Foamed nickel composite material, and preparation method and application thereof

A composite material and nickel foam technology, applied in the field of electrochemical materials, can solve the problems of low specific capacitance and cannot meet the requirements of practical applications, achieve excellent pseudocapacitance, facilitate mass production, and reduce electrode resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

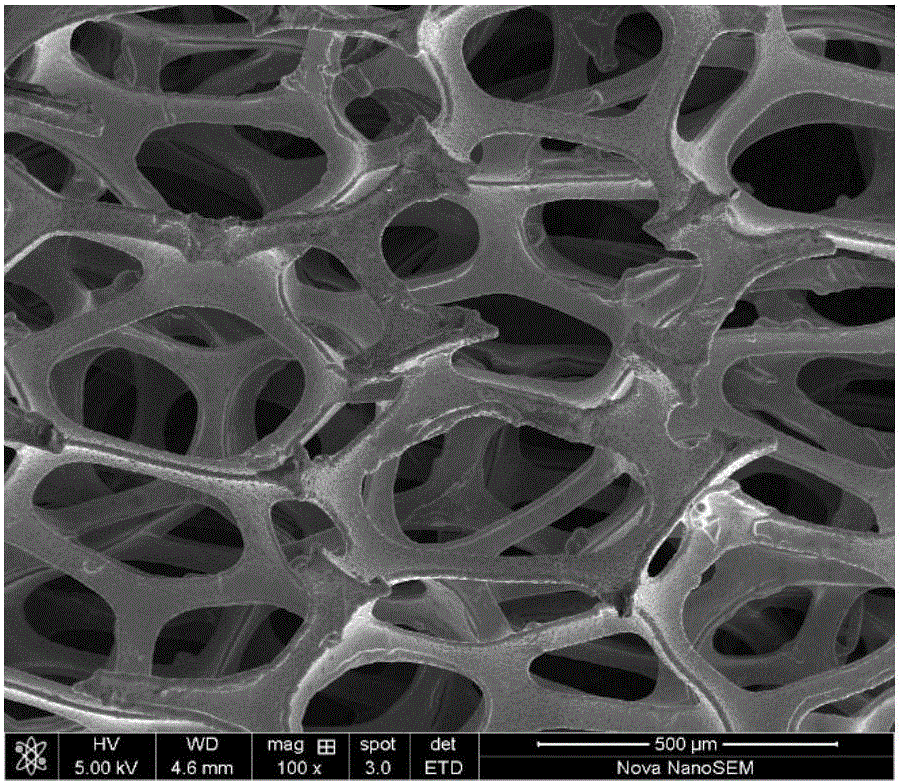

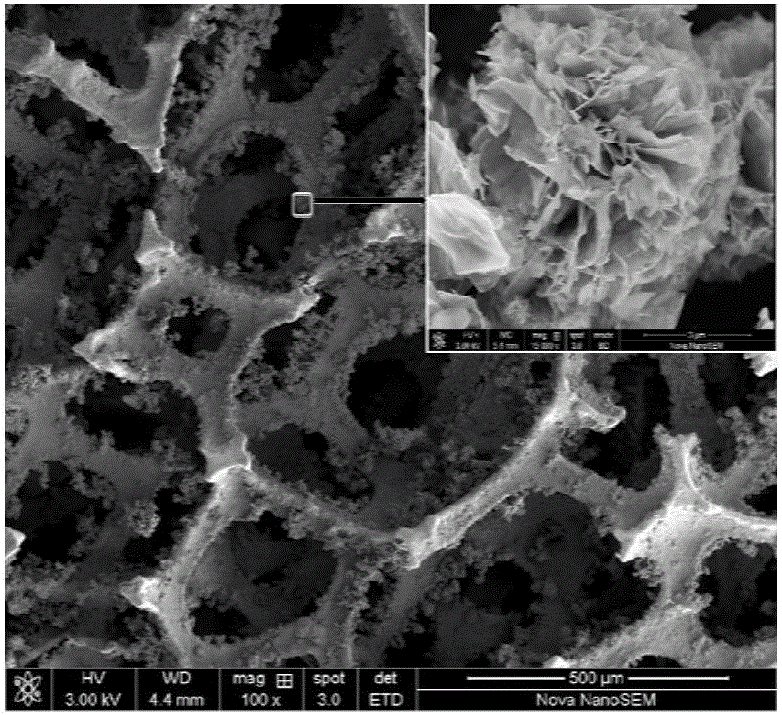

[0026] The preparation of embodiment 1 foamed nickel composite material

[0027] (1) Dissolve 0.01 g graphene oxide GO and 10 g surfactant sodium dodecylbenzene sulfonate in a mixed solution of 150 g methanol and 3 g water, and ultrasonically form a uniform graphene oxide suspension.

[0028] (2) Dissolving 0.81 mol of nickel nitrate and 0.27 mol of cobalt chloride in the graphene oxide suspension and stirring for 20 min to obtain a uniform suspension.

[0029] (3) Sonicate 1cm×1cm nickel foam with acetone, 0.01M hydrochloric acid, deionized water and absolute ethanol for 5 minutes respectively.

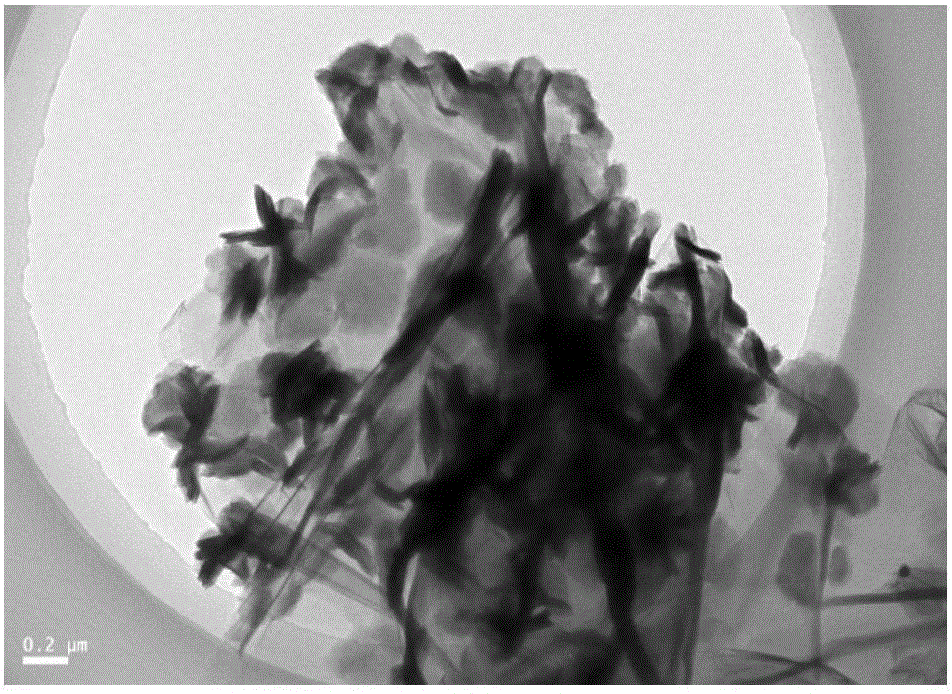

[0030] (4) Pour the homogeneous suspension described in (2) into a hydrothermal kettle, then immerse foamed nickel into the suspension, and react at 100° C. for 12 hours. After the reaction is finished, the nickel foam with graphene and nickel-cobalt hydroxide layered hydrotalcite-like growth is taken out, washed and dried to obtain a foamed nickel composite material with graphene a...

Embodiment 2

[0032] The preparation of embodiment 2 foam nickel composite material

[0033] (1) Dissolve 0.05 g of graphene oxide and 0.15 g of sodium dodecylsulfonate in a mixed solution of 75 g of methanol and 3 g of water, and ultrasonically form a uniform graphene oxide suspension.

[0034] (2) Dissolving 0.63 mol of nickel nitrate and 0.27 mol of cobalt chloride in the graphene oxide suspension and stirring for 20 min to obtain a uniform suspension.

[0035] (3) Sonicate 1cm×1cm nickel foam with acetone, 6M hydrochloric acid, deionized water and absolute ethanol for 30min respectively.

[0036] (4) Pour the homogeneous suspension described in (2) into a hydrothermal kettle, then immerse foamed nickel into the suspension, and react at 200° C. for 43 hours. After the reaction is finished, the nickel foam with graphene and nickel-cobalt hydroxide layered hydrotalcite-like growth is taken out, washed and dried to obtain a foamed nickel composite material with graphene and nickel-cobalt h...

Embodiment 3

[0037] The preparation of embodiment 3 foam nickel composite material

[0038] (1) Dissolve 0.05 g of graphene oxide and 1.5 g of sodium dodecylbenzenesulfonate in a mixed solution of 60 g of methanol and 20 g of water, and ultrasonically form a uniform graphene oxide suspension.

[0039] (2) Dissolve 0.39375 mol of nickel nitrate and 0.7875 mol of cobalt chloride in the graphene oxide suspension, and stir for 20 minutes to obtain a uniform suspension.

[0040] (3) Sonicate 1cm×1cm nickel foam for 30min with acetone, 3M hydrochloric acid, deionized water and absolute ethanol respectively.

[0041] (4) Pour the homogeneous suspension described in (2) into a hydrothermal kettle, then immerse foamed nickel into the suspension, and react at 180° C. for 30 h. After the reaction is finished, the nickel foam with graphene and nickel-cobalt hydroxide layered hydrotalcite-like growth is taken out, washed and dried to obtain a foamed nickel composite material with graphene and nickel-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com