Thermal transfer printing equipment

A technology of thermal transfer and thermal transfer film, which is applied in transfer printing, rotary printing machine, printing and other directions, which can solve the problems of large loss of hot melt powder, clogging of arc screen, and inability to achieve uniform spreading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] This part will describe the specific embodiment of the present invention in detail, and the preferred embodiment of the present invention is shown in the accompanying drawings. Each technical feature and overall technical solution of the invention, but it should not be understood as a limitation on the protection scope of the present invention.

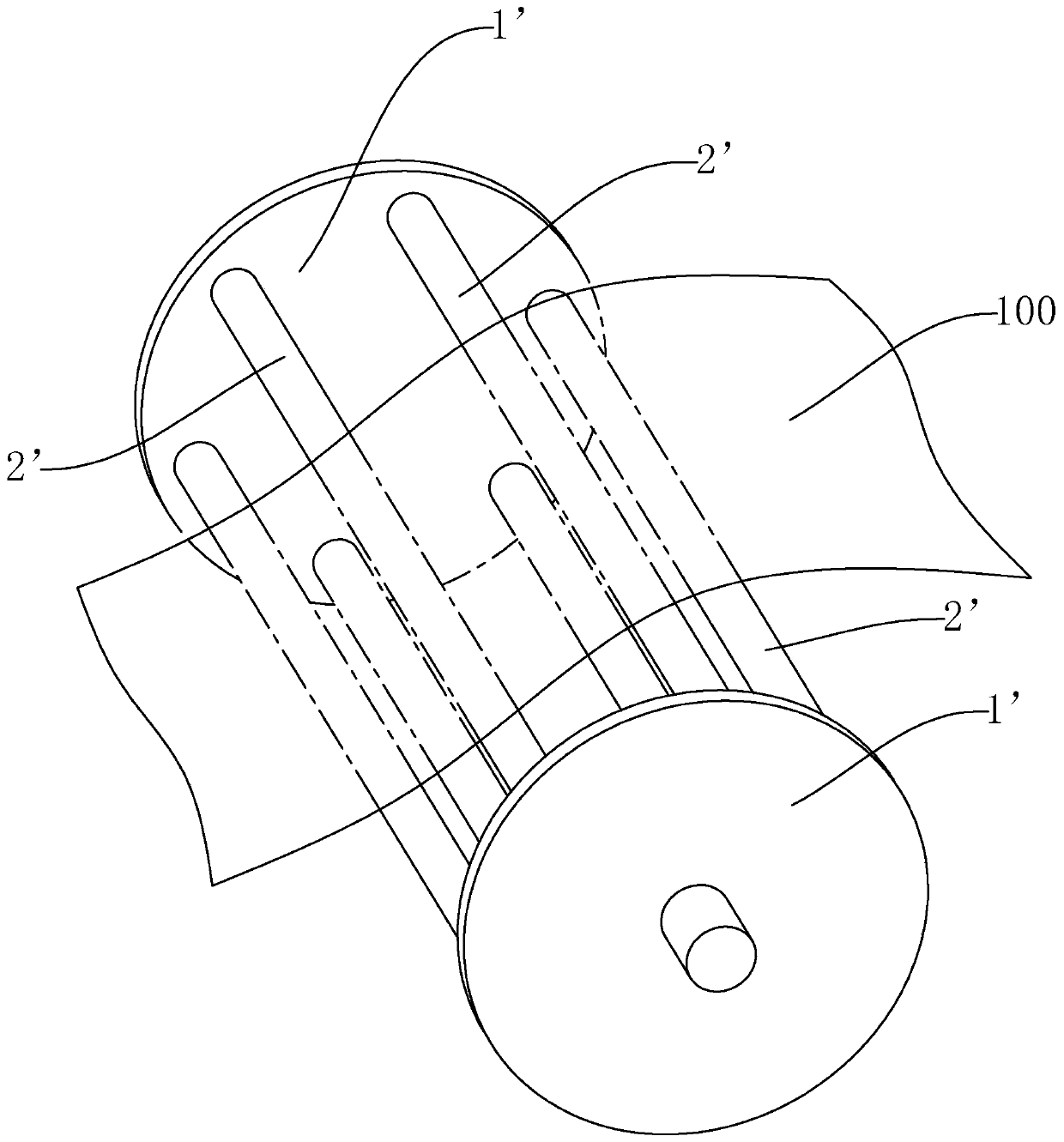

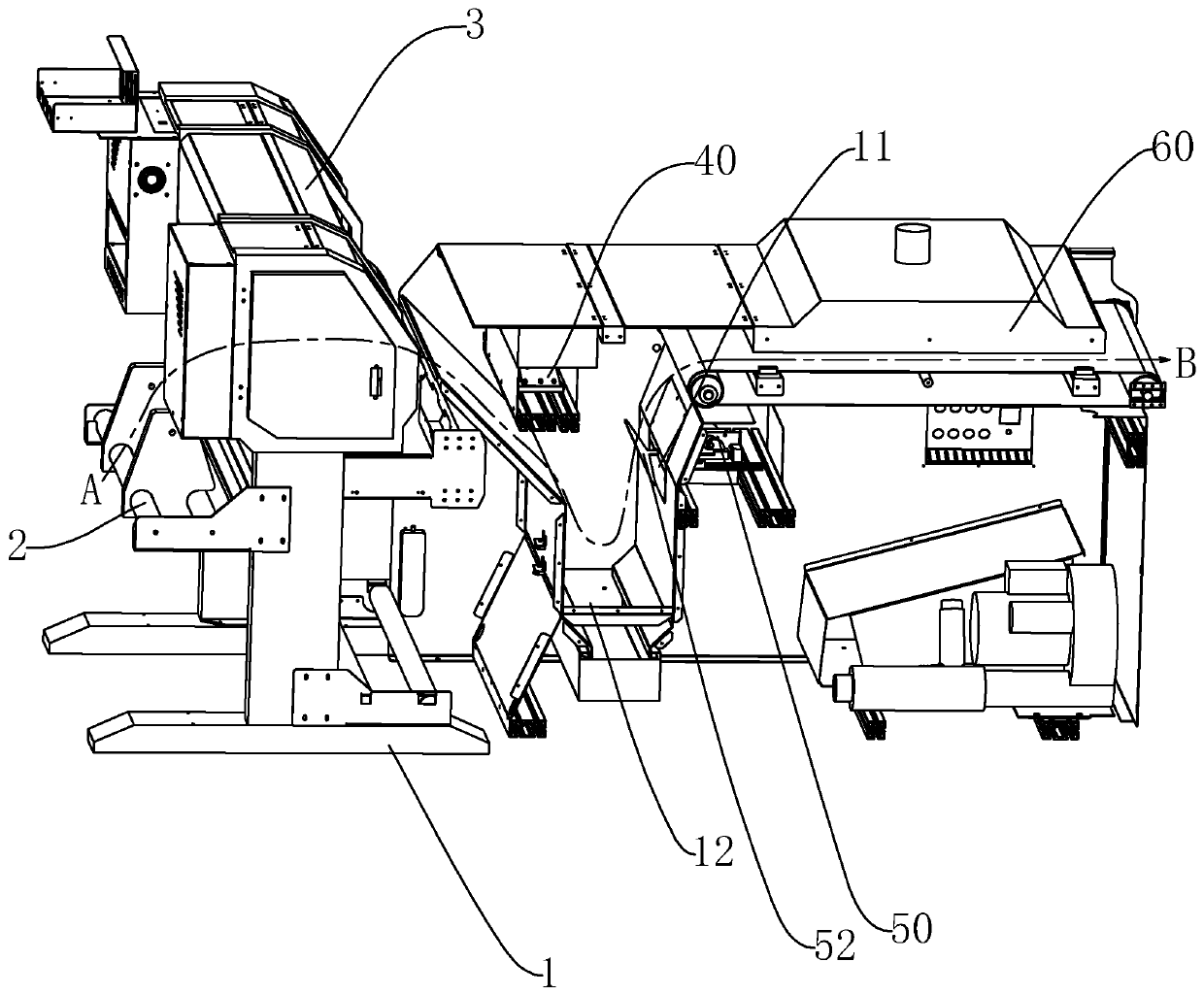

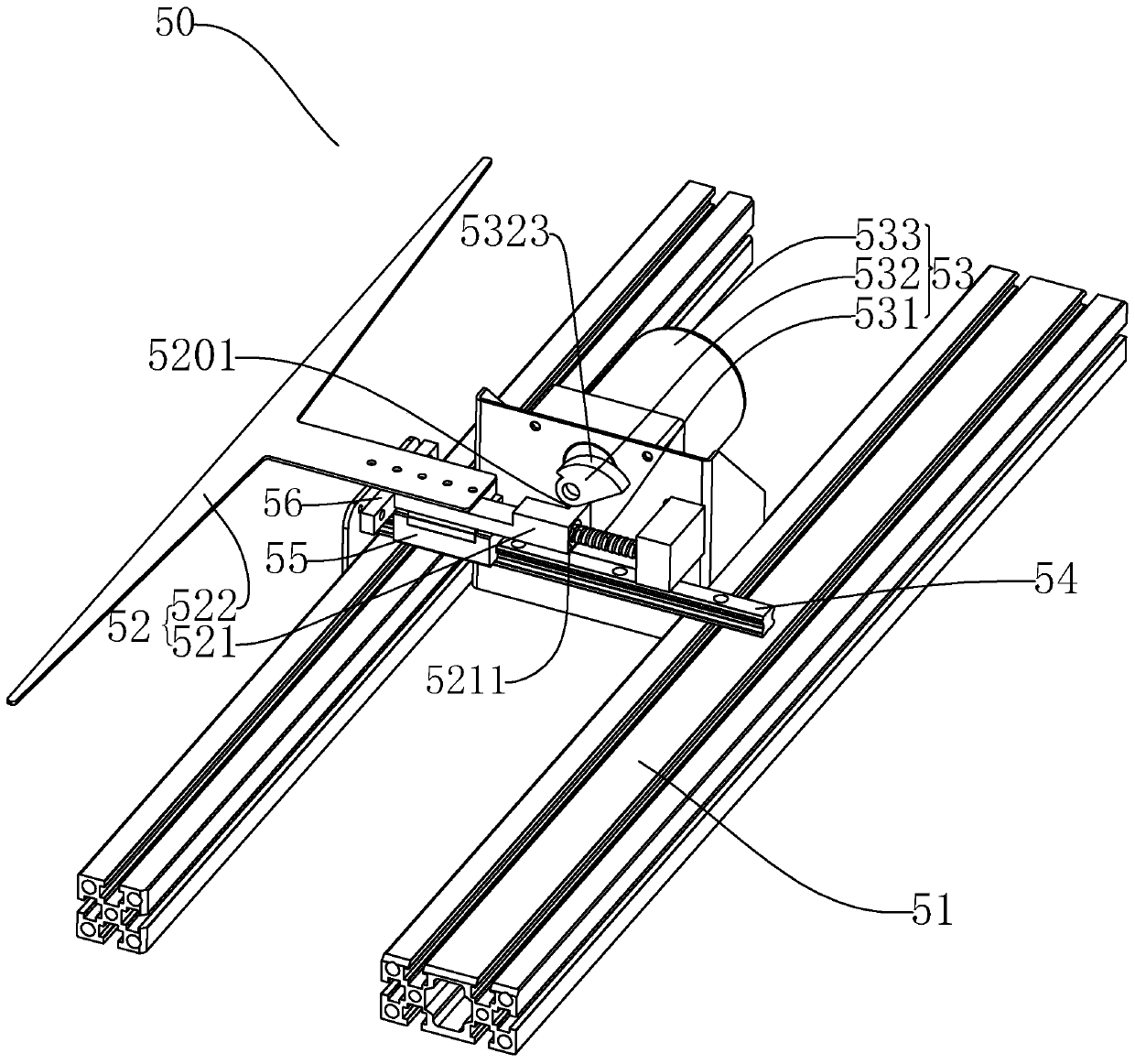

[0029] refer to figure 2 , a kind of thermal transfer equipment of the present invention, comprises frame 1, and described frame 1 is provided with unwinding mechanism 2, printing mechanism 3, powder spreading mechanism 40, powder Clearing device 50 and heating curing device 60, wherein, the conveying direction of thermal transfer film sees figure 2The trajectory shown by the line segment AB; the unwinding mechanism 2 is used to release the thermal transfer film, the printing device is used to print the pattern on the thermal transfer film, and the powder spreading mechanism 40 is used to apply hot melt powder Sprinkle on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com