Patents

Literature

33results about How to "Guaranteed processing yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

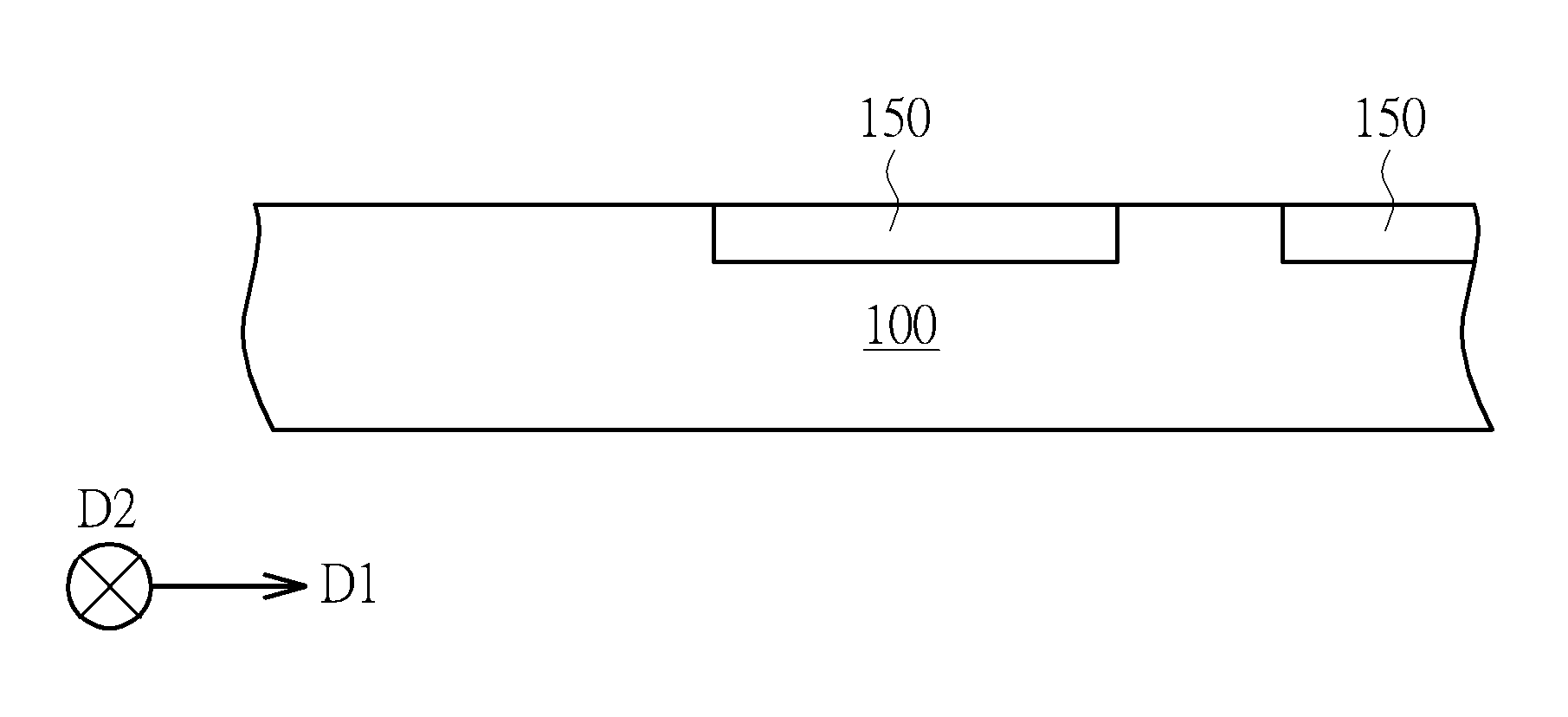

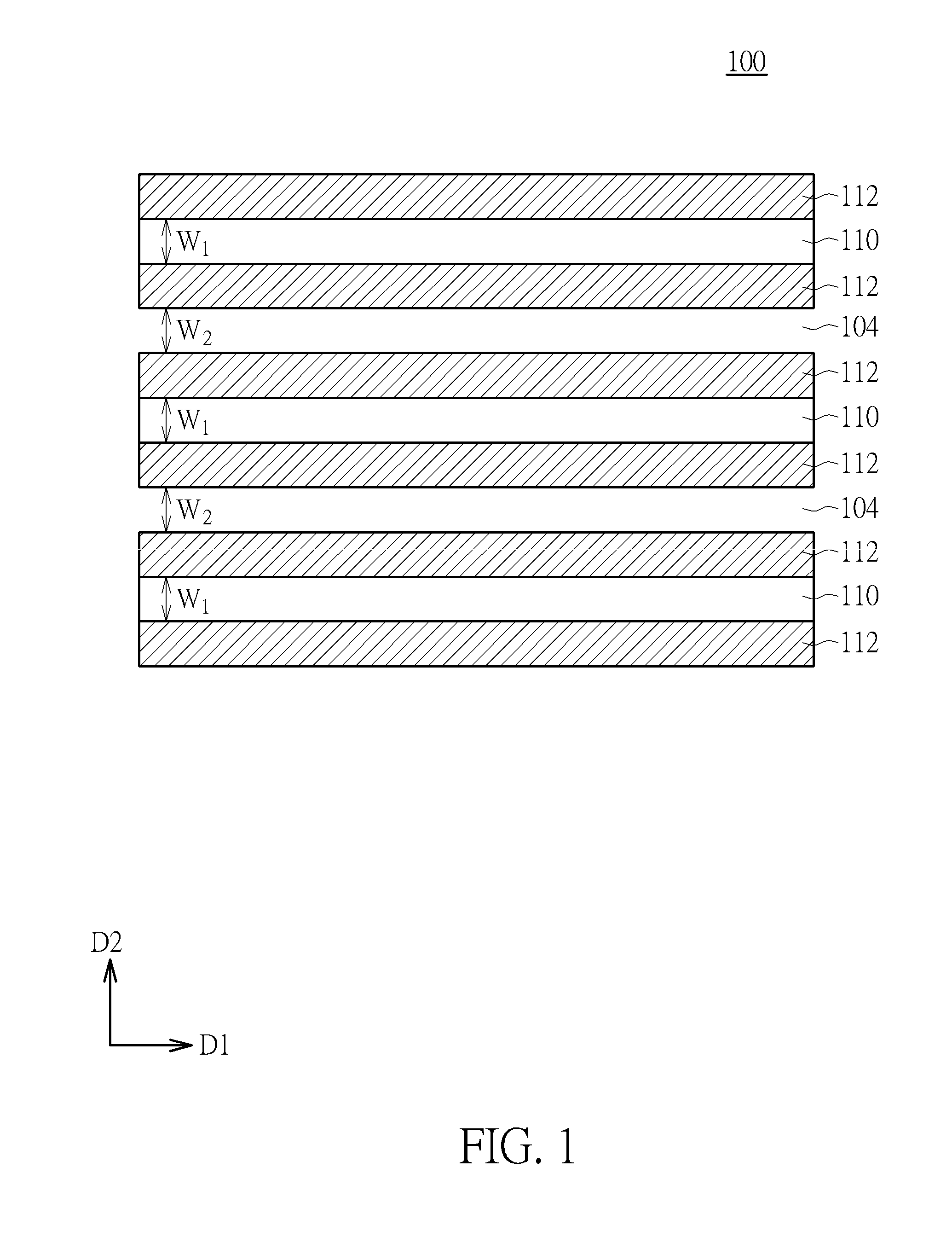

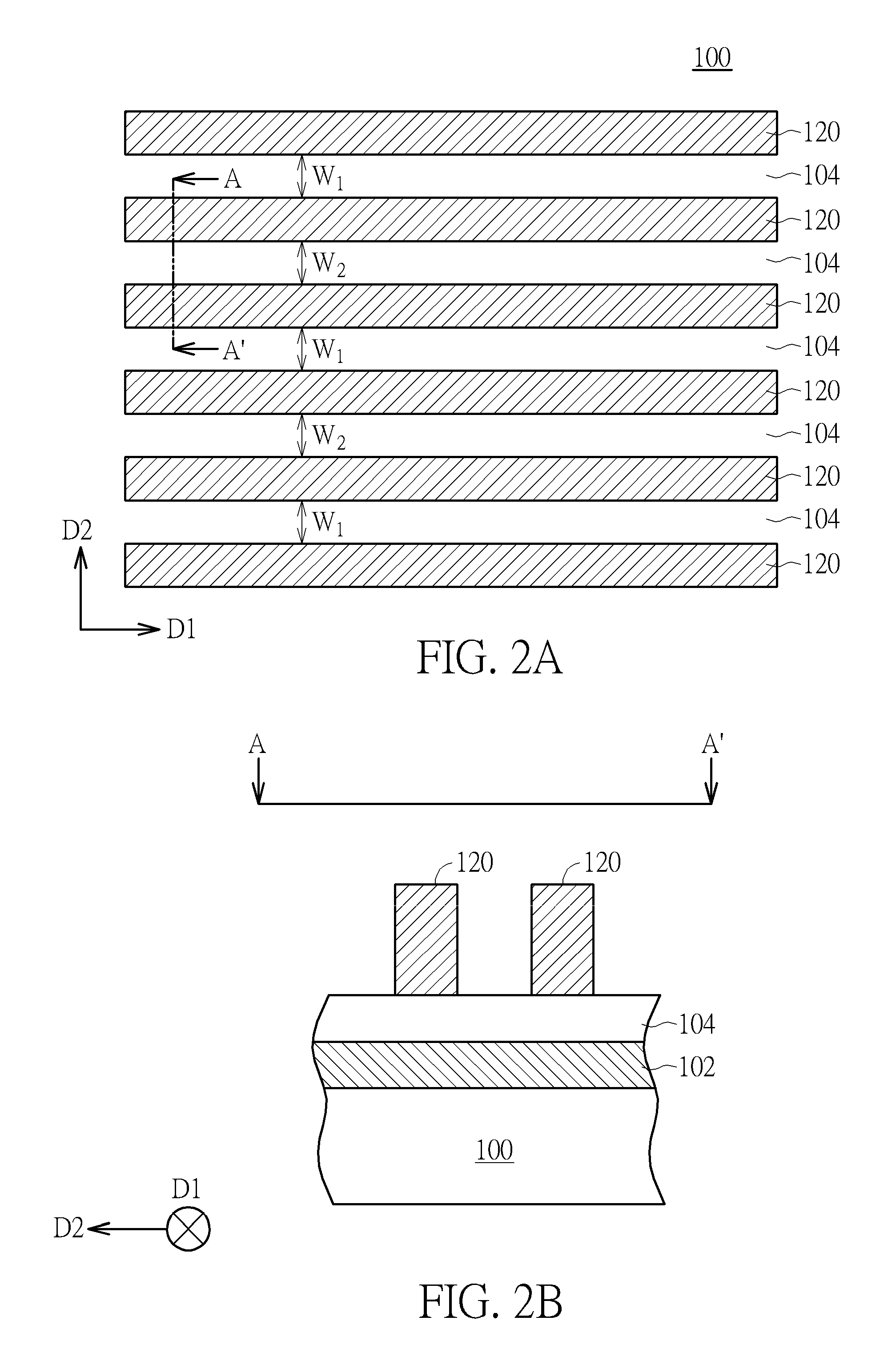

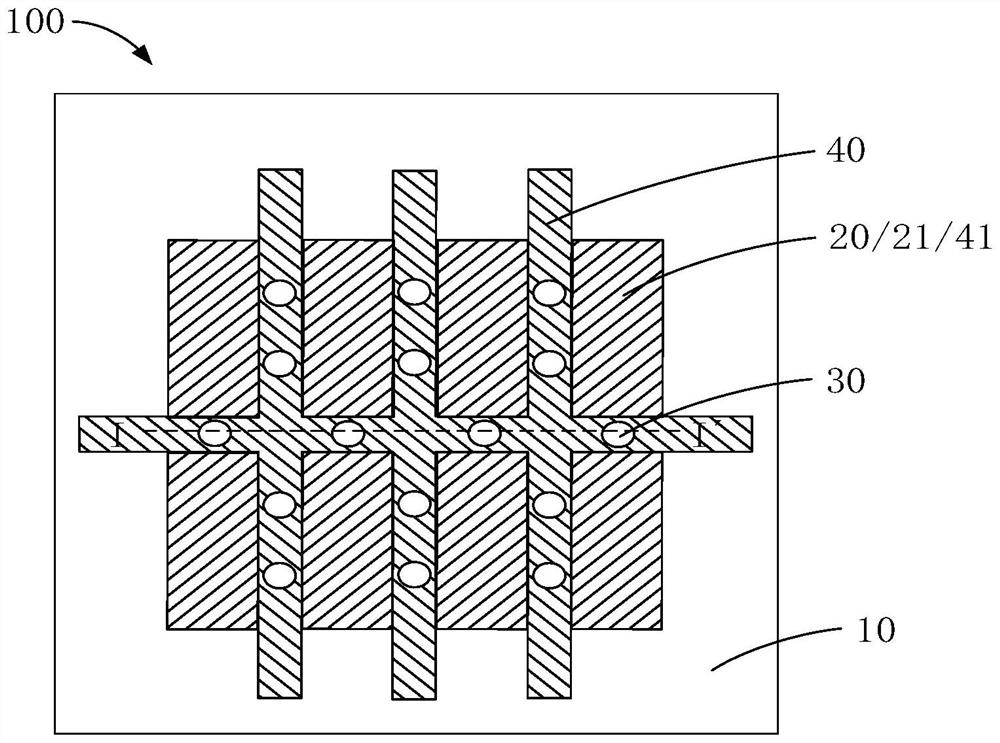

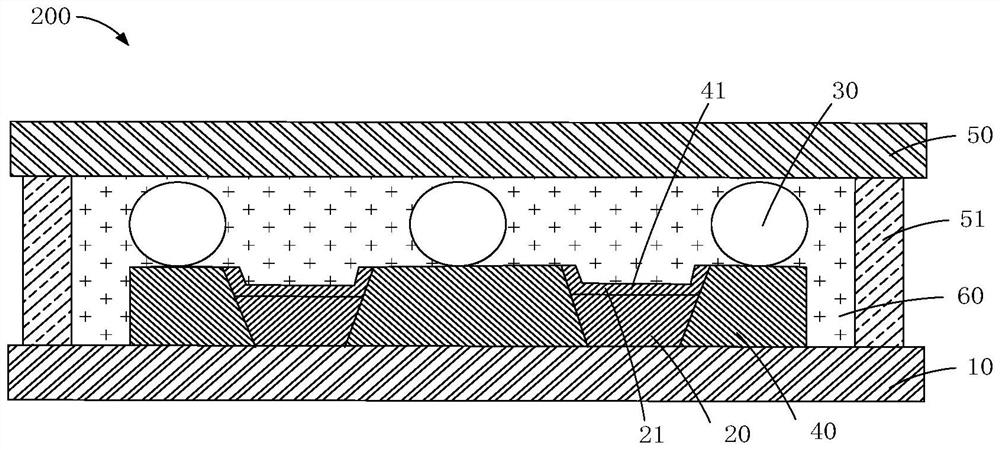

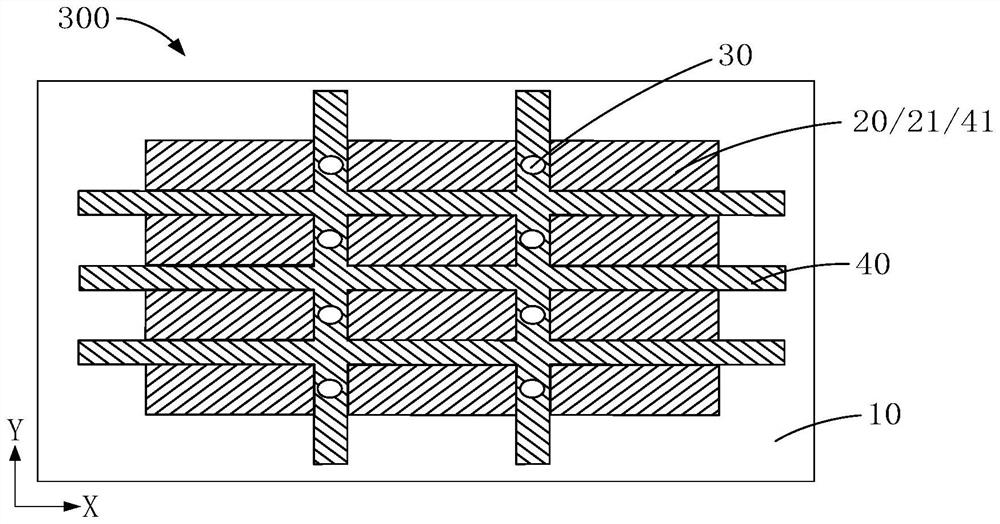

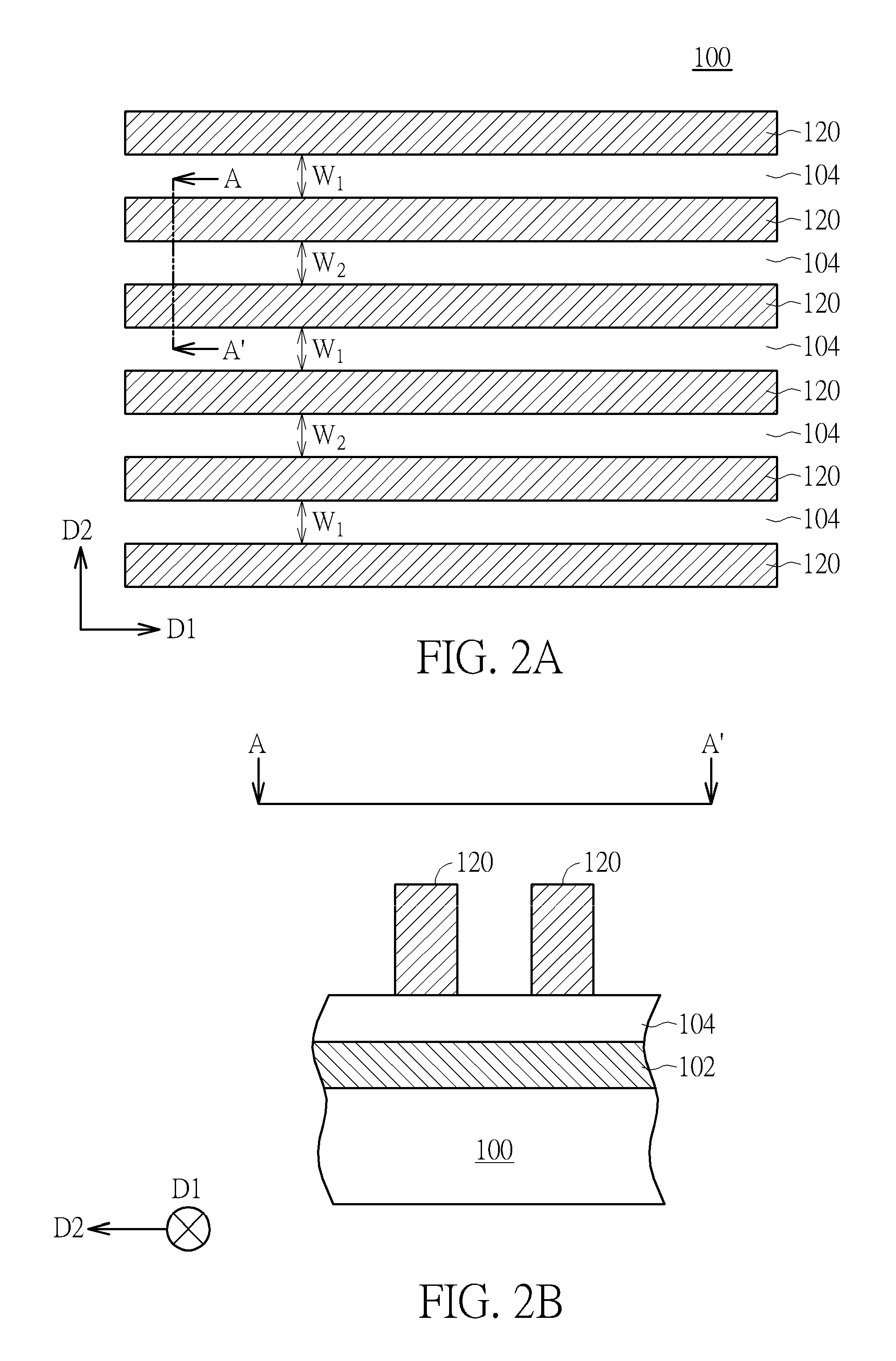

Method for forming patterns for semiconductor device

ActiveUS20160351410A1Guaranteed processing yieldSemiconductor/solid-state device manufacturingPower semiconductor deviceEngineering

A method for forming patterns for semiconductor device includes following steps. A substrate is provided. The substrate includes a hard mask layer and a sacrificial layer formed thereon. A plurality of spacer patterns parallel with each other are formed on the substrate. A plurality of first blocking layers are formed in the sacrificial layer after forming the spacer patterns. A plurality of second blocking layers exposing at least a portion of the sacrificial layer and at least a portion the first blocking layer are formed on the substrate after forming the first blocking layer. Next, the sacrificial layer and the hard mask layer are etched with the spacer patterns, the first blocking layers and the second blocking layer being used as etching masks to form a patterned hard mask layer on the substrate.

Owner:UNITED MICROELECTRONICS CORP

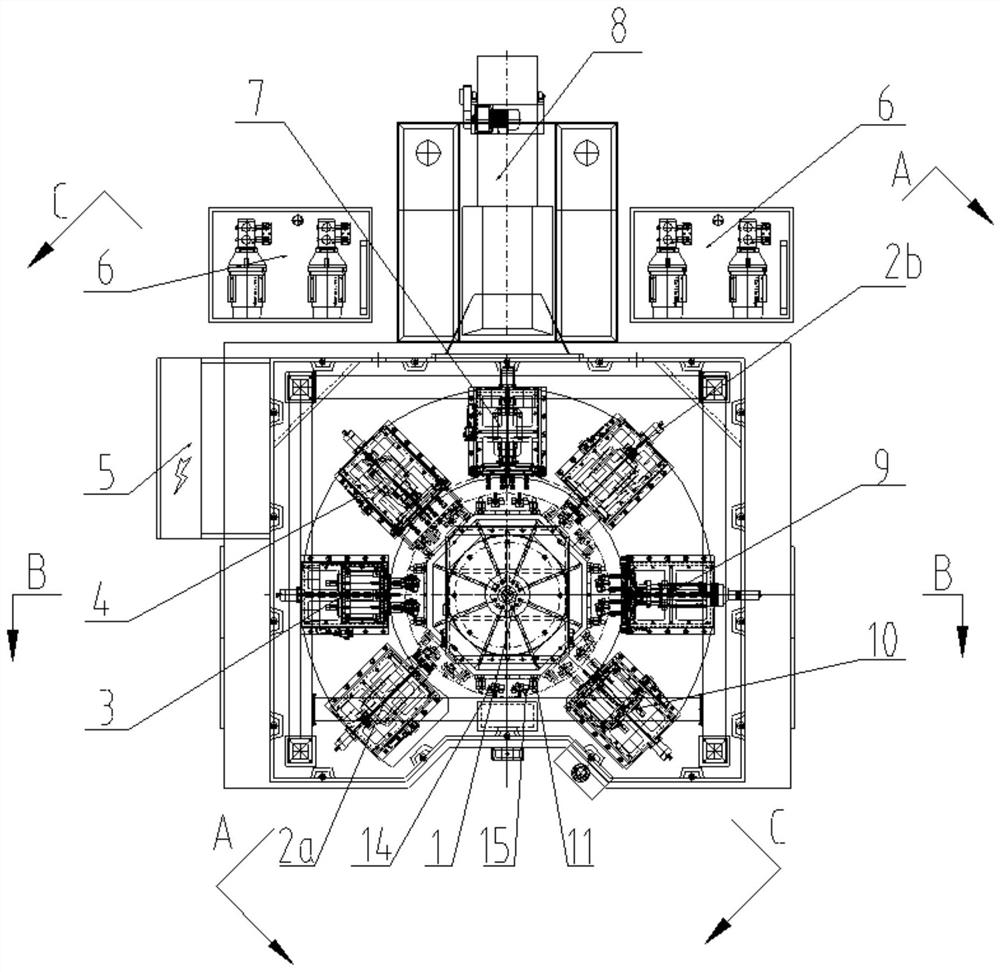

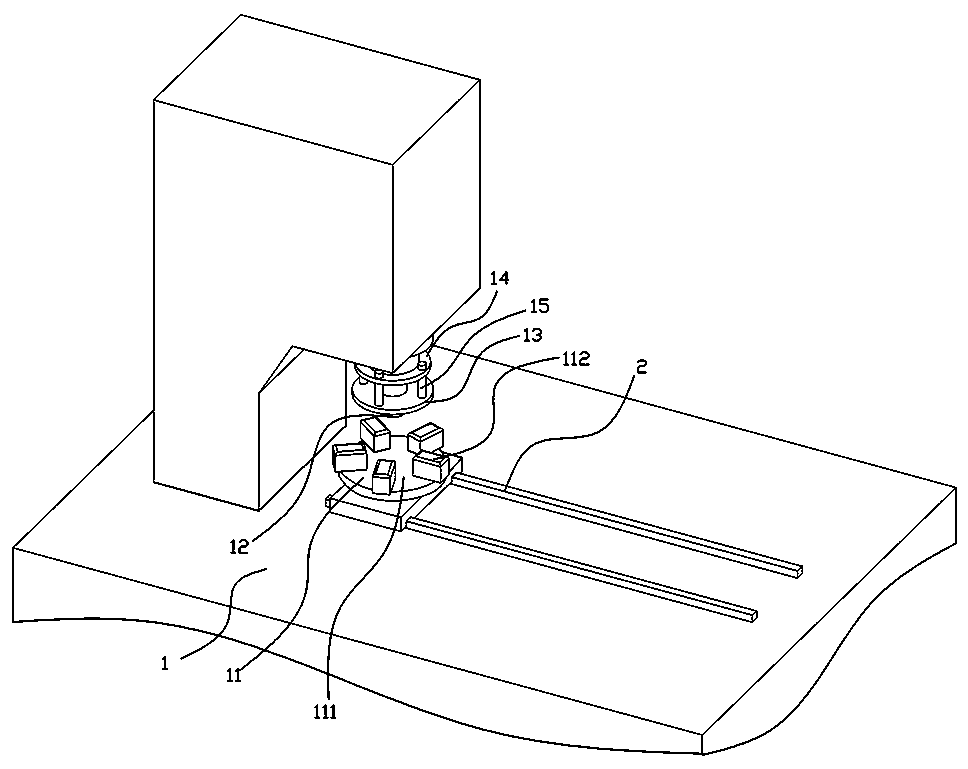

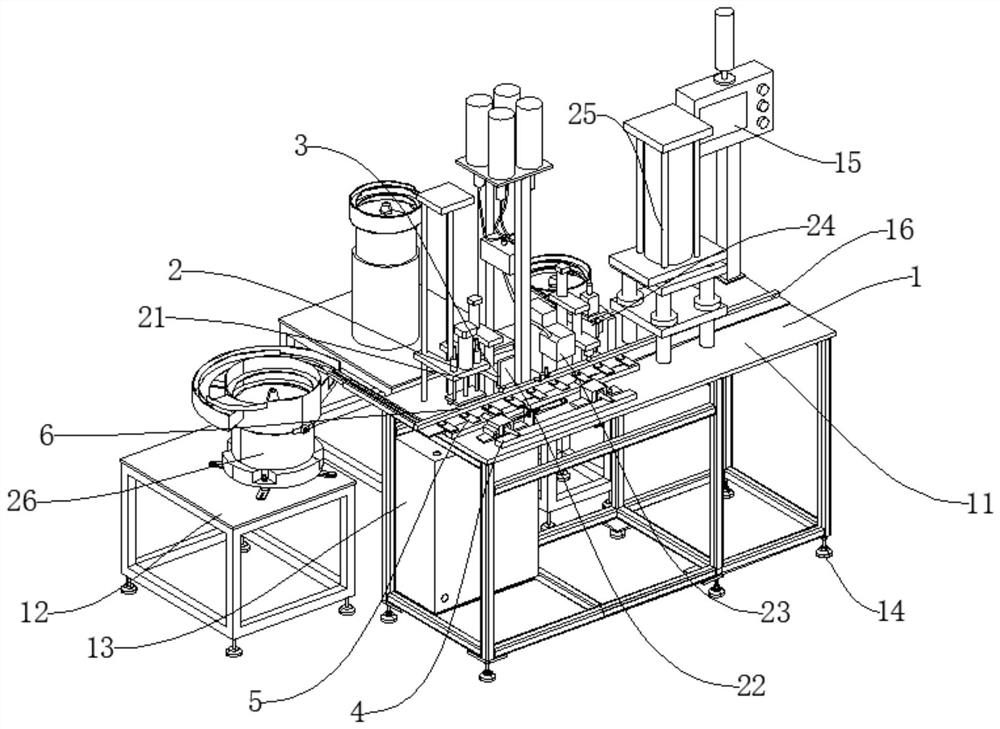

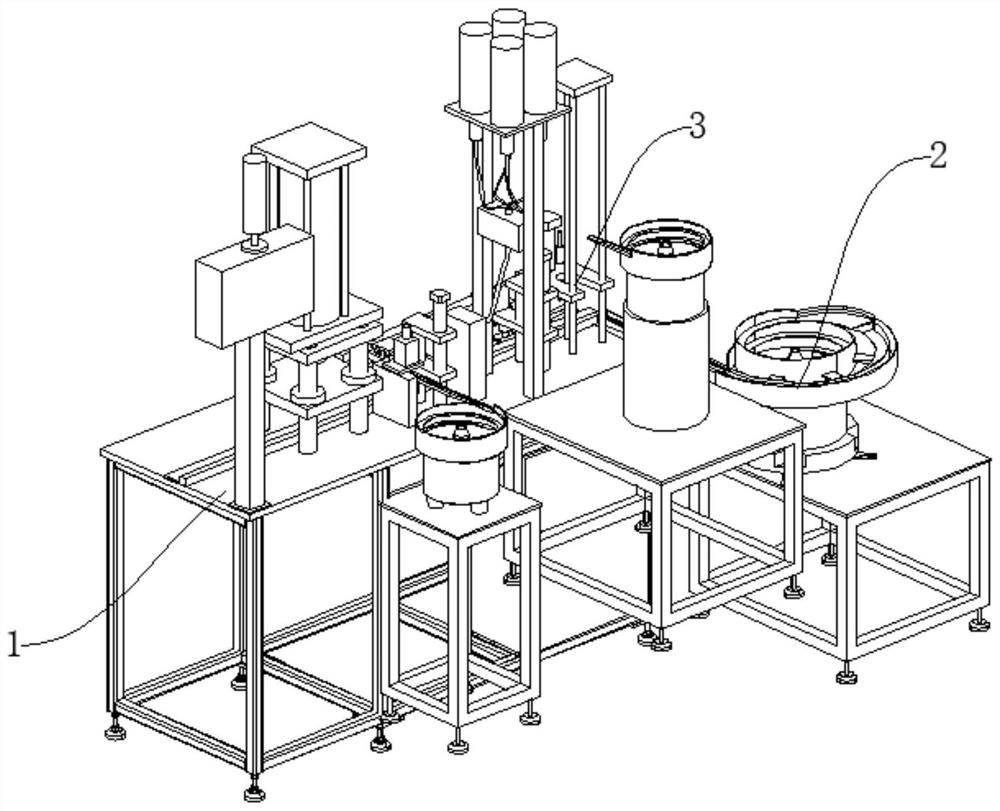

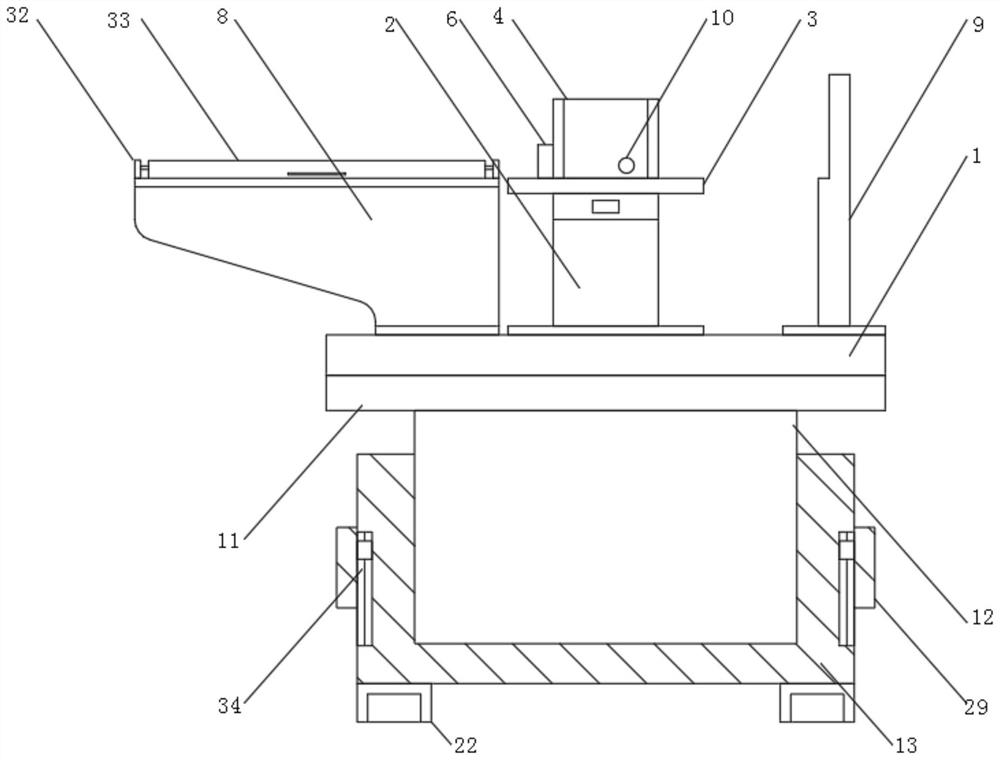

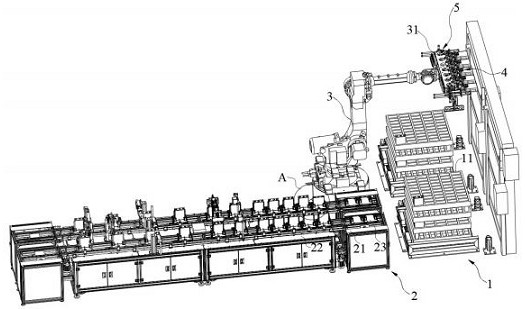

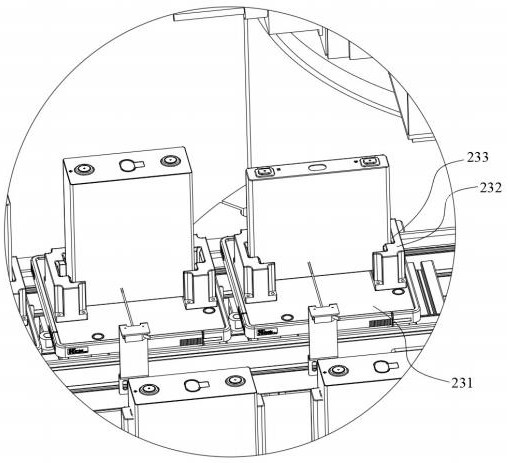

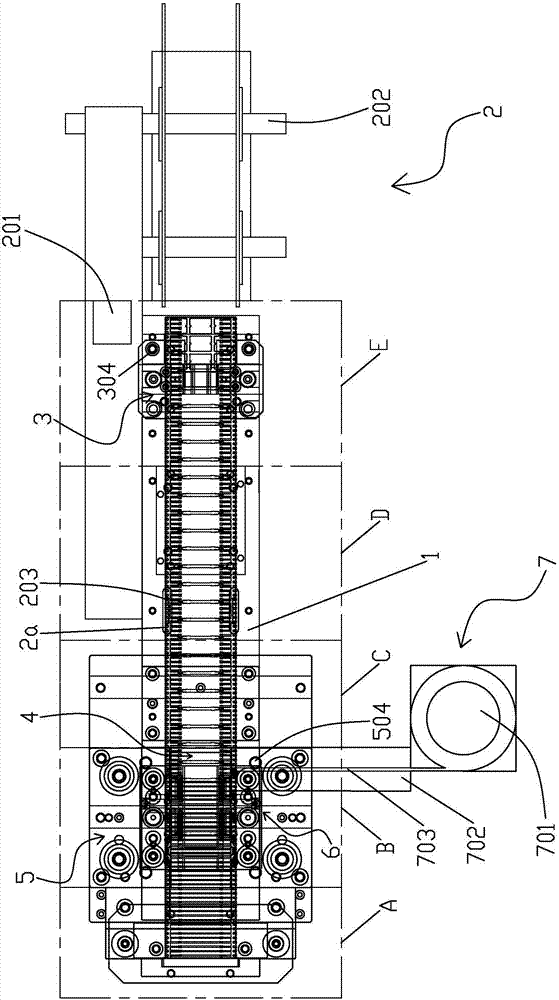

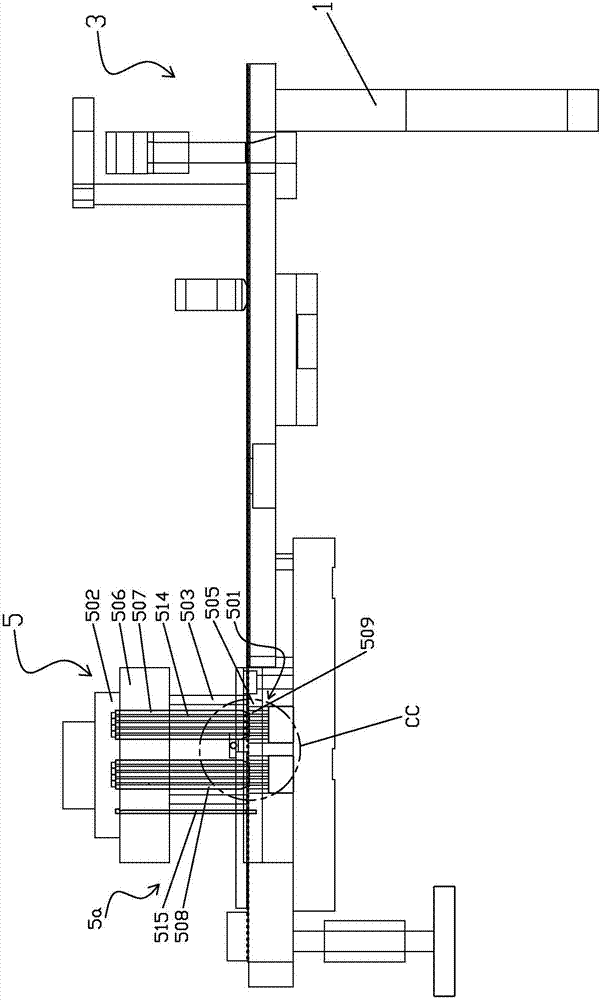

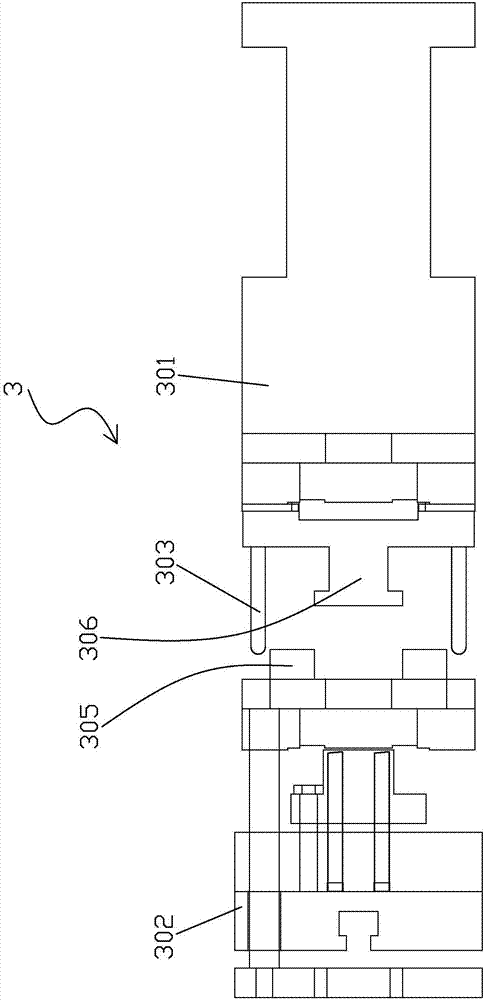

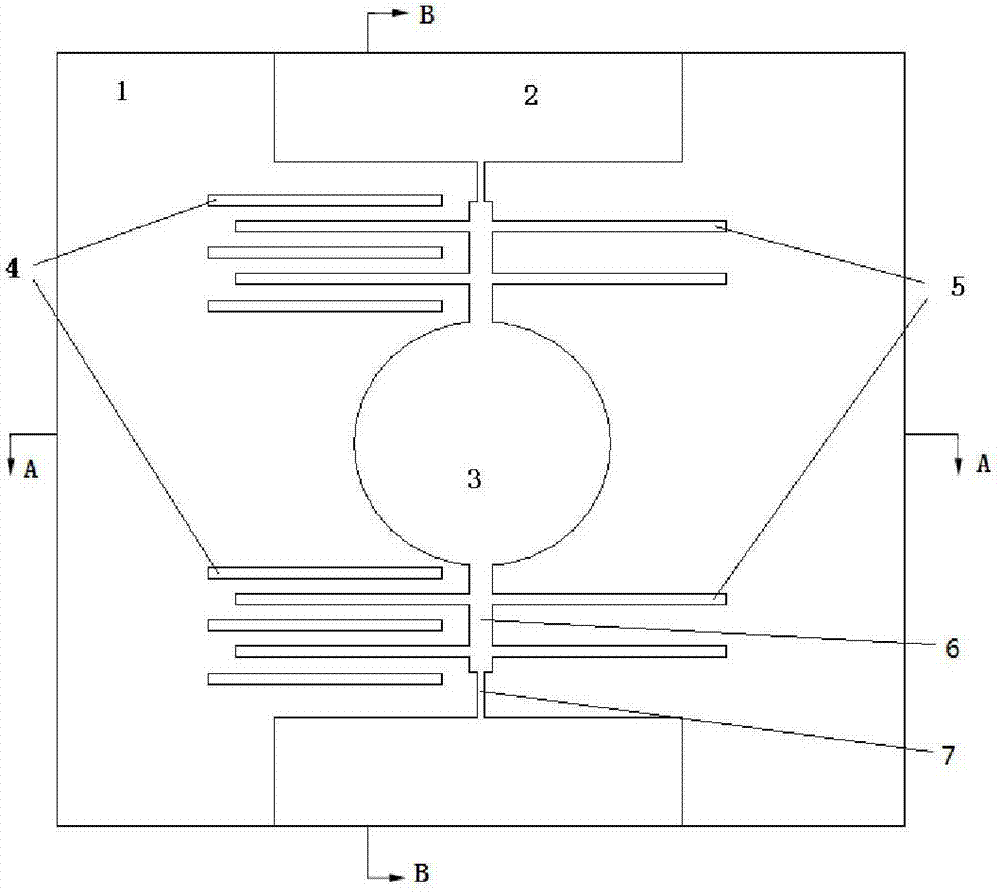

Eight-station crankcase stator combination machining device

PendingCN111673479ARealize multiple quantizationQuality assuranceOther manufacturing equipments/toolsPositioning apparatusCrankcaseControl theory

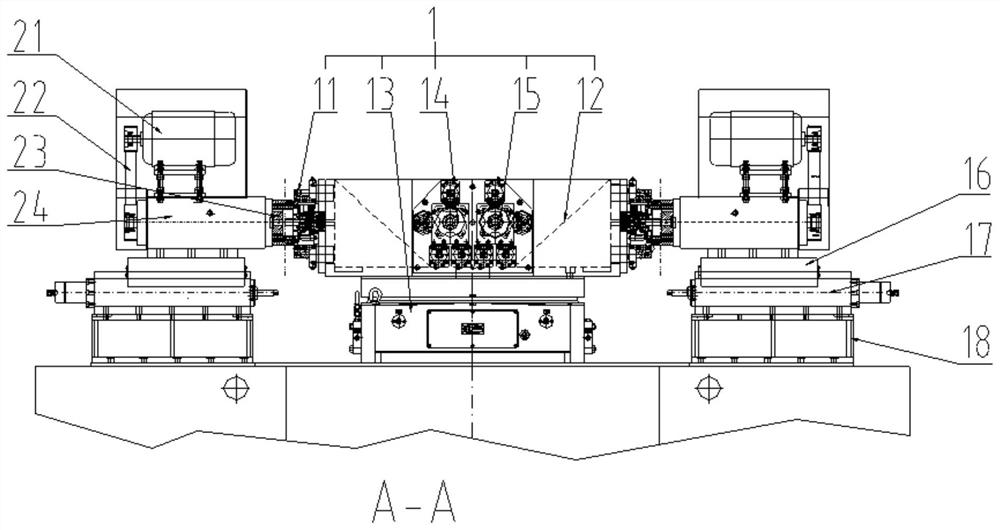

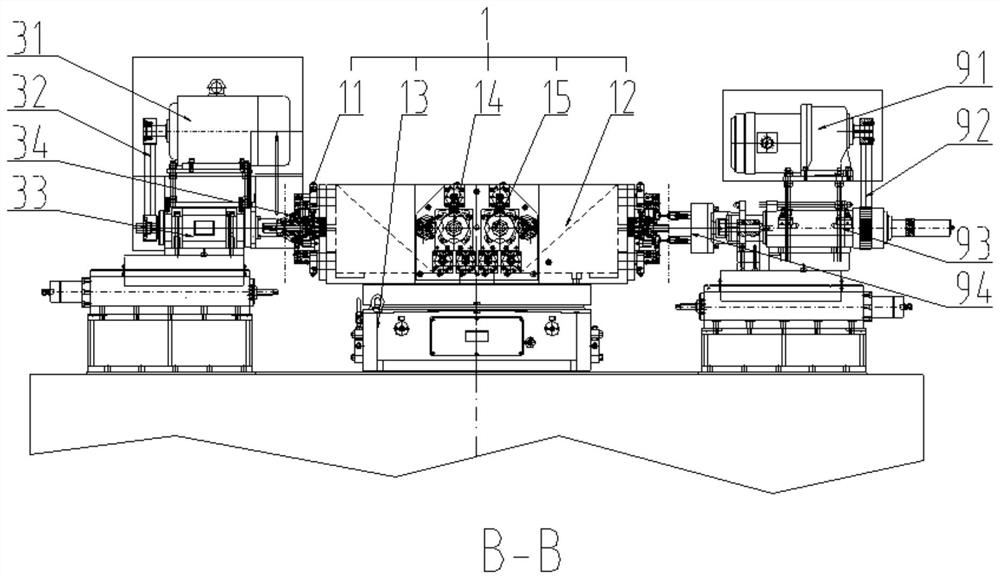

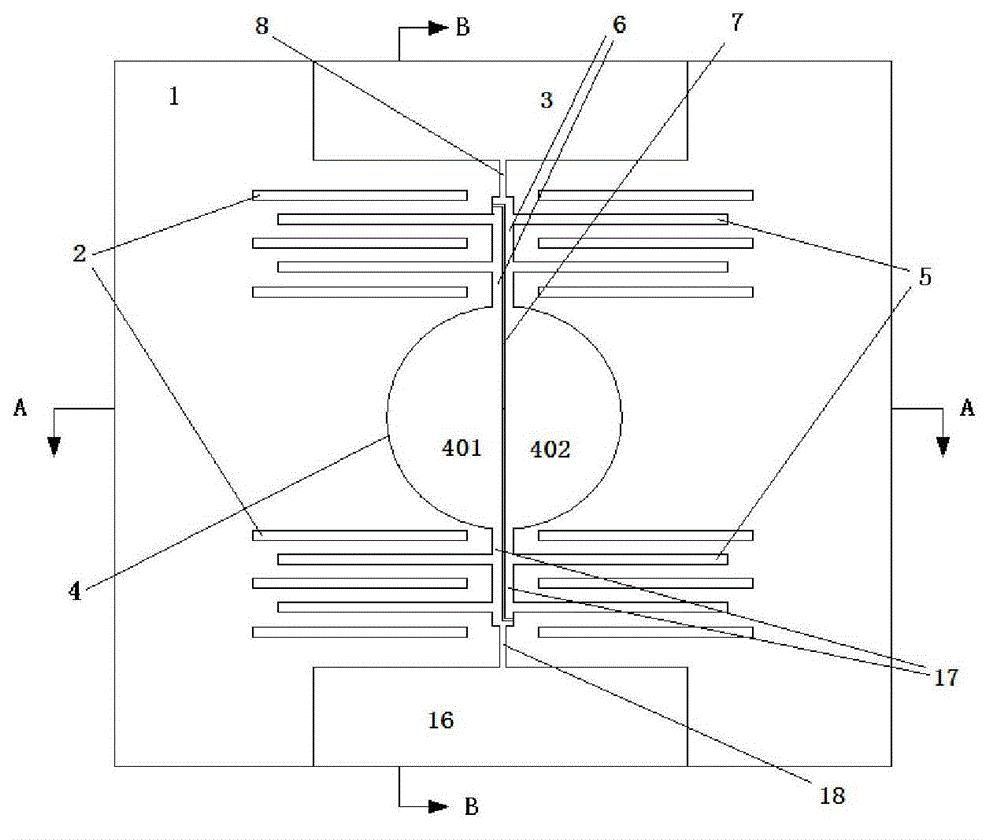

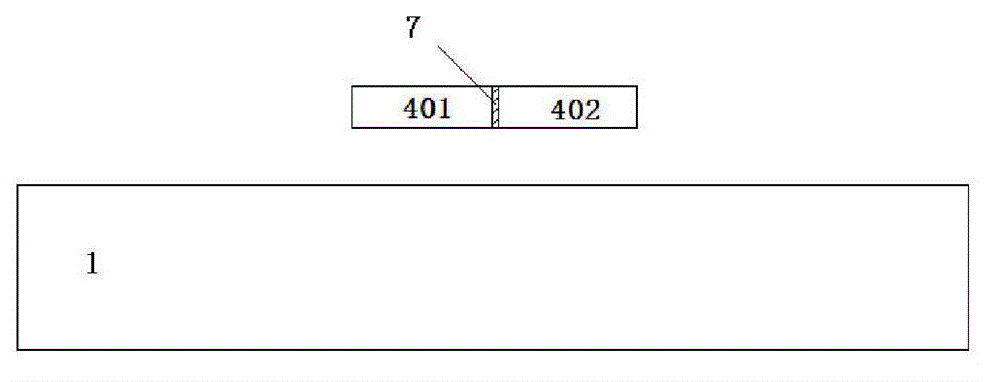

The invention discloses an eight-station crankcase stator combination machining device. The eight-station crankcase stator combination machining device comprises an eight-station rotating disc mechanism, crankcase stator combination machining mechanisms, moving sliding table mechanisms, a cooling mechanism and a control mechanism. The eight-station rotating disc mechanism comprises a rotating frame and a rotating disc arranged on the rotating frame. The rotating disc is rotationally connected with the rotating frame. Workpiece tools are arranged on the rotating disc in the circumferential direction in an array manner. The workpiece tools are used for fixing workpieces. The crankcase stator combination machining mechanisms are arranged in the circumferential direction of the rotating disc in an array manner. The moving sliding table mechanisms are arranged at the bottoms of the crankcase stator combination machining mechanisms and used for driving the crankcase stator combination machining mechanisms to move in the radial direction of the rotating disc. The cooling mechanism is used for cooling the crankcase stator combination machining mechanisms and the workpieces. By the adoptionof the eight-station crankcase stator combination machining device, simultaneously continuous machining of multiple workpieces and multiple processes can be achieved, and the machining efficiency andprecision are high.

Owner:HUANGSHI HUADAN MACHINE MFG

Roll harnessing equipment and rolling method

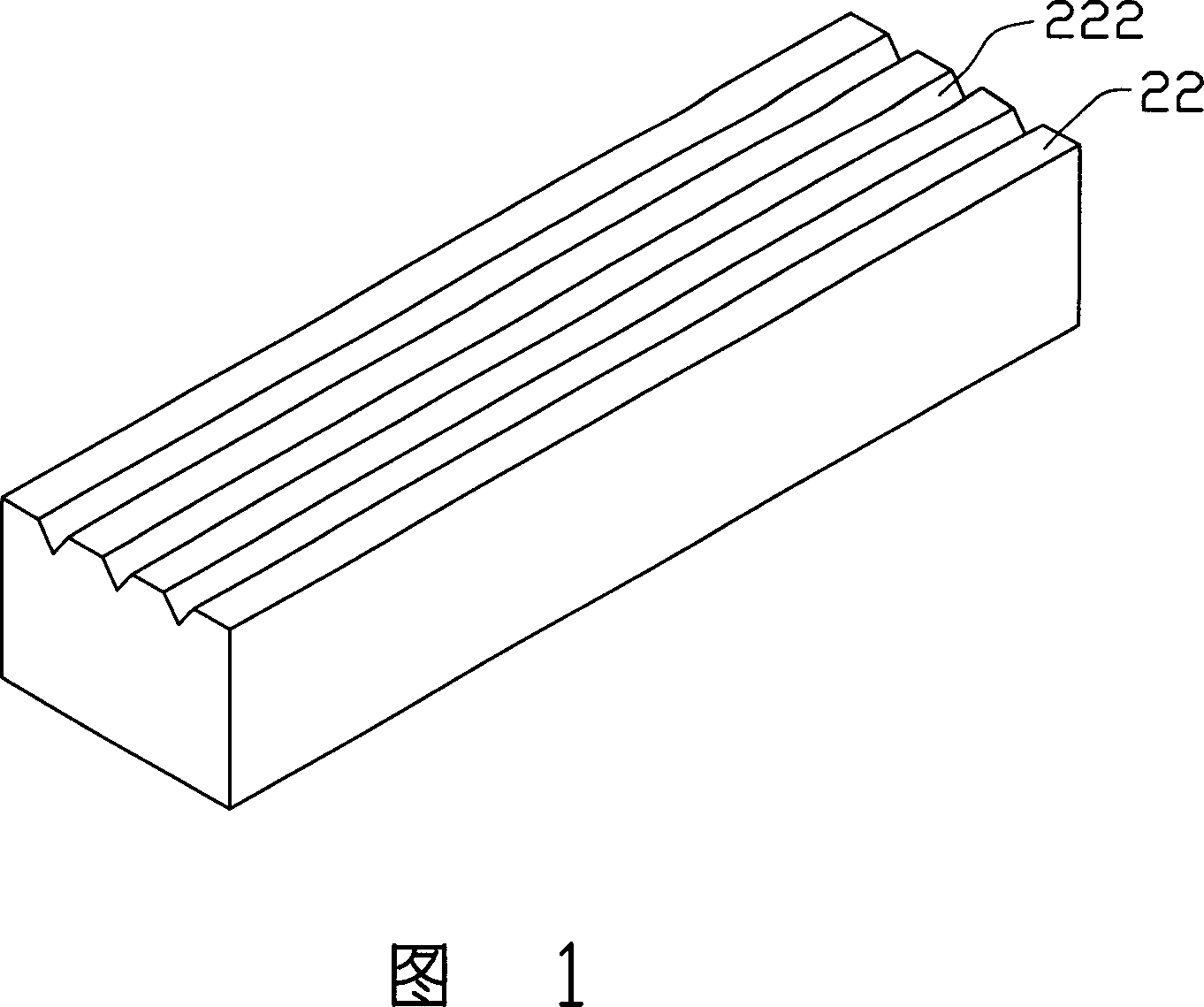

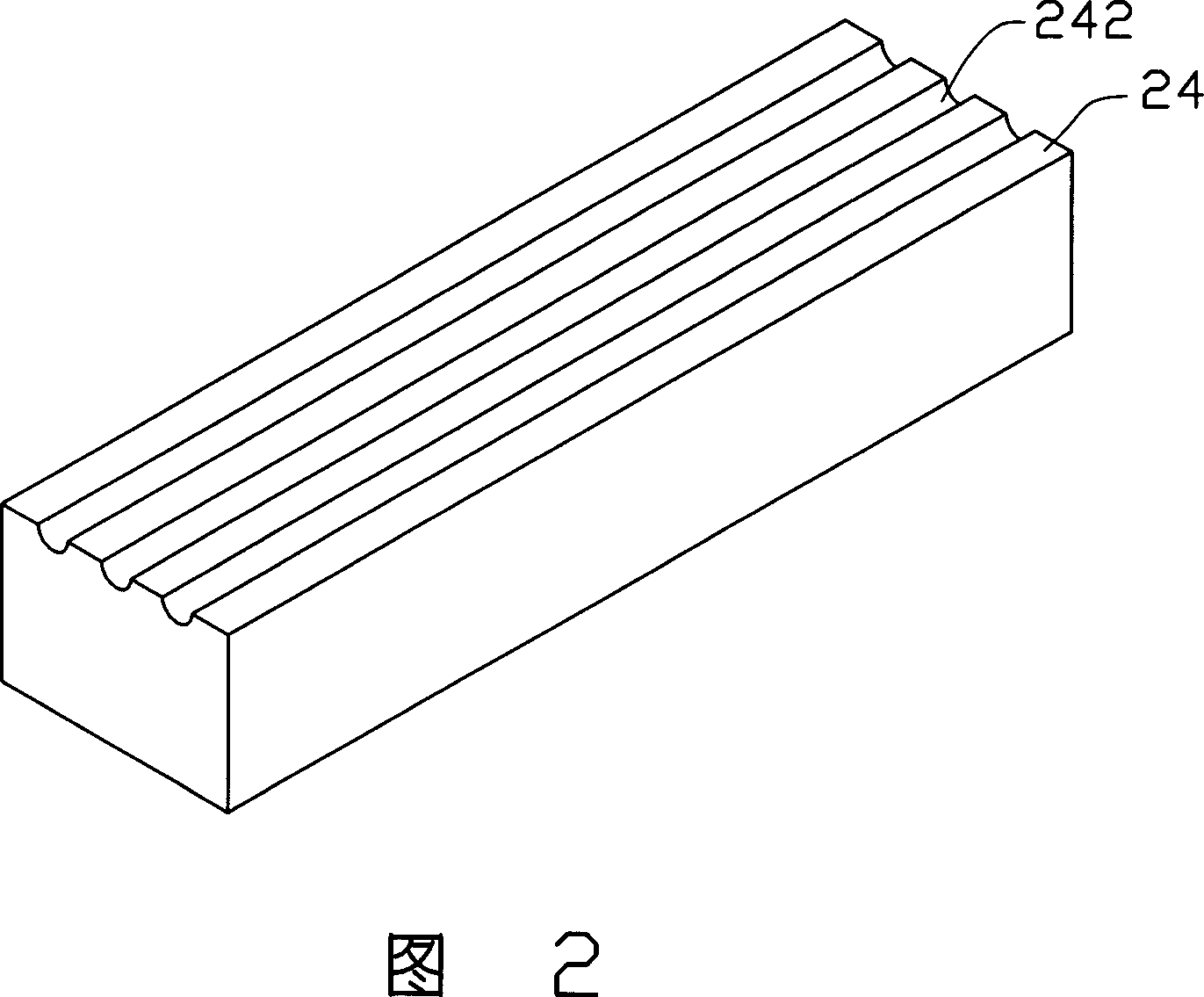

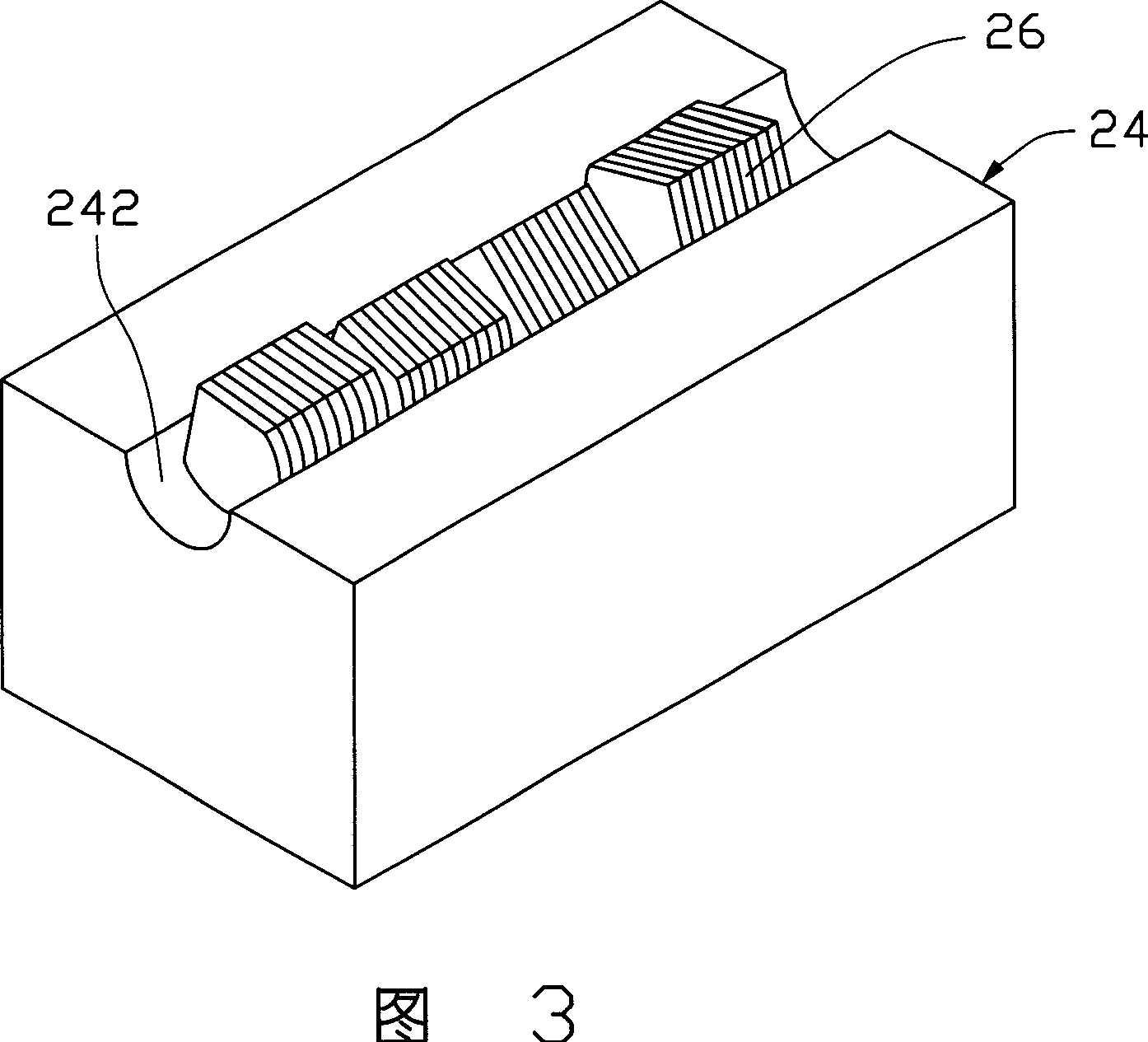

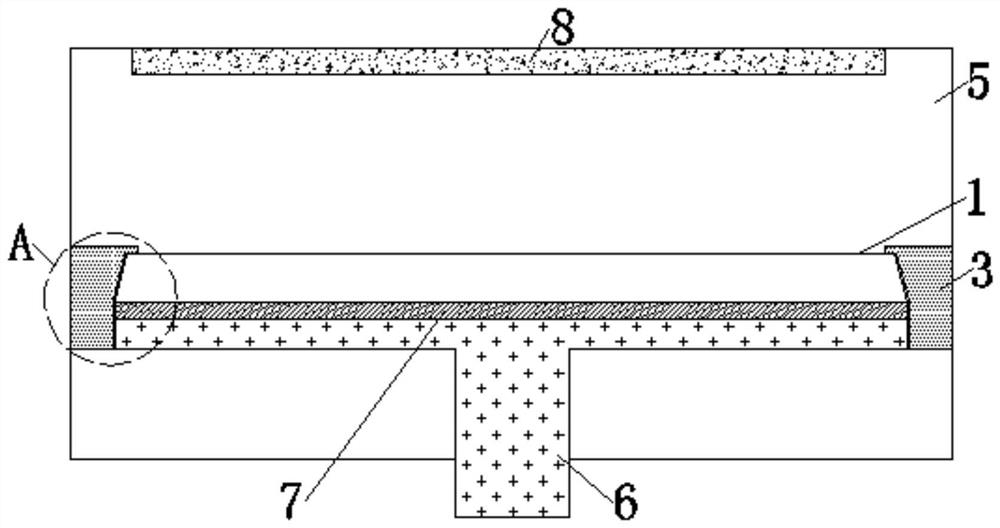

InactiveCN1939658AImprove qualityGuaranteed processing yieldRevolution surface grinding machinesPositioning apparatusEngineeringLens plate

A die set for grinding circular lens is composed of the first die with a slot on its top surface, and the second die with semi-circular slot. Its method for grinding circular lens includes such steps as providing said die se, fixing the lens in the slot of the first die, grinding the exposed part of the lens to become semi-circular shape, putting the second die on the first one to make the semi-circular part of the lens in the semi-circular slot of the second die, removing the first die, fixing the lens, grinding the exposed part of the lens to become a circular lens and separating the lens from the second die.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Camera module and assembling method thereof

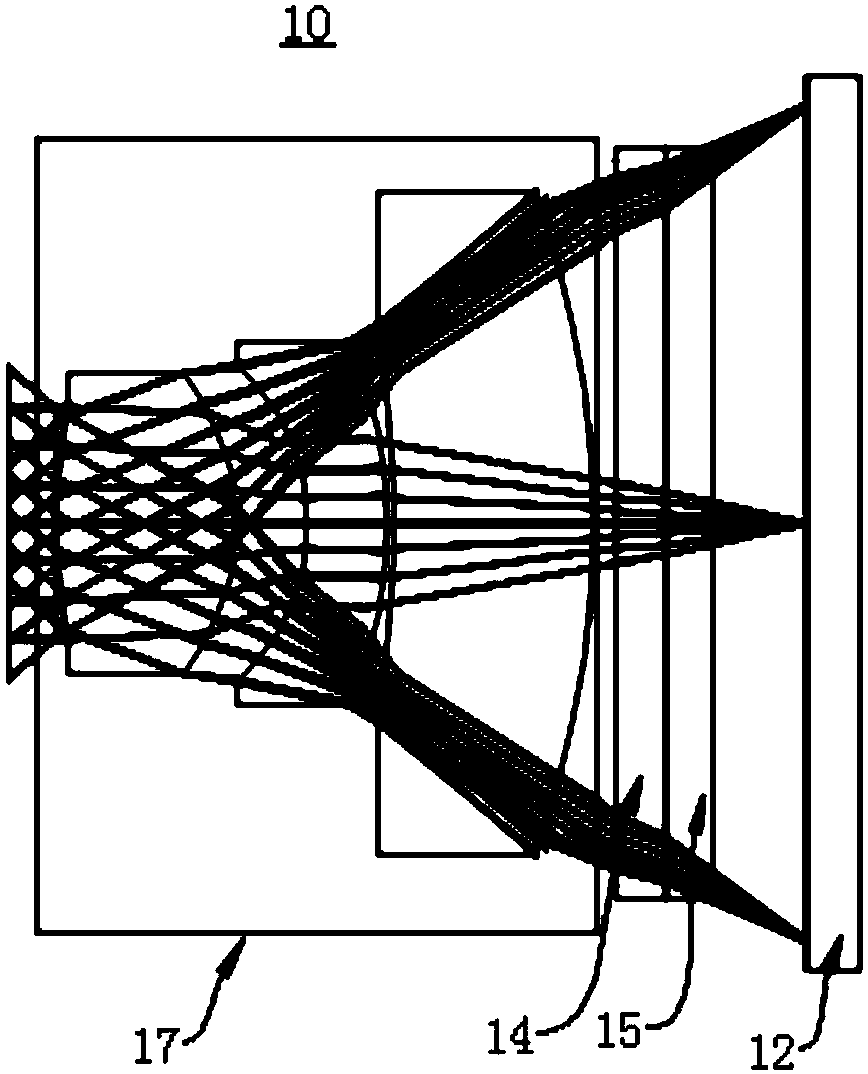

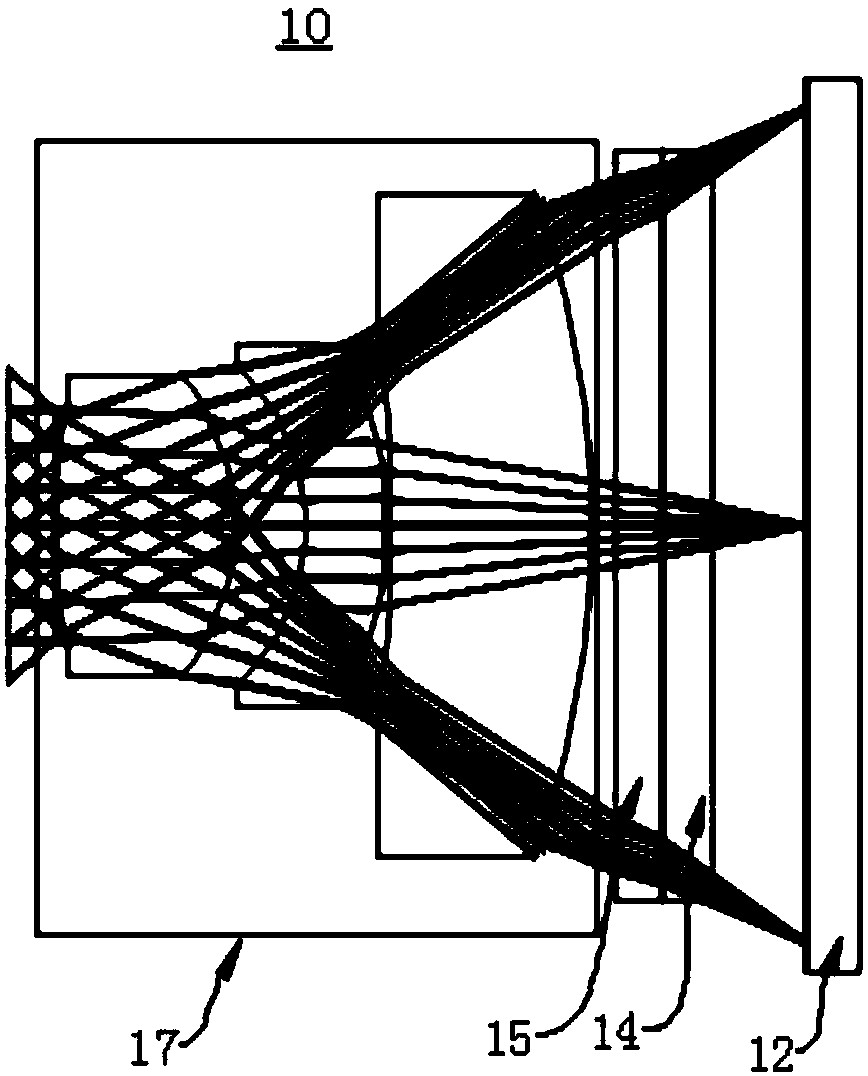

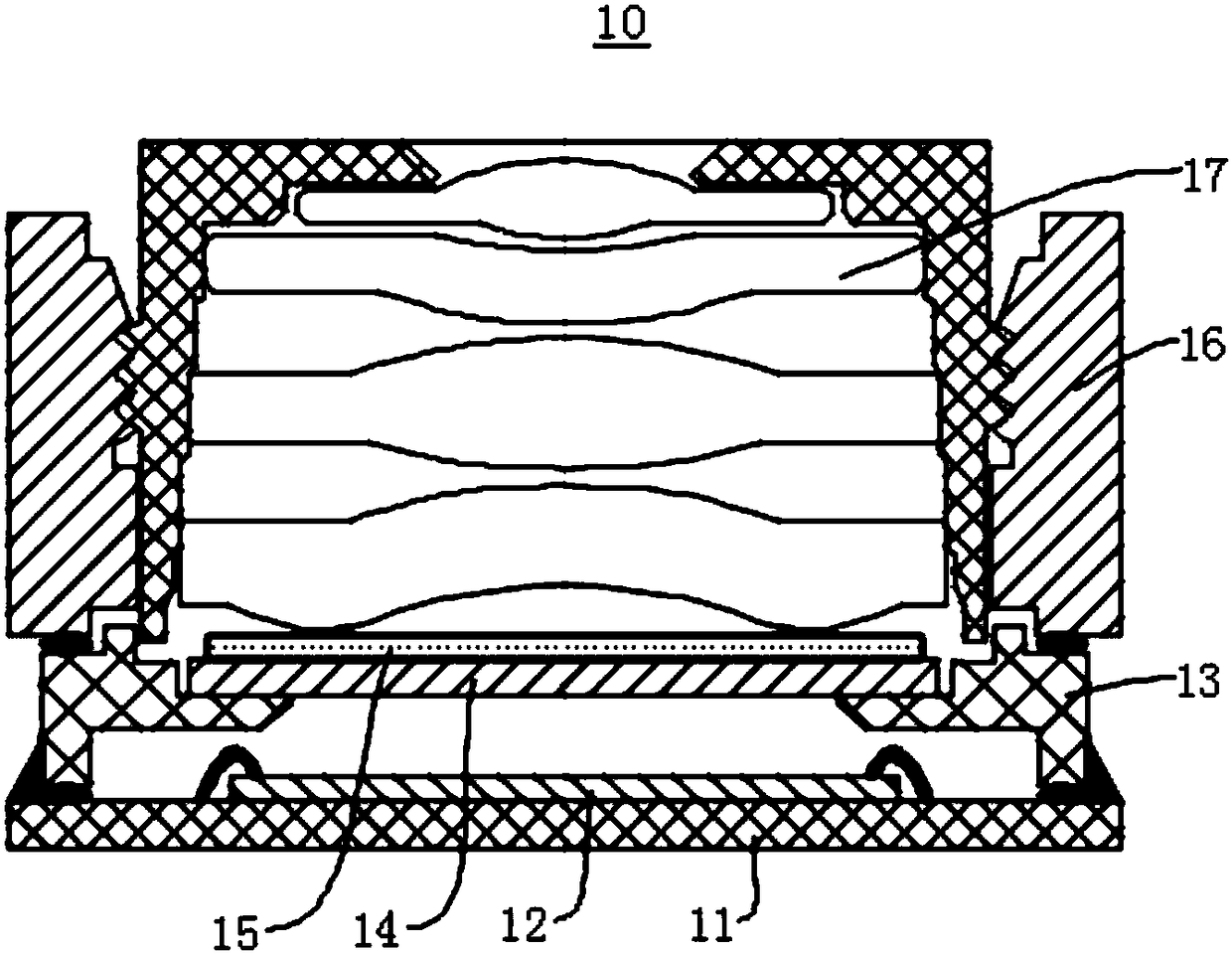

PendingCN108600598ANo need to change the packaging processNo need to change optical designTelevision system detailsMaterial gluingCamera lensImaging quality

The invention provides a camera module and an assembling method thereof, and relates to the field of the camera module. The camera module comprises an image sensor chip, an optical filer, a lens component and an optical transmitter; the optical filter is arranged between the image sensor chip and the lens component; the optical transmitter is arranged between the image sensor chip and the lens component and used for enabling to the light to image on a bent imaging surface formed by the warping of the image sensor chip. The camera module can fill a defect that the warping of the image sensor chip causes the bending of the imaging surface, so that the light can be imaged on the bent imaging surface, and the image quality is improved.

Owner:KUNSHAN Q TECH CO LTD

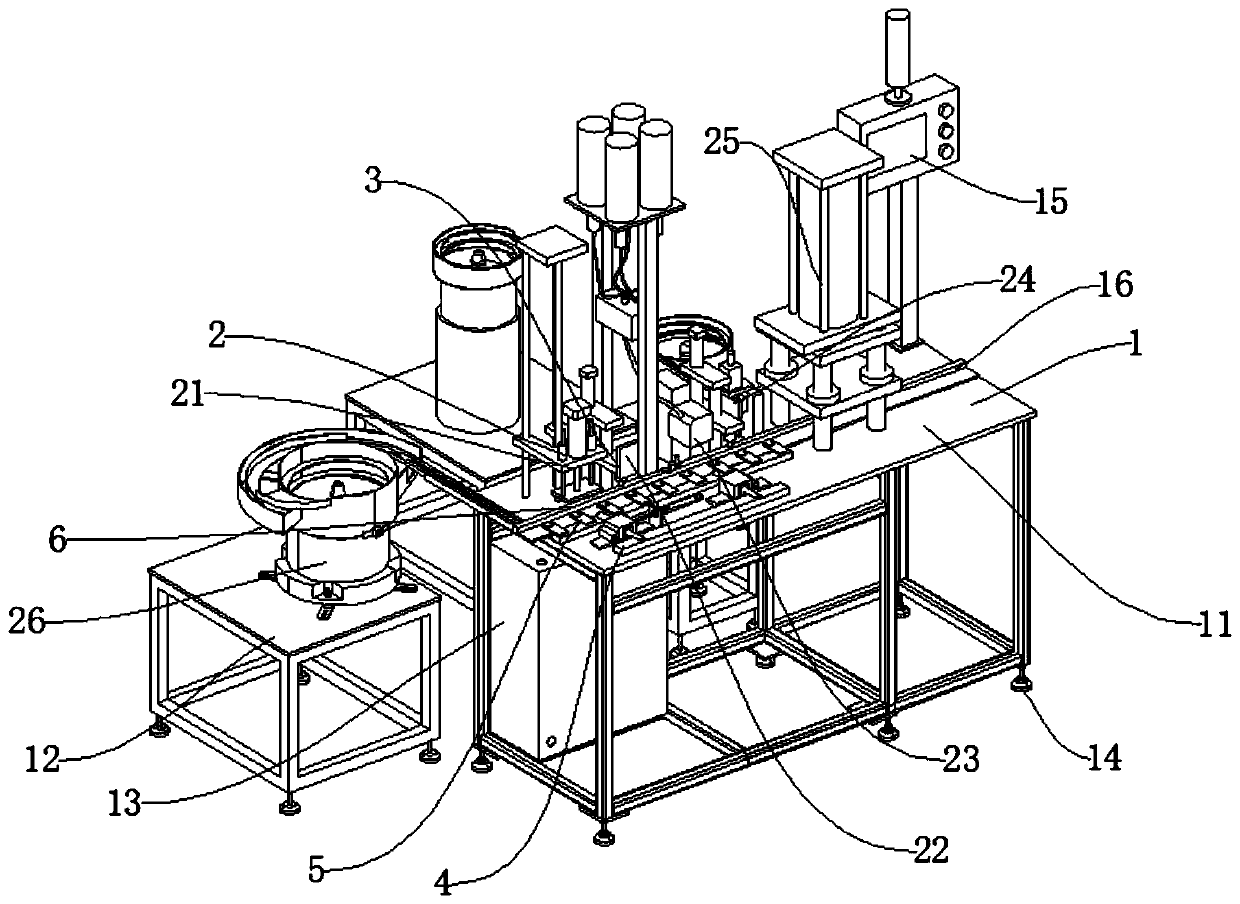

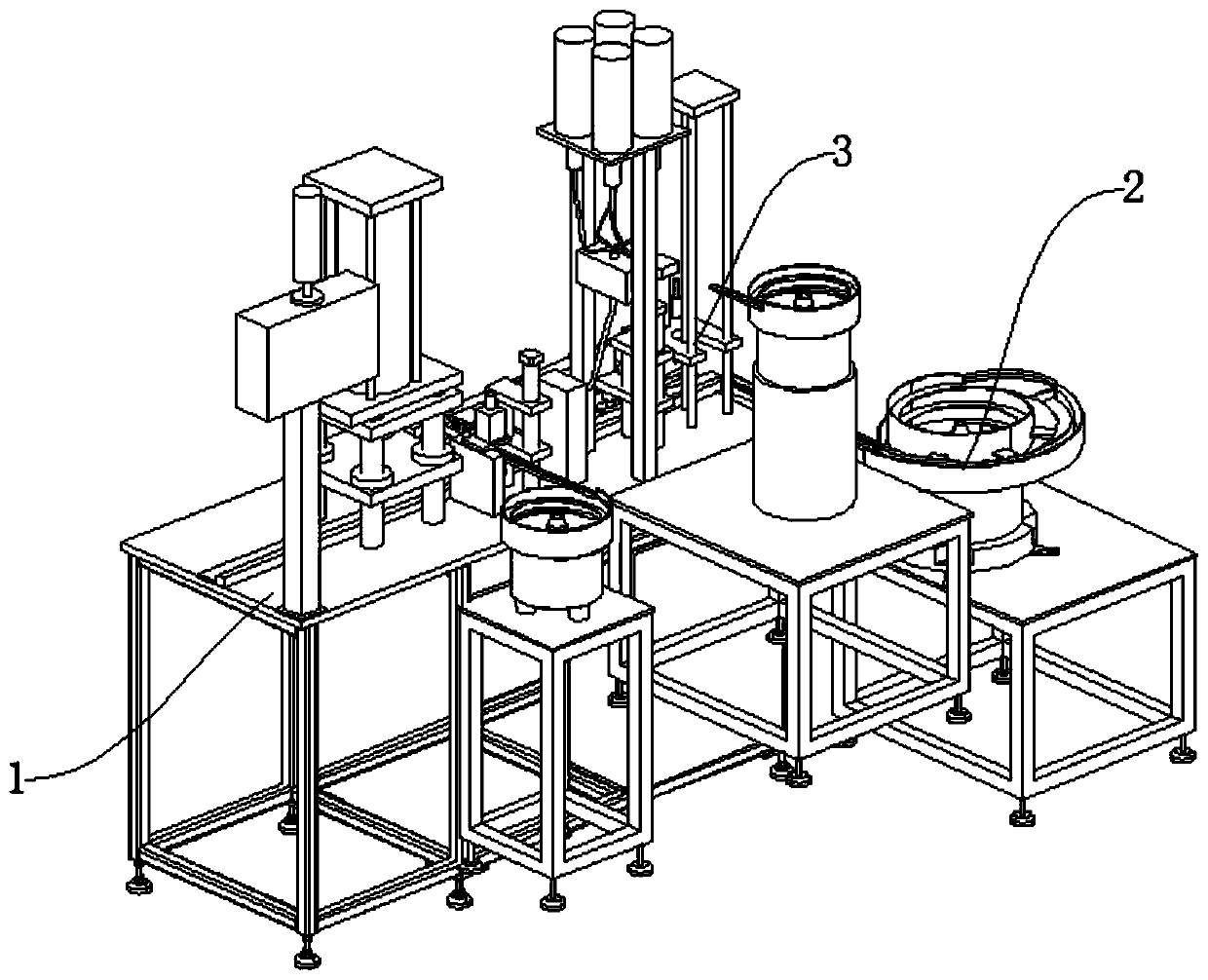

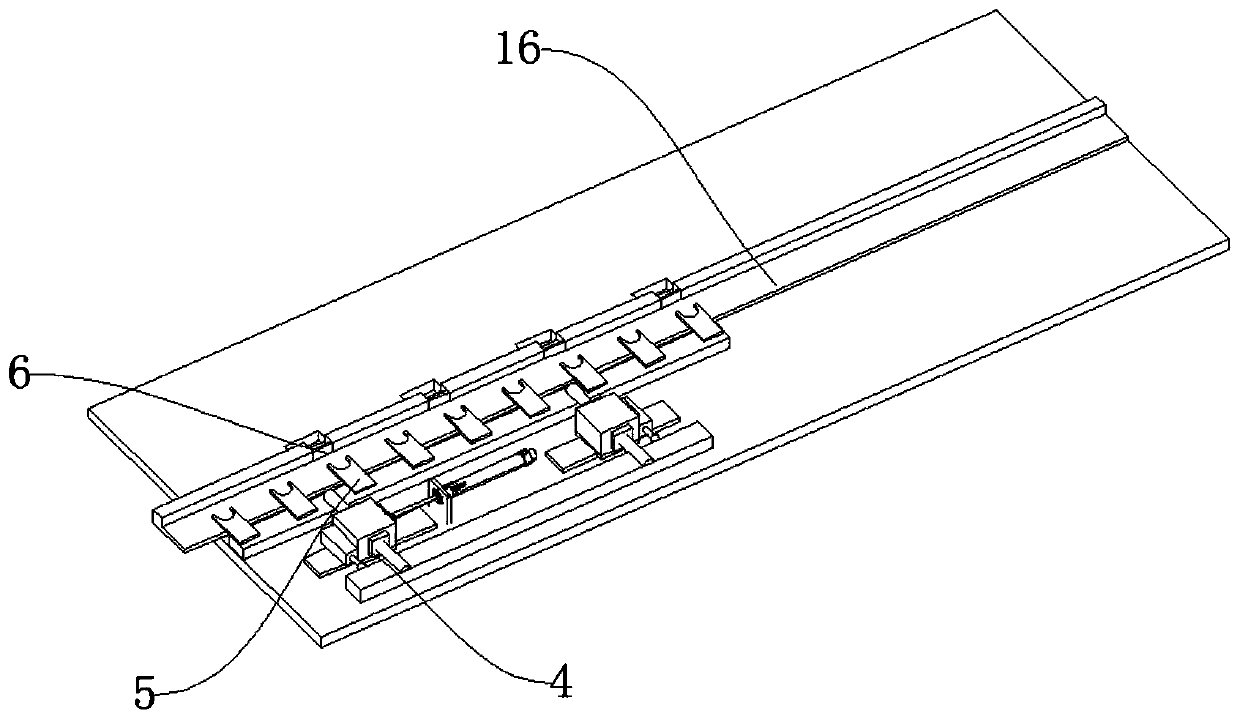

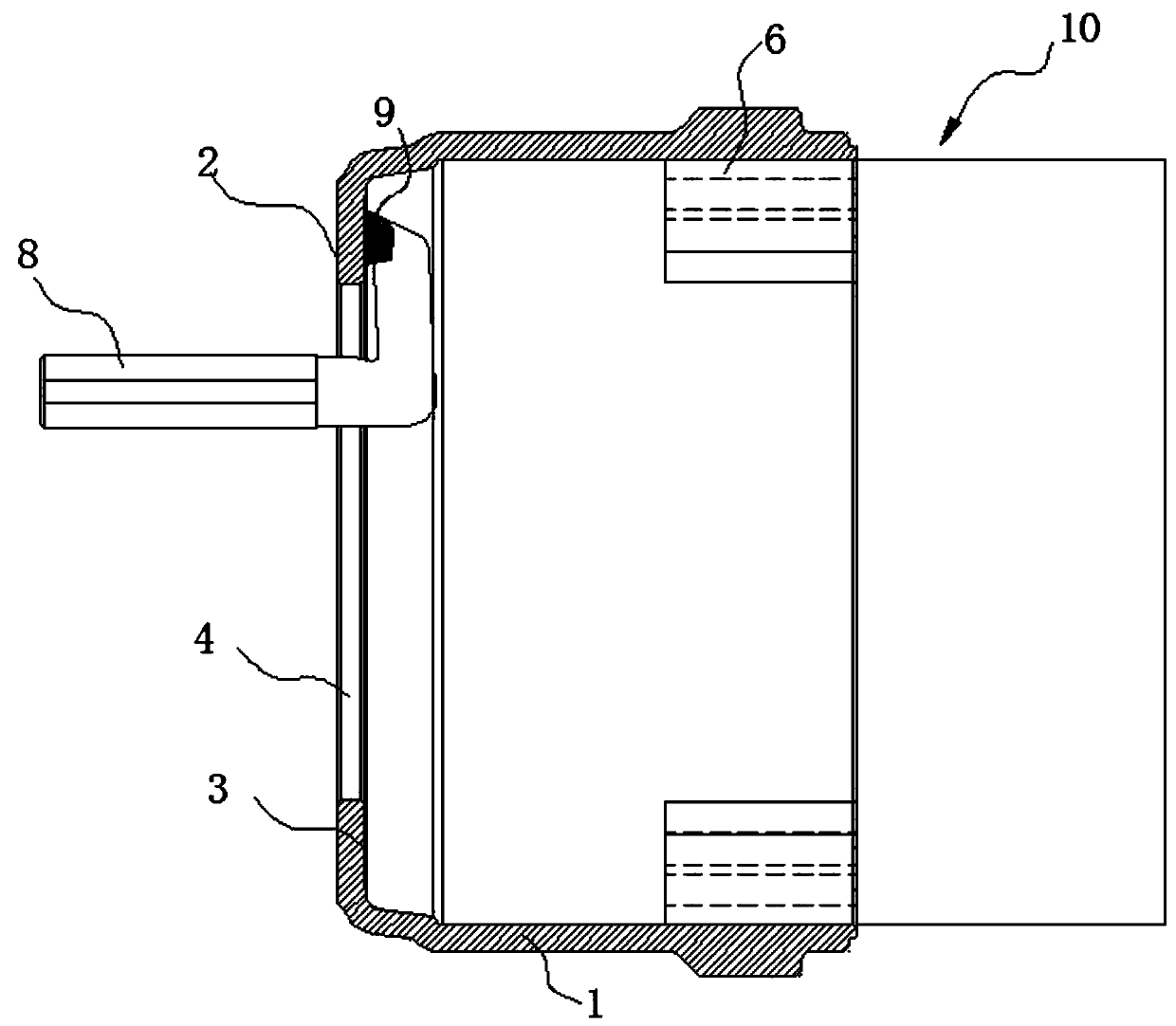

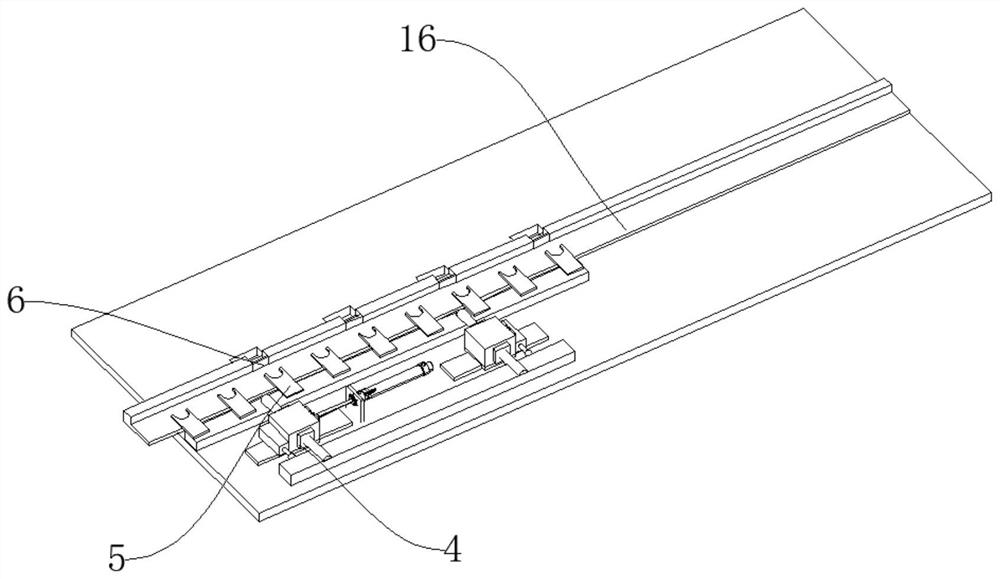

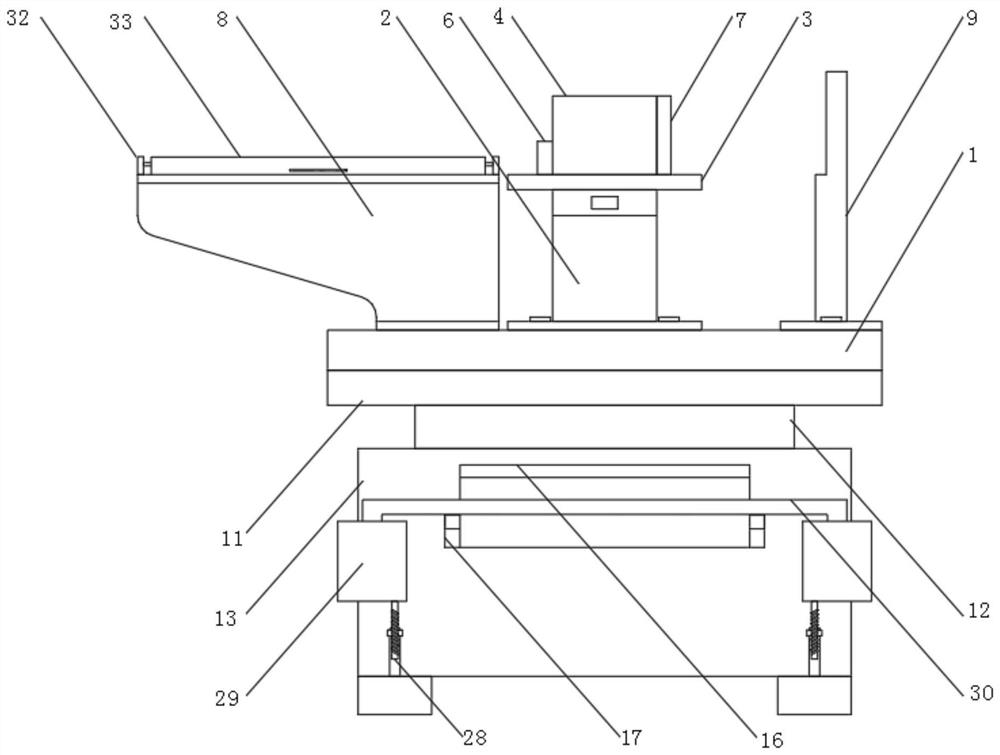

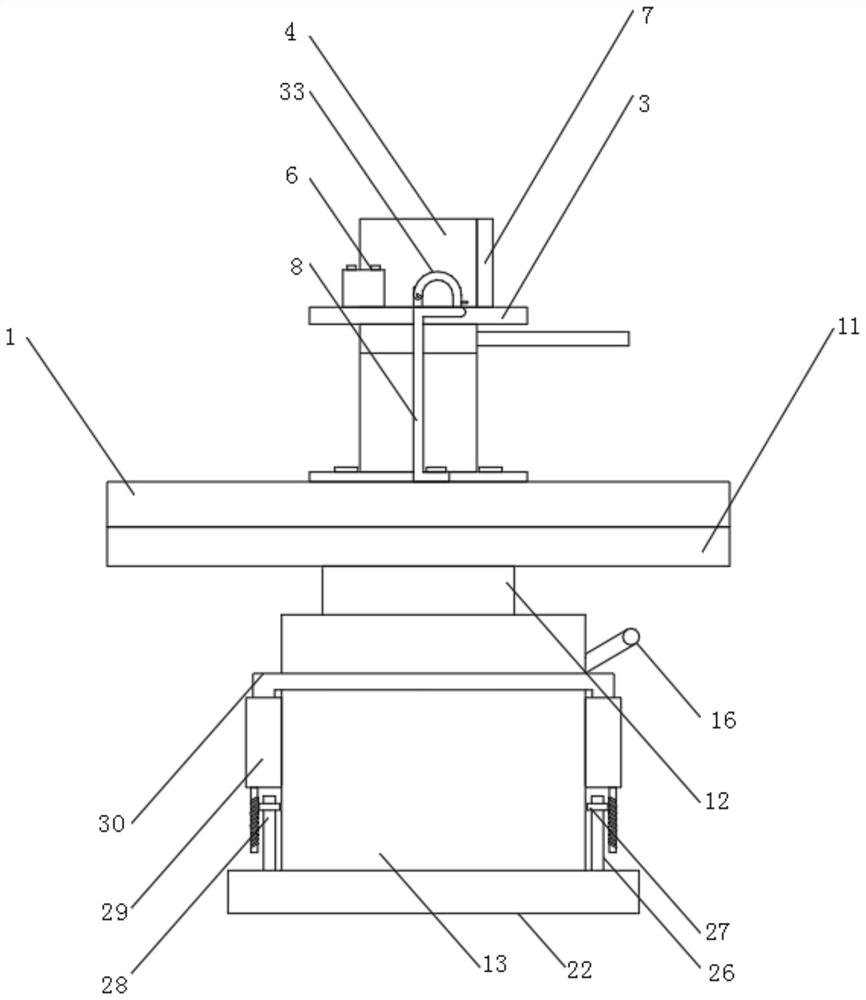

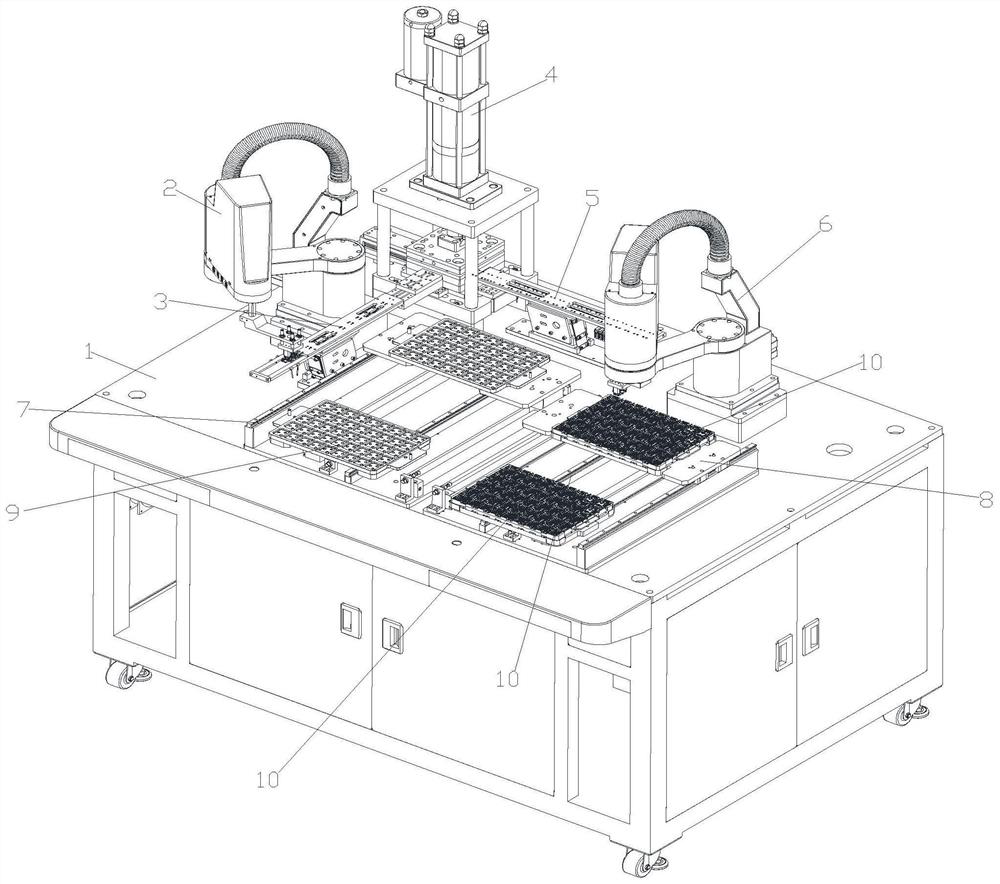

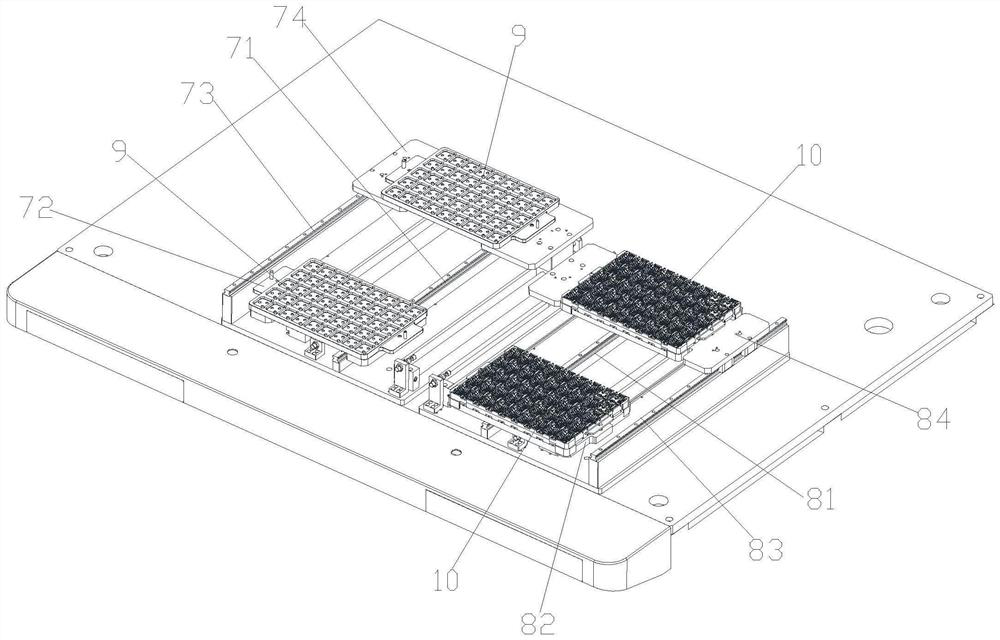

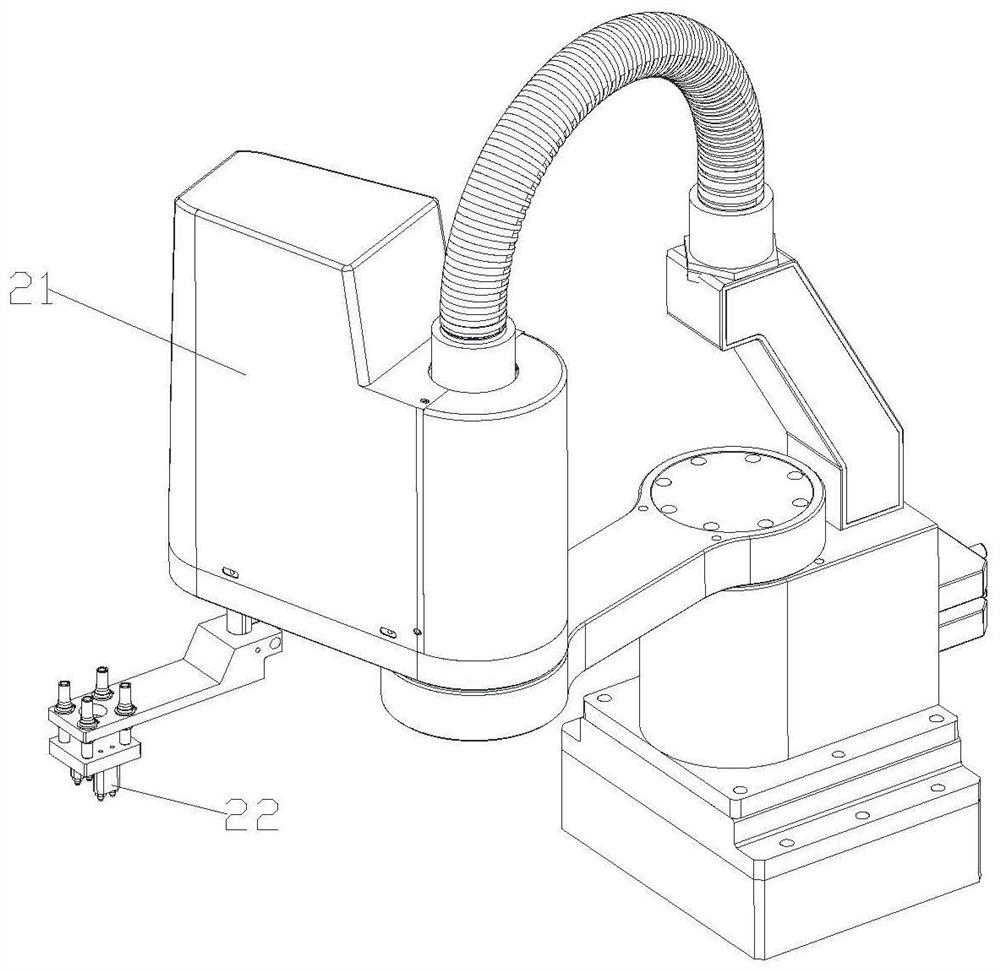

Bearing assembling equipment and using method thereof

ActiveCN111266864AGuaranteed processing efficiencyGuaranteed processing yieldAssembly machinesMeasurement/indication equipmentsStructural engineeringMachining process

The invention discloses bearing assembling equipment and a using method thereof. The bearing assembling equipment comprises a machining mechanism for machining a cold-rolled steel bearing, a detectionhead for detecting a machining process, a moving mechanism and a clamping and pushing mechanism, the moving mechanism and the clamping and pushing mechanism are used for transmitting machining materials, the machining mechanism is arranged at the upper end of a supporting mechanism, the detection head is arranged at the discharging end of the machining mechanism, the moving mechanism is arrangedon the front side of the machining mechanism, the clamping and pushing mechanism is arranged between the moving mechanism and the detection head, and a collecting mechanism is arranged on the supporting mechanism. According to the bearing assembling equipment, the cold-rolled steel bearing is subjected to flow processing by adopting integral automation, the processing efficiency and the finished product rate are ensured by matching with the detection head, the moving mechanism, the clamping and pushing mechanism and the collecting mechanism are matched, unqualified products can be rapidly detected and removed during processing, the shutdown after the unqualified products are generated is avoided, and the working efficiency is improved.

Owner:文金凤

Machining technology for brake drum machine

InactiveCN110090968AGuaranteed processing yieldGuarantee quality stabilityChucksPositioning apparatusEngineeringMachining

The invention discloses a machining technology for a brake drum machine. The machining technology includes the following machining steps that firstly, an inner cavity of a to-be-machined brake drum isused for machining a flange face and a flange back face in a positioning clamping manner; secondly, a flange center hole is used for positioning, the flange back face is pressed, and the inner cavityis machined; and thirdly, an inner cavity seam allowance is used for positioning, and all bolt holes of the flange face are machined. The roughness of the machined faces is effectively ensured, the brake drum machining yield and quality stability are effectively ensured, the machining yield is effectively increased, defective product losses are effectively reduced, and process control is more stable.

Owner:SHENGRUI TRANSMISSION

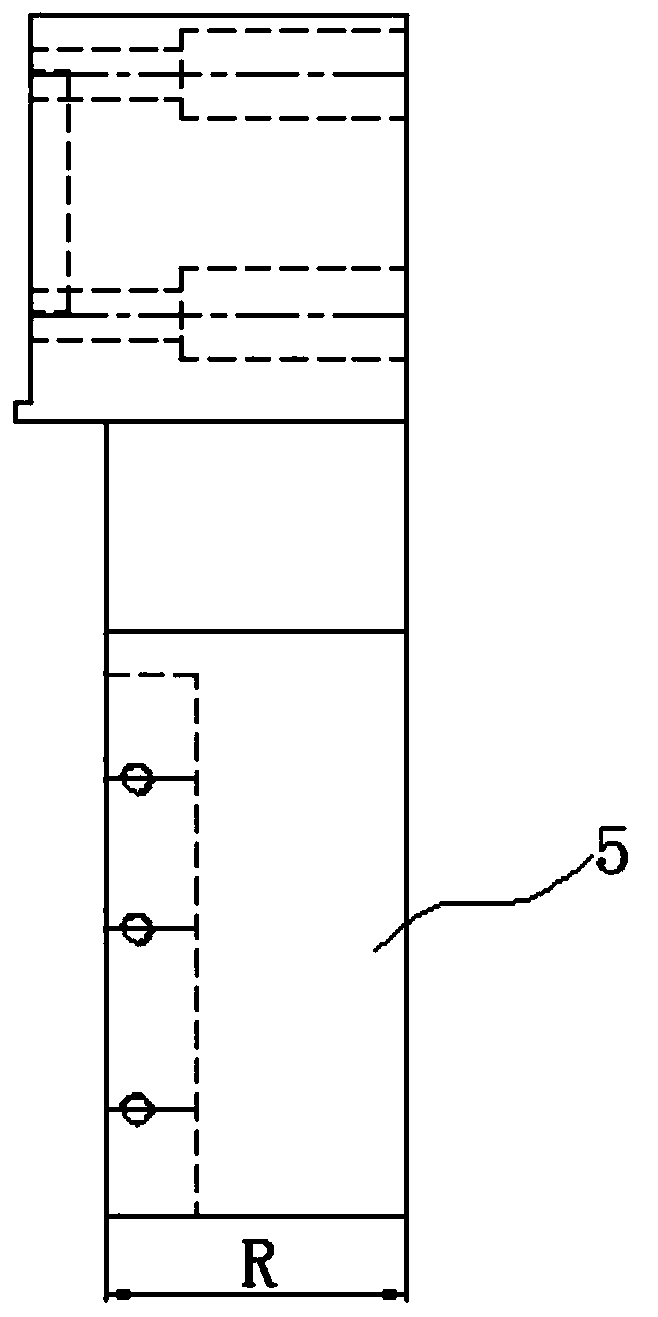

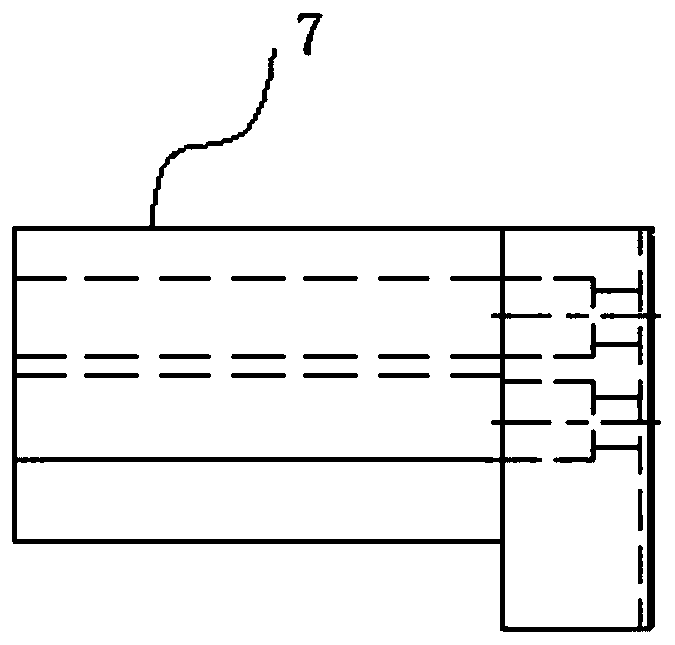

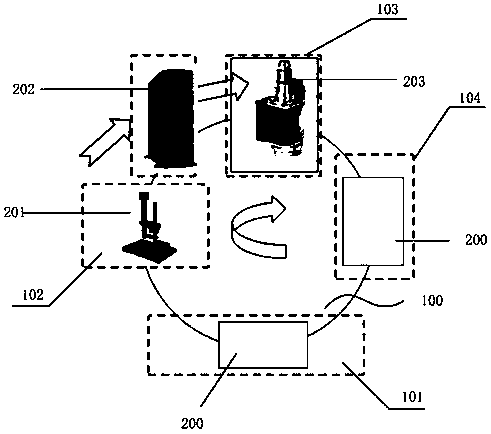

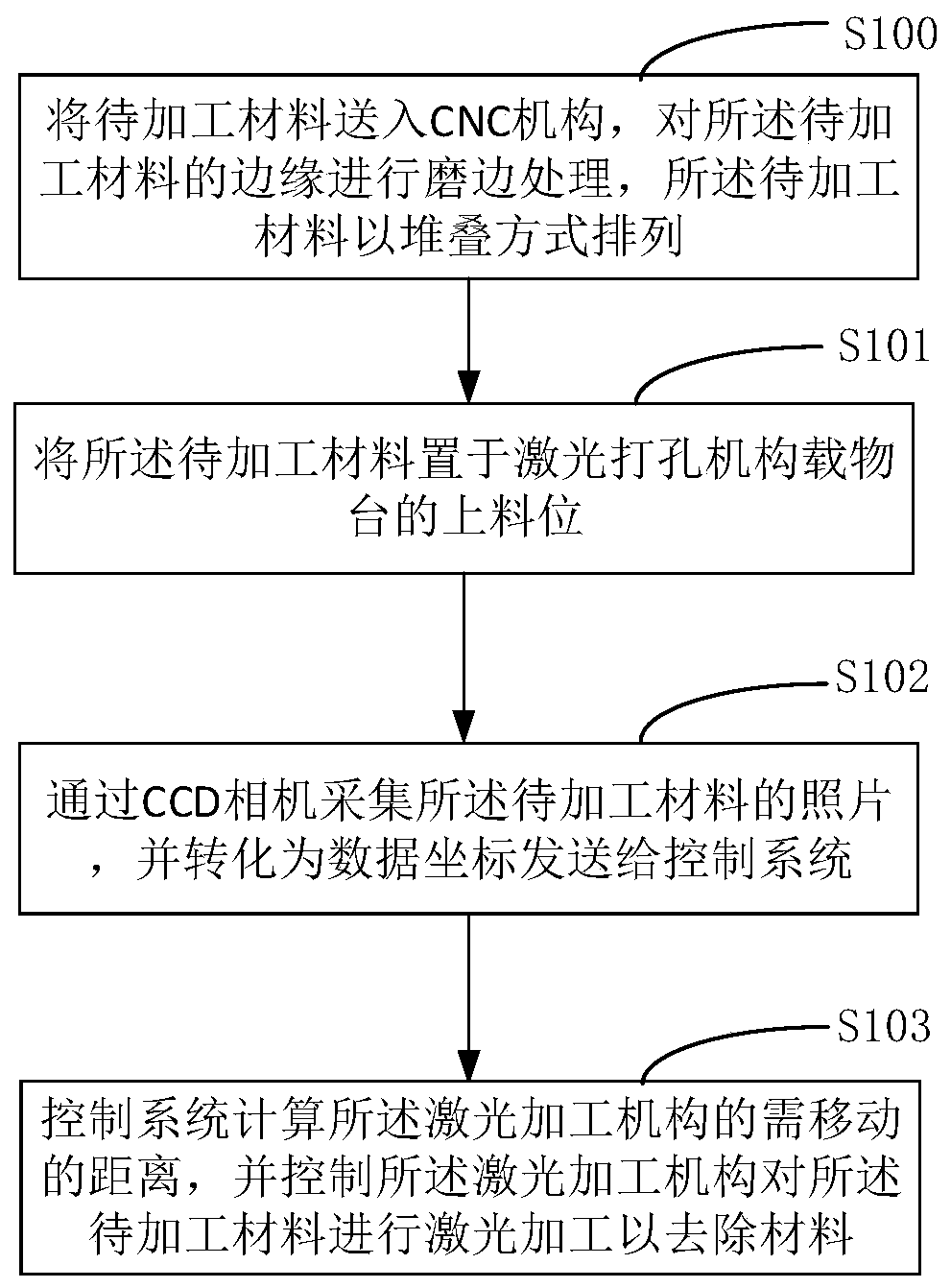

Edging and punching method and device capable of achieving high-precision rapid automatic alignment

InactiveCN111558787AGuaranteed processing efficiencyGuaranteed processing accuracy and yieldLaser beam welding apparatusCcd cameraProcessing accuracy

The invention discloses an edging and punching method and device capable of achieving automatic alignment. The method comprises the following steps of feeding materials to be processed into a CNC mechanism, and carrying out edging on the materials to be processed, wherein the materials to be processed are arranged in a stacking mode; placing the materials to be processed in a feeding position of an objective table of a laser processing mechanism; acquiring a photo of the materials to be processed through a CCD camera, and converting the photo into data coordinates and sending the data coordinates to a control system; and calculating the required moving distance of the laser processing mechanism and controlling the laser processing mechanism to perform laser processing on the materials to be processed so as to remove the materials through a control system. The materials to be processed are edged in a stacking mode through the CNC mechanism, processing efficiency is guaranteed, the materials to be processed are punched one by one through the laser processing mechanism, the CCD camera is used for assisting in alignment, and processing precision and yield are guaranteed.

Owner:深圳市南德谱光电有限公司

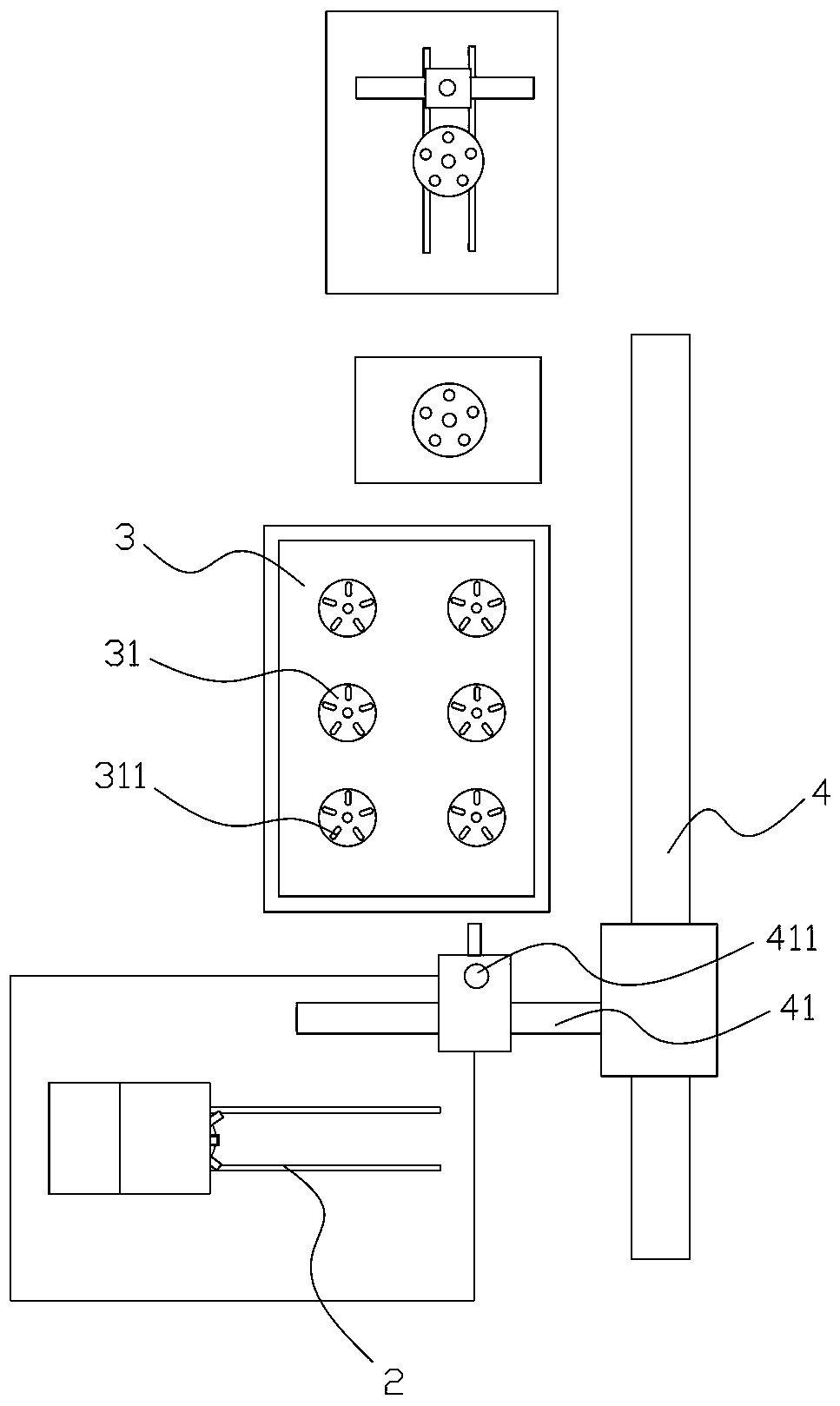

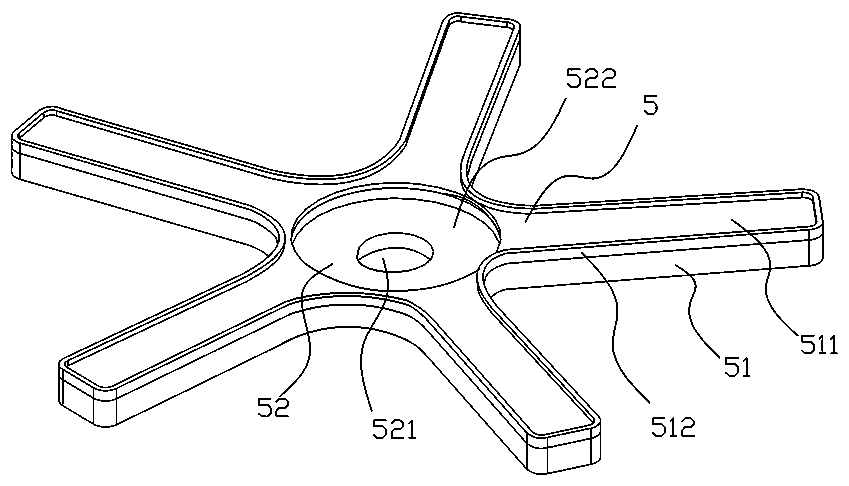

Automatic machining equipment for five-star feet

PendingCN108941685AGuarantee processing qualityGuaranteed processing yieldPositioning apparatusMetal-working holdersMachiningDrilling machines

The invention provides automatic machining equipment for five-star feet. The automatic machining equipment comprises a drilling machine; the drilling machine comprises a base table and a drill bit which is positioned at the upper end of the base table and can move relative to the base table, wherein the base table comprises a body and limiting protrusions which are uniformly arranged on the body;and further comprises a first limiting body and a second limiting body, wherein an opening hole is formed in the first limiting body and sleeves the outer side of the drill bit, and bolts are arrangedon the first limiting body and the second limiting body, and the bolts are parallel to the translation direction of the drill bit, and a pressure spring sleeves the bolt which is located between thefirst limiting body and the second limiting body. The automatic machining equipment for the five-star feet can guarantee the stability of a five-star-foot center body drilling process, and the machining quality of the five-star feet.

Owner:安吉隆博家具有限公司

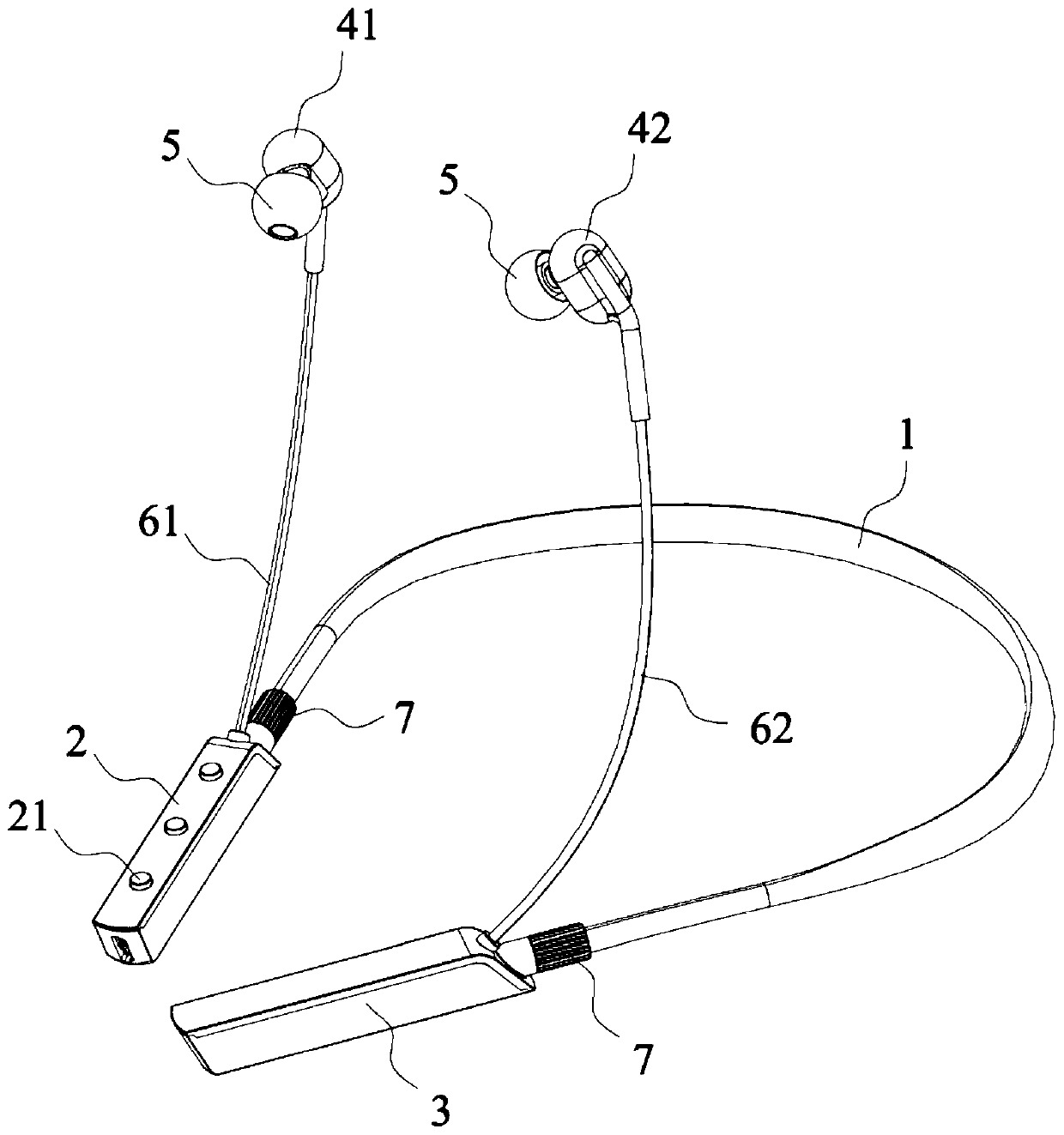

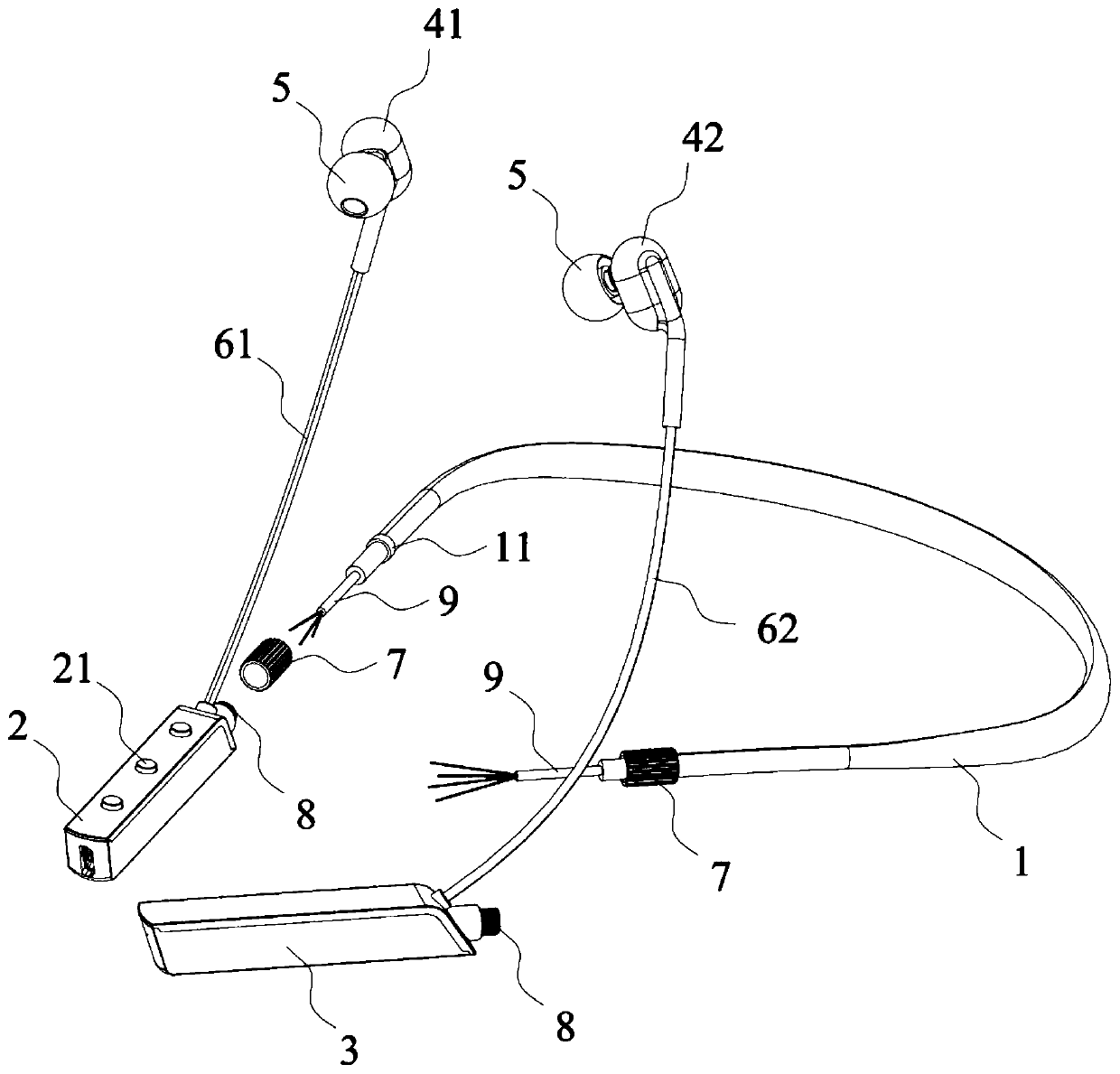

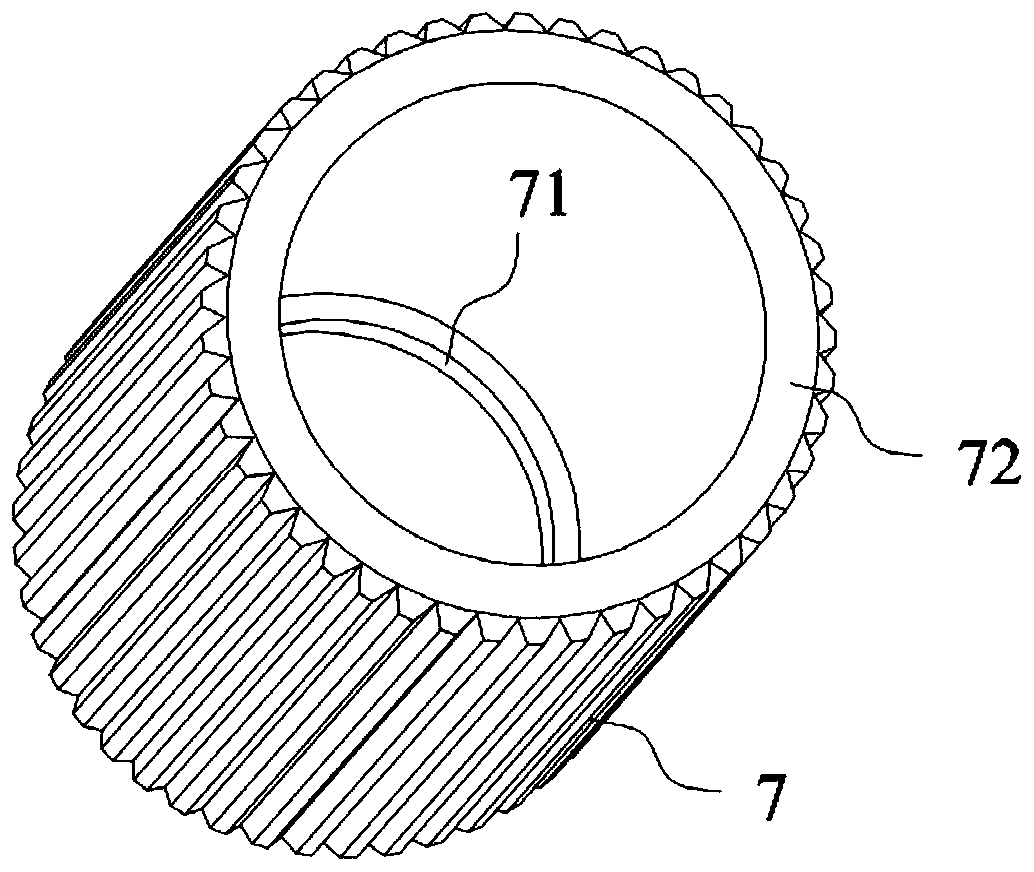

A connecting structure of a neckband Bluetooth earphone and the neckband Bluetooth earphone

InactiveCN109698987AGuaranteed connection strengthAvoid separationMicrophonesLoudspeakersHeadphonesBluetooth

The invention belongs to the technical field of earphones, and particularly discloses a connecting structure of a neckband Bluetooth headset and the neckband Bluetooth headset. The connecting structure is used for connecting a neck strap line, a first box body and a second box body of the neck strap Bluetooth earphone, and comprises a first connecting piece and a second connecting piece, the neckstrap line is sleeved with two first connecting pieces, and the first connecting pieces can rotate relative to the neck strap line; Second connecting pieces are arranged on the first box body and thesecond box body; One of the first connecting piece and the second connecting piece is provided with an external thread, the other one of the first connecting piece and the second connecting piece is provided with an internal thread, the two first connecting pieces and the two second connecting pieces are in threaded connection in a one-to-one correspondence mode to be used for connecting the neckstrap line with the two box bodies, and therefore the two box bodies and the neck strap line can be machined in a split mode, machining difficulty is reduced, and machining yield is guaranteed. Meanwhile, the connection strength of the two box bodies and the neck strap line can be ensured, and the two box bodies are prevented from being separated by accidental stress. The Bluetooth headset with the neck band comprises a connecting structure of the Bluetooth headset with the neck band.

Owner:美律电子(惠州)有限公司

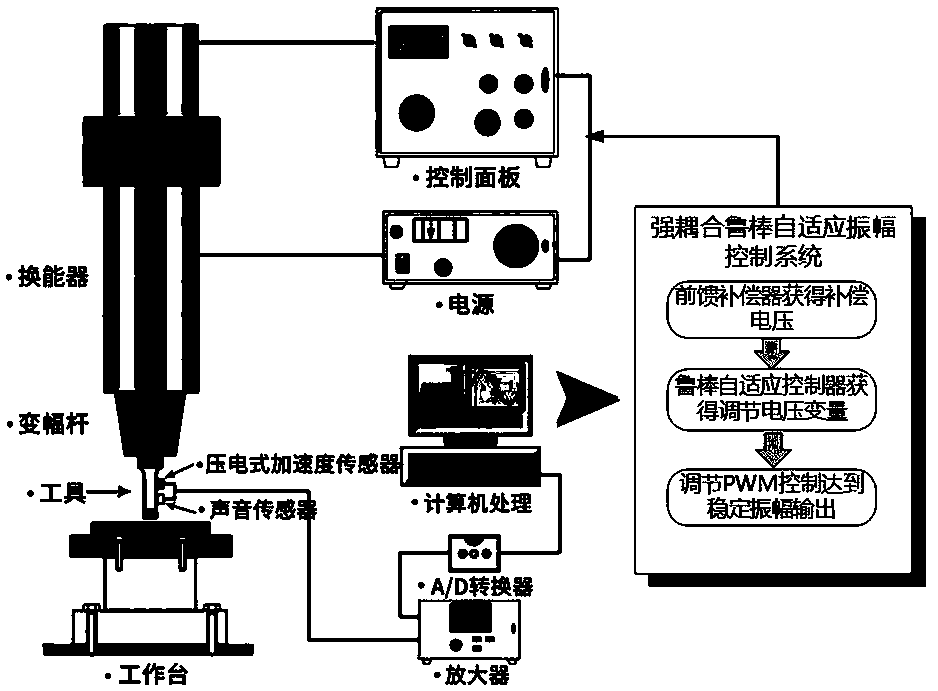

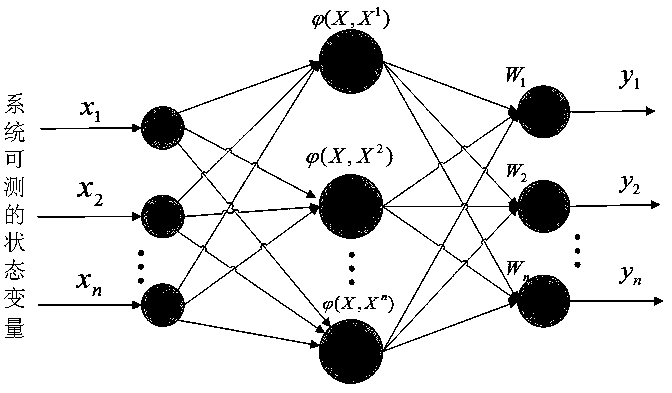

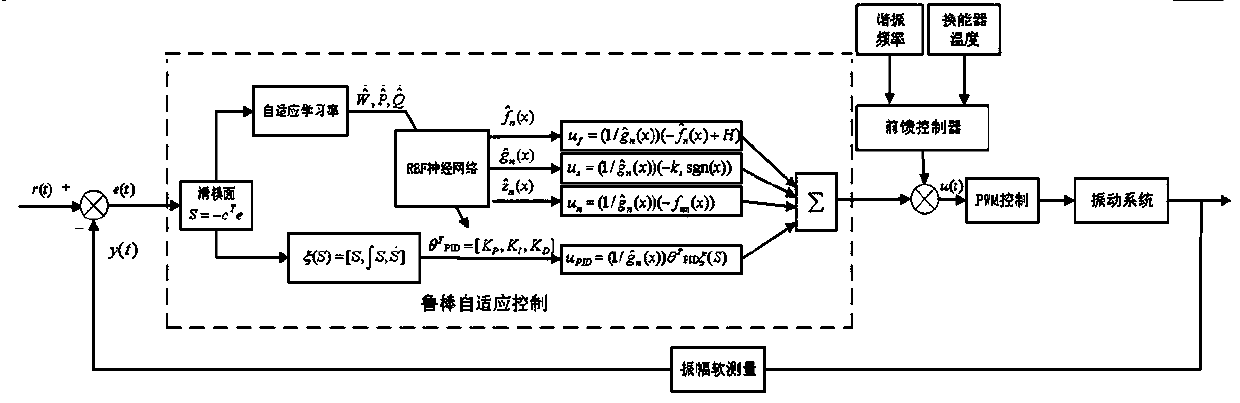

Robust adaptive amplitude control method for ultrasonic machining of hard and brittle materials

ActiveCN111596549AWith linear adjustment capabilityHigh precision and stable outputAdaptive controlUltrasonic machiningAmplitude control

The invention relates to a robust adaptive amplitude control method for ultrasonic machining of hard and brittle materials. Firstly, a feedforward compensation mode is designed, and the problem of amplitude variation caused by impedance variation of transducer temperature and matching inductance temperature is solved. And then, in order to ensure the amplitude control precision of the system, eliminate the influence of uncertainty of system parameters and improve the anti-interference performance of the system, a robust adaptive controller is designed to adjust the adaptive control rate on line to ensure the amplitude control precision when the system parameters are uncertain due to the strong coupling association between the ultrasonic amplitude and the resonant frequency. According to the invention, problems in complex processing environments can be solved; the problem of amplitude fluctuation caused by load, process and environment changes, transducer temperature, matching inductance temperature and the like in the machining process is solved. High-precision stable output of the amplitude is achieved through designed strong-coupling robust self-adaptive amplitude control, and the machining precision, the machining process requirement and the machining yield of the hard and brittle materials in the actual machining process are guaranteed.

Owner:杭州国彪超声设备有限公司

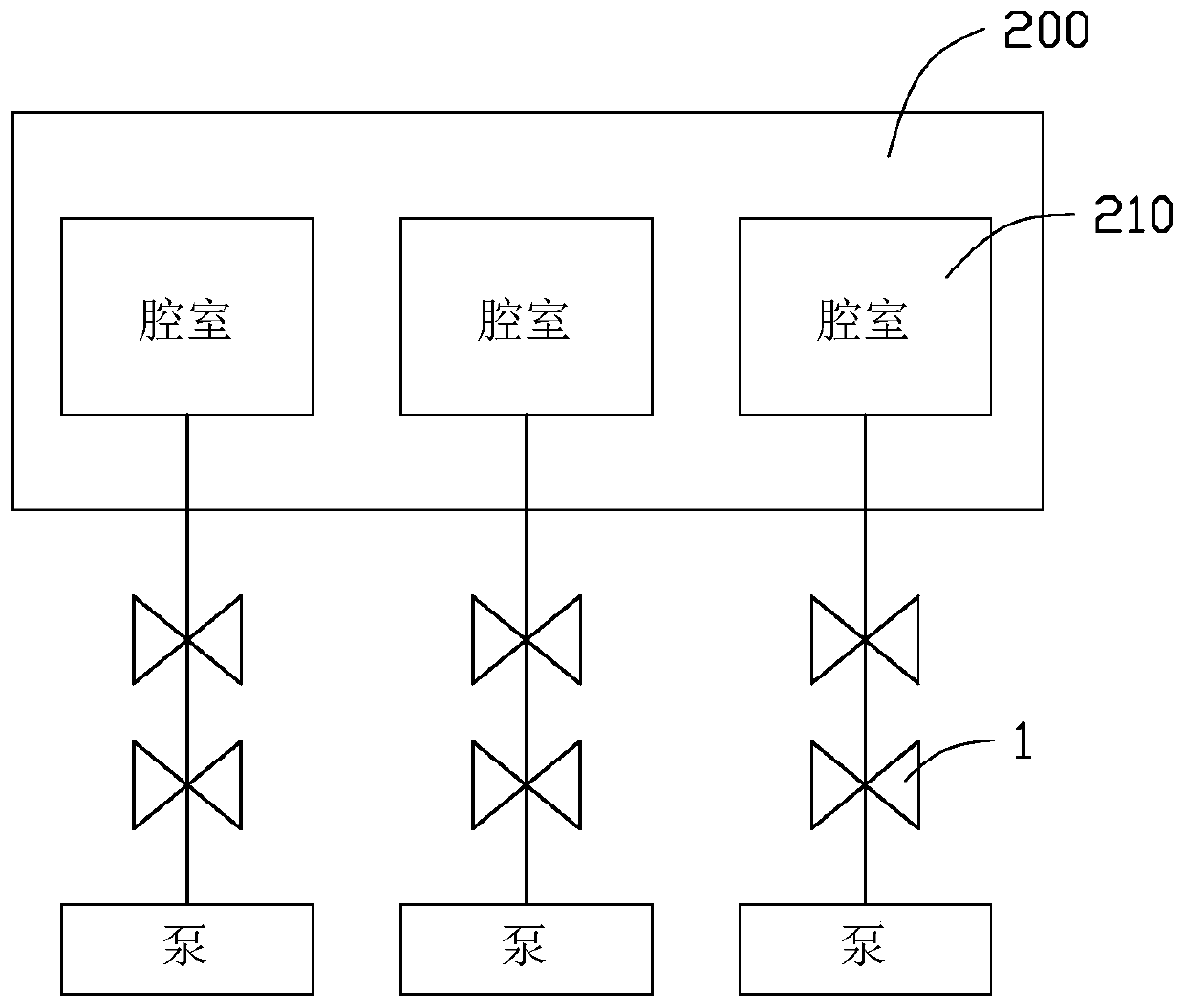

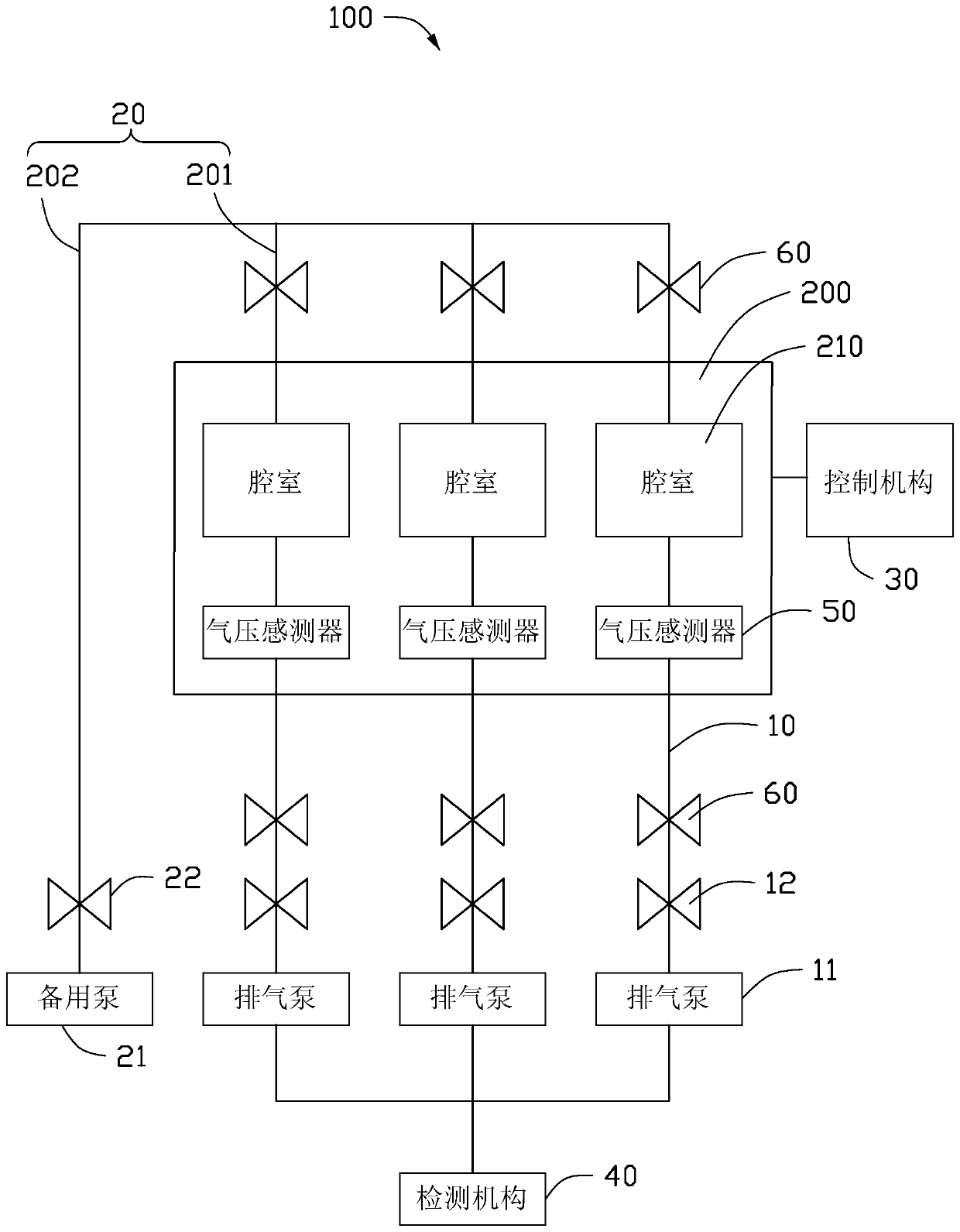

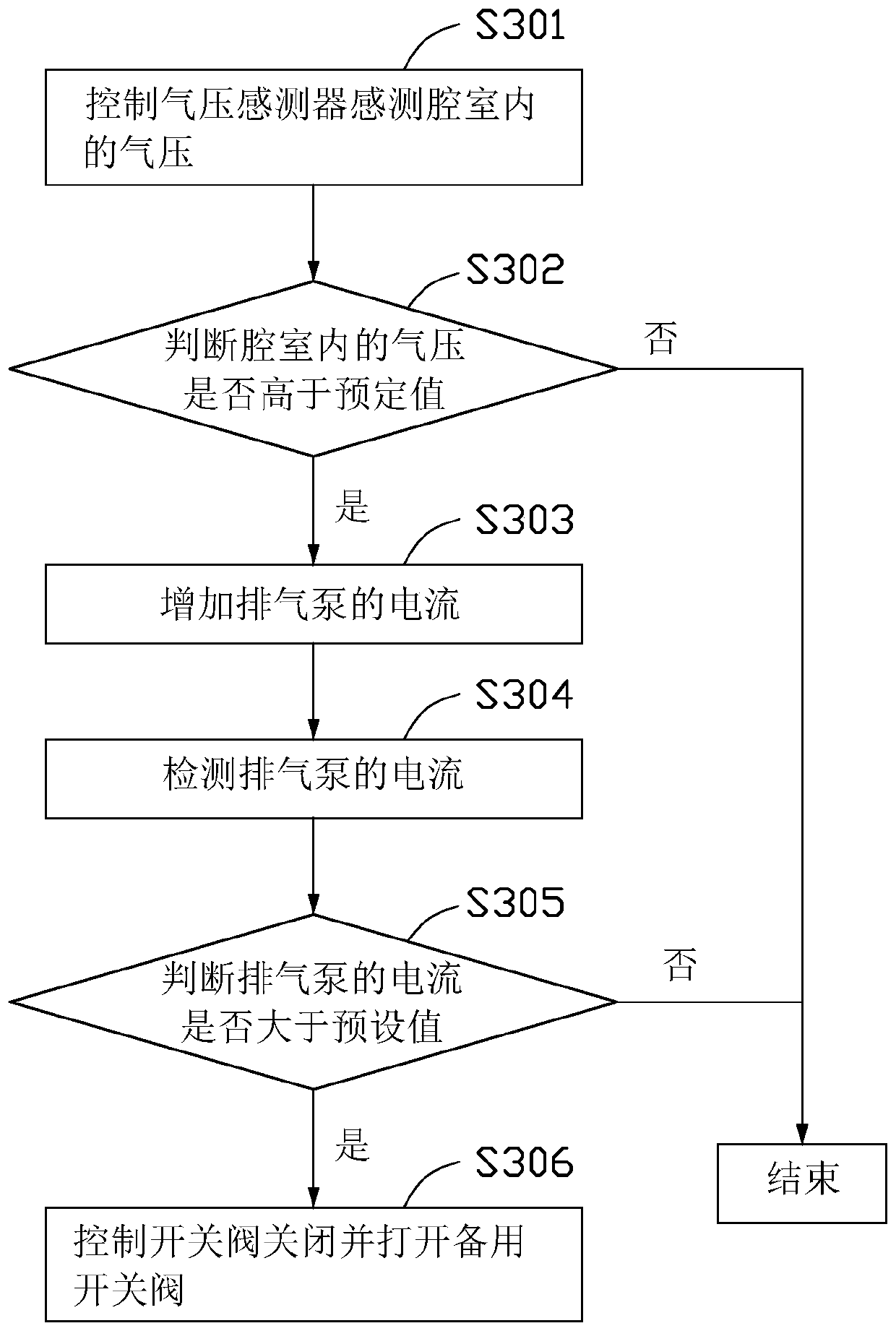

Vacuum exhausting system and control method thereof

InactiveCN111336093AAvoid pollutionBurn out preventionPump testingSemiconductor/solid-state device manufacturingControl engineeringControl switch

A vacuum exhausting system is used for sustaining a vacuum state in a chamber of semiconductor processing equipment. The semiconductor processing equipment comprises at least one chamber. The vacuum exhausting system comprises at least one exhausting pipeline, an exhausting pump and a switch valve which are arranged on the exhausting pipeline. Each exhausting pipeline is communicated with a chamber. The vacuum exhausting system further comprises a standby pipeline, a control mechanism, a standby pump and a standby switch valve which are arranged on the standby pipeline. The standby pipeline iscommunicated with the chamber. The control mechanism is in communication connection with the switch valve and the standby switch valve. The control mechanism controls the switch valve to switch off the switch valve and switch on the standby switch valve when the current of the exhaust pump is higher than a preset value. The vacuum exhausting system prevents system burndown and prevents a condition of incapability of sustaining the vacuum state of the chamber when the exhausting pump cannot work or is unsuitable for working, thereby ensuring processing yield. The invention further provides a vacuum exhausting system control method.

Owner:XIA TAI XIN SEMICON QING DAO LTD

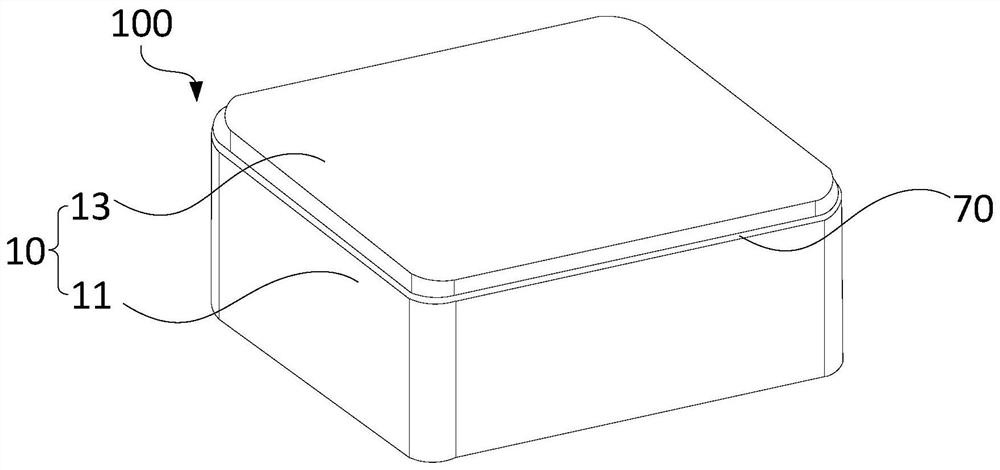

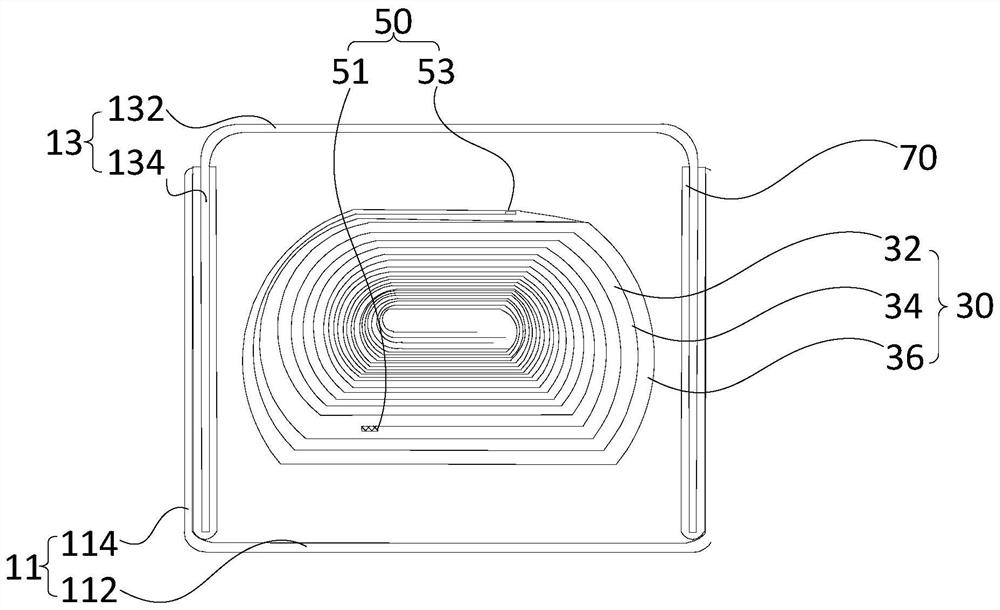

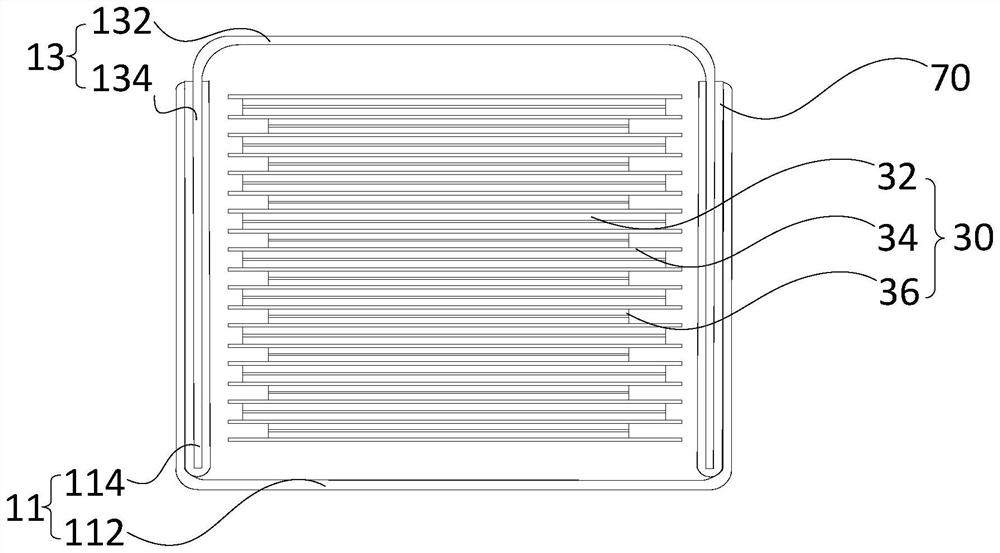

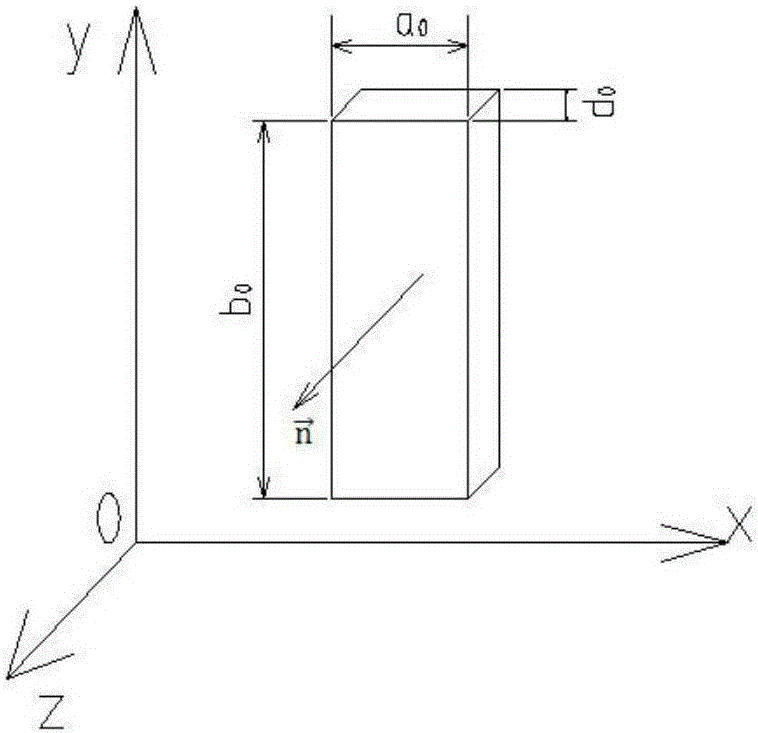

Button battery

PendingCN113013523AImprove automationGuaranteed processing yieldFinal product manufactureSecondary cellsButton batteryEngineering

The invention relates to a button battery. The button battery comprises: a shell, wherein the shell comprises a positive shell and a negative shell, the positive shell is connected to the negative shell in a matched mode, and a mounting space is defined by the positive shell and the negative shell; a battery cell arranged in the mounting space, wherein the battery cell comprises a positive plate, a diaphragm piece and a negative plate, the positive plate is connected to the positive shell, and the negative plate is connected to the negative shell; and a conductive terminal connected to the battery cell. The shell is square. The button battery can be made into a size standard part, so that the automation of the packaging, encapsulating and assembling processes of the button battery can be easily realized, the processing consistency is effectively improved, and the processing yield of the button battery is ensured.

Owner:广东弘捷新能源有限公司

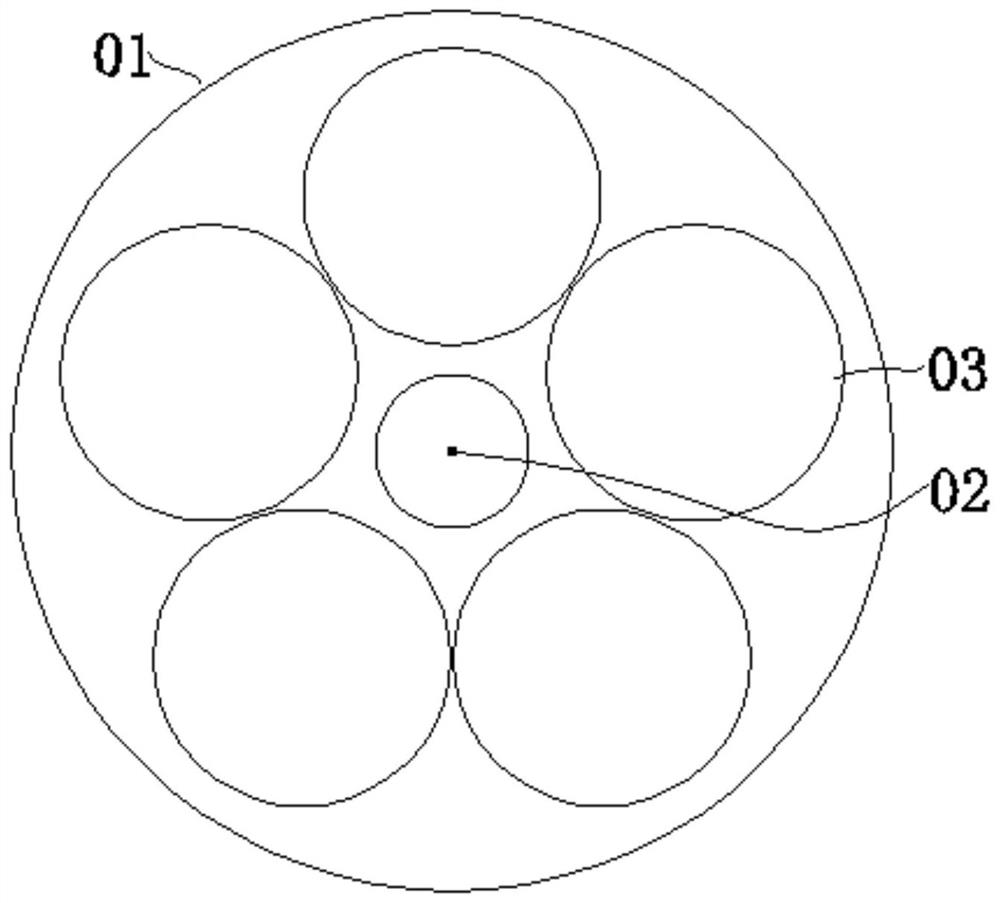

Grinding dynamometer for ultra-precise silicon chip

InactiveCN105014537AImprove machining accuracyImprove processing qualityGrinding feed controlAutomatic grinding controlCapacitanceDynamometer

The invention relates to a grinding dynamometer for an ultra-precise silicon chip. The grinding dynamometer for the ultra-precise silicon chip comprises an inner shaft, a grinding wheel, a three-dimensional force measurement platform and a sensing system signal processor. The measured silicon chip is fixed to the three-dimensional force measurement platform. The grinding wheel is fixed to the inner shaft to be used for grinding the measured silicon chip. The three-dimensional force measurement platform transmits grinding force in the machining process to the sensing system signal processor. The three-dimensional force measurement platform comprises an X-direction differential capacitor unit combination and a Y-direction differential capacitor unit combination. The X-direction differential capacitor unit combination and the Y-direction differential capacitor unit combination each comprise two or more capacitor unit modules which mutually form differentials. Each capacitor unit module is of a comb-shaped structure composed of two or more strip-shaped capacitor units. The dynamic characteristics of a grinding machine and the grinding performance of the grinding wheel are monitored, and the technological parameters such as the feeding speed of the grinding wheel are adjusted in real time according to the grinding force.

Owner:ANHUI KECHUANG PRODUCTIVITY PROMOTION CENT CO LTD

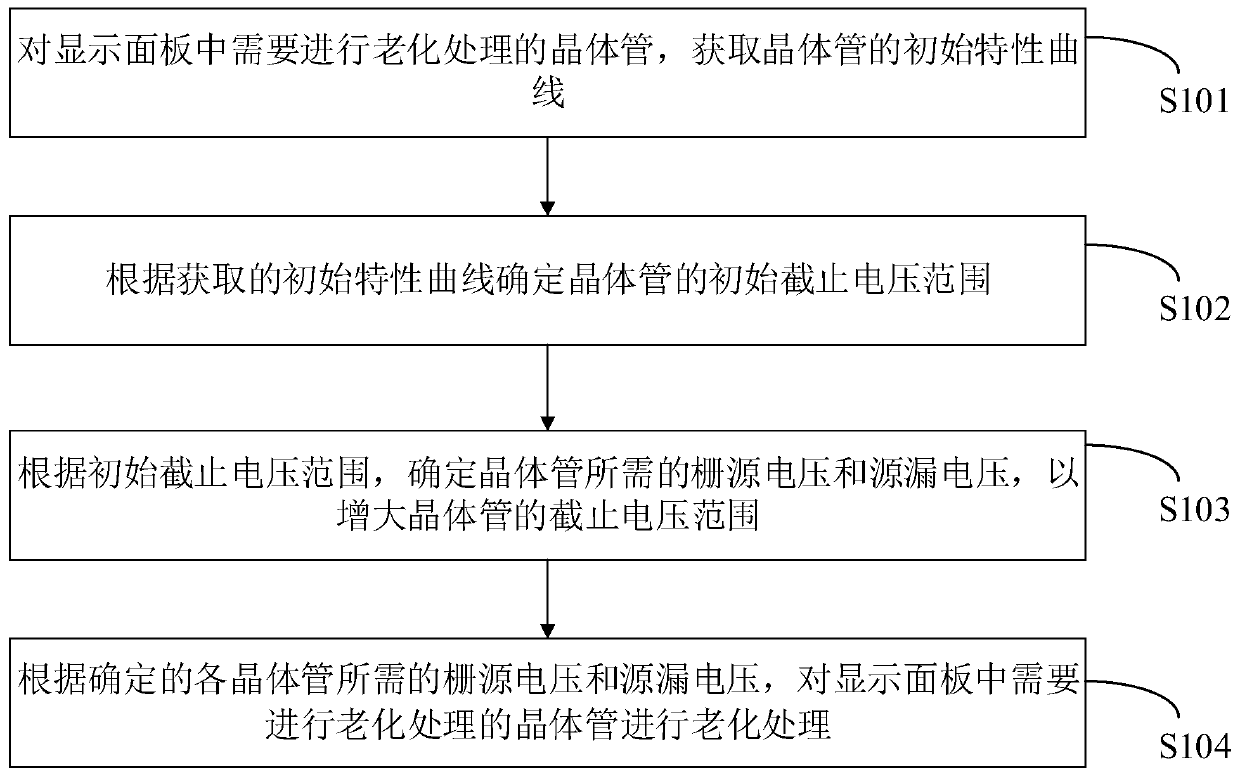

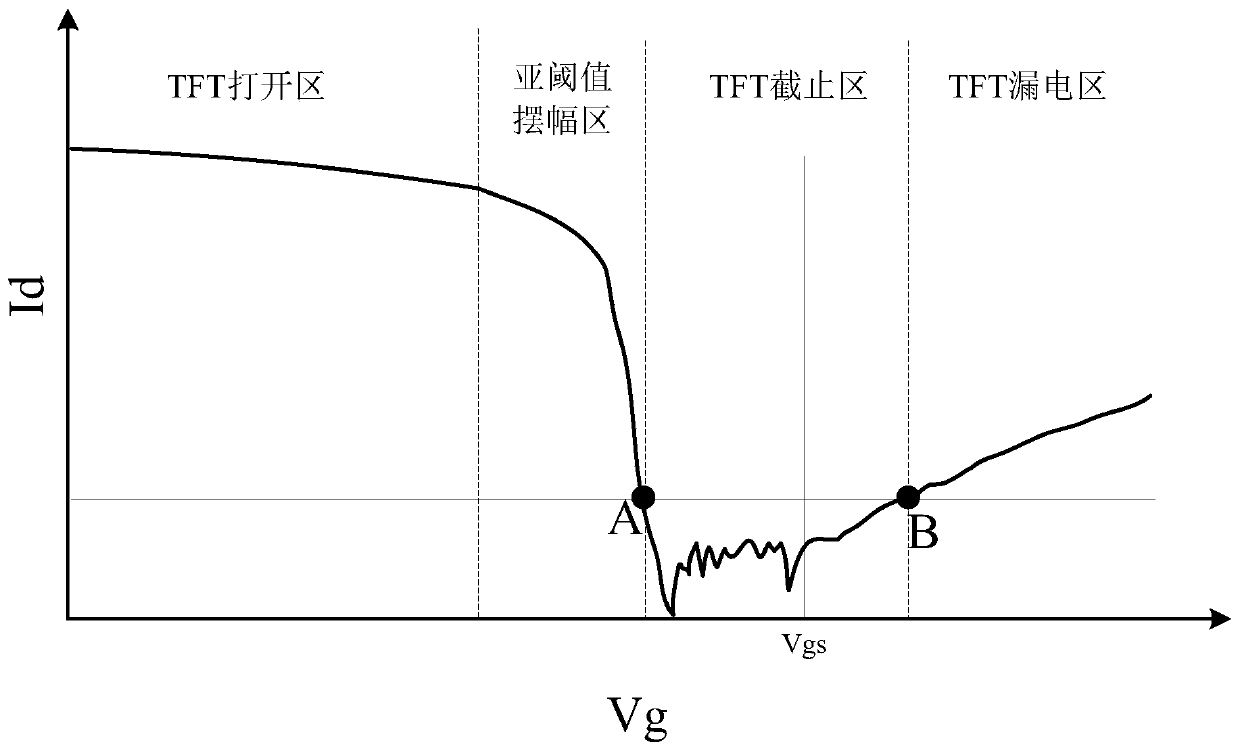

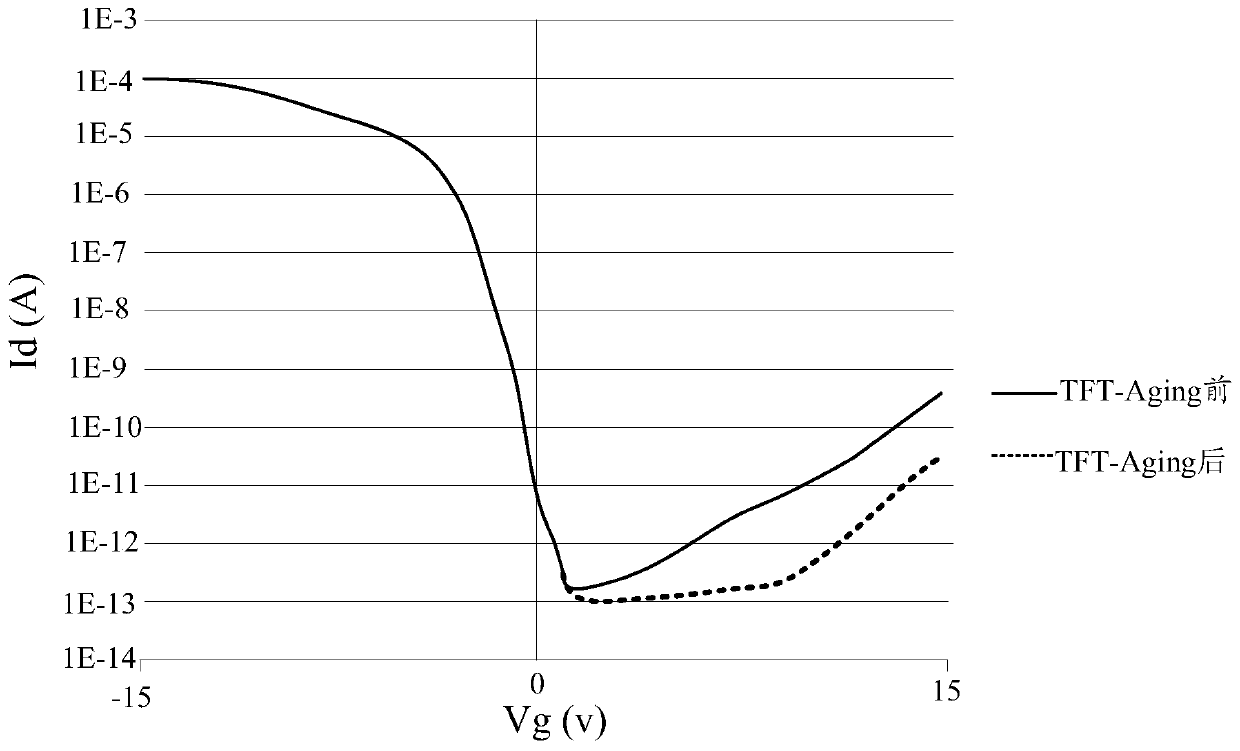

Aging treatment method and aging treatment system applied to display panel

ActiveCN108120915BIncreased cut-off voltage rangeGood effectSemiconductor/solid-state device testing/measurementStatic indicating devicesVoltage rangeMaterials science

The invention discloses an aging treatment method and an aging treatment system applied to a display panel. The initial cut-off voltage range of the transistor is determined according to the initial characteristic curve of the transistor that needs aging treatment in the display panel; and the initial cut-off voltage range is determined according to the initial cut-off voltage range. The gate-source voltage and drain-source voltage required by the transistor to increase the cut-off voltage range of the transistor; according to the determined gate-source voltage and drain-source voltage required by each transistor, perform aging treatment on the transistors that need aging treatment in the display panel . In this method, since the aging treatment voltage applied to each display panel is obtained according to the transistors in the display panel, the effect after aging treatment is good, and the process yield and the stability of product TFT characteristics can be effectively guaranteed.

Owner:BOE TECH GRP CO LTD +1

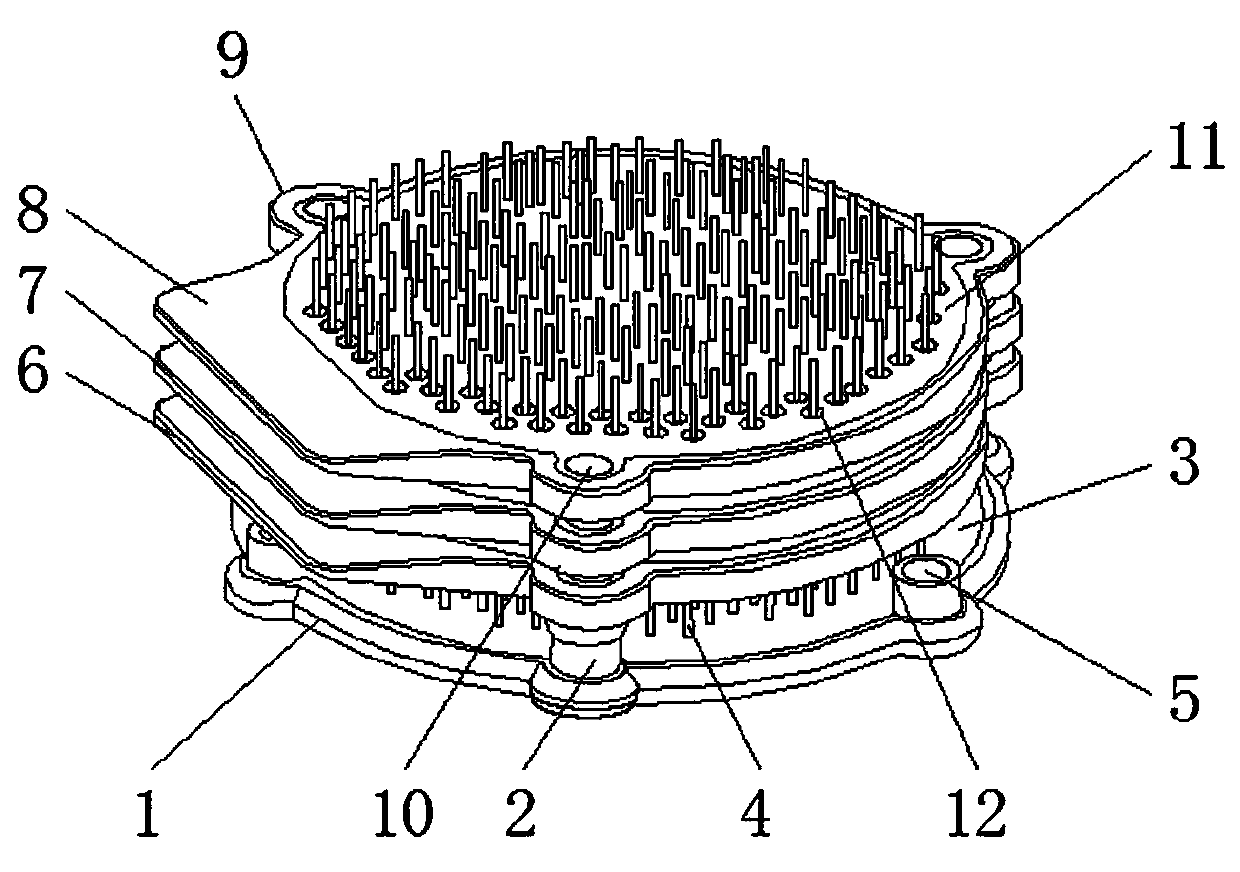

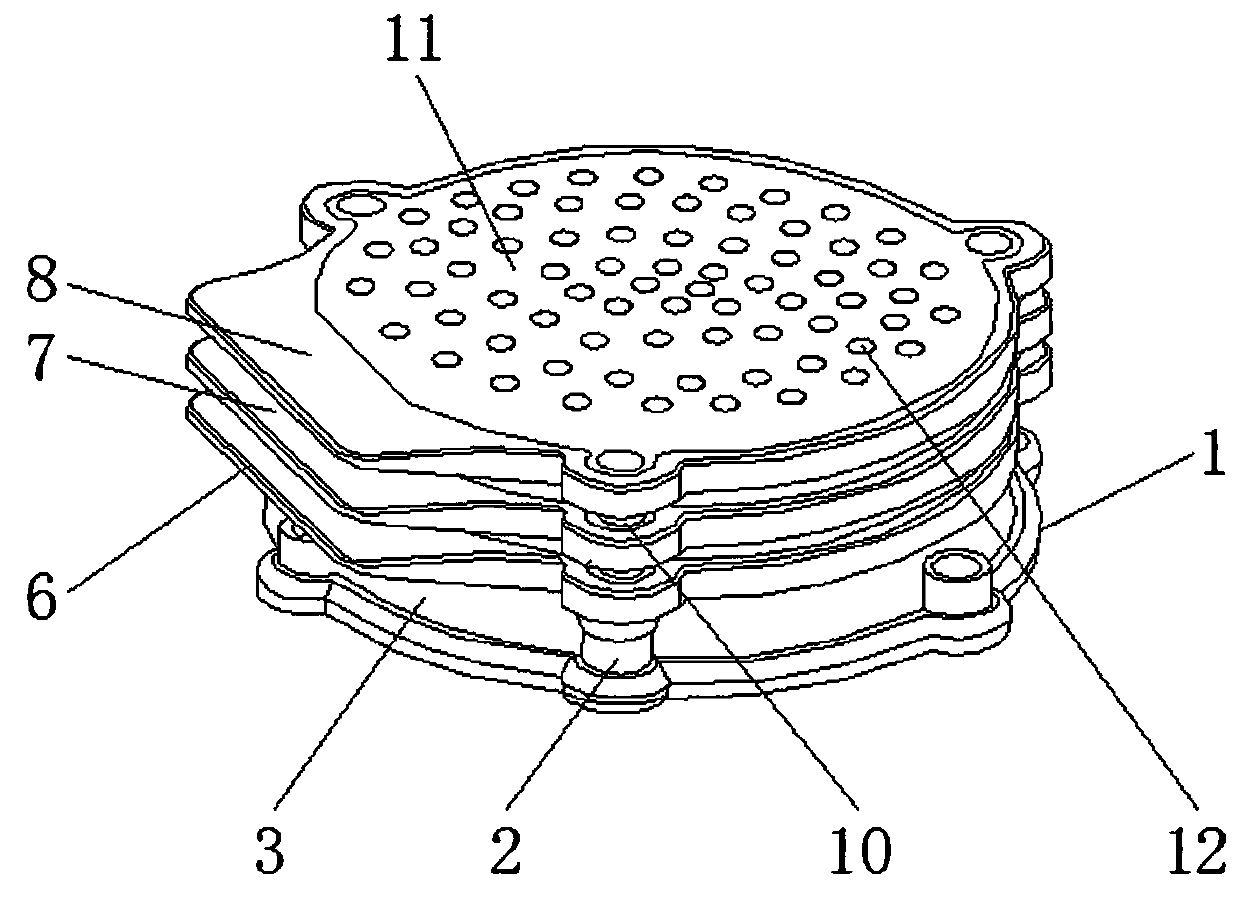

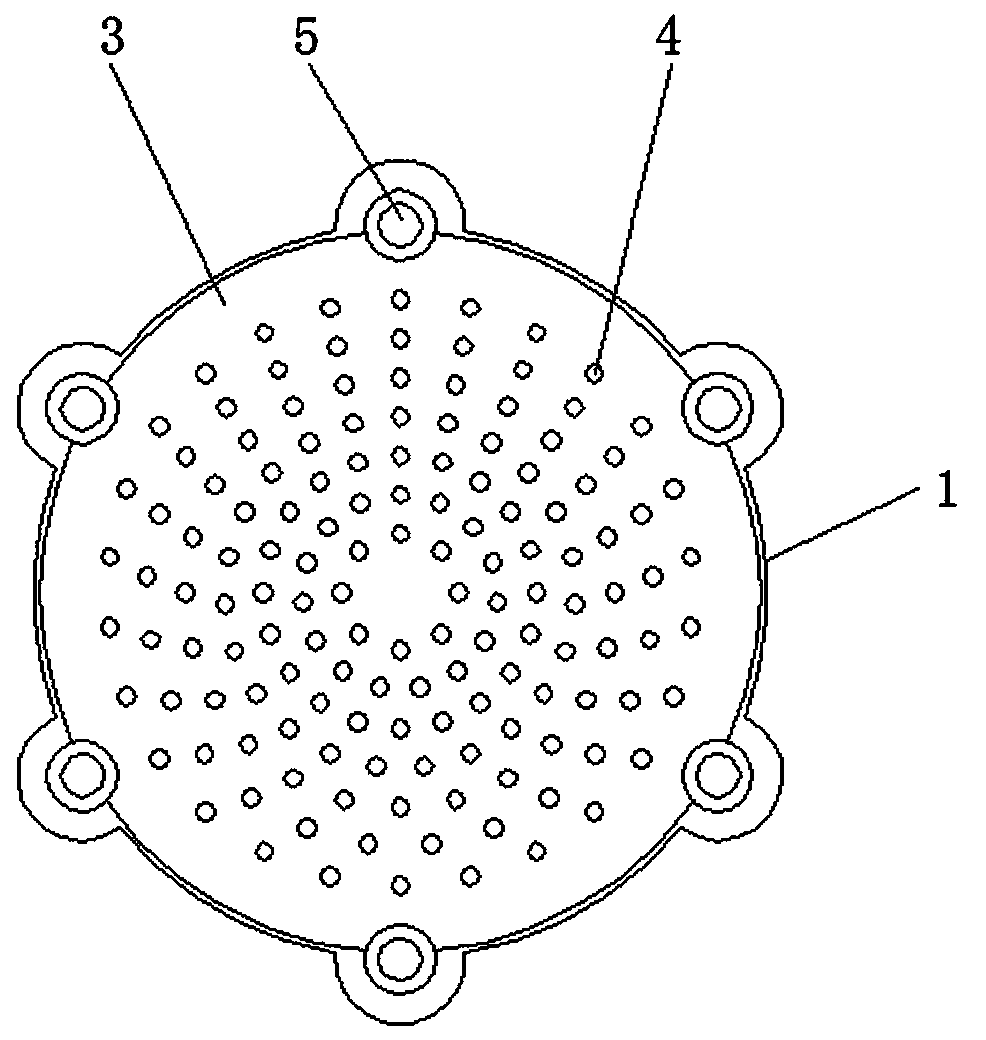

Jewelry precision punching plastic burning needle mold

InactiveCN110754747AGuaranteed structural strengthEnsure structural stabilityJewelleryGlass fiberPunching

The invention discloses a jewelry precision punching plastic burning needle mold. The mold comprises a bottom plate and a first fixed mold, wherein a matching column is fixed to the outer edge of thebottom plate; an assembly hole is formed in the matching column; a bottom panel is arranged on the upper surface of the bottom plate; a stainless steel punching needle is arranged on the upper surfaceof the bottom panel; a second fixed mold is mounted above the first fixed mold; the first fixed mold is located above the bottom plate; a third fixed mold is arranged above the second fixed mold; andlugs are fixed to the outer edges of the first fixed mold, the second fixed mold and the third fixed mold. The jewelry precision punching plastic burning needle mold is formed in a manner that the three fixed molds are superposed together, matched with the circular bottom plate and locked by three fixing screws; a fixed mold plate is formed by one-time injection molding of a precision plastic mold and is made of PC and glass fiber plastic raw materials with the temperature resistance and the high stability; and the circular bottom plate is also formed by one-time injection molding of the precision plastic mold and is made of the same materials the same as that of the fixed mold plate.

Owner:深圳市东德宇科技有限公司

Process for eliminating static electricity of polaroid

PendingCN112770468AEliminate static electricityReduce staticNon-linear opticsElectrostatic chargesAlcoholSkin contact

The invention discloses a process for eliminating the static electricity of a polaroid. The process comprises the following steps of: 1) selecting a quaternary ammonium salt cationic surfactant, preparing static electricity elimination liquid from the quaternary ammonium salt cationic surfactant and absolute ethyl alcohol in proportion, pouring the static electricity elimination liquid into a special container, making a mark, and avoiding contact with skin in the process, otherwise, washing the skin with clear water in time; (2) manufacturing a cleaning tool by using dust-free cloth and a special fixture, forbidding the exposure of edge opening of the fixture, so as to avoid scratches caused by direct contact between the fixture and the polaroid in a subsequent process; and (3) taking a supplied polaroid, removing inner and outer packages, flatly placing the polaroid on a working table, and confirming that a release film faces upward. The invention belongs to the technical field of displays. With the process for eliminating the static electricity of the polaroid adopted, the static electricity of the polaroid is reduced to be (-) 0.2 KV or below, and the phenomena of polaroid adhesion and polaroid connection do not occur in the polaroid machining process and before the attachment of the polaroid to a client.

Owner:深圳市南德谱光电有限公司

A kind of bearing assembly equipment and using method thereof

ActiveCN111266864BGuaranteed processing efficiencyGuaranteed processing yieldAssembly machinesMeasurement/indication equipmentsProcess engineeringWater processing

The invention discloses a bearing assembly device and a method for using it, comprising a processing mechanism for processing cold-rolled steel bearings, a detection head for detecting the processing progress, a moving mechanism for transferring processed materials, and a clamping and pushing mechanism. The processing mechanism is installed on the upper end of the support mechanism, the detection head is arranged at the discharge end of the processing mechanism, the moving mechanism is arranged on the front side of the processing mechanism, and a The clamping and pushing mechanism is provided with a collection mechanism on the support mechanism. The device of the present invention adopts overall automation to process the cold-rolled steel bearing in flow water, and cooperates with the detection head to ensure the processing efficiency and yield rate, and uses the cooperation of the moving mechanism, the clamping and pushing mechanism, and the collecting mechanism to quickly detect and reject during processing Drop unqualified products, avoid downtime after producing unqualified products, and improve work efficiency.

Owner:文金凤

Device for LED wafer manufacturing process

PendingCN114334756AGuaranteed lifeGuaranteed wafer processing yieldVacuum evaporation coatingSputtering coatingPhysicsEngineering

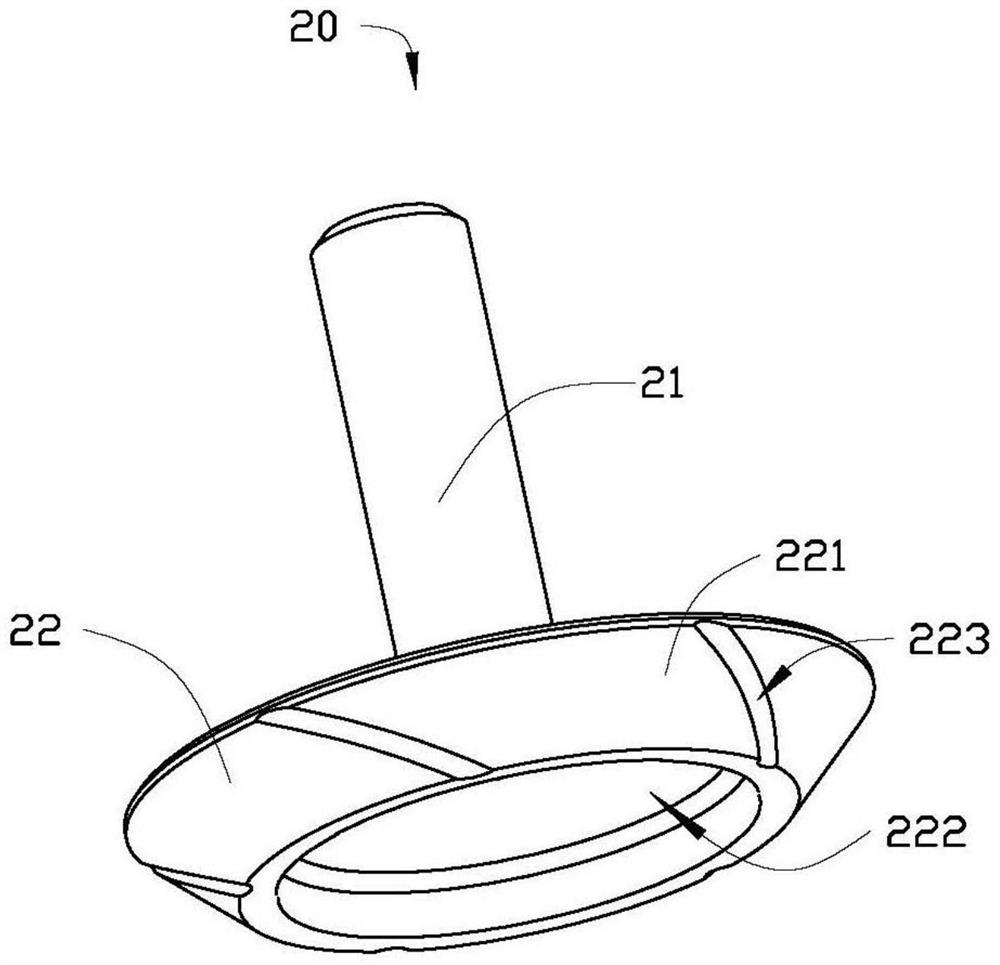

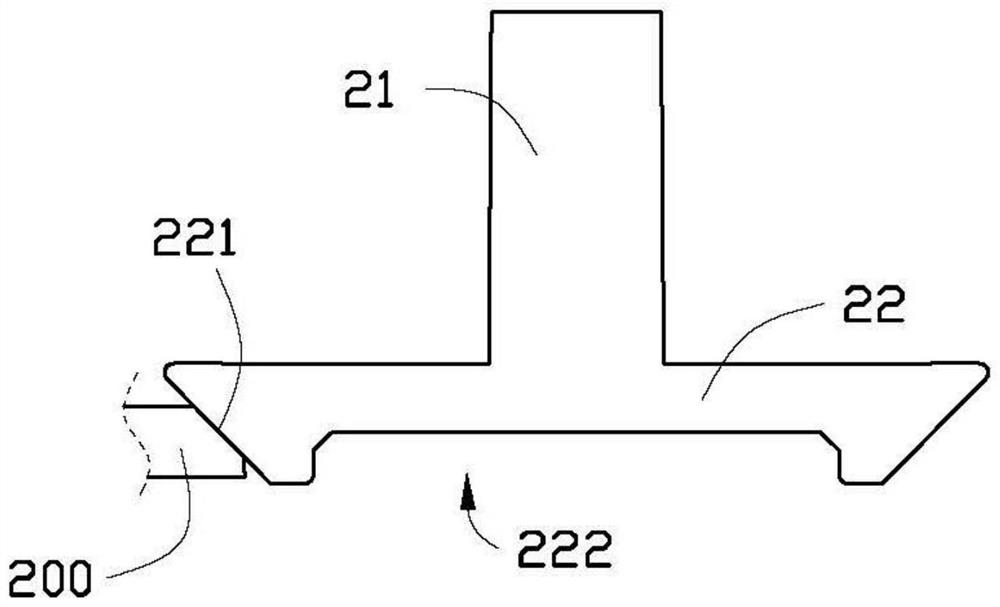

The invention provides a device for LED wafer processing, which comprises a carrying disc and a pressing ring, the side surface of the carrying disc is an inclined surface, a carrying disc inclination angle is formed between the side surface of the carrying disc and a wafer placing surface, the pressing ring is used for fixing the carrying disc, a pressing ring positioning angle is used for positioning the carrying disc inclination angle, and a sheet pressing part is used for pressing the edge of the carrying disc. The shape and the angle of the press ring positioning angle are matched with the shape and the angle of the carrier plate inclination angle, the size of the carrier plate is properly increased, meanwhile, the problem that the press ring cannot press the carrier plate due to the fact that the carrier plate is too large is avoided, a machine table can work normally, and the phenomenon that the carrier plate is prone to deviating from fixation of the press ring in the process that the carrier plate is conveyed into a cavity in the manufacturing process and rubs with the press ring can be avoided. The service life of the carrying disc and the wafer processing yield can be effectively guaranteed, and stable large-scale mass production is achieved.

Owner:XIAMEN CHANGELIGHT CO LTD

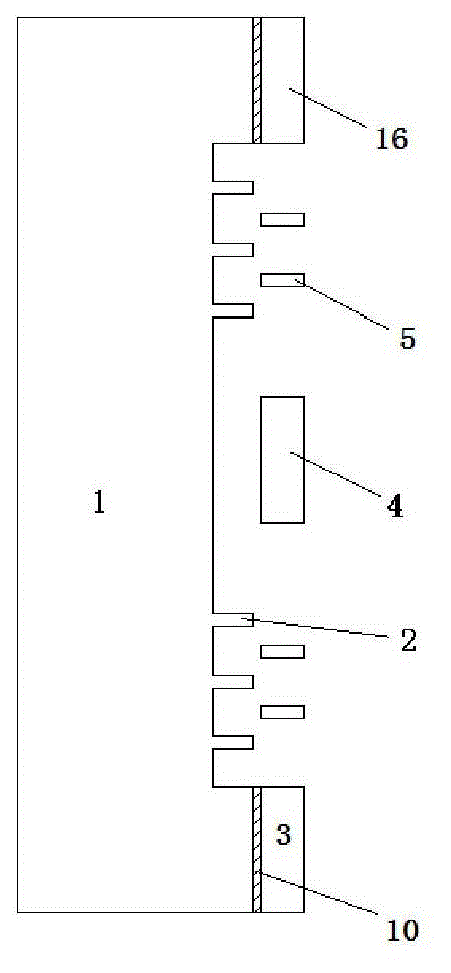

Bending forming device

The invention discloses a bending forming device. The bending forming device comprises a top plate, wherein a forming mechanism is fixedly arranged at the top of the top plate. The forming mechanism comprises a cylinder, wherein the top end of the cylinder is sleeved with a rotating column, a barrel body is fixedly arranged at the top of the rotating column, two first openings are formed in the top of the barrel body, a first push rod is fixedly arranged at the top of the rotating column, a second push rod is arranged on one side of the first push rod, and a material supporting support is arranged on one side of the cylinder. By rotating a handle, the handle lifts the rotating column to drive the first push rod and the second push rod to rotate, in the process, a plate is slowly pushed to the position of a positioning pin till the outer wall of the plate makes contact with the outer wall of the barrel body, the outer wall of the first push rod and the outer wall of the second push rod at the same time, and the two different positions of the plate are bent and formed at a time. The bending forming device can be fixed on a stand, the machining yield is ensured, the efficiency is improved, and the cost is saved.

Owner:苏州市富通精密机械有限公司

OLED display device and manufacturing method thereof

ActiveCN114122291APrevents degradation of display qualityGuaranteed processing yieldSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The embodiment of the invention discloses an OLED (Organic Light Emitting Diode) display device and a manufacturing method thereof. The OLED display device comprises a substrate, a plurality of OLED devices and a plurality of spacers, the plurality of OLED devices are arranged on the substrate, and one side, far away from the substrate, of at least part of the OLED devices is provided with an inorganic layer; and at least part of the spacers are distributed in gaps between the OLED devices. The OLED display device provided by the invention is provided with the spacer, so that the problem that the display quality of the OLED display device is reduced due to external impact is avoided.

Owner:HUIZHOU CHINA STAR OPTOELECTRONICS TECHNOLOGY CO LTD +1

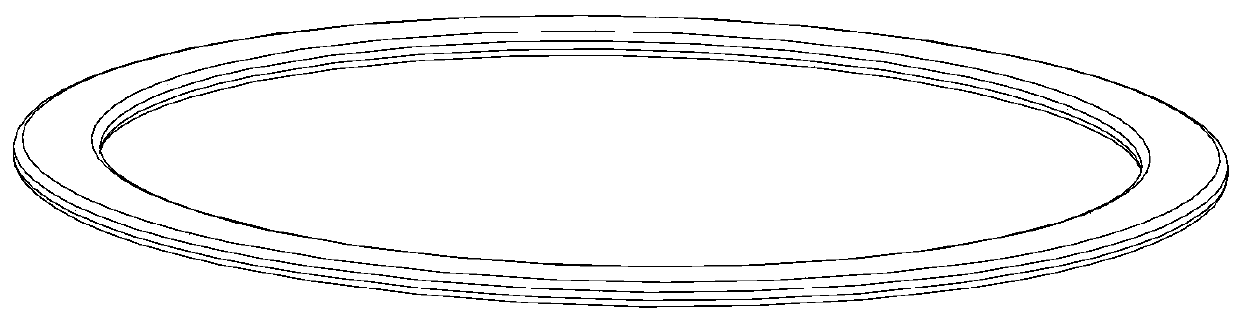

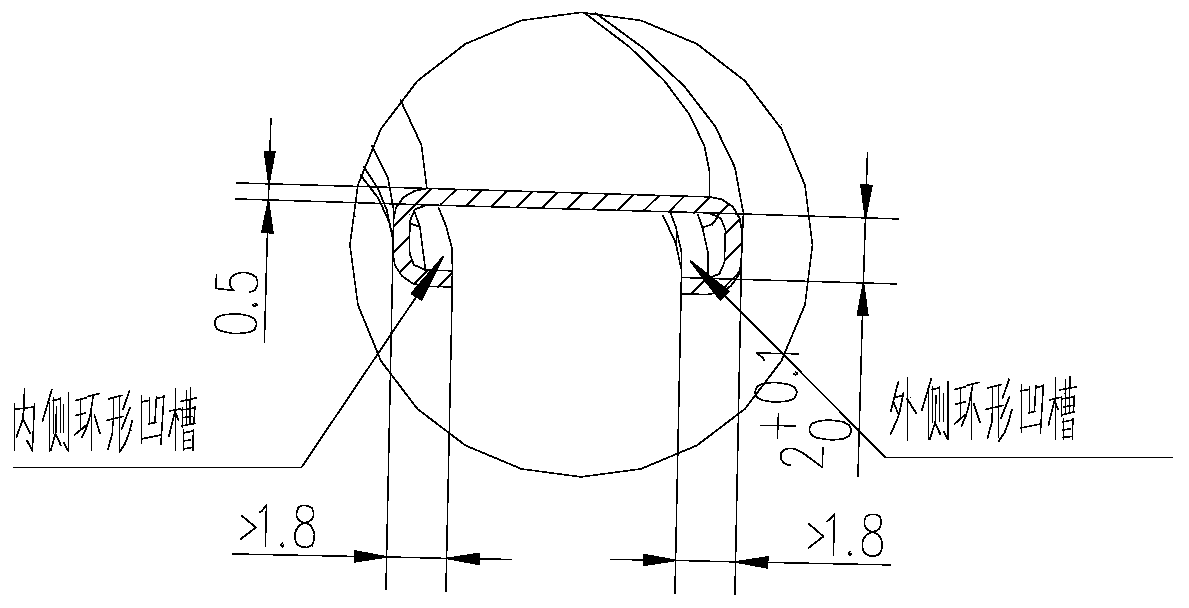

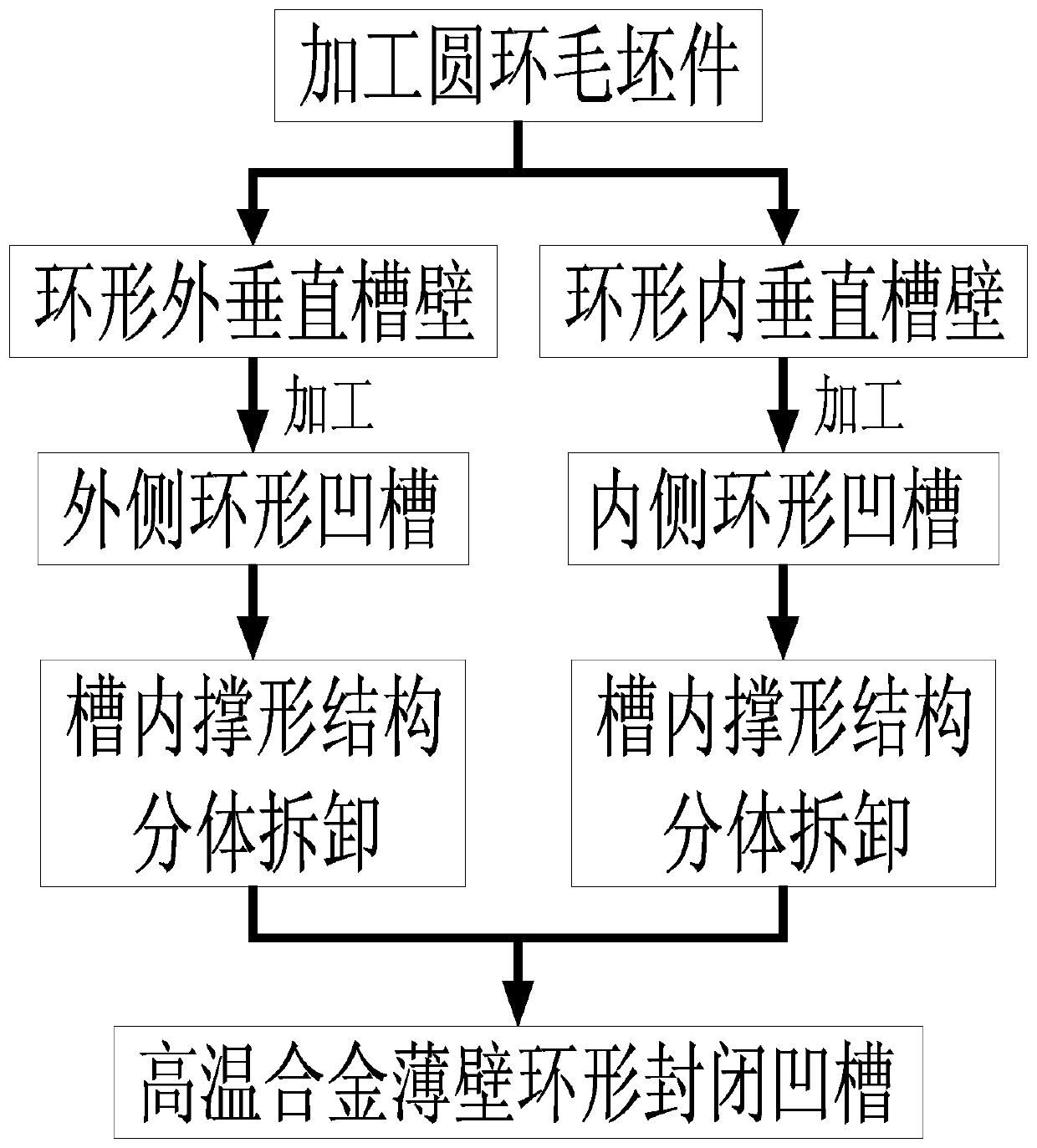

Forming method of superalloy thin-walled annular closed groove

ActiveCN109604475BGuaranteed machining accuracyGuaranteed processing yieldMetal-working apparatusSuperalloyThin walled

The invention discloses a forming method of a thin-wall annular sealing groove of a superalloy. The forming method of the thin-wall annular sealing groove of the superalloy comprises the following steps that a circular ring blank member with a cross-sectional shape in a right-angled groove shape is obtained by machining, and the annular blank member is provided with an annular outer vertical groove wall, an annular groove bottom plate and an annular inner vertical groove wall; the annular groove bottom plate is clamped and fixed, and a notch of the annular blank member is distributed downward;the groove inner shape supporting is carried out on the annular inner vertical groove wall, and the annular outer vertical groove wall is machined by adopting a rolling method; a split type structureis adopted in the groove inner shape supporting of the annular inner vertical groove wall, and disassembling and demoulding are separately carried out after an outer side annular groove is machined;the groove inner shape supporting is carried out on the annular inner vertical inner groove wall, and the annular inner vertical grove wall is machined by adopting the rolling method; the split type structure is adopted in the annular inner vertical groove wall, and disassembling and demoulding are separately carried out after an inner side annular groove is machined; and parts after machined areremoved to obtain the thin-walled annular sealing groove of the superalloy.

Owner:CHINA HANGFA SOUTH IND CO LTD

Large-bevel-edge 2.5 D cover plate machining device and machining method

ActiveCN114589574ASolve rigid problemsSolve the strength problemEdge grinding machinesBonded abrasive wheelsEdge surfaceStructural engineering

The invention provides a large-bevel-edge 2.5 D cover plate machining device and method, and relates to the field of glass machining and manufacturing, the large-bevel-edge 2.5 D cover plate machining device comprises a cover plate fixing mechanism, a first grinding wheel rod and a second grinding wheel rod, the first grinding wheel rod is provided with a first cutting edge face, and the first cutting edge face is a first conical face with the large upper portion and the small lower portion; the second grinding wheel rod is provided with a second cutting edge surface and a third cutting edge surface which are consistent in shape, the second cutting edge surface comprises a second conical surface, a third conical surface, a fourth conical surface, a cylindrical surface and a fifth conical surface which are sequentially connected from top to bottom, and the roughness of the first cutting edge surface, the second cutting edge surface and the third cutting edge surface is sequentially reduced. A large bevel edge is machined at a time through the first cutting edge face, a contour is formed at the upper position and the lower position of the large bevel edge at a time through the second cutting edge face, and finally the contour of a rough product is finely trimmed through the third cutting edge face, so that the cover plate is obtained through complete forming, and beveling trimming is not needed. The processing yield and the processing efficiency are higher, and the standard reaching rate of the product size and the processing precision are improved.

Owner:LENS TECH CHANGSHA

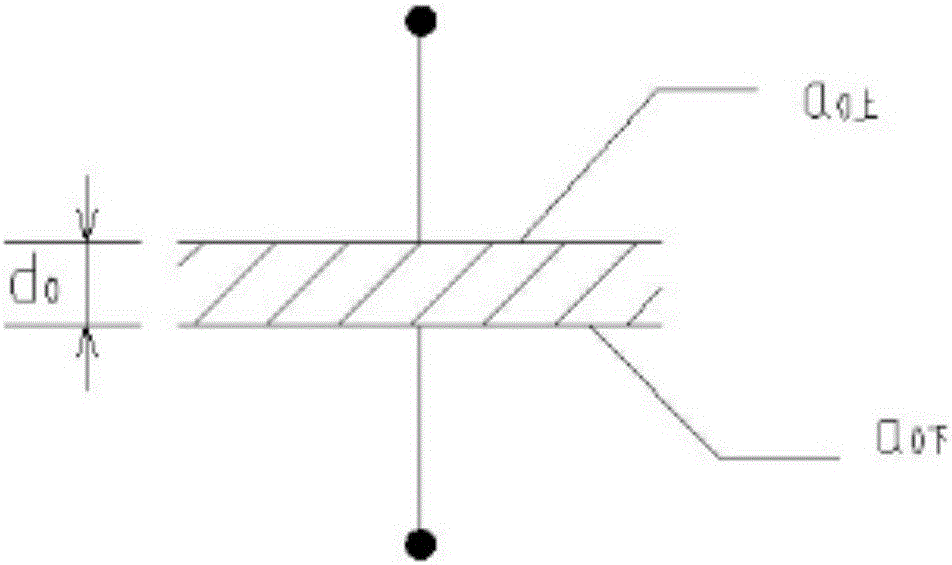

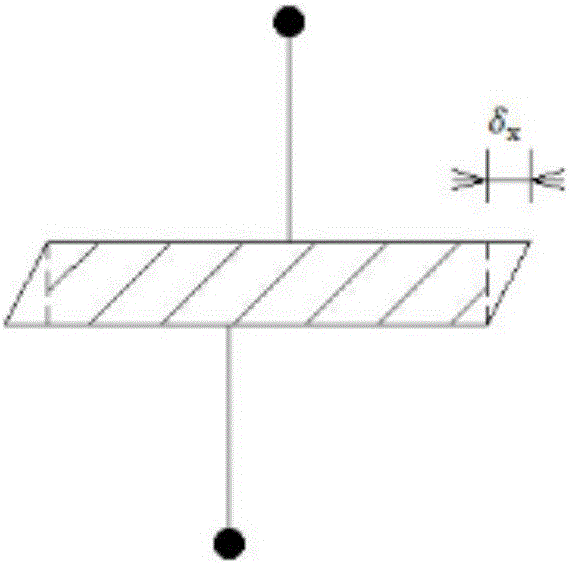

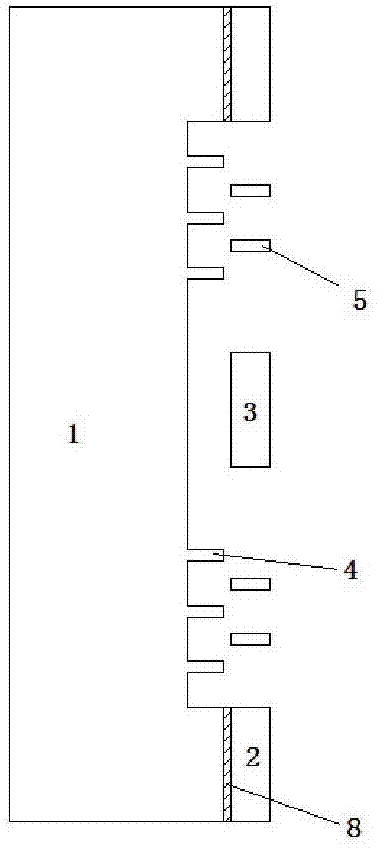

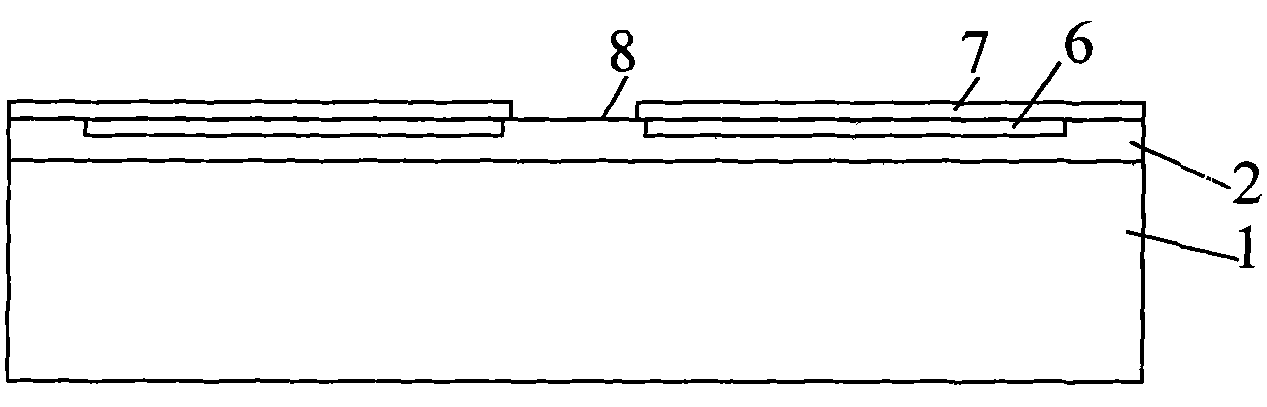

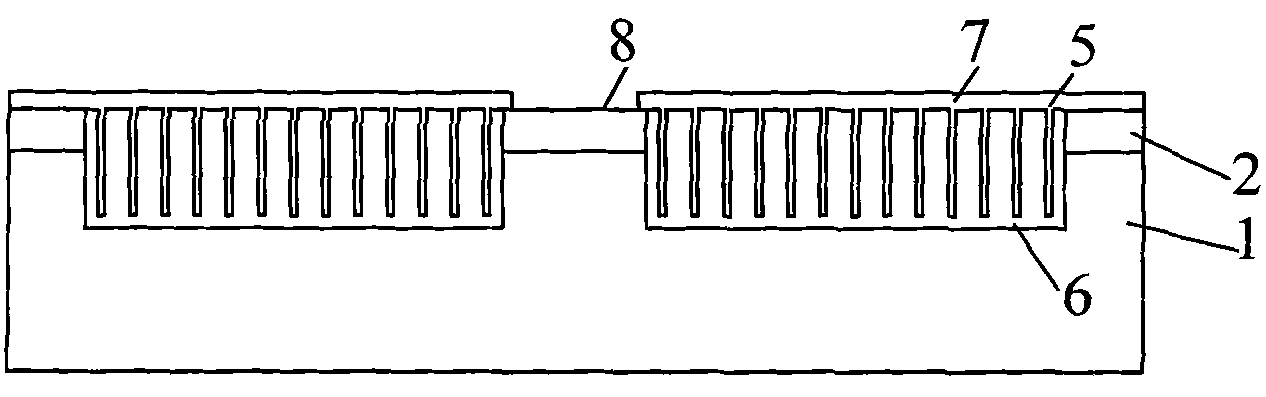

Two-way twistable staggered-comb teeth electrostatic driving variable optical attenuator and manufacture method thereof

InactiveCN103149684BPrecise control of twist angleRealize two-way torsionSolid-state devicesFluid speed measurementEngineeringOptical attenuator

The invention discloses a two-way twistable staggered-comb teeth electrostatic driving variable optical attenuator which comprises a substrate, fixed comb teeth units, a micromirror, movable comb teeth units, two support rods, insulating medium layers, two twisting rods and two movable electrode regions, wherein an oxidation insulating layer is fixedly connected between each of the two movable electrode regions and the substrate, and the insulating medium layers are respectively embedded to the middle parts of the two support rods, the two twisting rods and the micromirror; one ends of the two support rods are fixedly connected onto the micromirror, and the other ends of the two support rods are fixedly connected onto the movable electrode regions by the twisting rods; and two movable comb teeth units which are symmetrically arranged with each other along the support rods are respectively and fixedly connected onto the two support rods, and movable comb teeth in each movable comb teeth unit and fixed comb teeth in each fixed comb teeth unit are distributed with one another in a staggered way. According to the variable optical attenuator, the two-way twisting can be realized, and the twisting position of the micromirror can be accurately controlled. Meanwhile, the invention further discloses a preparation method of the variable optical attenuator, which is high in reliability and high in machining precision.

Owner:SOUTHEAST UNIV

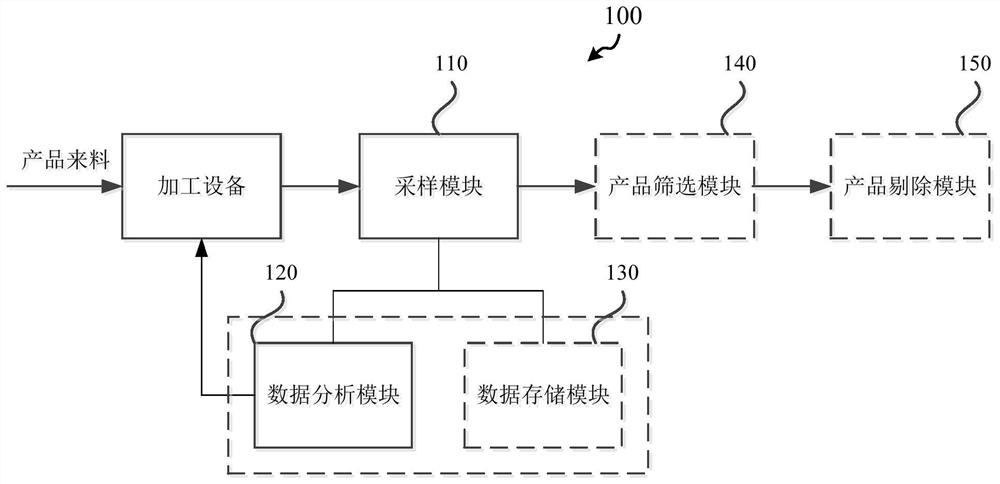

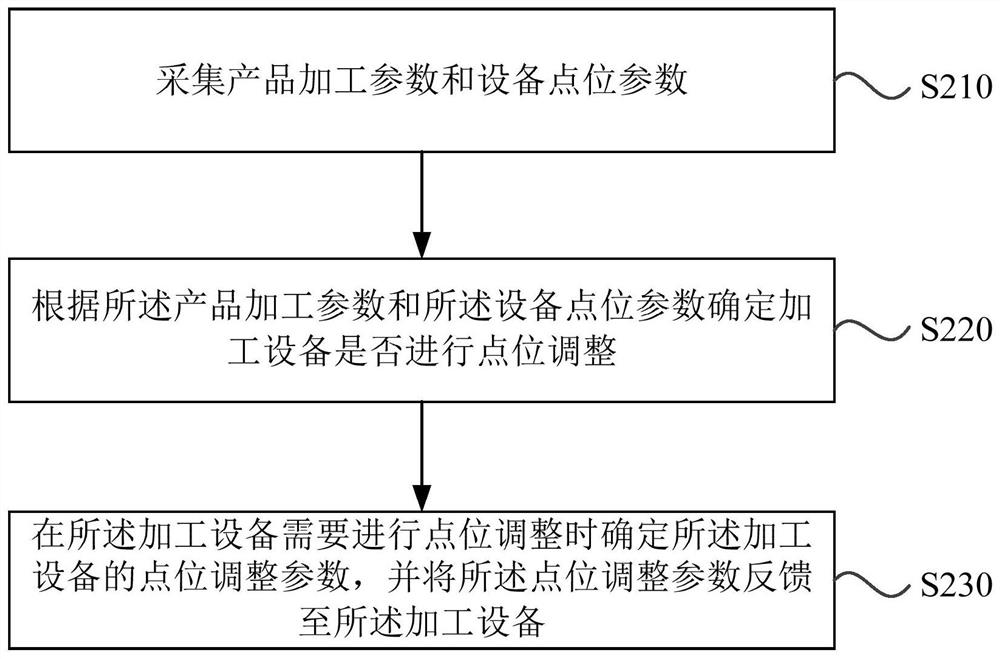

Production line parameter adjusting device, production line parameter adjusting method and storage medium

PendingCN111883458ASolve processing problemsGuaranteed processing yieldSemiconductor/solid-state device manufacturingProduction lineProcess engineering

The embodiment of the invention discloses a production line automatic parameter adjusting device and a production line parameter adjusting method. The production line parameter adjusting device comprises a sampling module used for collecting product processing parameters and equipment point position parameters; and a data analysis module used for determining whether processing equipment performs point location adjustment or not according to the product processing parameters and the equipment point location parameters, and further used for determining point location adjustment parameters of theprocessing equipment when the processing equipment needs to perform point location adjustment, and feeding back the point location adjustment parameters to the processing equipment. According to thetechnical scheme of the embodiment of the invention, the equipment processing yield is ensured in a production line of the electronic and semiconductor industries, and the productivity is improved.

Owner:昆山泽旭自动化科技有限公司

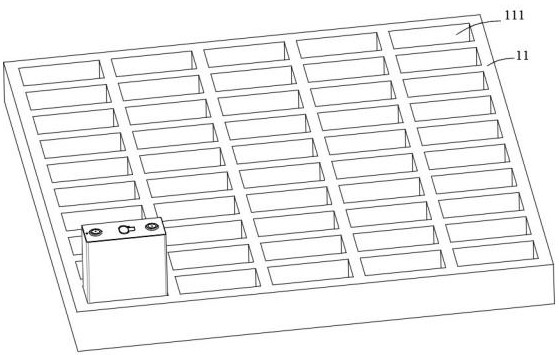

Feeding device and feeding method for battery conveying system

ActiveCN113148649BGuaranteed clamping stabilityImprove clamping effectConveyor partsEngineeringMechanical engineering

The present invention relates to the technical field of lithium batteries, in particular to a feeding device and a feeding method for a battery delivery system, wherein a feeding device for a battery delivery system includes: a six-axis manipulator, a feeding bracket, and several clamping materials The clamping part and the clamping part, as well as the clamping surface of the clamping part, have two opposite clamping plates, the two clamping plates are arranged obliquely and the distance between the two clamping plates is from the side far away from the feeding bracket to close to the feeding One side of the bracket gradually increases; there are several clamping blocks fixedly connected to the end surface of each clamping plate, and the clamping block is located on the side close to the two clamping plates; the ring six-axis manipulator is equipped with an incoming material placement mechanism and an upper Material conveying mechanism and incoming material placement mechanism are suitable for placing trays with materials; when the six-axis manipulator is located in the area of the incoming material placement mechanism, the two clamping plates can be rotated to be parallel to the outer side walls of the material; after the material is clamped by the two clamping plates , the pressing part can push the material to offset against the clamping block, so that the clamping block can position the material.

Owner:中科摩通(常州)智能制造股份有限公司

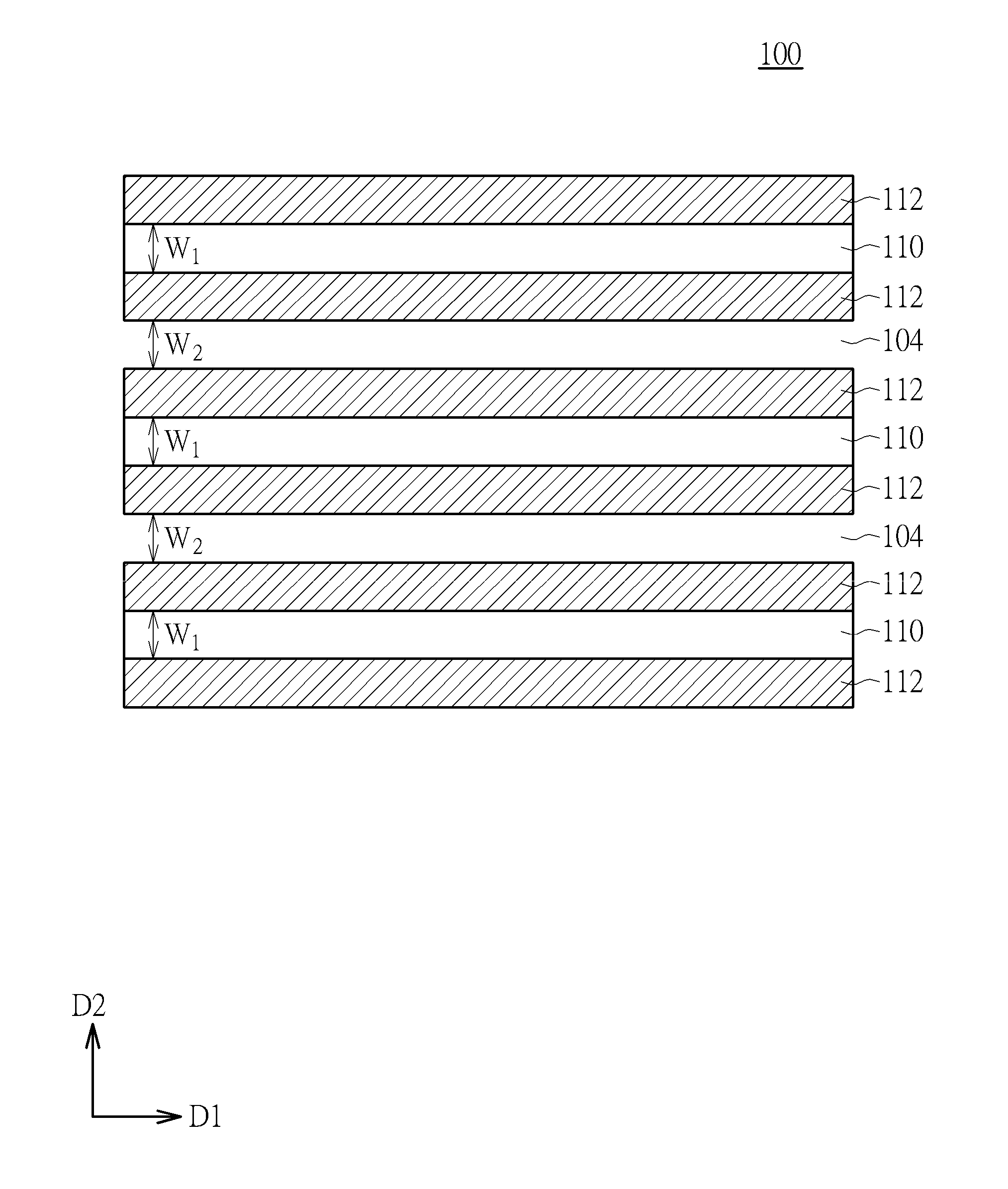

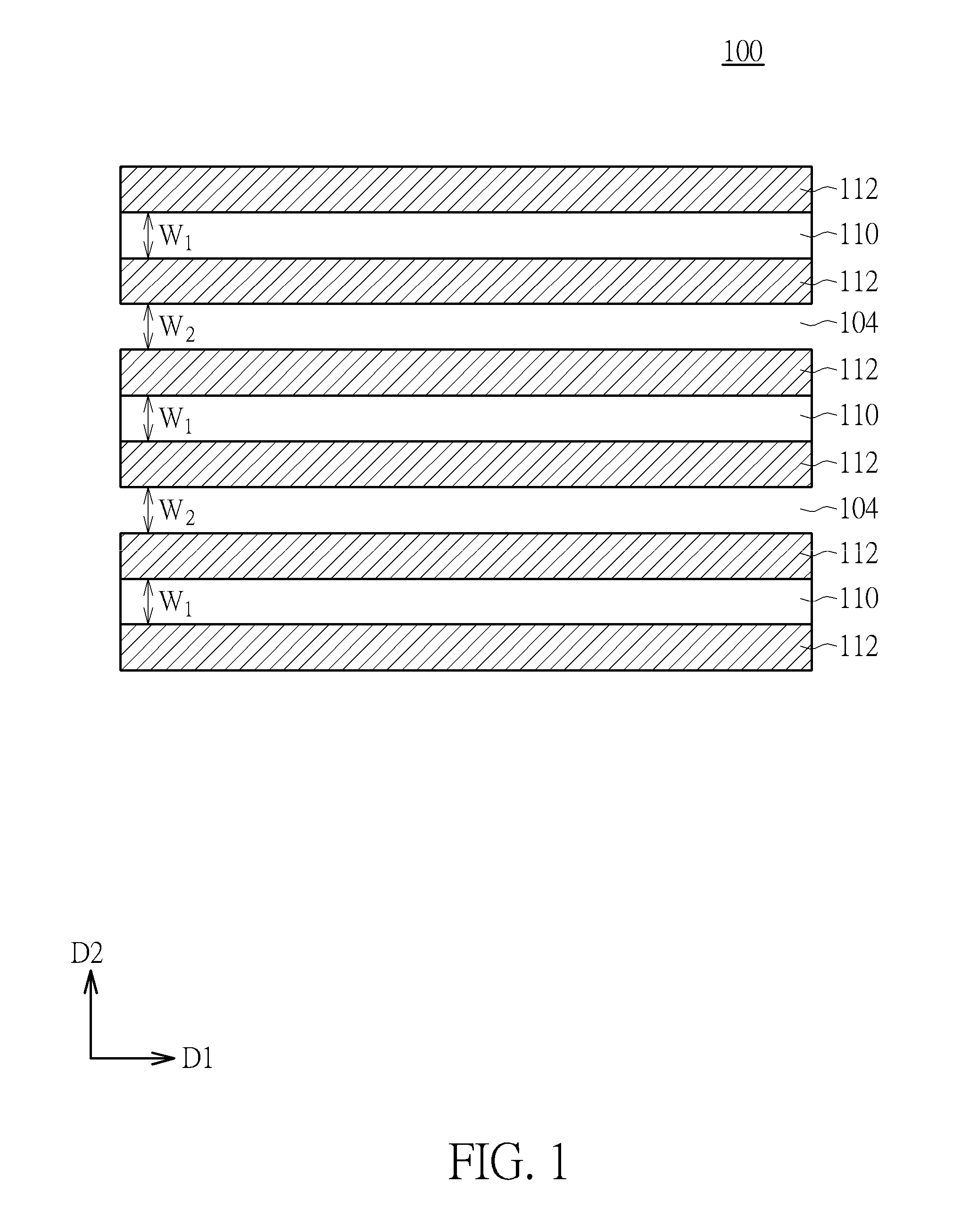

Method for forming patterns for semiconductor device

ActiveUS9536751B2Guaranteed processing yieldSemiconductor/solid-state device manufacturingEngineeringBlocking layer

A method for forming patterns for semiconductor device includes following steps. A substrate is provided. The substrate includes a hard mask layer and a sacrificial layer formed thereon. A plurality of spacer patterns parallel with each other are formed on the substrate. A plurality of first blocking layers are formed in the sacrificial layer after forming the spacer patterns. A plurality of second blocking layers exposing at least a portion of the sacrificial layer and at least a portion the first blocking layer are formed on the substrate after forming the first blocking layer. Next, the sacrificial layer and the hard mask layer are etched with the spacer patterns, the first blocking layers and the second blocking layer being used as etching masks to form a patterned hard mask layer on the substrate.

Owner:UNITED MICROELECTRONICS CORP

Copper part thin-wall fine punching equipment

PendingCN112296163AGuaranteed process yieldGuaranteed contourMetal-working feeding devicesStripping-off devicesPunchingStructural engineering

The invention discloses copper part thin-wall fine punching equipment. The copper part thin-wall fine punching equipment comprises a machine table, a feeding device, a feeding conveying channel, a punching device, a discharging conveying channel, a discharging device, a first material tray device and a second material tray device. The feeding device, the feeding conveying channel, the punching device, the discharging conveying channel, the discharging device, the first material tray device and the second material tray device are arranged on the machine table; the first material tray device isused for placing a first material tray, and the first material tray is used for bearing a to-be-punched workpiece; the second material tray device is used for placing a second material tray, and the second material tray is used for bearing the punched workpiece; the feeding device is arranged on one side of the feeding conveying channel and is configured to convey the to-be-punched workpiece on the first material tray to the feeding conveying channel; the feeding conveying channel is configured to convey the to-be-punched workpiece to the punching device; the punching device is configured to punch the to-be-punched workpiece; the discharging conveying channel is configured to output the punched workpiece; and the discharging device is arranged on one side of the discharging conveying channel and used for conveying the punched workpiece to the second material tray. The equipment can realize fine punching, and is high in production efficiency and high in automation degree.

Owner:DONGGUAN LINGJIE PRECISION MACHINING TECH CO LTD

A fully automatic and intelligent end-typing machine for filament

The invention discloses a full-automatic intelligent lamp filament terminal machine which comprises a machine body. A conveying device for conveying a terminal metal material strap is arranged on the machine body. The full-automatic intelligent lamp filament terminal machine is characterized in that the conveying device is sequentially provided with a connecting rib precut die, a solder paste injecting device and a terminal pressing die in the conveying direction of the metal material strap, a lamp filament conveying device which can automatically send a lamp filament into a terminal pressing groove in the terminal metal material strap is arranged on one side of the terminal pressing die, the terminal pressing die comprises a lower die holder and an upper die holder, an outer guide column is arranged on the upper die holder, an outer guide hole for guiding the outer guide column to slide therein is formed in the lower die holder, a female die back plate is arranged on the upper side of the lower die holder, a pushing and ejecting device for making a lamp filament located in the middle of the terminal metal material strap is arranged on the female die back plate, and a lamp filament terminal pressing device is arranged on the lower side of the upper die holder.

Owner:ZHONGSHAN GUOAO INTELLIGENT SCI & TECH CO LTD

One-direction torsion and high-balance variable optical attenuator and preparation method thereof

InactiveCN103149683BPrecise control of twist angleImprove reliabilitySolid-state devicesFluid speed measurementEngineeringOptical attenuator

The invention discloses a one-direction torsion and high-balance variable optical attenuator which comprises a substrate, fixed comb tooth units, two movable electrode regions, a micromirror, movable comb tooth units and two support rods, wherein a cavity is arranged at the upper part of the substrate; a first silicon dioxide insulating layer is arranged between each movable electrode region and the substrate; one ends of the two support rods are respectively and fixedly connected with the micromirror; the other ends of the two support rods are respectively and fixedly connected with the movable electrode regions through torsion rods; the movable comb tooth unit is fixedly connected to the lateral surface of each support rod; the movable comb tooth units are positioned above the fixed comb tooth units; the fixed comb tooth unit is positioned on one side of each support rod; fixed comb teeth in the fixed comb tooth units and movable comb teeth in the movable comb tooth units are arranged in a staggered manner; and the micromirror, the movable comb tooth units, the support rods and the torsion rods are respectively positioned in a suspension state. The one-direction torsion and high-balance variable optical attenuator can realize accurate control over the torsion angle at any position; meanwhile, the invention also provides a preparation method for the one-direction torsion and high-balance variable optical attenuator; and the preparation method is simple, high in reliability and high in processing precision.

Owner:SOUTHEAST UNIV

Method for forming planar thick isolation medium

InactiveCN101702405BReduce parasitic capacitanceGuaranteed flatnessSemiconductor/solid-state device manufacturingCapacitanceMicrowave

The invention relates to a method for forming planar thick isolation medium, which is particularly applicable to the development and the production of the silicon microwave power transistor and microwave monolithic integrated circuit. The method for forming the planar thick isolation medium is characterized by comprising the following process steps: (1) etching an deep hole array on the surface of a silicon wafer; (2) oxidizing all the silicon substrates left on the edges of the deep hole into silicon dioxide with the oxidization process; and (3) covering the deep holes with CVD isolation medium to form the thick isolation medium. The invention has the advantages that the thickness of the isolation medium can be adjusted by the etching depth of the deep holes, an isolation medium film which is as thick as the chip can be obtained, the surface flatness of the silicon wafer and the yield of the isolation medium which is finely processed can be ensured, and less capacitance can parasitize on the isolation medium.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com