A kind of optical processing defect passivation process

An optical processing and defect technology, applied in the field of magnetorheological polishing, can solve problems such as difficulty in controlling the size and depth of defects, and achieve the effects of reducing relative light field intensity, improving laser damage resistance, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

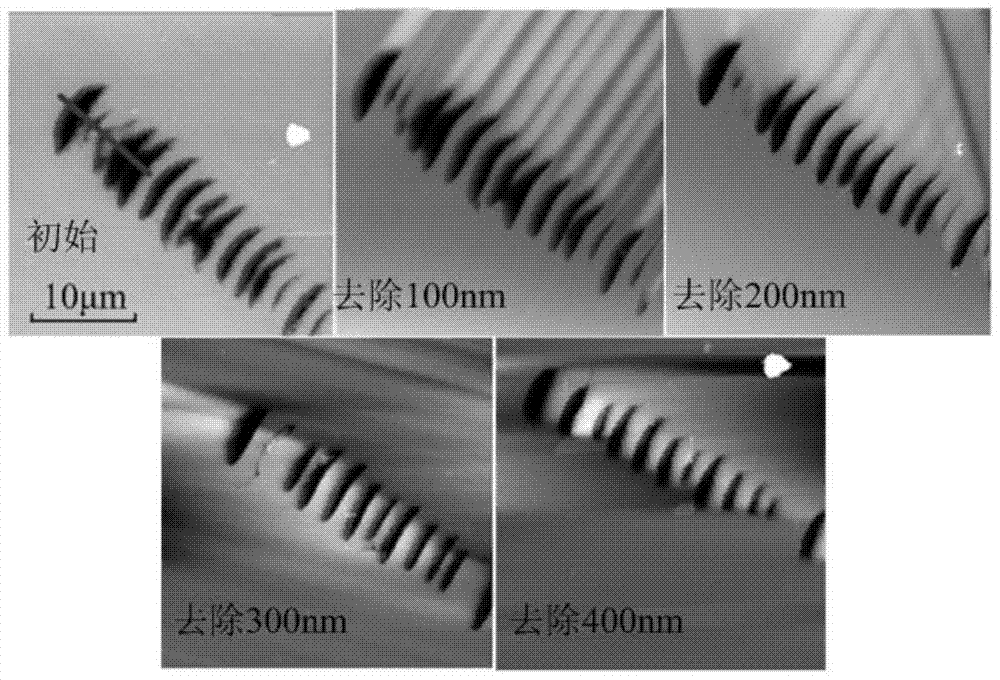

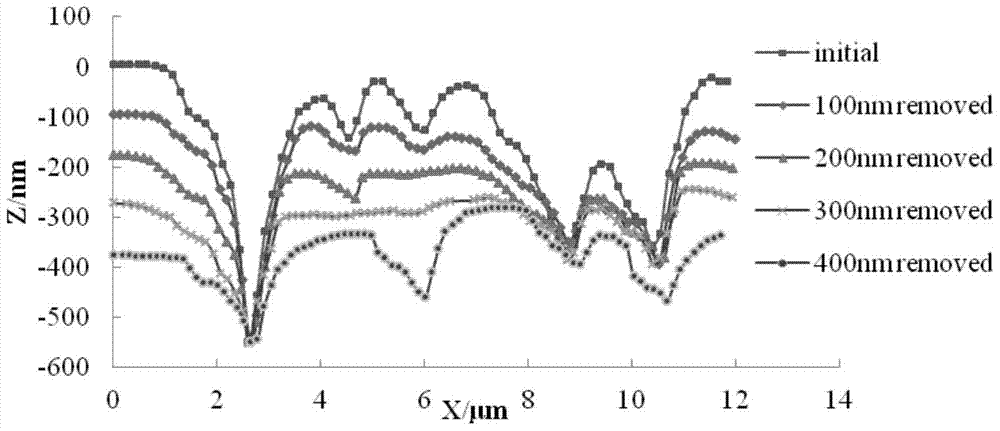

[0022] The processing object is a square fused silica element of 100mm×100mm×10mm. The pre-processing of the element is single-axis machine polishing. After polishing, there is no obvious scratch on the surface of the element. After the hydrolyzed layer is removed by light pickling, subsurface damage is exposed. Performing an optical processing defect passivation process on it, including the following steps:

[0023] (1) Before processing, the fused silica element is first lightly pickled to expose the subsurface scratches, and the initial depth of the scratches is measured to determine the depth of magnetorheological polishing. Pickling with 10% HF acid solution for 3 minutes, the material removal depth is 50nm.

[0024] (2) Carry out magnetorheological polishing on the fused silica element four times. When polishing, the relative speed of the polishing wheel and the fused quartz element is 2-3m / s, the flow rate of the magnetorheological polishing liquid is 150-170L / h, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com