Method for improving laser damage threshold of near-infrared high-reflective film

A technology of damage threshold and high reflection film, which is applied in ion implantation plating, metal material coating process, coating, etc., can solve the problems of insignificant effect, low efficiency, high cost, etc., and achieve threshold increase, low cost, high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

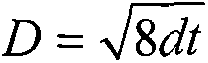

[0034] We choose nodules with particle sizes of 0.6, 1.0, 1.5, and 2.0um as the experimental objects. Calculate the opening angle for each size of nodule. We choose a flat-rotating coating machine, and our nodule geometry meets: Table 1 shows the maximum incident angle calculated according to formula (3).

[0035] Table 1

[0036] Seed source particle size 0.6um 1.0um 1.5um 2.0um maximum angle of incidence 30.4° 40.1° 50.8° 61.7°

[0037] Selected materials: high refractive index material is HFO2, low refractive index material is SIO2; working wavelength is 1064nm; initial film system: S / 1.28(HL)^18(HL)^182L / A; control wavelength is 1150nm; optimization results It is: the total physical thickness is about 9um, T>99%, and the reflection band angular width: 65°;

[0038] Take JGS1 quartz glass as the substrate, first put it into the cleaning solution and ultrasonically clean it for 15 minutes, take it out and blow it dry with high-purity nitrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| optical damage threshold | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com