Preparation method and application of nitrogen-doped porous carbon-loaded cobalt catalyst

A nitrogen-doped porous carbon and cobalt catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve the problems of reduced catalytic activity, easy cobalt agglomeration, unfavorable large-scale application, etc., to achieve cobalt The effect of increased load capacity, enhanced cycle stability, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0021] A preparation method of nitrogen-doped porous carbon-supported cobalt catalyst, the steps are as follows:

[0022] Three parts of 100mg N,N-disalicylaldehyde ethylenediamine cobalt(II) were added into respective crucibles, and then placed in a tube furnace, under the hydrogen-argon mixture gas atmosphere with the volume ratio of argon to hydrogen at 95:5 , heating and heating to 600°C, 700°C, and 800°C for calcination, the heating rate is 5° / min, and the calcination time is 1h; after the reaction is completed, cool to room temperature to prepare nitrogen-doped porous carbon-supported cobalt catalysts, which are named respectively It is CoN-C-600, CoN-C-700 and CoN-C-800 nanocomposite catalysts.

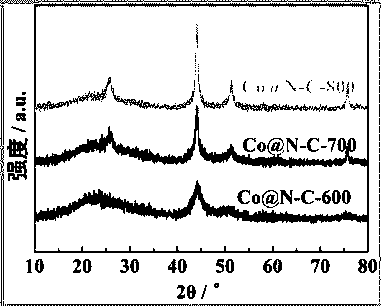

[0023] The XRD of CoN-C-600, CoN-C-700 and CoN-C-800 nanocomposite catalyst prepared by this embodiment are as follows: figure 1 As shown, where 2θ is equal to 26° is the diffraction peak of carbon, and the remaining three peaks are the diffraction peaks of simple cobalt. As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com