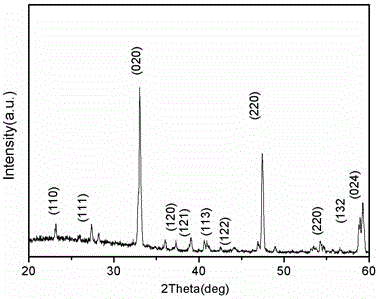

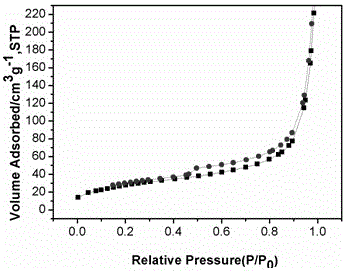

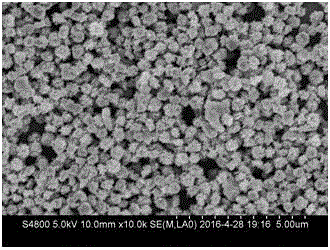

Solid phase preparation method of porous calcium titanate micro-nano particle spheres

A technology of micro-nano particles and solid-phase preparation, which is applied in the direction of titanate, alkaline earth metal titanate, chemical instruments and methods, etc., can solve the problem of few porous calcium titanate micro-nano spheres, and achieve convenient manipulation and application , Uniform shape and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0025] (1) Add 30mL of isopropanol and 5mL of dimethylformamide to a 50mL reaction flask in sequence, then add 0.6g of n-butyl titanate, and stir for 5min; The temperature of the system was raised to 140°C and maintained for 48 hours; after the thermal reaction was completed, the autoclave was allowed to cool down to room temperature naturally;

[0026] (2) The product obtained in step (1) was suction filtered, precipitated, and washed three times with absolute ethanol to obtain a precursor of porous dititanic acid submicron particle balls with a white hierarchical structure;

[0027] (3) Put 20g of calcium carbonate into a high-energy ball mill, and use three kinds of mixed beads with different particle sizes (Φ0.3mm:Φ0.6mm:Φ0.9mm=2:5:3 mass ratio) to pulverize calcium carbonate for 1 hour;

[0028] (4) In a stirring state, sequentially add the porous dititanic acid submicron-sized particle balls obtained in step (2) and the pulverized calcium carbonate in step (3) into a mix...

example 2

[0032] (1) Add 17.5mL of isopropanol and 5mL of dimethylformamide to a 50mL reaction flask in turn, then add 1.2g of n-butyl titanate and stir for 5min; then transfer the resulting solution to a high-pressure reactor, and The temperature of the reaction system was raised to 260°C and maintained for 2 hours; after the thermal reaction was over, the autoclave was allowed to cool down to room temperature naturally;

[0033] (2) The product obtained in step (1) was suction filtered, precipitated, and washed three times with absolute ethanol to obtain a precursor of porous dititanic acid submicron particle balls with a white hierarchical structure;

[0034] (3) Put 20g of calcium carbonate into a high-energy ball mill, and use three kinds of mixed beads with different particle sizes (Φ0.3mm:Φ0.6mm:Φ0.9mm=2:5:3 mass ratio) to pulverize calcium carbonate for 1 hour;

[0035] (4) In a stirring state, sequentially add the porous dititanic acid submicron-sized particle balls obtained in...

example 3

[0038] (1) Add 20mL of isopropanol and 15mL of dimethylformamide to a 50mL reaction flask in turn, then add 2g of n-butyl titanate, and stir for 5min; then transfer the resulting solution to a high-pressure reactor, and the reaction system Raise the temperature to 200°C and maintain it for 20 hours; after the thermal reaction is over, let the autoclave cool down to room temperature naturally;

[0039] (2) Suction filter the product obtained in step (1); precipitate and wash three times with absolute ethanol; obtain the precursor of porous dititanic acid submicron particle balls with white hierarchical structure;

[0040] (3) Put 20g of calcium carbonate into a high-energy ball mill, and use three kinds of mixed beads with different particle sizes (Φ0.3mm:Φ0.6mm:Φ0.9mm=2:5:3 mass ratio) to pulverize calcium carbonate for 1 hour;

[0041] (4) In a stirring state, sequentially add the porous dititanic acid submicron-sized particle balls obtained in step (2) and the pulverized cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com