Ferric oxide/manganic oxide hollow porous sphere material, preparation and application thereof

A hollow porous and hollow sphere technology, applied in the field of nanomaterials and electrochemistry, can solve the problems of fast capacity decay and improved cycle life of lithium-ion batteries, and achieve the effects of easy amplification, abundant reserves, and favorable market promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

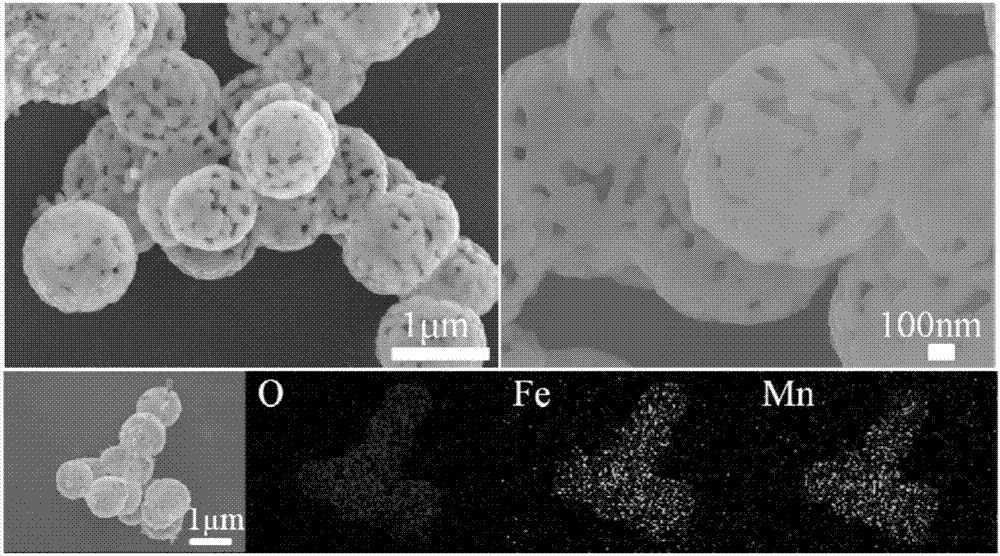

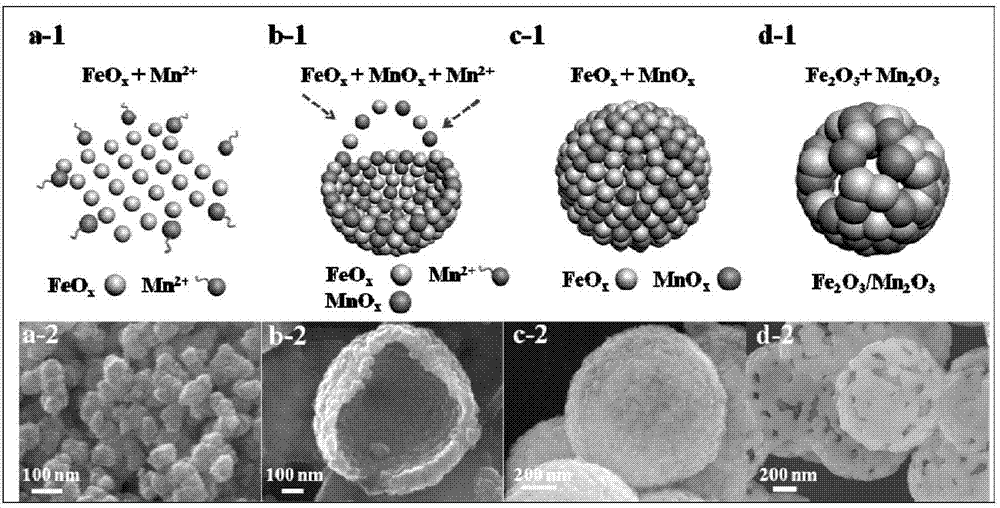

[0027] Fe 2 o 3 / Mn 2 o 3 The production method of hollow porous ball electrode material, it comprises the steps:

[0028] 1) Add 1mmol Fe(NO 3 ) 3 9H 2 O, 1mmol Mn(CH3 COO) 2 4H 2 O, 3 mmol H 2 C 2 o 4 2H 2 O was dissolved in 35mL DMF, stirred in a water bath at 70°C for 30min to obtain a wine red solution;

[0029] 2) Transfer the solution obtained above to a polytetrafluoroethylene liner and put it into a reaction kettle and take it out after hydrothermal heating at 200°C for 24 hours;

[0030] 3) After it is cooled to room temperature, the obtained yellow-brown precipitate is washed several times with alcohol and deionized water, and then dried in an oven at 70°C in an air atmosphere to obtain a precursor powder;

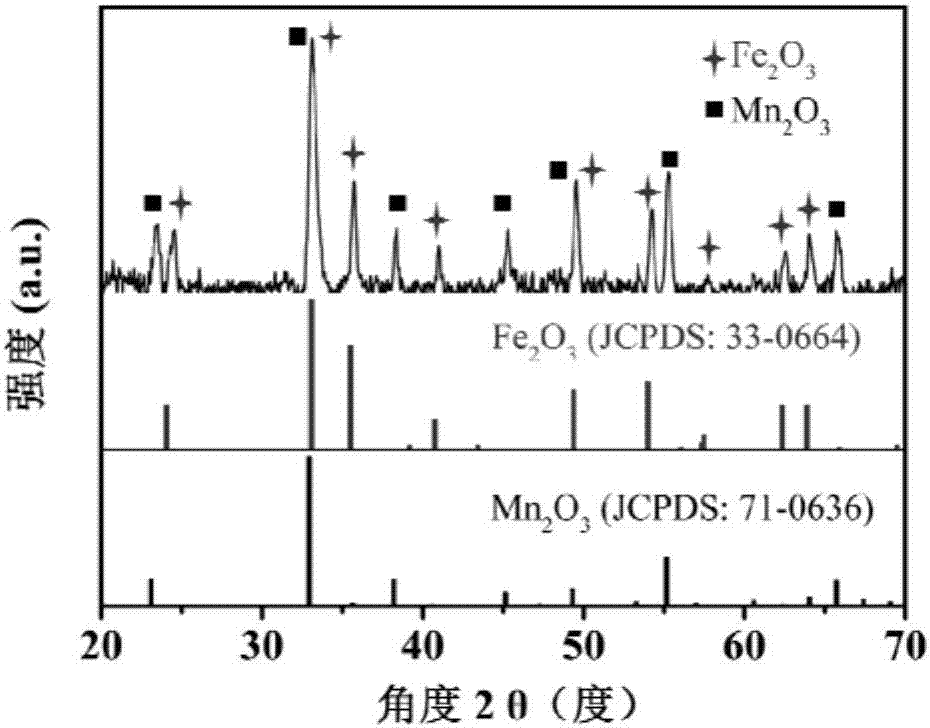

[0031] 4) Finally, the precursor was heated in an air atmosphere at 5°C min -1 The heating rate was raised to 450°C for 5 hours and then continued at 5°C min -1 Raise the temperature to 750°C for 10 hours to obtain Fe 2 o 3 / Mn 2 o 3 Hollow po...

Embodiment 2

[0041] 1) Add 1mmol Fe(NO 3 ) 3 9H 2 O, 1mmol Mn(CH 3 COO) 2 4H 2 O, 2.8 mmol H 2 C 2 o 4 2H 2 O was dissolved in 35mL DMF, stirred in a water bath at 70°C for 30min to obtain a wine red solution;

[0042] 2) Transfer the solution obtained above to a polytetrafluoroethylene liner and put it into a reaction kettle and take it out after hydrothermal heating at 200°C for 24 hours;

[0043] 3) After it is cooled to room temperature, the obtained yellow-brown precipitate is washed several times with alcohol and deionized water, and then dried in an oven at 70°C in an air atmosphere to obtain a precursor powder;

[0044] 4) Finally, the precursor was heated in an air atmosphere at 5°C min -1 The heating rate was raised to 500°C for 5 hours and then continued at 5°C min -1 Raise the temperature to 750°C for 10 hours to obtain Fe 2 o 3 / Mn 2 o 3 Hollow porous spherical electrode material.

[0045] With the Fe obtained in this example 2 o 3 / Mn 2 o 3 Hollow porous sph...

Embodiment 3

[0047] 1) Add 1mmol Fe(NO 3 ) 3 9H 2 O,1mmol Mn(CH 3 COO) 2 4H 2 O, 2.5 mmol H 2 C 2 o 4 2H 2 O was dissolved in 35mL DMF, stirred in a water bath at 70°C for 30min to obtain a wine red solution;

[0048] 2) Transfer the solution obtained above to a polytetrafluoroethylene lining and put it into a reaction kettle, heat it under water at 200°C for 8 hours, and then take it out;

[0049] 3) After it is cooled to room temperature, the obtained yellow-brown precipitate is washed several times with alcohol and deionized water, and then dried in an oven at 70°C in an air atmosphere to obtain a precursor powder;

[0050] 4) Finally, the precursor was heated in an air atmosphere at 5°C min -1 The heating rate was raised to 450°C for 5 hours and then continued at 5°C min -1 Raise the temperature to 750°C for 10 hours to obtain Fe 2 o 3 / Mn 2 o 3 Hollow porous spherical electrode material.

[0051] With the Fe obtained in this example 2 o 3 / Mn 2 o 3 Hollow porous sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Initial discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com