Surface treatment method for increasing fused silica element threshold value through wet etching-dry etching combination

A dry etching and surface treatment technology, which is applied in the field of optical materials and optical components, can solve the problems of reducing the laser damage threshold of components, reducing the ability of components to resist laser damage, and the uncontrolled surface morphology of components, so as to improve the laser resistance Damage ability, fast laser damage threshold, effect of increasing laser damage threshold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

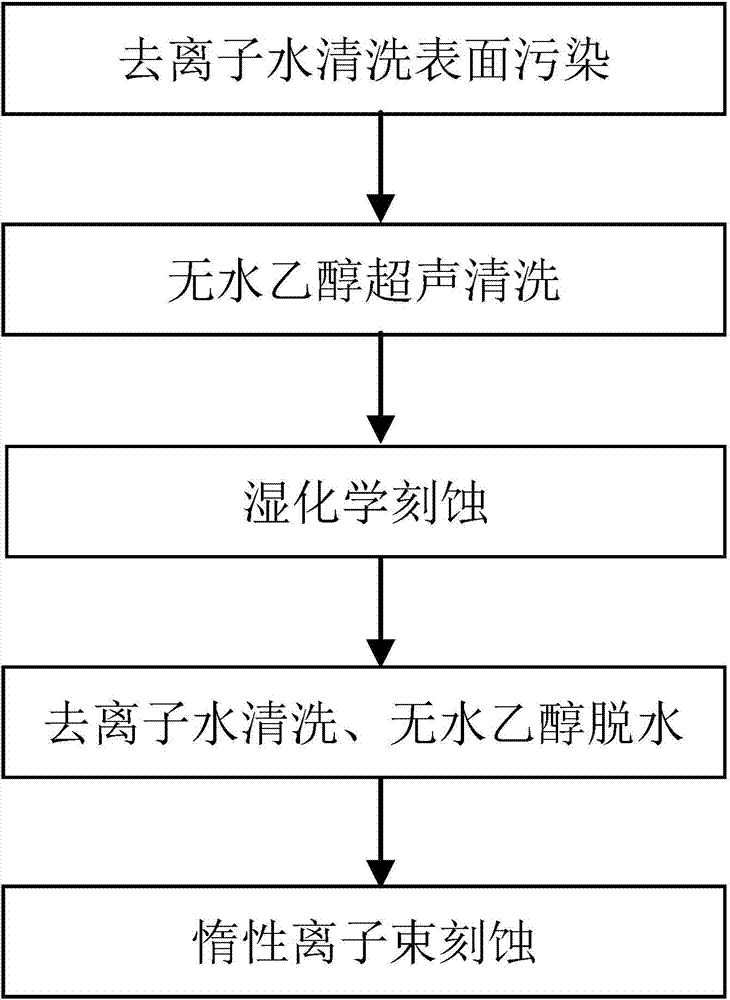

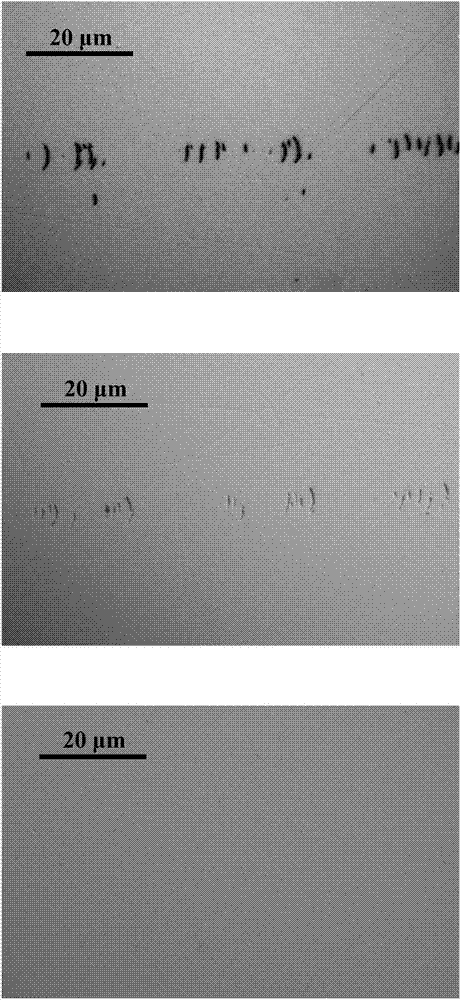

[0018] Traditional optically polished fused silica elements measure 60mm x 60mm and have a thickness of 5mm. First, use deionized water to clean the surface of the fused silica element processed by the traditional grinding and polishing process, then use absolute ethanol to perform ultrasonic cleaning, etch in 1% hydrofluoric acid solution for 10 minutes, and then use deionized water to clean and dry After dehydration of water and ethanol, the surface is polished with an argon ion beam with an energy of 600eV. The polishing method is fixed-point polishing with a large beam spot, and the ion beam current density is 3mA / cm 2 , the ion incident angle was 60°, and the polishing time was 10 minutes. The surface roughness and 355nm ultraviolet laser damage threshold test (R-on-1 method) was carried out on samples in three states of traditional polishing, hydrofluoric acid etching and ion beam polishing. The results are as follows: the roughness peak-valley value is : 21nm, 32nm, 9n...

Embodiment 2

[0020] The size of the traditional optically polished fused silica element is 30mm×30mm, and the thickness is 4mm. First, the surface of the fused silica element processed by the traditional grinding and polishing process is cleaned with deionized water, and then ultrasonically cleaned with anhydrous ethanol. After etching in the solution for 5 minutes, cleaning with deionized water and dehydrating with absolute ethanol, the surface was polished with an argon ion beam with an energy of 400eV. The polishing method was scanning polishing, and the scanning speed was 200mm / min. 15mA / cm 2 , the ion incident angle was 45°, and the polishing time was 50 minutes. The surface roughness and 355nm ultraviolet laser damage threshold test (R-on-1 method) was carried out on samples in three states of traditional polishing, hydrofluoric acid etching and ion beam polishing. The results are as follows: the roughness peak-valley value is : 18nm, 41nm, 11nm; root mean square roughness: 0.7nm, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com