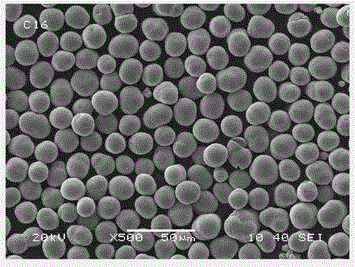

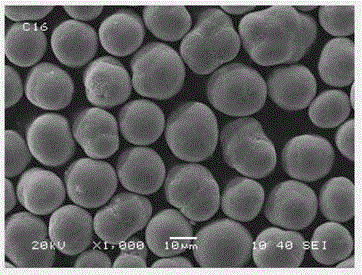

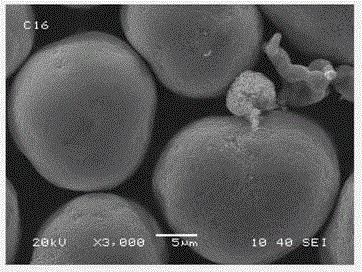

Method for preparing high-sphericity-degree and large-particle cobaltosic oxide

A technology with high sphericity of cobalt trioxide, which is applied in the direction of cobalt oxide/cobalt hydroxide, electrical components, battery electrodes, etc., can solve the problem of rapid capacity cycle decay of lithium cobalt oxide batteries, battery energy density has not been improved, particle sphericity and serious problems. Density difference and other problems, to achieve the effect of strengthening natural ecological protection, high voltage, and less environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment one: the cobalt salt raw material is made into the cobalt salt solution that cobalt salt content is 90g / L with deionized water; Precipitant is dissolved in deionized water, is mixed with the precipitant solution of 220g / L; Cobalt salt solution and The precipitant solution is injected into the reactor in a parallel flow mode, and stirred and heated for reaction. The injection rate of the cobalt salt solution is 800L / h, the injection rate of the precipitant solution is 900L / h, and the temperature in the reactor is controlled at 55 ℃, the rotation speed is 60r / min, and the particle size of the cobalt carbonate synthesized for the first time is controlled at about 8.0um; the cobalt carbonate synthesis process adopts a separate kettle process. After a period of reaction, when the number of crystallization reaches 6 times, the reaction kettle Transfer 1 / 2 of the slurry to other empty tanks to continue the reaction. After the reaction is complete, the product is wash...

Embodiment 2

[0043] Embodiment two: the cobalt salt raw material is made into the cobalt salt solution that cobalt content is 120g / L with deionized water; Precipitant is dissolved in deionized water, is filtered and is mixed with the precipitant solution of 250g / L; Cobalt salt solution and The precipitant solution is injected into the reaction kettle in parallel flow, and stirred and heated for reaction. The injection rate of the cobalt salt solution is 1200L / h, the injection rate of the precipitant solution is 1200L / h, and the temperature in the reaction kettle is controlled at 45 ℃, the rotation speed is 90r / min, and the particle size of cobalt carbonate synthesized for the first time is controlled at about 6.0um; the cobalt carbonate synthesis process adopts a separate kettle process. After a period of reaction, when the number of crystallization reaches 8 times, the reaction kettle Transfer 1 / 2 of the slurry to other empty tanks to continue the reaction. After the reaction is complete, ...

Embodiment 3

[0045] Embodiment three: the cobalt salt raw material is made into the cobalt salt solution that cobalt content is 110g / L with deionized water; Precipitant is dissolved in deionized water, is filtered and is mixed with the precipitant solution of 240g / L; Cobalt salt solution and The precipitant solution is injected into the reactor in parallel flow for synthesis reaction, the injection rate of the cobalt salt solution is 1200L / h, the injection rate of the precipitant solution is 1120L / h, the temperature in the reactor is 52°C, and the rotation speed is 80r / min, the particle size of the cobalt carbonate synthesized for the first time is controlled at about 7.0um; the cobalt carbonate synthesis process adopts a separate kettle process, and after a period of reaction, when the number of crystallization reaches 7 times, the slurry in the reactor is transferred 1 / 2 to other empty kettles. After the reaction is complete, the product is washed and centrifuged to finally obtain large-p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com