A method for modifying graphite oxide to improve its ability to adsorb acid dyes

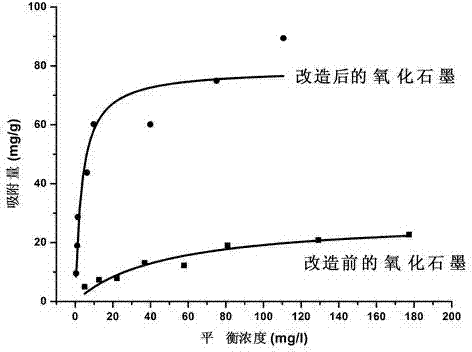

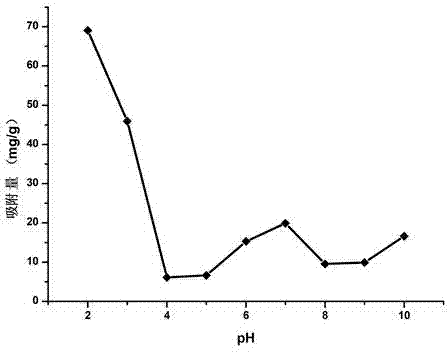

A technology of acid dyes and graphite, applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, can solve problems such as poor adsorption performance, limitations of graphite oxide, and restrictions on the application of graphite oxide, achieving magnetic, Improves adsorption performance and facilitates recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

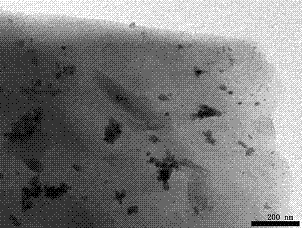

[0019] Graphite oxide (GO) was prepared by Tongshi's improved Hummer method using graphite as raw material.

[0020] 0.1g nano-Fe 3 o 4 Evenly dispersed in 80 ml ethanol, 20 ml water and 1 ml ammonia water, then added 0.03 g TEOS, stirred at room temperature for 6 hours. The resulting solid product was evenly dispersed in a mixed solution of 0.3g CTAB, 80ml deionized water, 1.5ml ammonia water and 60ml ethanol, and after stirring for 30min, 3.05g ZrOCl was added 2 , after the completion, the resulting solid product was refluxed with acetone for 48h, and after drying, Fe 3 o 4 -ZrO 2 .

[0021] Mix 0.1 g GO with 0.1 g Fe 3 o 4 -ZrO 2 Mix and disperse evenly in a mixed solution composed of 15mL ethanol and 60mL deionized water, ultrasonically disperse for 30 min, add 5 ml ethylenediamine, transfer to an autoclave, react at 180°C for 15 h, cool to room temperature, and use The solid product is separated by the magnet, and the product is obtained after drying at 70°C.

...

Embodiment 2

[0024] Graphite oxide (GO) was prepared by Tongshi's improved Hummer method using graphite as raw material.

[0025] 0.1g nano-Fe 3 o 4 Evenly dispersed in 80 ml ethanol, 20 ml water and 1 ml ammonia water, then added 0.03 g TEOS, stirred at room temperature for 6 hours. The resulting solid product was evenly dispersed in a mixed solution of 0.3g CTAB, 80ml deionized water, 1.5ml ammonia water and 60ml ethanol, and after stirring for 30min, 3.05g ZrOCl was added 2 , after the completion, the resulting solid product was refluxed with acetone for 48h, and after drying, Fe 3 o 4 -ZrO 2 .

[0026] Mix 0.1 g GO with 0.1 g Fe 3 o 4 -ZrO 2 Mix and disperse evenly in a mixed solution composed of 15mL ethanol and 60mL deionized water, ultrasonically disperse for 45 min, add 5 ml ethylenediamine, transfer to a high-pressure reactor, react at 180°C for 15 h, cool to room temperature, and use The solid product is separated by the magnet, and the product is obtained after drying a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com