A method for preparing composite material, composite material and application thereof

A composite material and graphite foam technology, applied in the field of materials, can solve the problems of poor stability and low specific capacitance of metal oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

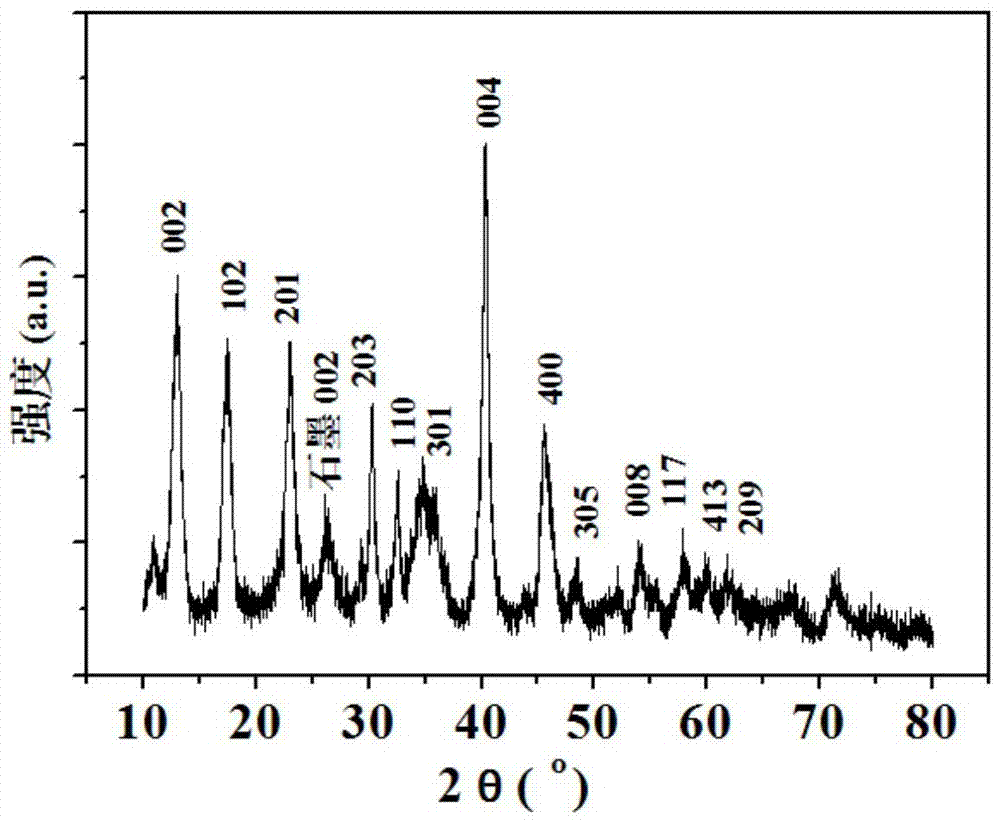

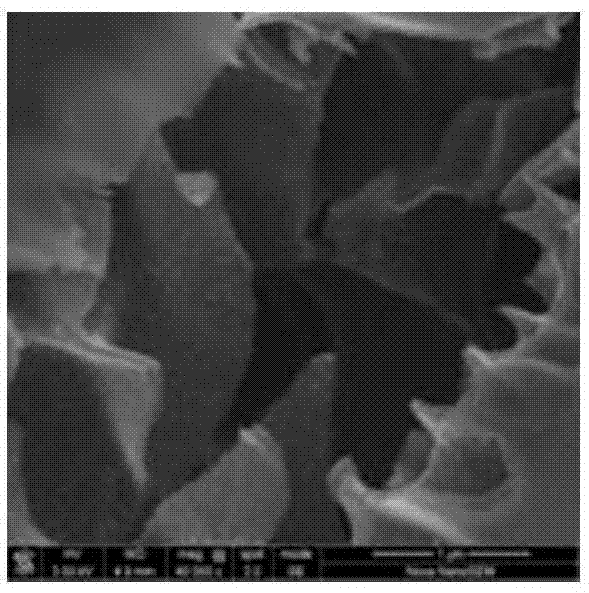

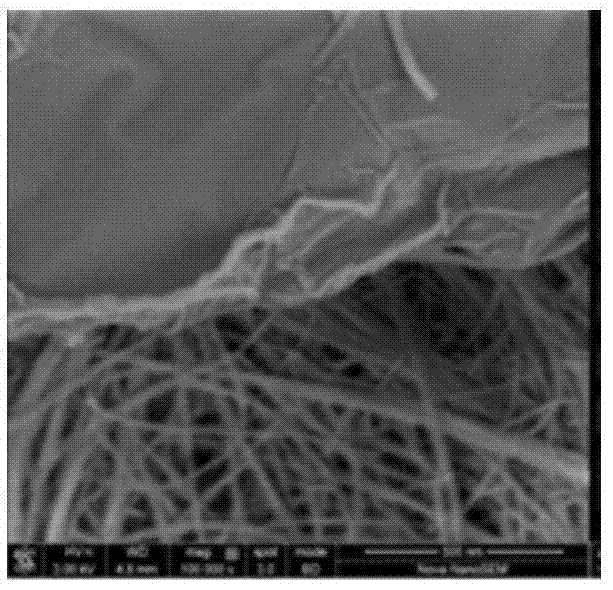

[0028] The mass percent of embodiment 1 nickel hydroxide nanowire is the preparation of the composite material of 85%

[0029] (1) Calcining sucrose and ammonium chloride at a molar ratio of 1:2 at 1000°C under an argon atmosphere for 2 hours to obtain foamed graphite with a three-dimensional porous structure.

[0030] (2) foamed graphite was added in the potassium hydroxide solution of 7mol / L (mass ratio 0.1, the quality of the potassium hydroxide in the potassium hydroxide solution is 10 times of the quality of foamed graphite) and stirred for 4 hours, left standstill for 20 After a small hour, it was filtered and dried at 60°C for 24 hours to obtain activated foam graphite.

[0031] (3) Activated foamed graphite and mixed acid (volume ratio: sulfuric acid: nitric acid = 1:1) were acidified under ultrasonic for 2 hours, and acidified foamed graphite was obtained after washing and drying.

[0032] (4) Acidified foamed graphite is added to nickel sulfate solution (mass ratio ...

Embodiment 2

[0034] Preparation of embodiment 2 composite material

[0035] (1) Calcining sucrose and ammonium chloride at a molar ratio of 2.5:1 at 1500°C under an argon atmosphere for 5 hours to obtain foamed graphite with a three-dimensional porous structure.

[0036] (2) The foamed graphite was added to potassium hydroxide solution (mass ratio 1) and stirred for 4 hours, filtered after standing for 20 hours, and dried at 60° C. for 24 hours to obtain activated foamed graphite.

[0037](3) Activated graphite foam and mixed acid (sulfuric acid: nitric acid = 3:1) were acidified under ultrasonic for 5 hours, and acidified graphite foam was obtained after washing and drying.

[0038] (4) Add the acidified foamed graphite into the nickel sulfate solution (mass ratio 0.03) and mix to form a uniform suspension, maintain vigorous stirring and slowly add the solution of sodium hydroxide (nickel sulfate and sodium hydroxide mol ratio is 3) dropwise to in the suspension. Hydrothermal treatment ...

Embodiment 3

[0040] The mass percent of embodiment 3 nickel hydroxide nanowires is the preparation of the composite material of 30%

[0041] (1) Calcining sucrose and ammonium chloride at a molar ratio of 1:2 at 1500°C under an argon atmosphere for 2 hours to obtain foamed graphite with a three-dimensional porous structure.

[0042] (2) The foamed graphite was added to potassium hydroxide solution (mass ratio 1) and stirred for 4 hours, filtered after standing for 20 hours, and dried at 60° C. for 24 hours to obtain activated foamed graphite.

[0043] (3) Activated foam graphite and mixed acid (sulfuric acid: nitric acid = 3:1) were acidified under ultrasonic for 2 hours, and acidified foam graphite was obtained after washing and drying.

[0044] (4) The acidified foamed graphite is added into the nickel sulfate solution (mass ratio 0.82) and mixed to form a uniform suspension, and the sodium hydroxide (nickel sulfate and sodium hydroxide mol ratio is 1) solution is slowly added dropwise u...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com