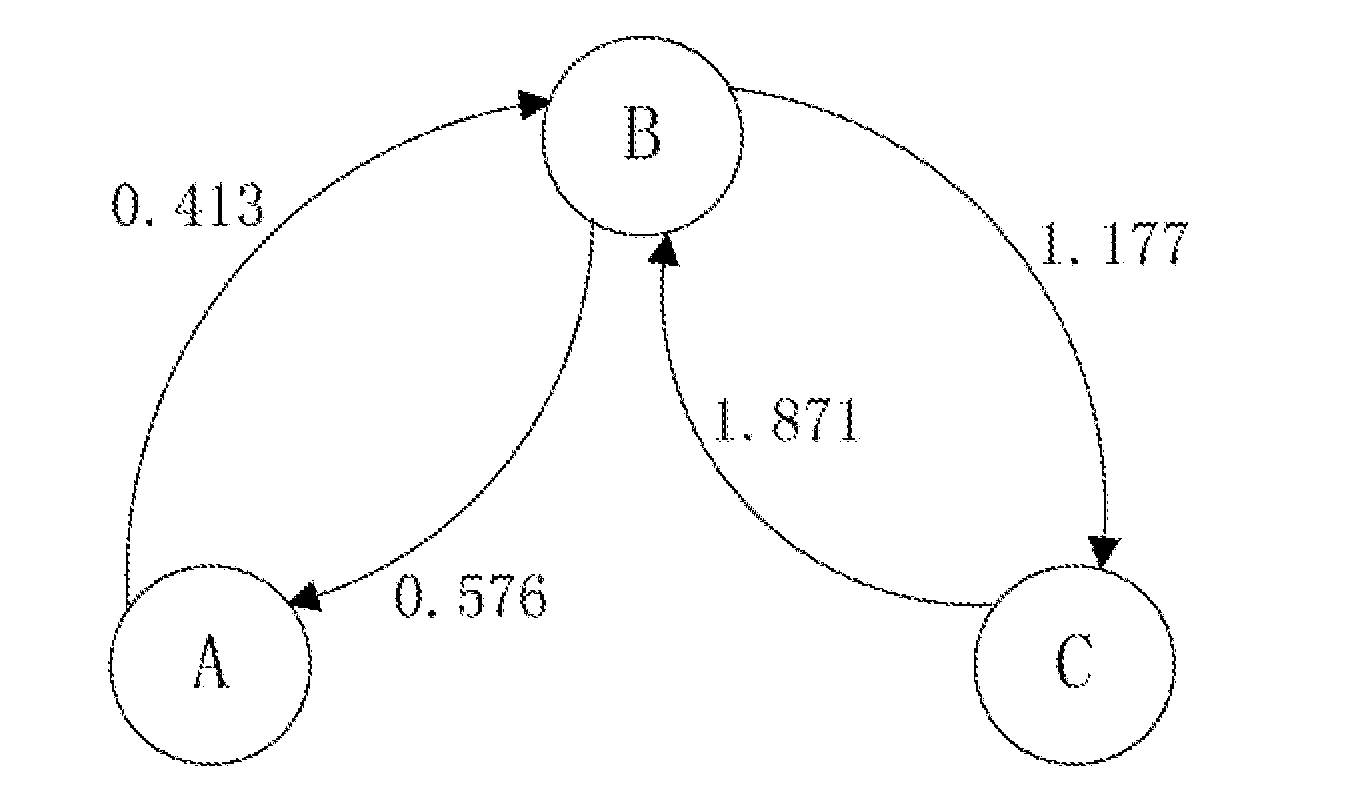

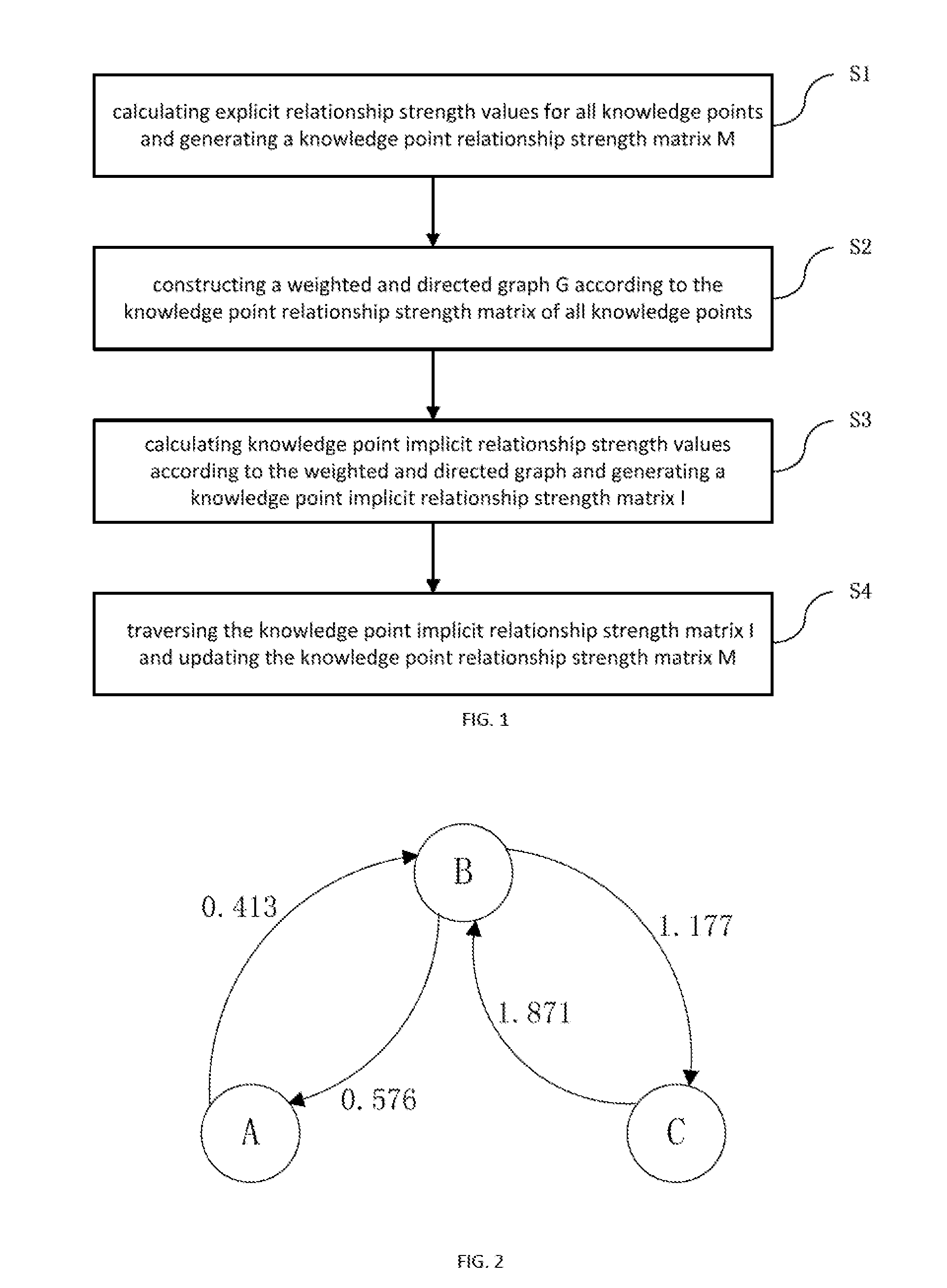

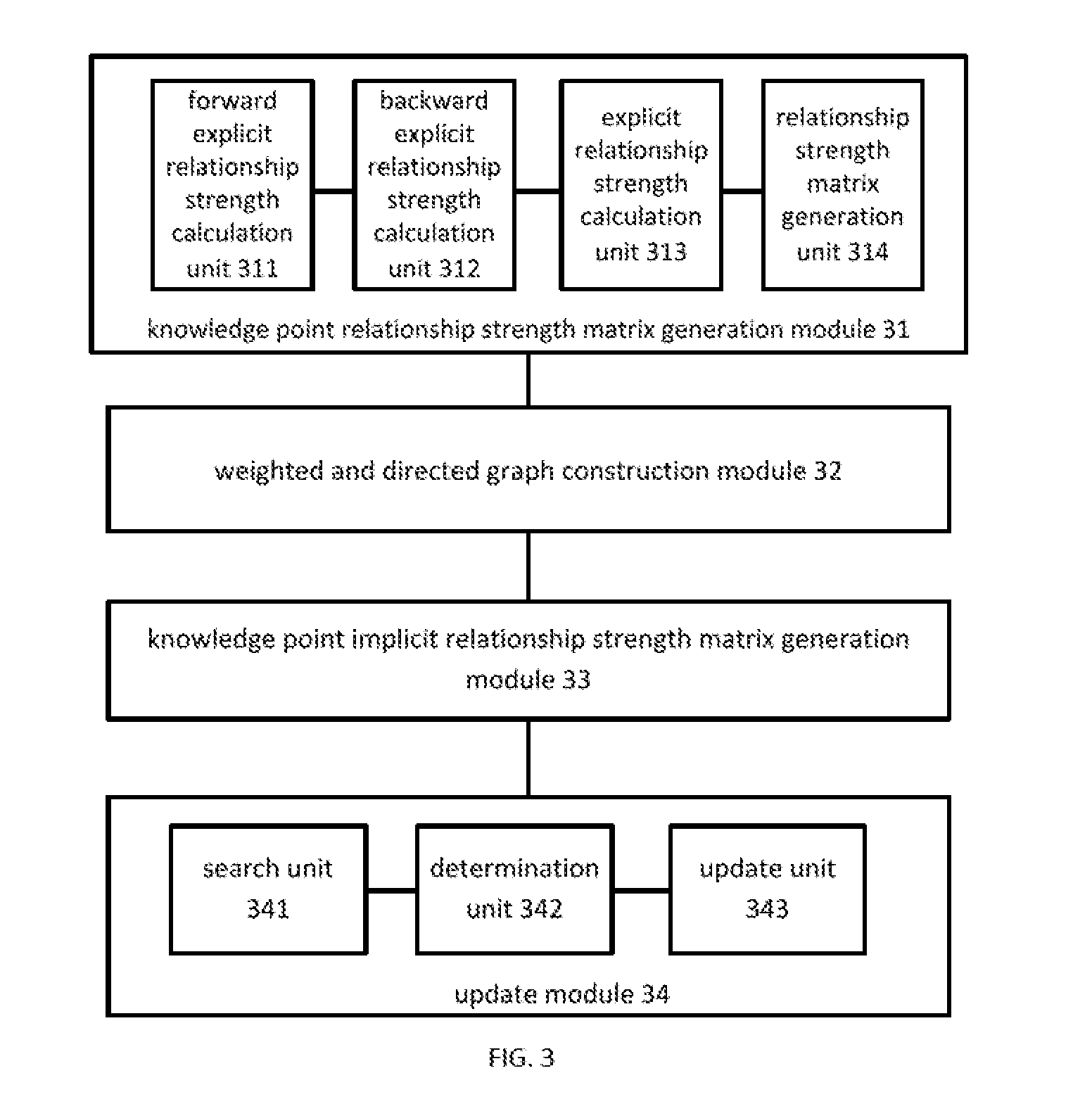

Method and system for measurement of knowledge point relationship strength

InactiveUS20160217373A1Calculation speedImprove response speedKnowledge representationSpecial data processing applicationsDirected graphArtificial intelligence

The present invention provides a method and system of measuring knowledge point relationship strength, the method comprising calculating explicit relationship strength for all knowledge points and generating a knowledge point relationship strength matrix M; constructing a weighted and directed graph G according to the knowledge point relationship strength matrix of all knowledge points; calculating knowledge point implicit relationship strength values according to the weighted and directed graph and generating a knowledge point implicit relationship strength matrix I; traversing the knowledge point implicit relationship strength matrix I and updating the knowledge point relationship strength matrix M. The above technical solution may effectively avoid the problem of lack of an absolute measurable value for the determination of relationship strength, incorrect measurement of relationship strength, or unable to discover some stronger relationship strength in the prior art.

Owner:PEKING UNIV FOUNDER GRP CO LTD +2

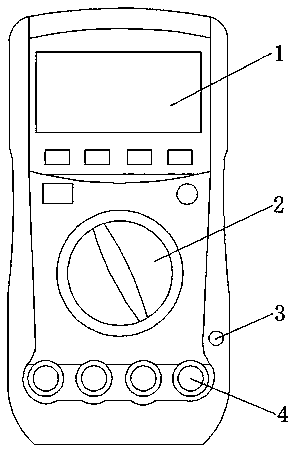

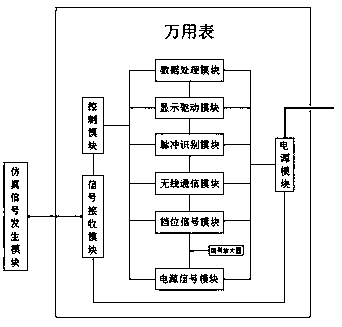

Monitoring system for instrument operation process and using method of monitoring system

InactiveCN110197605AShow measurement resultsReduce the risk of practicingCosmonautic condition simulationsSimulatorsElectrical resistance and conductanceMonitoring system

The invention relates to the technical field of simulation multimeter, in particular to a monitoring system of an instrument operation process and a using method of the monitoring system. The problemthat incorrect measurement results or instrument damage is prone to occurring due to the fact that a beginner uses a real universal meter in the prior art is solved. The monitoring system includes a simulation multimeter and a simulation signal generating module, wherein a data processing module is embedded in the simulation multimeter, the data processing module is connected with a display driving module in a communicating mode, and the display driving module is connected with a pulse identification module in a communicating mode; the pulse identification module is connected with a gear signal module in a communicating mode, the gear signal module is connected with a power signal module in a communicating mode; and the simulation signal generating module uses a pulse signal to define an analog power source or a period connector and uses a unidirectional power source and a resistor plug to define different pulses, the plug is enabled to be inserted into an inserting hole of the simulation multimeter to read the pulse signal and display the measurement results.

Owner:HANGZHOU SHENBANG TECH CO LTD

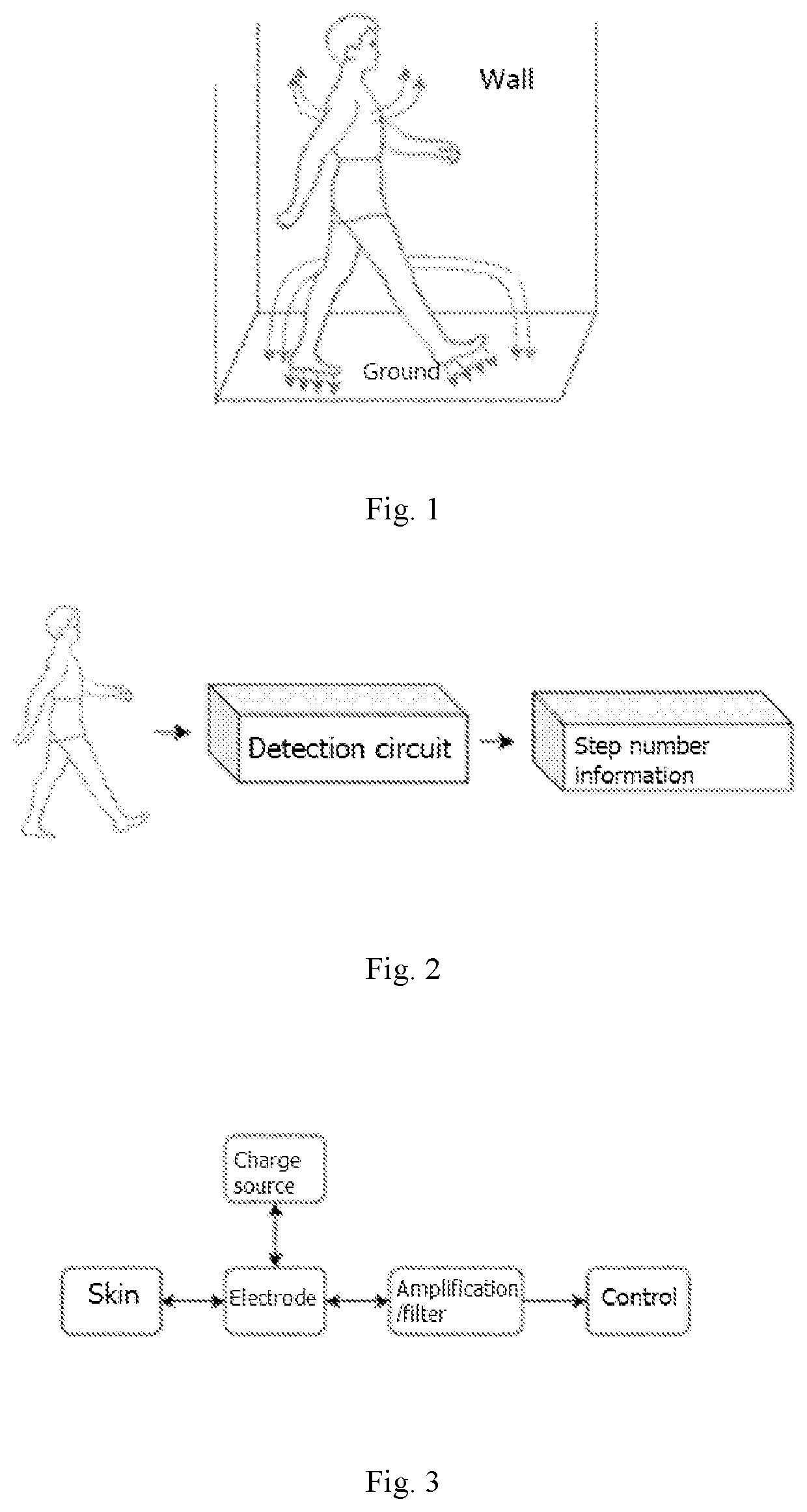

Precise Step Counting Method Using Human Body Capacitance

PendingUS20220184455A1Accurate measurementGymnastic exercisingDiagnostic recording/measuringHuman bodyPhysical medicine and rehabilitation

Disclosed is a precise step counting method using human body capacitance, relating to the field of electronic communications, and in particular to a method for implementing precise step counting using human body capacitance. At present, a wearable intelligent device having a step counting function measures a number of steps by means of an inertial sensor, but has limited precision in a measurement result. Due to the complexity of motion of a human body, missed measurement and incorrect measurement often occur in the inertial sensor-based measurement of the number of steps. The recognition and calculation of the number of steps also occupy a large number of hardware resources. In this respect, a precise step counting method based on human body capacitance, a human body's electrostatic field, or a human body surface potential is provided. When a human body is walking, the actions of leg lifting and leg lowering would change human body capacitance, and the number of steps can be conveniently and quickly measured by detecting a change in a physical signal caused by a change in the human body capacitance, such as a change in a voltage signal of human body skin and a change in a frequency. The method implements precise step counting without occupying hardware spaces and resources, has the advantage of low power consumption, and can be embedded into all current wearable intelligent devices that require a step counting function).

Owner:WANG YONGFANG

Service frame sending method and device

InactiveCN101394224BInterconnection arrangementsRadio transmission for post communicationSpeech soundIncorrect Measurement

Owner:HUAWEI TECH CO LTD

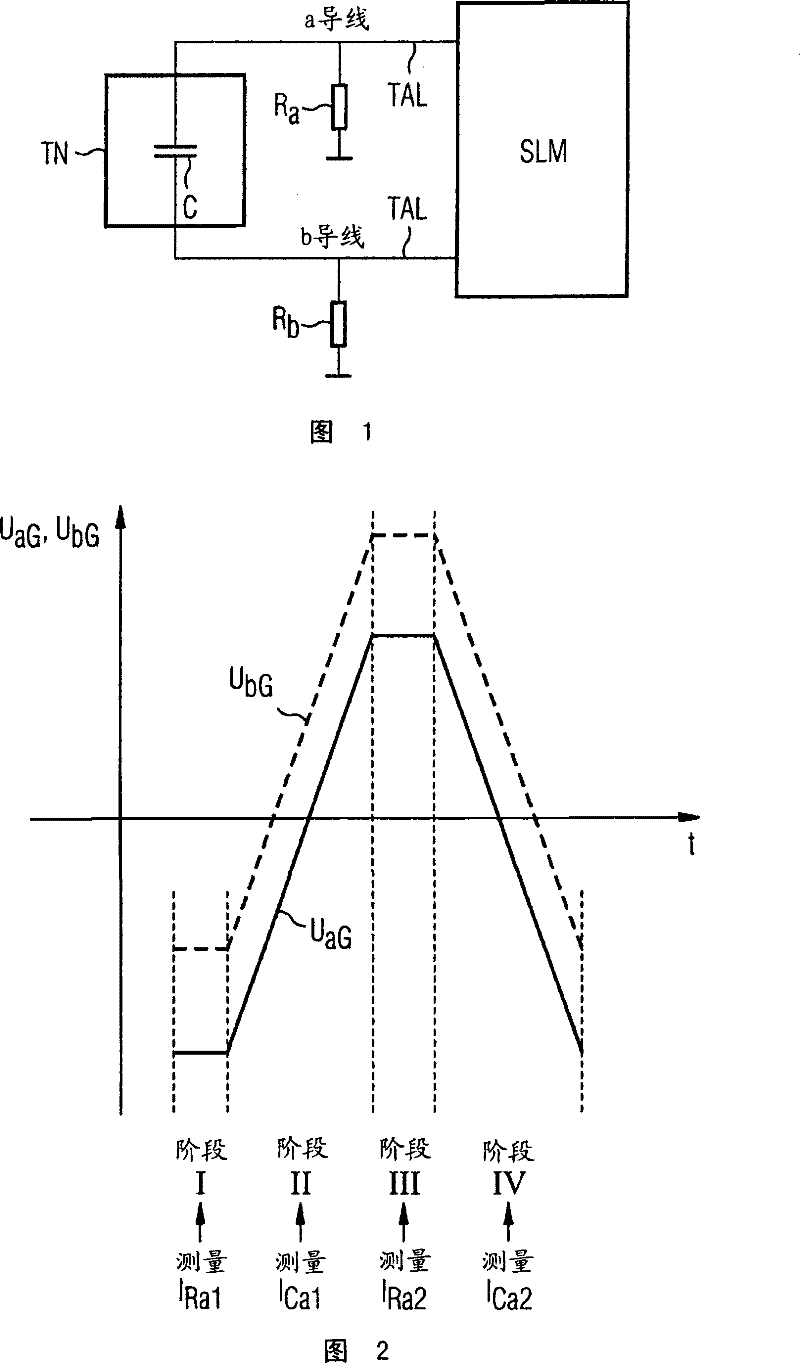

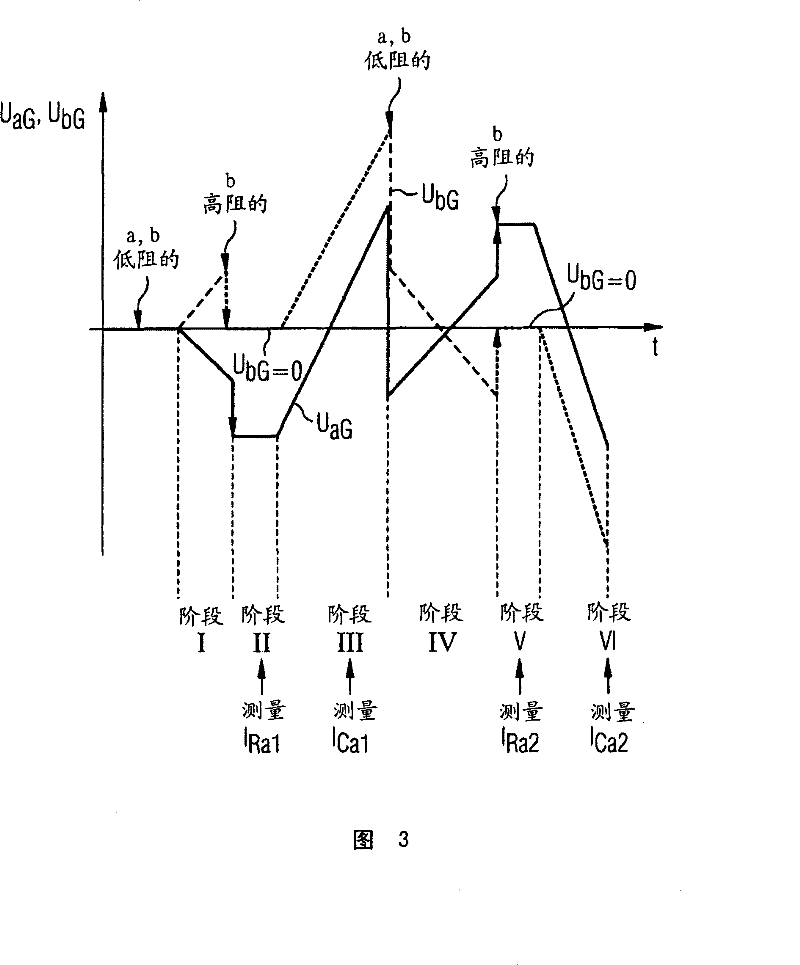

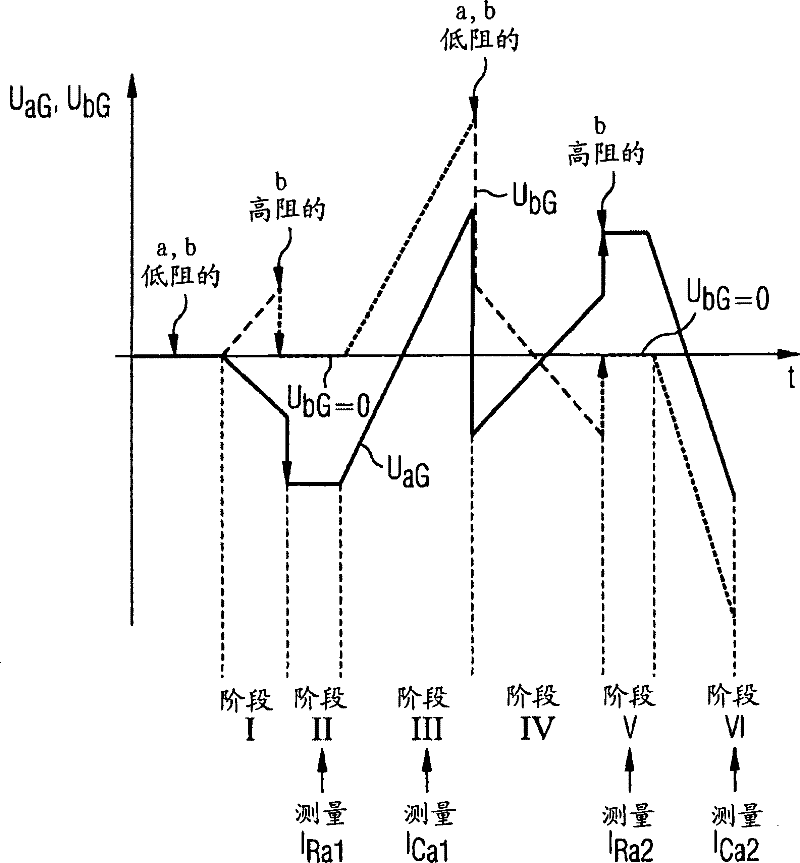

Method and device for determining a leak resistance for at least one wire of a subscriber connection line comprising several wires in a communications network

InactiveCN101248654BVery high resistance measurementsElectronic circuit testingHigh resistanceCapacitance

While determining a leak resistance (Ra, Rb) of a subscriber connection line (TAL) provided, for example, with two wires (a, b) in a communications network, a capacitor (C) connected between said two wires is discharged prior to measuring leakage currents (IRa1, IRa2). For this purpose, prior to be connected to a high resistance of the other wire (b), the measurable wire (a) and the other mentioned wire (b) are supplied with a constantly falling and increasing voltage (UaG, UbG). For that, the final value of said tensions (UaG, UbG) is determined in such a way that, when the connection to the high resistance of the other wire (b) is produced, the voltage of said wire (b) is equal to 0 volt. The leakage current is measured only when the discharge process is over, thereby making it possible to avoid an incorrect measurement caused by a current coming from the capacitor (C).

Owner:ノキアソリューションズアンドネットワークスゲゼルシャフトミットベシュレンクテルハフツングウントコンパニーコマンディトゲゼルシャフト

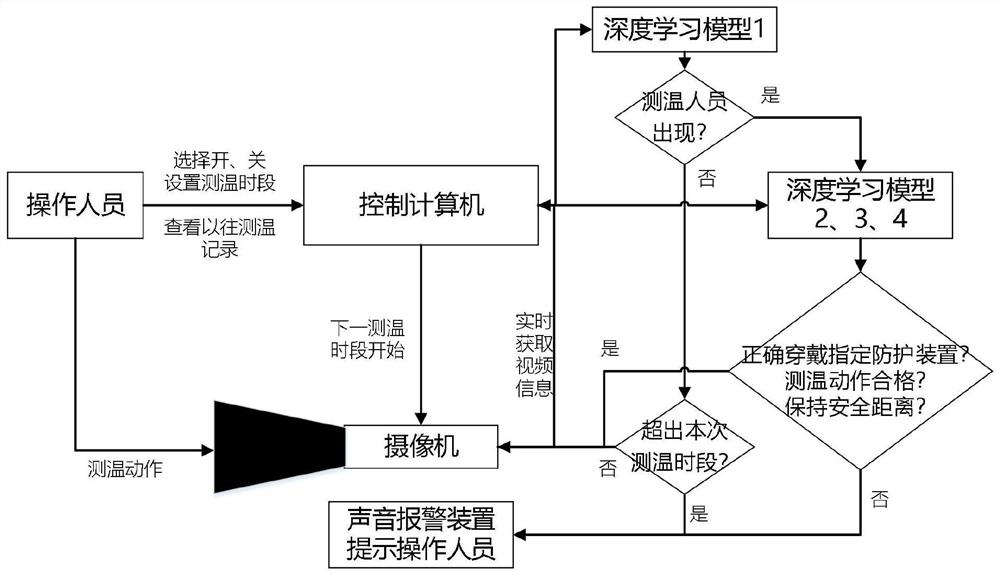

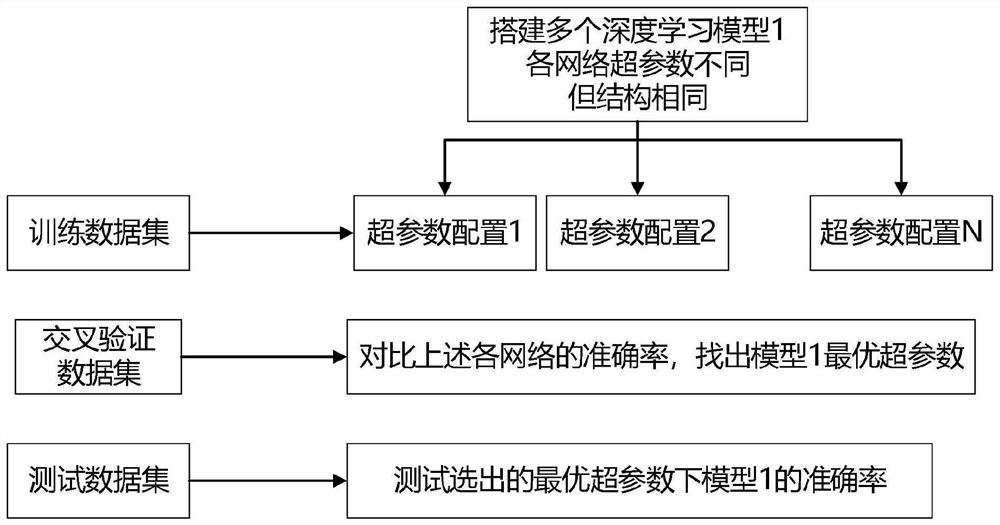

Molten iron temperature measurement process auxiliary method and system based on deep learning

PendingCN113901886AAccurate judgmentJudge safetyCharacter and pattern recognitionNeural architecturesProcess engineeringComputer science

The invention provides a molten iron temperature measurement process auxiliary method and system based on deep learning. Whether the position of an operator is safe, whether protection is in place and whether a temperature measurement action is qualified in real time can be monitored, and an alarm sound prompt can be given to avoid risks when the operator is unsafe or the temperature measurement action is unqualified so as to avoid risks, and temperature measurement operators can be effectively assisted to safely and correctly measure the temperature of molten iron, thereby effectively avoiding casualty events of the operators caused by incorrect measurement and unqualified rate of cast products caused by inaccurate temperature measurement.

Owner:WUHAN UNIV OF TECH +1

Device and method for automatic detection of incorrect measurements by means of quality factors

ActiveUS8154595B2Solving precise measurementsHigh measurement accuracyElectric discharge tubesMaterial analysis by optical meansImage structureTransmitted light

What is disclosed is a device (1) for automatic detection of a possible incorrect measurement, wherein the device (1) comprises at least one reflected light illumination apparatus (14) and / or a transmitted light illumination apparatus (6) and at least one imaging optical system (9) and one detector (11) of a camera (10) for imaging structures (3) on a substrate (2), wherein a first program portion (17) is linked to the detector (11) of the camera (10), said detector being provided for determining the position and / or dimension of the structure (3) on the substrate (2), wherein the device (1) determines and records a plurality of measurement variables Mj, jε{1, . . . , L}, from which at least one variable G can be determined, wherein a second program portion (18) is linked to the detector (11) of the camera (10), said program portion calculating an analysis of the measurement variables Mj with regard to a possible incorrect measurement. Also disclosed is a method for automatic detection of a possible incorrect measurement wherein an analysis of the measurement variables Mj with regard to a possible incorrect measurement is calculated with a second program portion (18) which is linked to the detector (11) of the camera (10).

Owner:VISTEC SEMICON SYST JENA

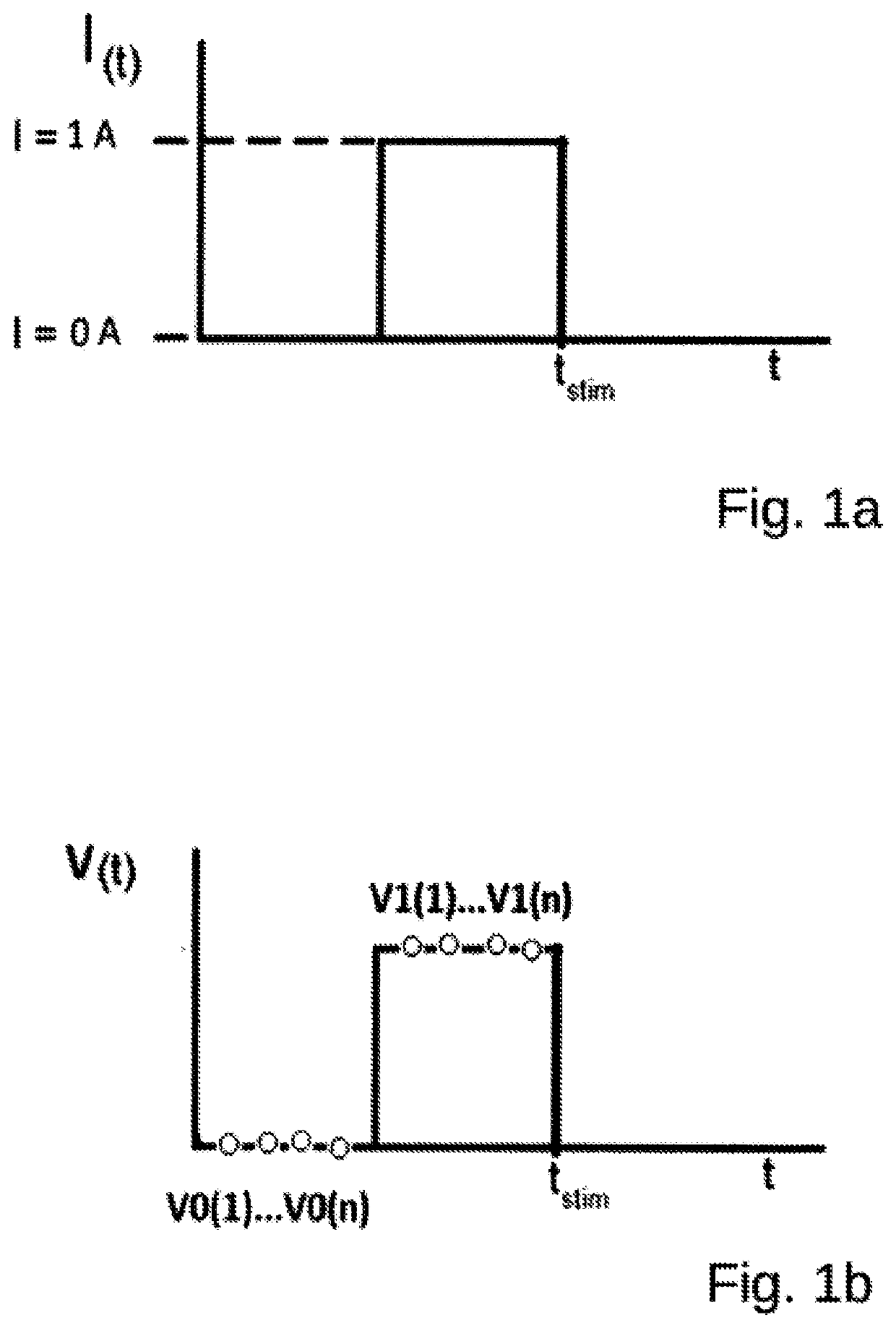

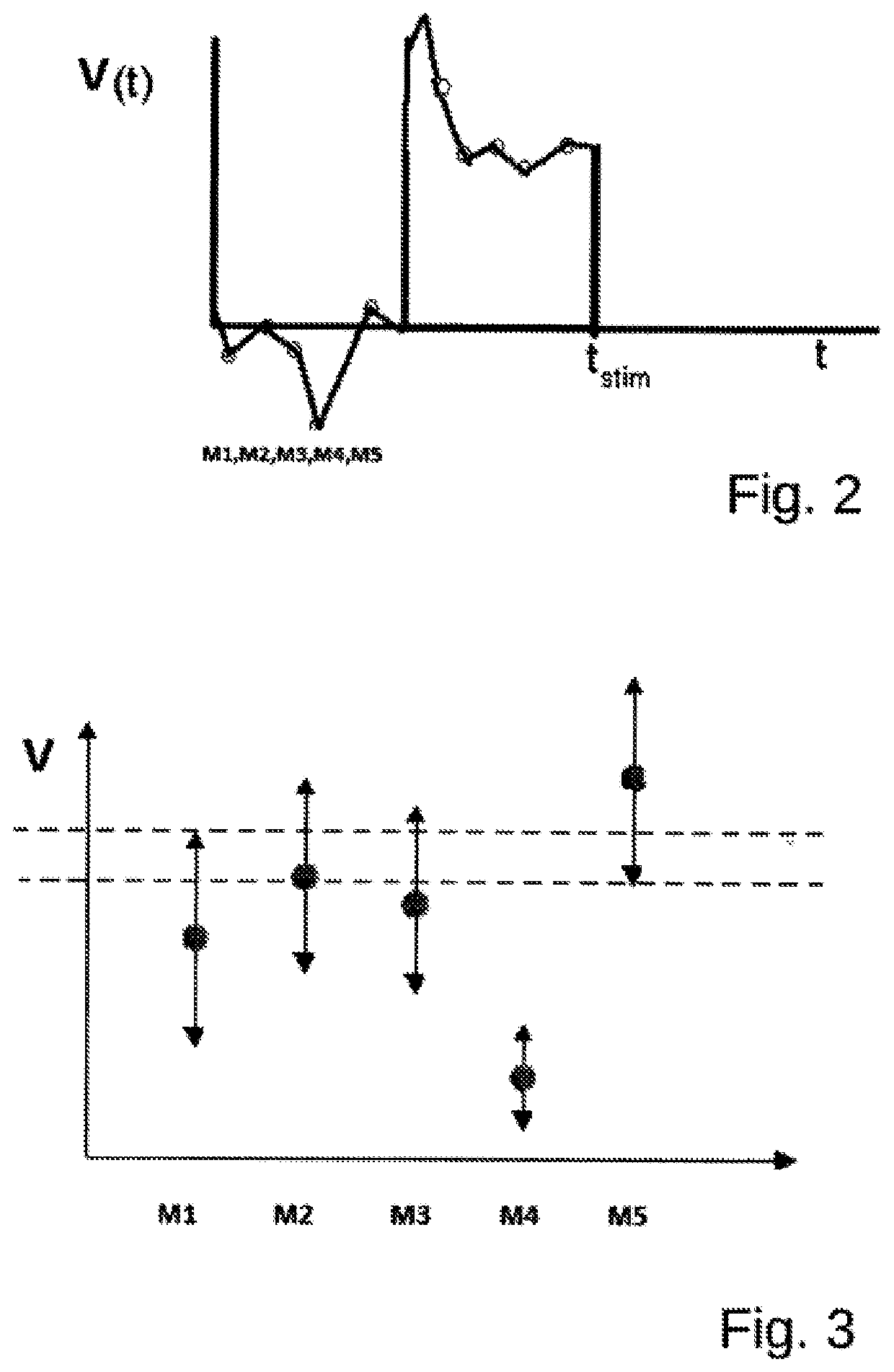

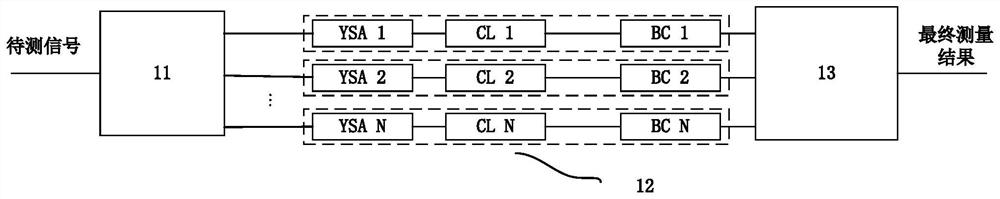

Method and device for reducing incorrect measurements during the determination of electrical parameters of electrical components

ActiveUS20200271730A1Error can be reduced and eliminatedImprove measurement reliabilityCurrent/voltage measurementElectrical testingEngineeringComputational physics

Before technical components are further processed, they are checked for the functionality thereof. In this case, an incorrect judgment of the functionality can occur due to measurement errors or incorrect measurements, which in turn results in a very inefficient test. The invention provides a method and a device by which an increased measurement accuracy can be achieved. This is achieved in that at least one first electrical voltage value is measured at a first constant measurement current and at least one second electrical voltage value is measured at a second constant measurement current at terminals of the component. Every measured voltage value is scaled respectively using a profile factor PF to form a measured value M, and only measured values M that are located at least with a tolerance range in a common value range are used for the determination of an electrical parameter.

Owner:ACCULOGIC

Three-dimensional shape measurement apparatus

A technology is provided that makes it possible for even a beginner to determine whether a measurement result is correct, to thereby prevent the use of incorrect measurement data, and to improve the reliability of an analysis result. In a three-dimensional shape measurement apparatus 100 that measures a three-dimensional shape of a specimen 3 in a non-contacting manner, a score that evaluates the reliability of measurement data is calculated for each measurement point by use of information obtained during a process of estimating the height of the specimen 3 or the estimated height. Measurement data is processed according to a result of evaluating the measurement data for each measurement point by use of the score.

Owner:EVIDENT CORP

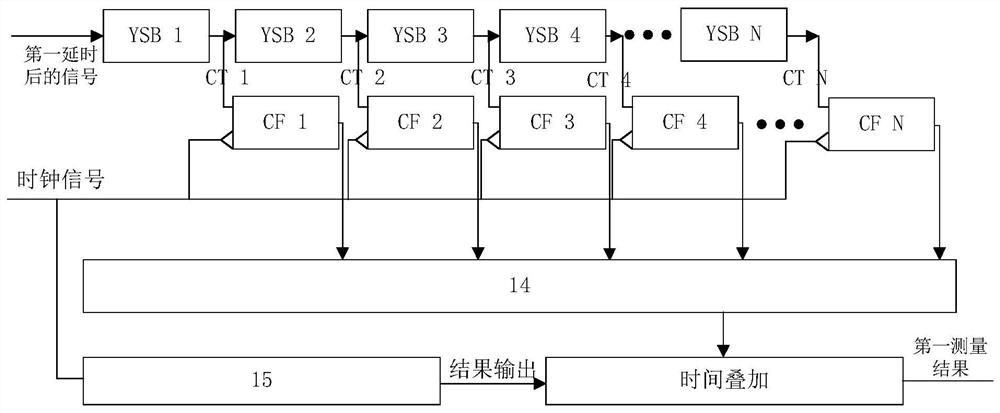

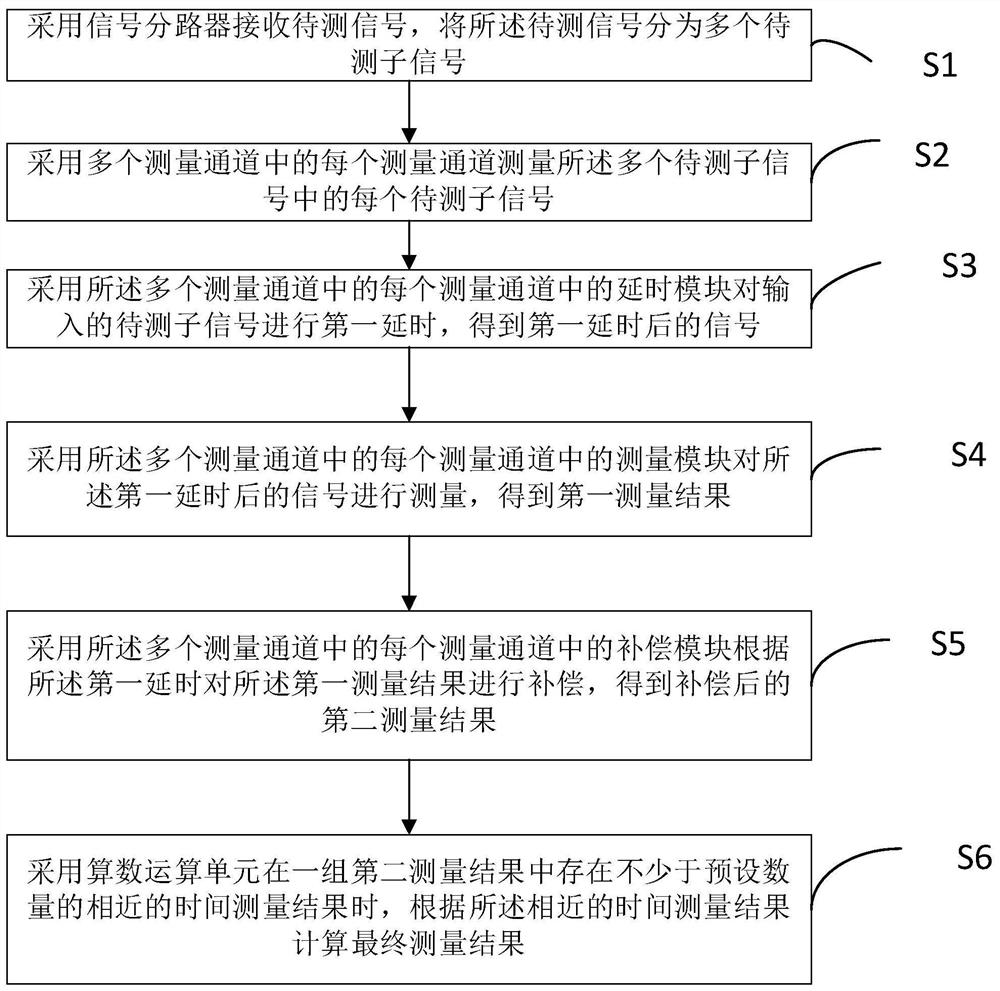

A time measurement device and method

ActiveCN112764342BEliminate measurement inaccuraciesHigh precisionWave based measurement systemsElectric unknown time interval measurementRadarEngineering

Owner:ZVISION TECH CO LTD

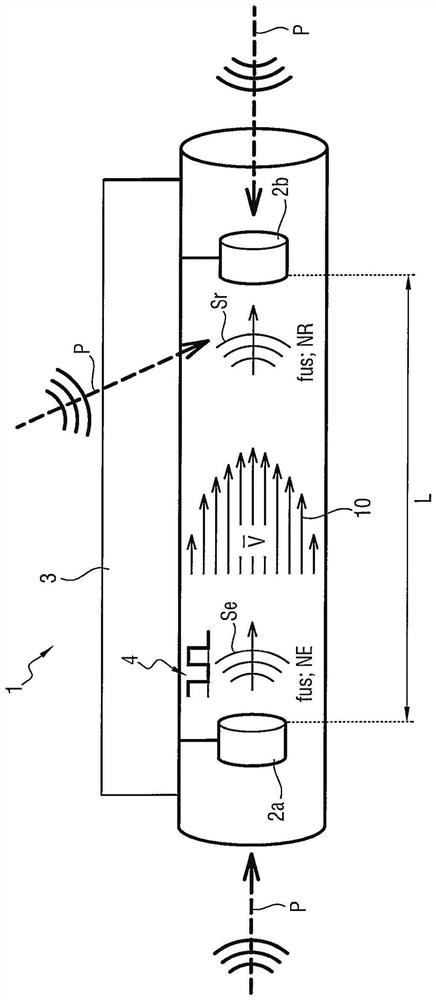

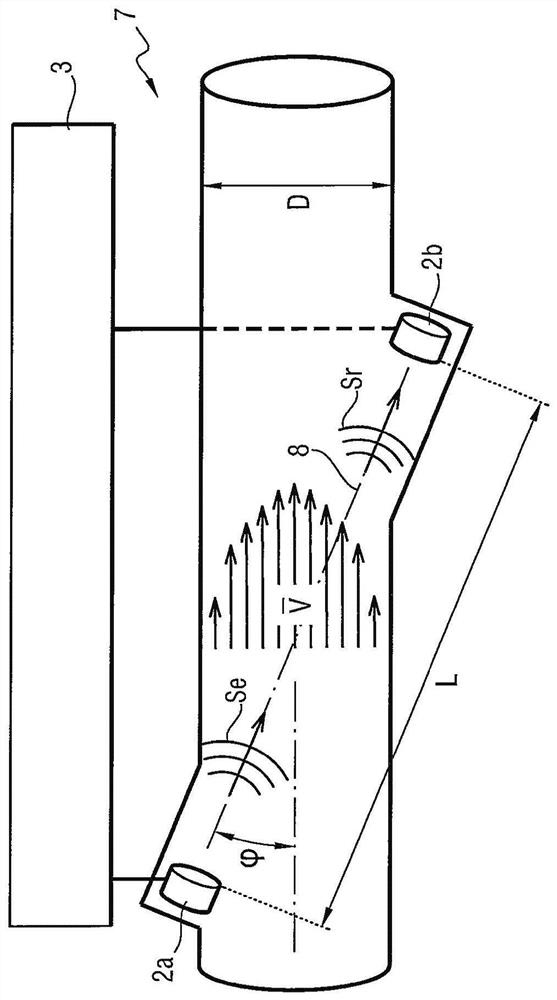

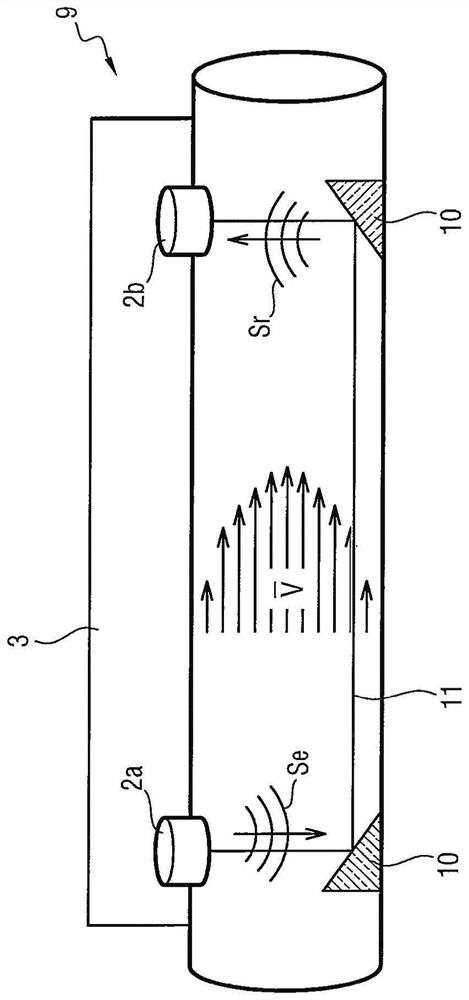

Method for Measuring Fluid Velocity

ActiveCN110383076BTariff metering apparatusVolume/mass flow measurementMechanical engineeringMechanics

A method for measuring the velocity of a fluid comprising the steps of: generating a plurality of pseudorandom frequencies (fus n); for each pseudorandom frequency (fus n), producing a measurement of travel time and using The resulting measurement of frequency is used to assess the velocity of the fluid. In order to evaluate the accuracy of the time measurements, inaccurate measurements are identified and the frequency with the lowest number of inaccurate measurements is selected as the transmit frequency with the highest accuracy.

Owner:SAGEMCOM ENERGY & TELECOM

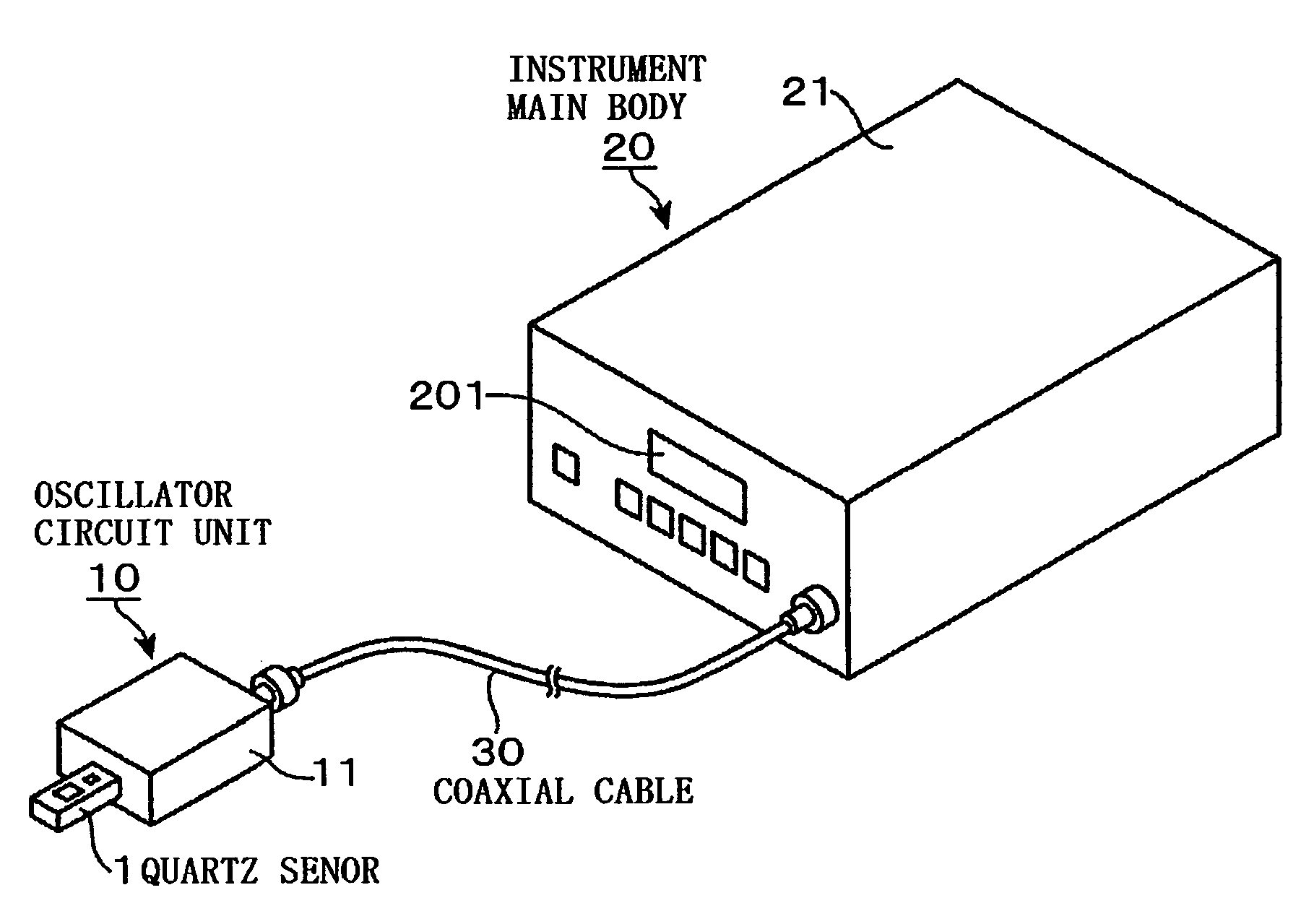

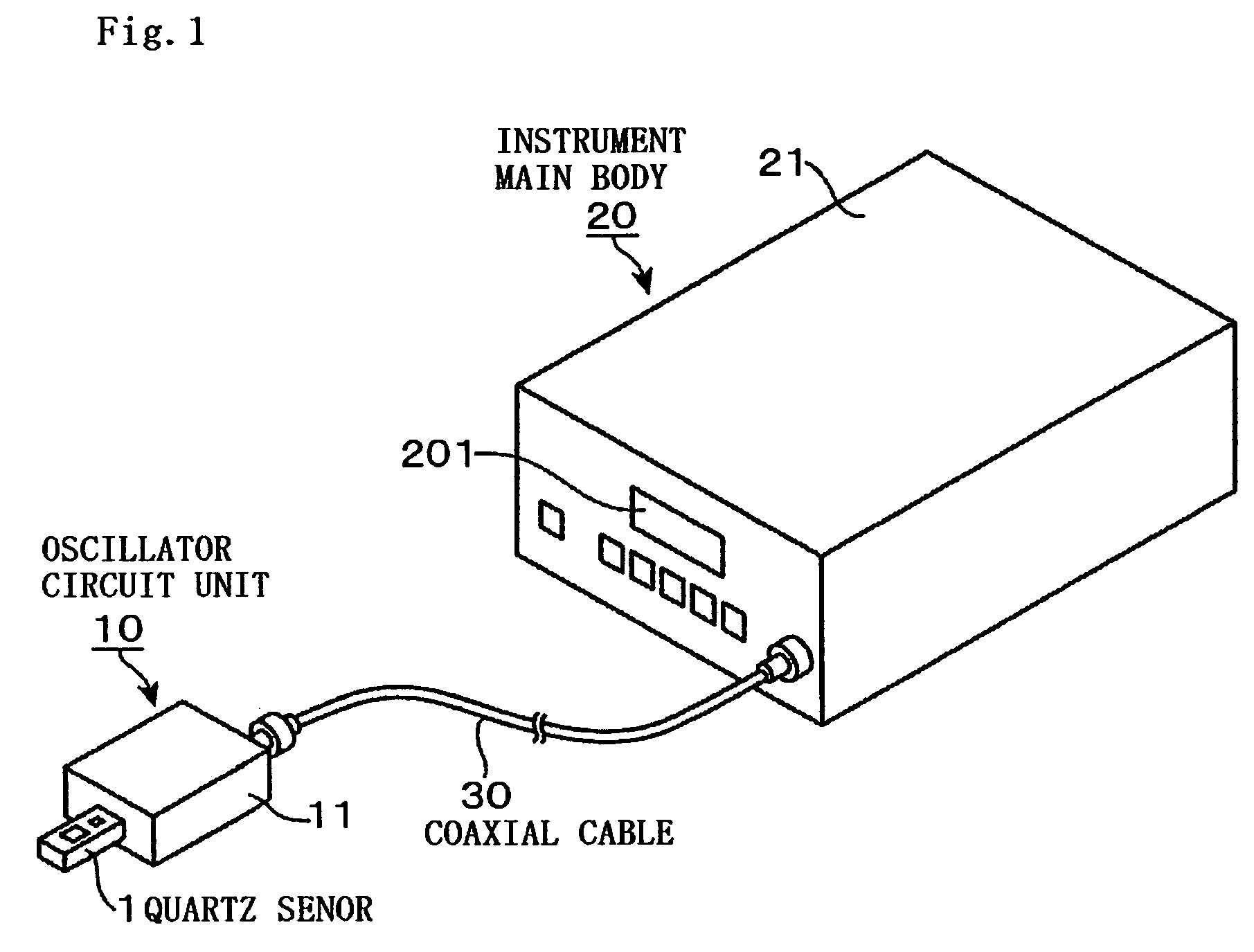

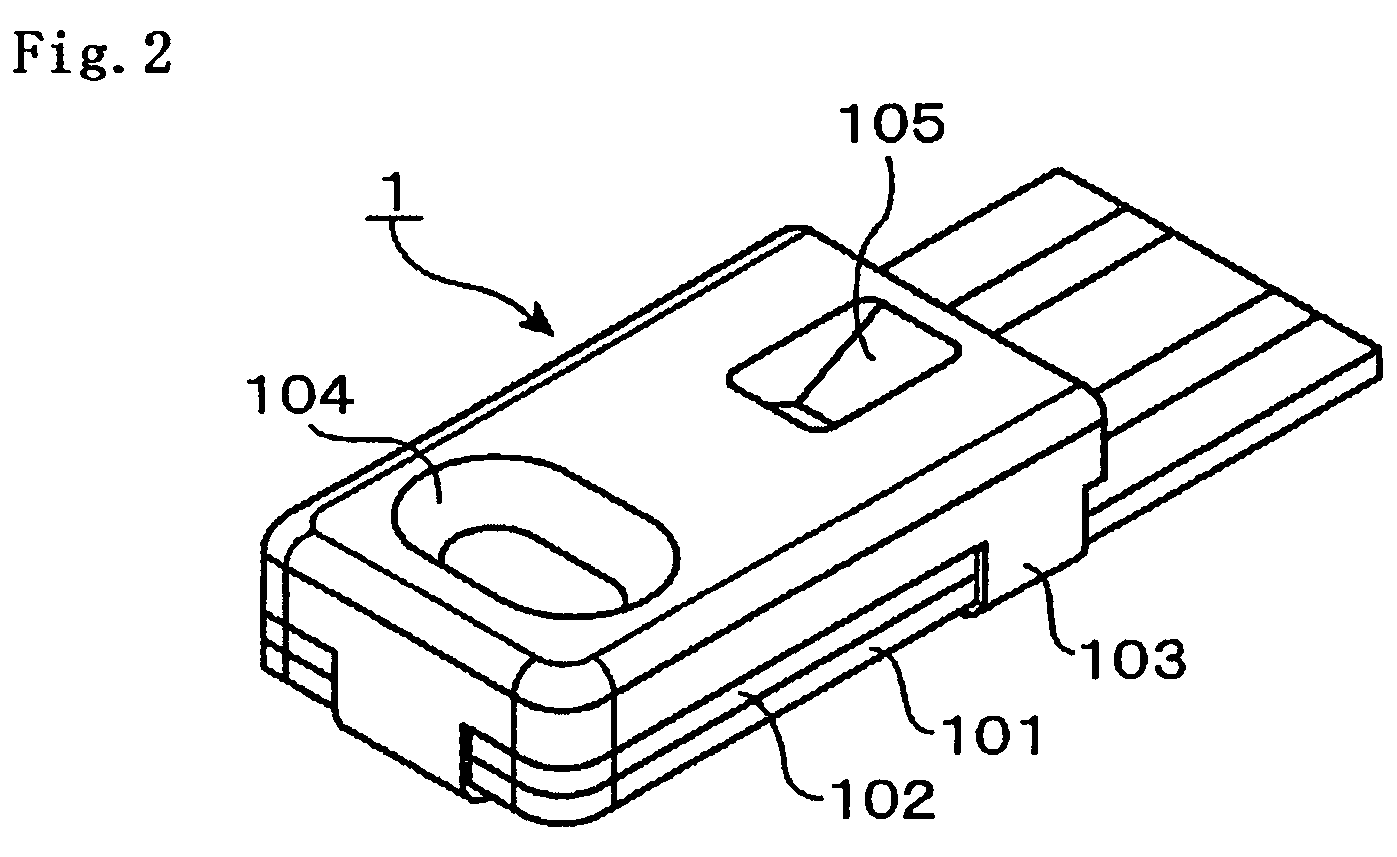

Sensing instrument

ActiveUS8051714B2Measurement result is preventedQuick checkVibration measurement in solidsWeighing apparatus using elastically-deformable membersQuartzInstrumentation

Owner:NIHON DEMPA KOGYO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com