A kind of cleaning method before coating on lbo crystal surface

A crystal surface and crystal technology, applied in the field of laser crystal ultrasonic cleaning, can solve the problems of difficult to remove sub-micron-scale particles, affect the optical properties of substrates, increase surface roughness, etc., achieve efficient cleaning solutions, and improve anti-laser damage characteristics. , the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

[0031] 1. Cleaning steps

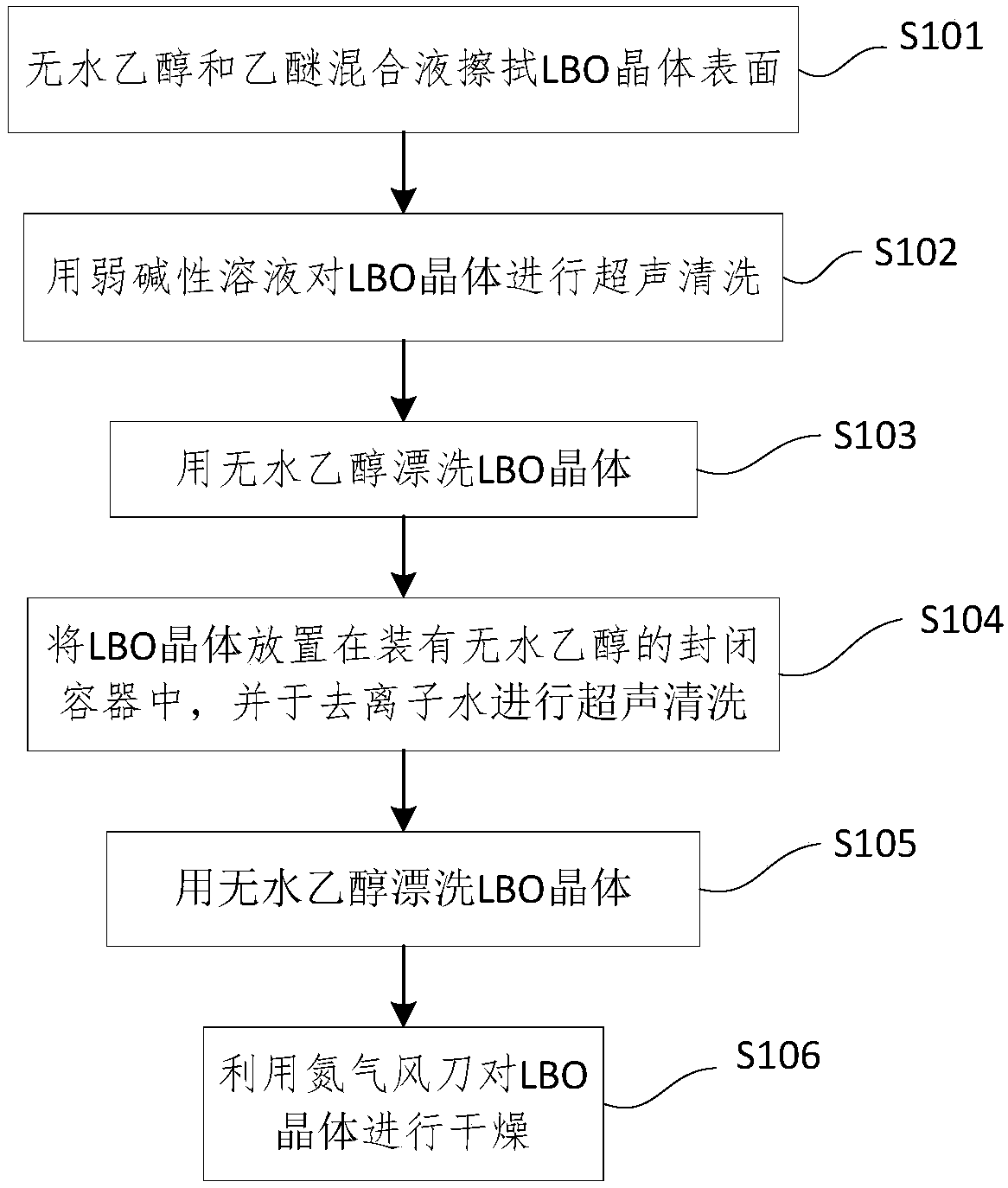

[0032] like figure 1 As shown, the cleaning method before coating the surface of the LBO crystal provided in this embodiment includes the following steps:

[0033] In step S101, the surface of the LBO crystal is wiped with a mixed solution of absolute ethanol and ether, which can be achieved by wiping lightly with a cotton swab dipped in a mixed solution of absolute ethanol and ether.

[0034] In step S102, the wiped LBO crystal is placed in the first cleaning tank, a weak alkaline solution is added, and the LBO crystal is ultrasonically cleaned. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com