Methods for preparing porous spherical titanium dioxide and light positive pole

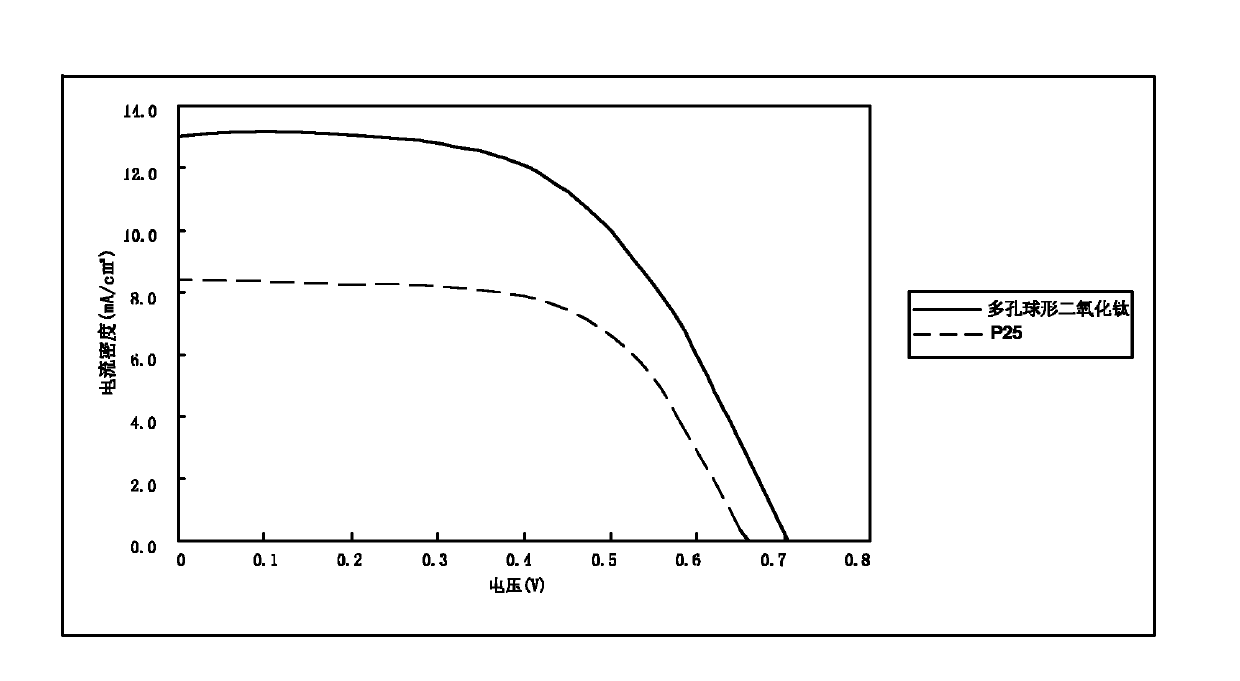

A titanium dioxide, porous spherical technology, applied in the field of dye-sensitized solar cells, can solve the problems of easy particle agglomeration and low DSC efficiency, and achieve the effects of good repeatability, simple operation and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A preparation method of porous spherical titanium dioxide, comprising the following specific steps:

[0020] Add 6 grams of hexadecylamine into 600 milliliters of absolute ethanol, ultrasonically disperse until completely dissolved; add 2.5 milliliters of potassium chloride aqueous solution with a molar concentration of 0.1 mol / liter while stirring to obtain a mixed solution I; Add 13 grams of isopropyl titanate, stir to obtain a milky white suspension, let stand, separate, and obtain the solid in the suspension; dry the solid in the suspension to obtain a titanium dioxide precursor, which is a white powder. The yield is not lower than 90%.

[0021] Weigh 3.2 grams of titanium dioxide precursor and disperse it in a mixture of 40 milliliters of absolute ethanol, 20 milliliters of deionized water and 1 milliliter of ammonia water with a mass concentration of 25%, and transfer it to a closed reaction kettle, heat it to 160 ° C, and react at a constant temperature 16 hours...

Embodiment 2

[0023] A method for preparing a dye solar cell photoanode with porous spherical titanium dioxide as slurry, comprising the steps of:

[0024] Add 6 grams of hexadecylamine into 600 milliliters of absolute ethanol, ultrasonically disperse until completely dissolved; add 2.5 milliliters of potassium chloride aqueous solution with a molar concentration of 0.1 mol / liter while stirring to obtain a mixed solution I; Add 13 grams of isopropyl titanate, stir to obtain a milky white suspension, let stand, separate, and obtain the solid in the suspension; dry the solid in the suspension to obtain a titanium dioxide precursor, which is a white powder. The yield is not lower than 90%.

[0025] Weigh 3.2 grams of titanium dioxide precursor and disperse it in a mixture of 40 milliliters of absolute ethanol, 20 milliliters of deionized water and 1 milliliter of ammonia water with a mass concentration of 25%, and transfer it to a closed reaction kettle, heat it to 160 ° C, and react at a cons...

Embodiment 3

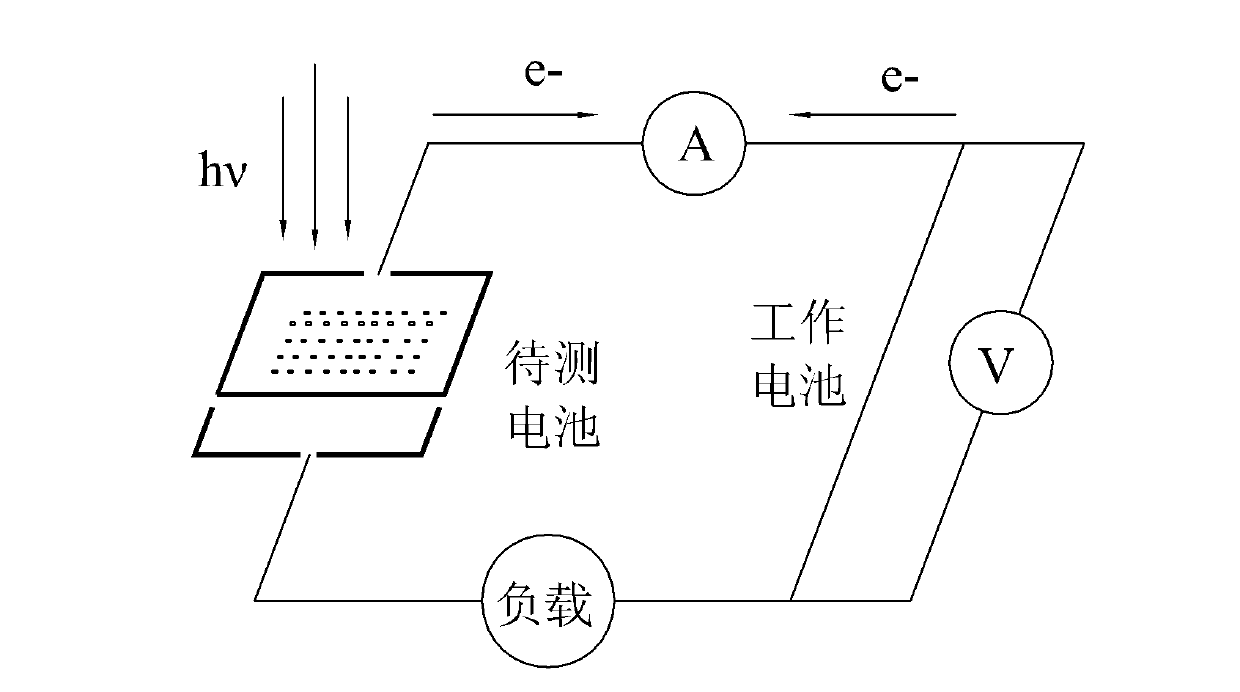

[0029] A dye-sensitized solar cell, the dye-sensitized solar cell includes an anode and a cathode, an electrolyte solution is injected between the anode and the cathode, and the anode is the photoanode of the dye solar cell prepared in Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com